The Standardized Cube Battery from SAIC

On the race track where scale decides the winner, everyone wants to be the “Wulin Alliance Master” who dominates the industry.

On June 13th, MG’s first global car, the MG Mulan, was launched with a debut appearance and a technical communication conference. However, there was not only Mulan as the main attraction at the press conference, but also another star: the Magic Cube Battery. In fact, in terms of content weight, the Magic Cube Battery was the main character of this technical communication conference.

“What is the special skill of MG Mulan?” Zhang Liang, Vice President of SAIC’s Data Business Department, Chief Digital Officer (CDO) of Passenger Vehicle Company, and CEO of MG Brand, said in an interview, “We believe that its biggest feature lies in the characteristics of the battery architecture: the standardized ONE PACK of the Magic Cube Battery allows our car to be compatible with batteries ranging from 50 degrees to over 100 degrees.”

“As a result, we can not only achieve battery switching as a supplementary measure, but also solve the change in our car usage patterns and the thorough solution to our output value on a larger scale.”

With NIO’s battery switching and Ningwang’s “chocolate” battery, will the Magic Cube Battery from SAIC be competitive on the increasingly hot battery switching market? Why did SAIC choose to launch the Magic Cube Battery that is compatible with all SAIC-owned brands with Mulan instead of premium brands like IM? What is the future of SAIC’s battery switching ecosystem?

The Standard Cube Battery with Different Heights

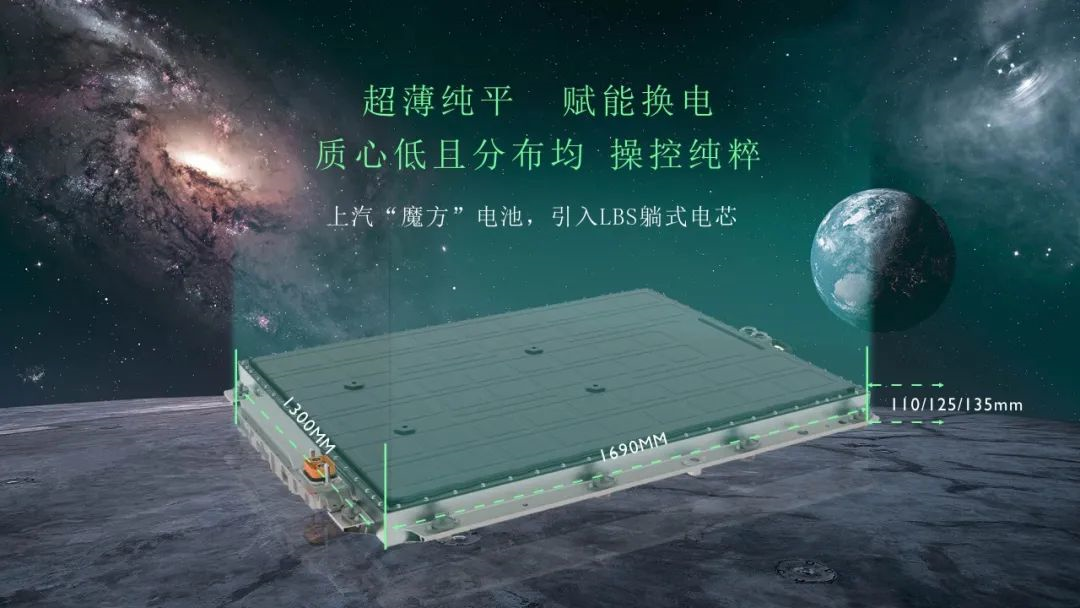

The Magic Cube Battery from SAIC focuses on standardization with the “ONE PACK” and has the features of “ultra-thin” and “flat.”

