Author: Zhu Yulong

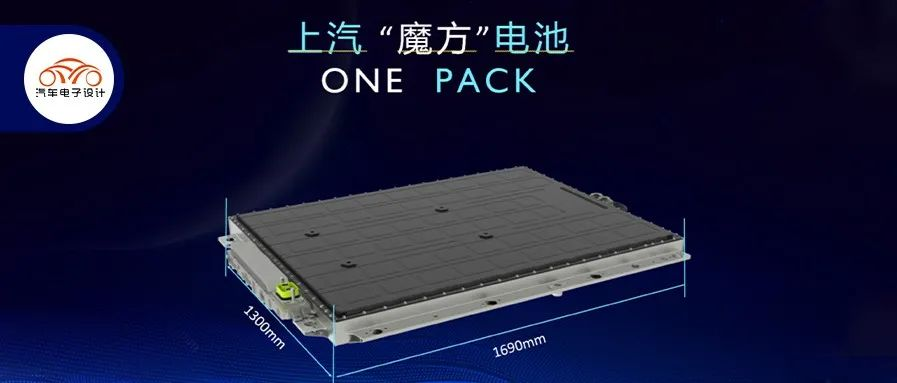

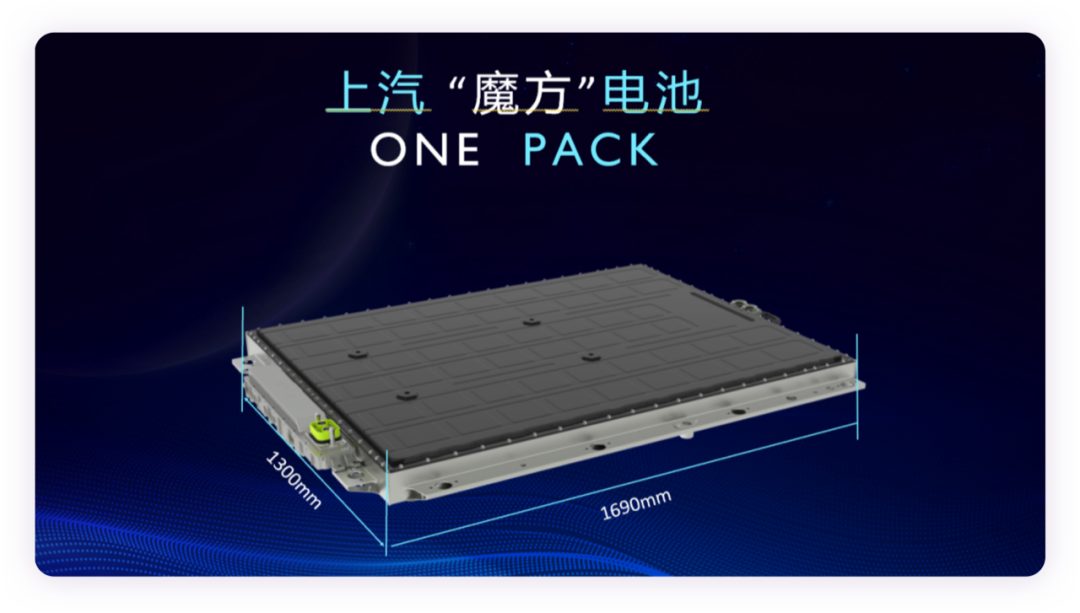

Recently, MG MULAN unveiled its new technological highlights. As a brand within SAIC Electric Vehicles, it was eager to showcase the SAIC Nebula pure electric exclusive system platform and the “super-thin and flat” Magic Cube battery. This design is equally challenging for the later phases, which include the creation of smart technology, Fei Fan and Rong Wei. As a battery technology expert who has worked at SAIC for four years, I will try to explain the design of this battery. Of course, due to my position, I will make a recommendation, but I will try to be as objective as possible.

Why Make Prismatic Batteries in a Horizontal Position?

