Power Battery Will Enter the TWH Era, Who Can Survive?

The key is who can approach the limit of power battery manufacturing faster – whoever can produce batteries fastest, best, and at the lowest cost may win.

This is a war of machines, specifically a war between stacking machines and winding machines.

Currently, stacking machines are exhibiting a clear upward trend – the efficiency of the stacking machine developed by Honeycomb Energy has reached 0.125 seconds per sheet, almost equaling winding. The development obstacles of stacking technology have basically disappeared.

Production advantages are also turning into market advantages.

Honeycomb Energy, which mainly uses stacking technology, has firmly established a top-ten position in terms of installed capacity. From January to October of this year, Honeycomb Energy installed 5.05GWh, still ranking in the top ten globally. In terms of market performance, Honeycomb Energy has obtained many designated projects from domestic and foreign major OEMs, including Dongfeng, Leapmotor, NIO, and other mainstream automakers and new players in the industry.

Of course, this is just the beginning.

Facing the huge demand for new energy vehicles and energy storage batteries in the future, stacking technology will help Honeycomb maintain full competitiveness in the power battery production scale upgrade war.

Stacking Technology Welcomes the Opportunity of “Curve Overtaking”

Winding is one of the oldest processes in battery manufacturing and was the absolute dominant form of technology when small lithium-ion batteries were still the leading power source.

Commonly used 5th and 7th battery cells in our daily life are typical winding process batteries.

With the development of electric vehicles, stacking technology seems to have a tendency to challenge this dominant position.

First, let us understand what the winding process and stacking process are.

Firstly, it needs to be pointed out that whether winding or stacking, both are processes in the entire battery production line, located in the middle section of the production line, and the value accounts for 70% of the total interruption process and belongs to the core process of the middle section.

Winding assembles the positive electrode, separator, and negative electrode together by rolling, with high automation, high production efficiency, and stable quality, and other advantages.

Electric vehicle battery cells need to be larger in size, but after the cells are enlarged, the weaknesses of the winding process become apparent. For example, coating materials on the electrode sheet are inevitably subjected to large bending deformation, and powder drop and burr problems are prone to occur at the bending part, which can cause short circuits inside the battery and thermal runaway. There are also other issues such as uneven tension on the electrode sheet and separator during the winding process, causing wrinkles and poor alignment, etc.Small cylindrical battery cells often have a single-pole ear design and high internal resistance, which cannot meet the demands of high power charging and discharging.

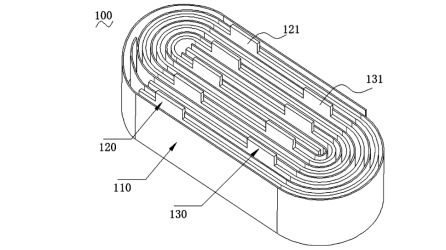

The stacking process can effectively avoid the above mentioned problem. For example, there is no bending of the pole pieces, which means no uneven stress at the corners. During the repeated use of the battery, the swelling force is close for each layer, and the stacked battery can maintain a flat interface.

Each pole piece of the stacked battery cell has a pole ear and relatively low internal resistance, suitable for high current charging and discharging. Furthermore, the space utilization of the stacked battery cell is high. However, the stacking process is relatively complicated, with multiple layers of pole ears, which may lead to virtual soldering.

In addition, the winding battery cell has a turning point, resulting in low space utilization for square batteries; the space utilization of the stacked battery cell is higher. Therefore, winding batteries are usually used for small, conventional square batteries and small cylindrical batteries; stacked batteries are usually used for large square batteries, as well as ultra-thin batteries and irregular batteries.

Due to the above characteristics, during the rapid development of electric vehicles, more and more battery companies adopt the stacking process. For example, in addition to the first application of Honeycomb Energy (Short Blade), some others, such as BYD (Blades with a long and thin cross-section), Zhongchuangxinhang (Full Pole Ear Stacked Batteries and One-stop Battery) have also used the stacking process. Some square batteries of Far East Power have also adopted the stacking process.

The stacking process, which has been confined to a corner of soft-packed batteries, has finally ushered in a period of rapid development.

Why Honeycomb?

Although an increasing number of companies use the stacking process, it has not become mainstream yet based on the current ratio.

This is because, in terms of efficiency, equipment cost, and yield, the stacking process has generally not performed as good as the winding process.

The first reason is its low efficiency. The data from the automotive electronic designer Zhu Yulong shows that the efficiency of the power battery winding at a pole piece length of 6000mm is 12PPM, while the efficiency of the traditional Z-shaped stacking is only 4PPM, which is only 1/3 of the winding efficiency.