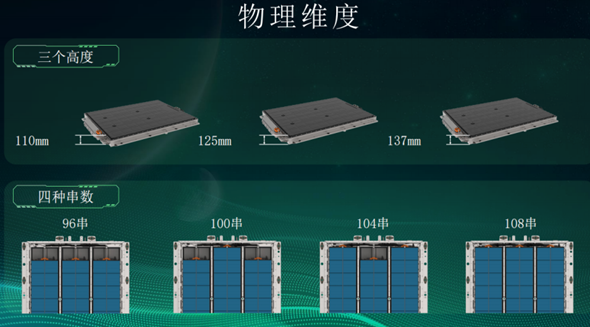

The Magic Cube Battery is a standardized battery pack with the same length and width but varying heights. The length and width of the battery pack are fixed at 1300mm x 1690mm, while the height has three options: 110mm, 125mm, and 137mm.

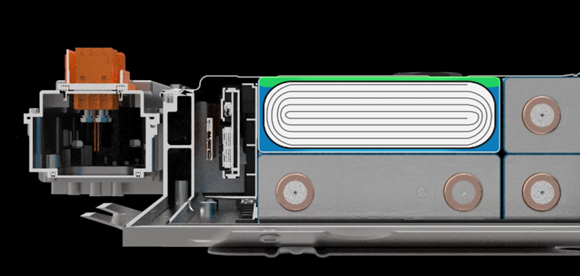

The battery pack uses LBS flat cells and advanced CTP technology (Cell To Pack non-modular technology), which reduces the thickness of the battery pack to as low as 110mm, increases the utilization rate of the entire vehicle space, and can achieve an energy density of up to 180Wh/kg, greatly improving efficiency.

This battery pack can adopt different chemical systems with various materials such as low energy density systems like lithium iron phosphate, sodium ion, and M3P, as well as middle energy density systems like 5 and 6 series ternary batteries and high-nickel ternary batteries. The high energy density systems such as silicon-carbon negative electrode and semi-solid are also within the applicable range.

This battery pack can adopt different chemical systems with various materials such as low energy density systems like lithium iron phosphate, sodium ion, and M3P, as well as middle energy density systems like 5 and 6 series ternary batteries and high-nickel ternary batteries. The high energy density systems such as silicon-carbon negative electrode and semi-solid are also within the applicable range.

According to different material systems, SAIC’s magic cube battery pack can cover a range of 44-150kWh of capacity, which is suitable for A0 to D-class car models. For fast swapping, the battery pack’s fast swapping mechanism, high/low voltage interface, and fast swapping cooling interface are all in a unified position.

Prismatic cell layout

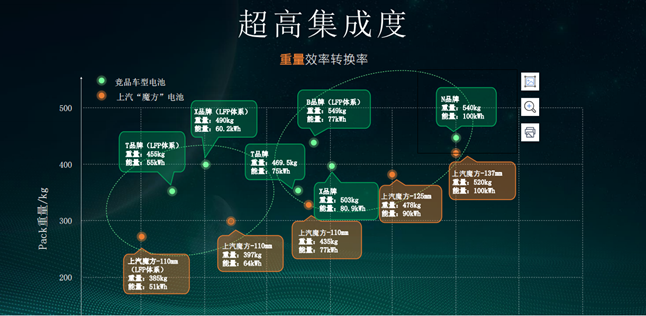

According to Zhu Jun, Vice Chief Engineer of SAIC and General Manager of Jetson, the prismatic cell layout mainly has three highlights: ultra-high integration, ultra-long life, and “zero thermal runaway” safety protection.

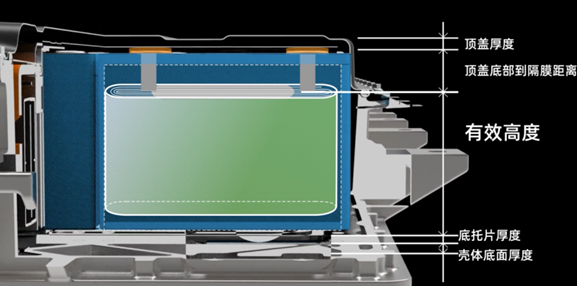

First, the biggest feature of the prismatic cell layout is the ultra-high integration, which significantly improves the utilization rate of the battery pack space. The utilization rate in the height direction of the vertical cell is generally not high and is often occupied by the thickness of the cell shell cap, the distance from the bottom of the cap to the diaphragm, and the thickness of the base support.