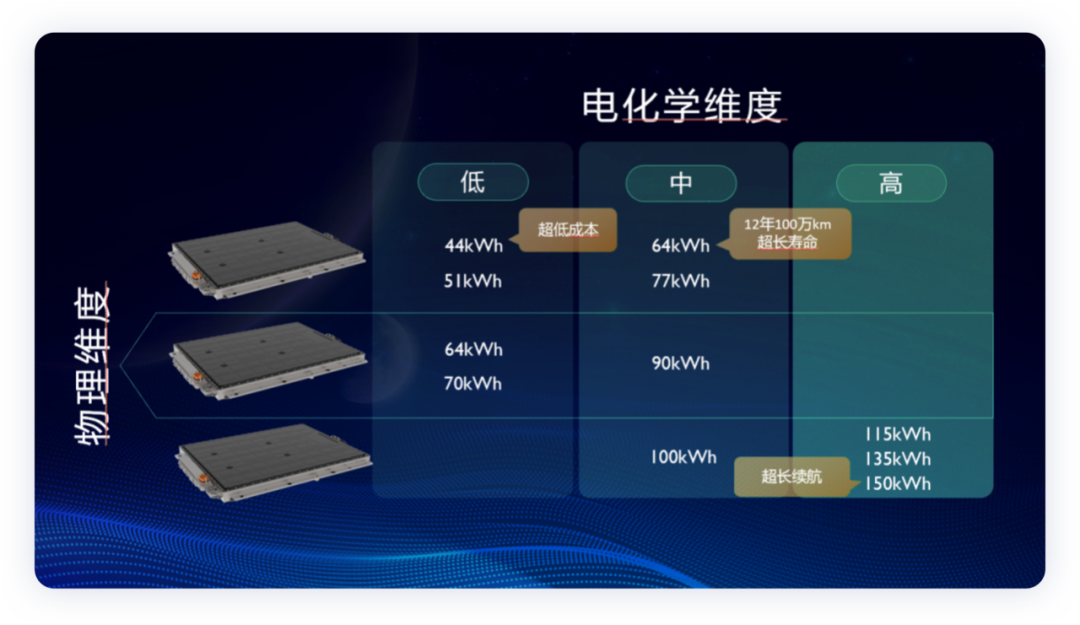

SAIC’s main partner is CATL. Therefore, in the early stage of research, it was necessary to achieve five design goals: “21103”:

- The highest energy density of 200Wh/kg.

- Pack cost of $100/kWh.

- Height of 110mm, suitable for sedans.

- No thermal runaway and absolute safety of various chemical systems.

- 3C fast charging.