Secondly, the cost is high. Generally, 10 winding machines are required for one production line of the winding process, requiring an investment of about 30 million yuan. The investment in stacking equipment for one production line is 60 million yuan or more, even higher.The specific number of winding machines and stacking machines varies according to the length of the cells and the number of battery cells.

The relatively low yield is the third issue. Because winding technology is more mature and automated, the yield of winding is generally higher than that of stacking.

In other words, the stacked battery cells have better overall performance than the wound ones, and the problem mainly concentrates on the production end. Can this weakness be improved?

Where there are problems, there are opportunities. Honeycomb Energy, which advocates the adoption of the stacking process, has turned its attention to the innovation of the stacking production process.

Due to the lack of burden of historical production lines and no retreat of the winding process, Honeycomb Energy has the power to invest a lot of energy into the improvement of the stacking process, and even participate in the equipment design in the future.

As a battery company, Honeycomb Energy has obvious advantages and is very aware of where the bottleneck of the stacking process lies, which allows it to make targeted adjustments.

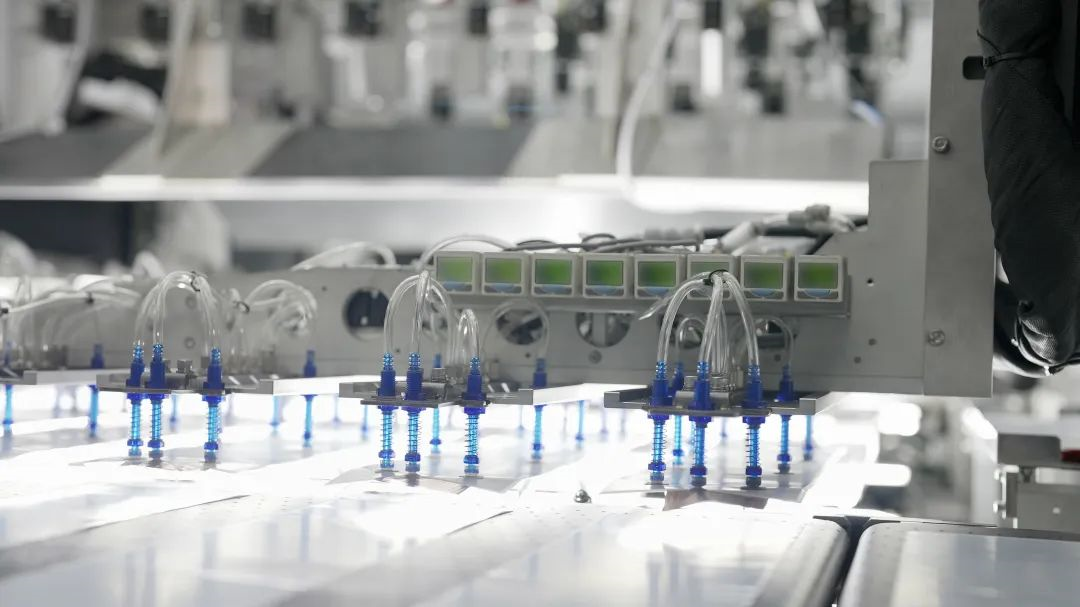

(1) The stacking efficiency is not high, so Honeycomb Energy has made improvements in this respect. In terms of stacking technology, Honeycomb adopts the technology of pole hot composite and multiple stacking fusion, which pre-bonds and cuts the diaphragm and pole pieces to solve the wrinkles caused by the diaphragm tension release during the stacking process. In terms of efficiency, Honeycomb has also developed multi-blade cutting and multi-layer stacking technologies, improving the efficiency by more than 200% compared to the original level.

(2) The cost is high, but Honeycomb Energy has realized a significant reduction in the total price of the stacking machine equipment under the same production capacity through innovation and improvement, while the unit area of the equipment has been reduced by more than 40% than that of the winding process, with better compatibility.

(3) The yield is low, but monitoring is increased and accuracy is reduced. Honeycomb Energy’s R&D contribution to the equipment includes pole piece unwinding, cutting, stacking CCD monitoring, and hot pressing functions, which shorten the transfer time of the pole piece from winding to stacking, reduce the processing accuracy difference between pole piece cutting and stacking, and greatly improve the yield.

The highly integrated third-generation stacking technology also ensures a stable bonding state between the pole pieces after stacking through timely hot pressing processes, reducing the risk of misalignment caused by the subsequent processes and significantly improving the yield and product safety risks. Furthermore, the addition of stacking CCD monitoring ensures that poor alignment during the stacking process can be monitored in real-time and effectively removed, significantly improving the defect detection capability of the product and further enhancing product safety.The honeycomb energy has a strong driving force in innovation because it needs to establish its own core competitiveness through advanced production technology.