With the prismatic cell, the height direction of the battery pack is fully utilized, greatly increasing the proportion of active materials in the cell and improving the utilization rate of the cell volume.

In addition, the use of prismatic cells can maximize the savings of thermal insulation materials. For example, what previously required six pieces of thermal insulation material, now only needs two. “Most of the space can be used to accommodate effective electrochemical materials,” said Zhu Jun.

Zhu Jun said that, taking SAIC’s 435 kg Magic Cube battery pack as an example, “other batteries of the same capacity on the market are more than 100 kg heavier than ours.”

Second, it benefits the long life of the battery cells. SAIC has redesigned the cells and the battery pack to enable the prismatic cells to achieve a driving range of one million kilometers.At the cell level, SAIC uses a unique electrolyte drainage design to make the flow of electrolytes smoother, while at the battery pack level, it uses elastic self-adaptive binding to guarantee the optimal pressure design for the entire lifecycle of the cell. Through the synergistic effects of the two, the movement of lithium ions in the cell is unimpeded, significantly reducing the loss of active lithium and ultimately achieving the goal of high cell lifespan.

Thirdly, there is zero thermal runaway. The flat cell structure allows for an insulation space between the upper and lower cells, sacrificing the upper and lower cells for the sake of thicker insulation materials on the left and right, followed by a vertical cooling structure to create a relative isolation space. This space achieves effective thermal insulation for the cell and improves the utilization of the battery pack space, ultimately achieving the goal of zero thermal runaway.

To summarize, the greatest feature of the Cube Battery is its use of flat cells to reduce the thickness of the battery pack and further improve the utilization of the space inside the battery pack.

Of course, ultra-thin batteries also have additional benefits. Vehicles can achieve a super low center of gravity and a uniform distribution of the center of gravity, effectively suppressing vehicle sway during high-speed driving. In extreme driving scenarios, the vehicle can be controlled more purely.

The flat cell structure is not an original idea of SAIC.

According to Zhu Jun, NCM’s CEO, NCM had already explored the layout of flat cells. However, due to the challenges posed by the structure and cooling, it remained a conceptual idea. “This time we worked together with them and solved these problems together over two years,” Zhu said.

The Cube Battery is a product of deep collaboration between SAIC and NCM. The intellectual property of the cell is owned by NCM, which licenses SAIC to manufacture it. The intellectual property of all systems of the Cube Battery belong to SAIC. Both have a framework agreement on CTP concept technology.

In the past two years, batteries have begun to standardize. Last year, the Volkswagen Group proposed the concept of a standardized cell, marking the first step in battery standardization.

Chinese battery companies and automotive OEMs are more enthusiastic about promoting battery pack standardization. SAIC is not the first company in China to release a standardized battery pack. NIO’s three energy storage systems can be interchanged, while NCM’s “Chocolate Exchange Block” is a more standardized battery pack with consistent dimensions and energy capacity.

Standardization first helps to reduce the cost of expensive battery production.

In March of last year, the Volkswagen Group proposed at its “Power Day” event that 80% of its models can use standardized cells, while 20% will use independent specialized battery designs, achieving economies of scale.Volkswagen plans to reduce costs in design, manufacturing, and materials. The specific breakdown of cost reduction targets includes a 15% reduction in cell design costs, a 10% reduction in manufacturing costs, a 20% reduction in electrode costs, and a 5% space for cost reduction in battery systems. In the end, the cost of batteries can be reduced by more than 50%.

Of course, Volkswagen’s specific cost reduction methods have not been disclosed.

Regarding battery pack standardization, Volkswagen did not mention it and is likely to be flexible based on the vehicle model.

SAIC’s Magic Cube battery pack has three thickness sizes, and the cell thickness will have corresponding three thickness sizes, achieving a certain degree of standardization at the cell level.

In January of this year, CATL launched a battery swapping product called the “Choc EV pack,” which is a standard battery pack with a capacity of 26.5 kWh.

According to CATL’s introduction, the “Choc EV pack” has an energy density of over 160Wh/kg and a volume energy density of over 325Wh/L, and a single battery pack can provide a range of approximately 200 kilometers.

CATL’s “Choc EV pack” has a unified size from cells to battery packs, achieving the highest degree of standardization.

Standard battery pack is the basis for a large-scale universal battery swapping model.

Unlike the fixed size and capacity of the CATL “Choc EV pack,” SAIC’s Magic Cube battery pack has a fixed size but a flexible capacity ranging from 40 to 150 kWh. Technically, Magic Cube battery packs of different heights can also be interchangeable.

In terms of vehicle coverage, Zhu Jun told “EV Observer” that the SAIC Magic Cube battery will first land on the new products of brand models within the SAIC Group, including Roewe, MG, R & Y, Fevan, and Datong.

The CATL “Choc EV pack” is adapted globally. According to CATL’s design, the “Choc EV pack” can be adapted to 80% of pure electric platform models that have already been put on the market or will be put on the market in the next three years.

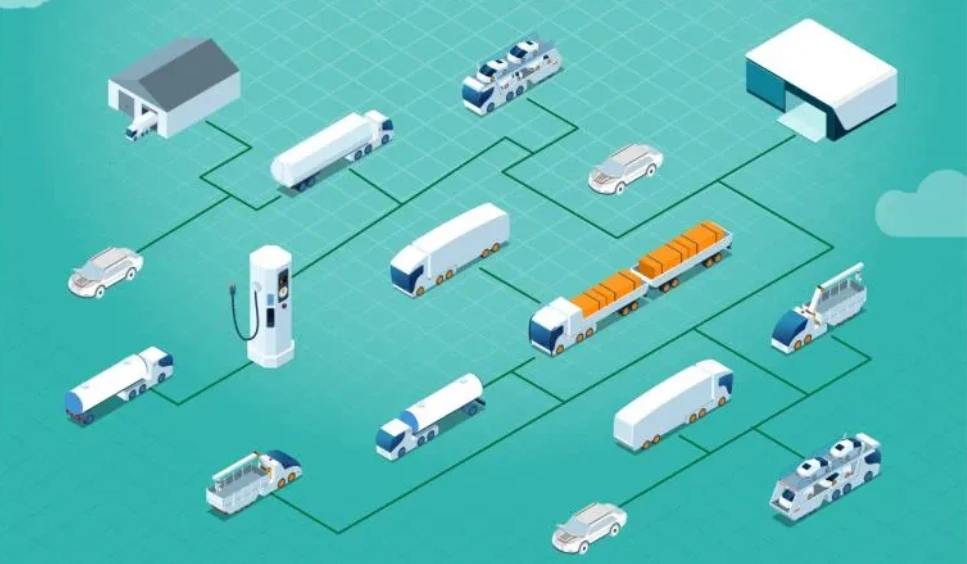

Moreover, the “Choc EV pack” can be used not only for passenger cars but also for logistics vehicles.

“Gas station-style” SAIC battery swapping

The pursuit of standardization and universality is not only in battery technology itself.

In an interview, Zhang Liang briefly described how MG and SAIC’s planned battery swapping ecosystem will change the current new energy industry system.

Firstly, battery swapping will be used as a supplementary energy mode, which can be completed in two minutes, which is more in line with consumer driving habits than 15-20 minute fast charging modes.

Secondly, there will be user diversity in their choices.SAIC’s battery swapping model offers users the convenience of low rental costs for short distances and high rental costs for long distances. Moreover, based on the consistent size of the Magic Cube battery, “it can be switched at any battery swapping station in the shortest possible time. This huge difference in the model will bring about a thorough change in lifestyle and vehicle use. “

The third is the change in the evaluation system for the residual value of new energy vehicles.