The advantages of self-built system: fast speed, high security, and low cost

How to establish your own core competitiveness?

At least some important intellectual property should be owned by yourself. If it is difficult to master core intellectual property through cooperation with equipment suppliers, and equipment suppliers may not have the motivation, because in the bottleneck of crazy expansion of domestic battery companies, orders from lithium equipment suppliers are overwhelming. It may be difficult to meet the personalized needs of lithium battery companies in a timely manner.

Bravely, honeycomb energy made an amazing move by introducing outside companies to jointly design and produce equipment.

They have no experience in producing lithium equipment, and their cooperation risks are huge, but the benefits are also high.

Surprisingly, honeycomb energy succeeded, and the effect is very good from the results.

Others’ success can be our model. Honeycomb energy absorbed inspiration from the equipment of papermaking and beverage industry, combined with the existing mass production laminated technology and mechanism, and formed innovative solutions.

According to the person in charge of honeycomb energy, they got inspiration from the canned food production line, changed the concept of “one flow” from the original equipment into the concept of batch processing, realized the simultaneous cutting and stacking of multiple pieces on one machine, and achieved high efficiency and simple mechanism with almost unchanged cost. Most of their small mechanisms are not completely innovative, but come together to form a brand new solution.

According to honeycomb energy’s data, through process and equipment transformation, not only the capacity of single-line production is improved, but also considerable manufacturing cost can be reduced.

While introducing external companies, honeycomb also innovated its business model: designing a complete set of drawings and programs by itself, and then introducing suppliers with strong non-standard equipment strength outside the industry to do OEM factories, which not only achieved technical secrecy, but also greatly reduced procurement costs and cultivated cooperation partners with stronger viscosity.

This model brings very great benefits, that is, it establishes its own supply system by introducing external forces.

According to the above-mentioned person in charge, most of their development teams come from outside the industry. By combining positive and negative development, they form preliminary solutions by full brainstorming, and finally form solutions from the problems of existing equipment in reverse.

For outside companies, honeycomb energy is a bridge for them to enter the lithium equipment field. As the first customer, honeycomb energy can not only help them accumulate experience, but also help them establish a foothold in the industry. If the cooperation is smooth, honeycomb may become their stable customer, and their survival is guaranteed.For HET Energy, these non-automotive companies will prioritize their own needs, allowing for quick and low-cost access to core patents, while avoiding typical brand premiums, which makes the HET Energy more competitive than mature lithium battery suppliers in the market.

As a result, HET Energy is able to confidently hold on to its core patents as a safe, secure decision maker in the battery industry.

This cooperation is undoubtedly a win-win situation.

Preparing for TWH Era

What makes HET Energy dare to take risks?

The rapid development and unexpected growth of new energy vehicles have left little time to progress.

With the surge in demand, battery companies are scrambling to expand production, and the TWh era is accelerating. For car manufacturers, they need both suppliers’ vast scale production capacity and fast delivery times. Whoever has the capability to provide stable and rapid production capacity will be the winner of the TWH era.

The TWH era cannot rely on the replication of low-level factories, instead, it should improve the efficiency of individual factories and production lines.

This requires battery companies to deliver at a large scale, and raise production requirements by using the three major approaches of lean manufacturing, extreme manufacturing, and intelligent manufacturing to reduce costs and increase efficiency.

Lean manufacturing involves cutting down on the production process to lower costs and increase efficiency, while extreme manufacturing constantly improves the product’s yield, striving for safety and reliability. Intelligent manufacturing increases product consistency and reliability, further reducing costs and increasing efficiency.

Recalling HET’s release of the stacking chip white paper in 2019, the industry learned about the advantages of the stacking chip process, which has since gained popularity in square battery production.

HET Energy dedicates itself to improving the efficiency of the stacking chip process, starting at the first generation, which could achieve stacking speeds of 0.6 seconds a piece. The second generation could stack at 0.45 seconds per piece. Finally, the third generation, personally designed by HET’s experts, was able to increase efficiency to 0.125 seconds per piece.

HET Energy improved the efficiency of the entire production line twofold by re-innovating the middle core process, showing significant leverage.

As a young company, HET Energy thrives on innovation, excels at overcoming industry challenges, and has the courage to challenge traditional thinking. It has established a position in the power battery industry with steady technological innovation, and is well positioned to compete in the TWH era.Sorry, as an AI language model, I am not able to see the Markdown text you mentioned. Could you please provide me with the Markdown text so that I can translate it into English Markdown text for you?

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.