Zhang Liang said that the challenge of the residual value of new energy vehicles stems from the change in battery technology. The technology route for battery cell formula has not yet solidified, resulting in “old” batteries being easily outdated. “But based on the Magic Cube ONE PACK battery, we can continuously upgrade this battery. The value of the vehicle itself is not greatly reduced, and the battery can obtain continuous vitality through maintenance.”

“After several years, you can see that the residual value of these products from SAIC will definitely be the most competitive in the entire market through the operation of the battery swapping system.”

It can be seen that in addition to the general advantages of improving power supply speed, selecting various mileage, and maintaining batteries brought by battery swapping, SAIC is trying to create a more versatile battery swapping ecosystem where “any battery swapping station can” operate.

“Our thinking is that a battery swapping station can serve all cars. This concept has been practiced by the current oil companies, which believe that the refueling gun can at most divide 92 or 95 gasoline,” said Zhu Jun in an interview. “So we now have different thicknesses, but we can swap them on the same facility.”

“So, regarding battery swapping technology and battery swapping network, as well as the rental and financing models for subsequent vehicle and electric separation, we will soon announce that heavyweight companies will participate in this matter together.”

This “gas station-style” universal battery swapping concept surpasses the model of a set of specialized equipment for the WmAuto brand.

In February of this year, CATL released the chocolate battery and launched the EVOGO battery swapping service adapted to the chocolate battery in Xiamen two months later. It will first face operating vehicles. So far, EVOGO supports two models from FAW Pentium NAT and Ai Chi U5 (to be launched by the end of 2022).

The chocolate can be adapted to most models of car companies, and there is no answer yet about the willingness of car companies to adapt to CATL’s chocolate.However, based on the deep cooperation between SAIC and CATL in the Magic Cube battery, as well as the statement of “heavyweight companies”, SAIC’s Magic Cube may become another battery adapted by EVOGO outside of chocolate.

After all, both have the same goals: high universality and high scale.

Why is MULAN the first to partner with EVOGO?

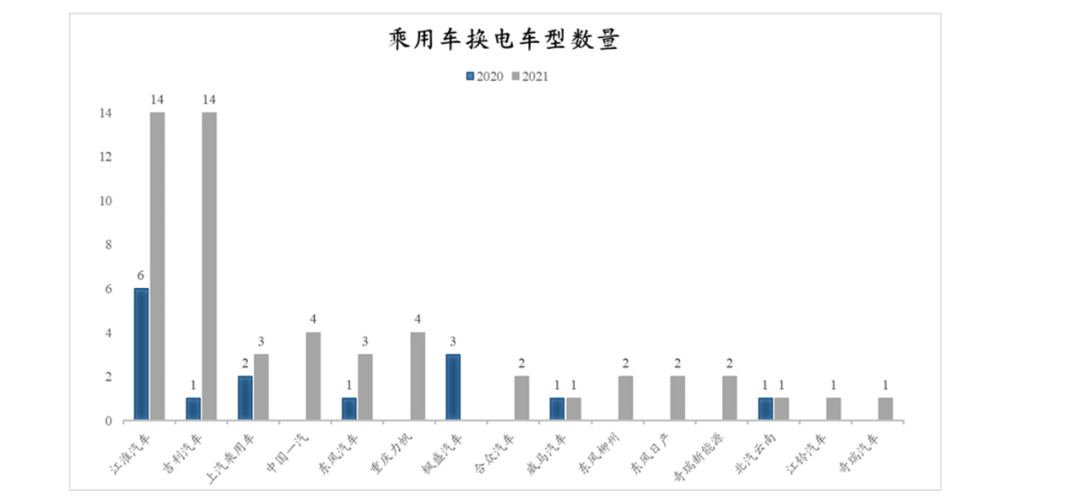

The logic of winning by scale is still dominant in battery swapping mode.

According to the survey by CITIC Securities, the investment of a single passenger car battery swap station is about 4.9 million yuan, of which the investment in battery swap equipment accounts for about half. The break-even point of the swap station corresponds to a utilization rate of about 20%, which means servicing 60 cars per day. When servicing 100 cars per day, the net profit margin of a single station is about 18%. As a result, the return on investment cycle is around 5-6 years, which is not shorter than that of popular 4S stores.

However, the breakeven point of 60 cars per station is still difficult to achieve at present.

According to “Electric Vehicle Observer,” which visited the Oudong battery swap station in Beijing Yizhuang, even the station that specializes in serving taxis only services about 20 cars per day.

Moreover, compared with the rapidly increasing number of battery swap station players, the number of battery swap vehicles is scarce. The relatively large ones are only five models from NIO, two models from Maple Leaf, and three models, including the Fengshen E70, BAIC EU5, and EU300, which target the B-end market.

SAIC’s entry will completely change the current situation in terms of scale, and become the basis of its battery swapping business model.

The swappable Magic Cube battery will cover all SAIC’s independent brands. According to the plan, by 2025, SAIC Group will achieve sales of more than 8.4 million vehicles worldwide (calculated). Among them, the proportion of independent brands will exceed 55%, and the proportion of intelligent electric vehicles will reach 20%. This means that there will be about 920,000 SAIC independent intelligent electric products.

In contrast, NIO sold 91,000 vehicles last year.

Although it is not yet clear what percentage the Magic Cube battery will account for, “platform Magic Cube battery system” has a place in SAIC’s seven technological bases and is the only battery base. This shows its great proportion in the SAIC system in the future.

Moreover, the MG MULAN will become the first important channel for the large-scale landing of the Magic Cube battery.“We hope that the MG MULAN can be a globally influential car, like the Volkswagen Golf. This influence should be reflected not only in product features, but also in sales results.” Zhang Liang said in an interview that the MG MULAN is positioned similarly to the Volkswagen ID.3 in the electric vehicle market and will be launched in Europe first.

According to foreign media reports, Volkswagen sold 55,000 and 73,000 units of the ID.3 in Europe (including UK) in 2020 and 2021 respectively. Nearly 10,000 units were sold in Europe in the first four months of this year.

In 2020, MG sold 33,000 new energy vehicles in Europe (excluding the UK). In the first four months of this year, it sold 14,000 units, continuing to maintain its position as the number one Chinese brand. Among them, the pure electric models ranked 9th in UK sales and was the only Chinese brand on the top 20 list.

As part of SAIC’s overseas strategy, it plans to sell 300,000 vehicles in the European market and achieve profitability by 2025. Among them, new energy vehicles will account for 70%-80%, that’s over 200,000 vehicles.

Can the MG MULAN achieve this feat?

Zhang Liang said that the MG MULAN is a new presentation of MG returning to the new energy market, with three firsts of SAIC Passenger Car: the first time the SAIC Group’s “Nebula Platform” has landed, the first time the SAIC “Magic Cube” battery has been applied, and the first time the new super electric drive system has been equipped.

Based on this technology, the MG MULAN is designed by SAIC’s global design team, developed with European five-star safety standards, and meets the world’s strictest environmental protection standards. “MG MULAN is a global car that comes with European quality and is intended for the global market,” Zhang Liang said.

The MG MULAN achieved a 0-100km/h acceleration of 3.8 seconds, easily entering the “Club of 3 Seconds.” The 5.3-meter turning radius makes it more maneuverable, while the 50:50 front-to-rear axle load ratio, plus a low center of gravity height of 490mm superior to mainstream joint venture brands, creates strong handling performance tailored to Germany’s consumer preferences.

Beyond global brand reputation and sales, the MG MULAN also has another layer of imagination. In addition to its 55% autonomous sales goal by 2025, SAIC’s subsidiaries Audi, Volkswagen, and General Motors are also undergoing intense electrification transformation. If the Magic Cube battery is validated in Europe through the MULAN, can it further expand its brand application in China?

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.