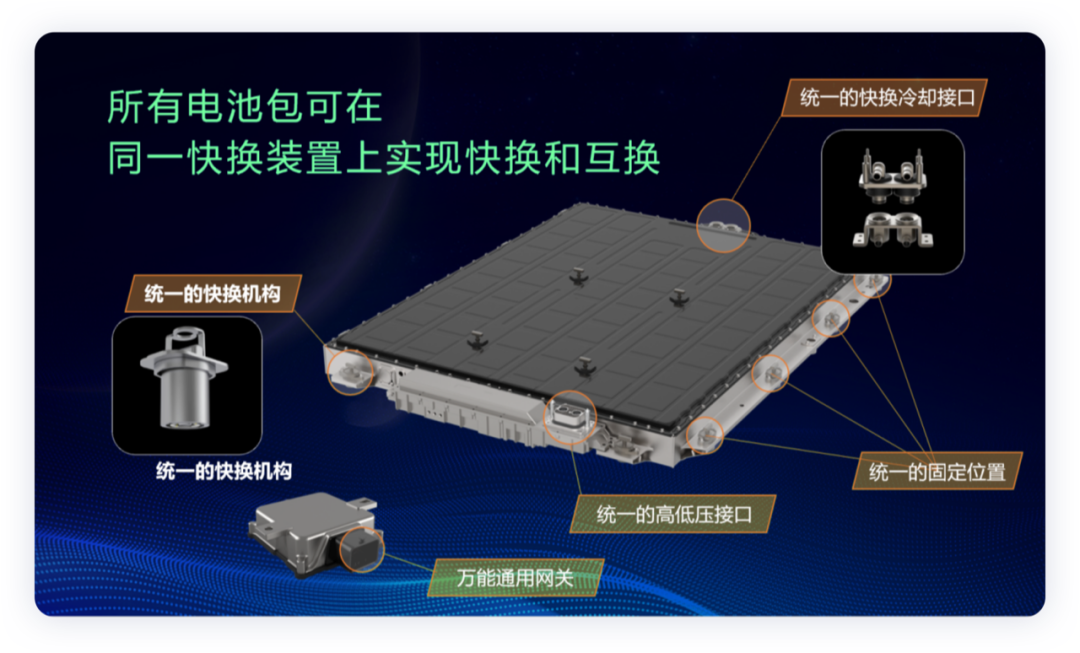

Subsequently, wider energy gradients and quick-change designs were added to this target.

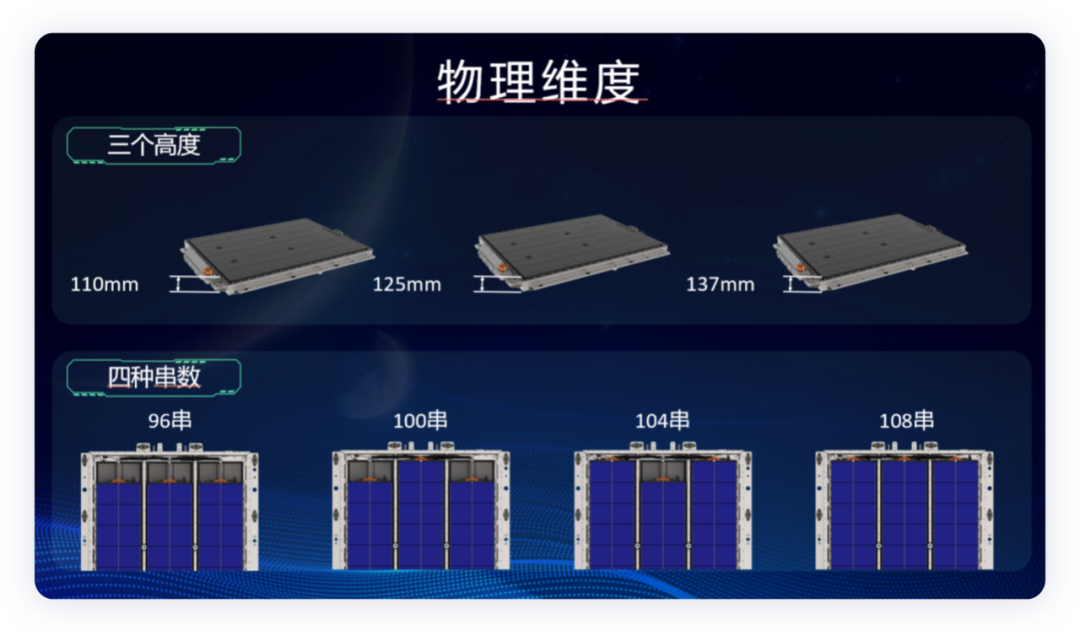

You may first notice that the cost and safety targets are rigid, while the 110mm height can be expanded into different specifications in the future. Therefore, the core demand for using LBS prismatic batteries is safety. After fixing the XY dimensions of the battery, we can see that due to the energy demands of the entire vehicle enterprise, when the energy density and grouping rate reach their limits, the only way to continue increasing energy storage is through an increase in height. Three types of battery packs correspond to three different battery cell specifications (fixed length and width, variable thickness).

The biggest problem here is that the gradient of the chemical system has not been stretched out. The original medium-density, high-density, and low-density chemical systems make it impossible to cover as many configurations under the same battery cell specifications. Because of the difference in the formulation of the battery cells, three different size specifications with three major chemical systems can produce an endless number of battery cells.

## Translation

## Translation

Facing this issue, the size and specification can be achieved by using lithium iron phosphate (LFP) with a range from 44kWh to 70kWh, but the 70kWh can only be achieved by M3P. In fact, the battery energy is not considered high with the use of LFP.

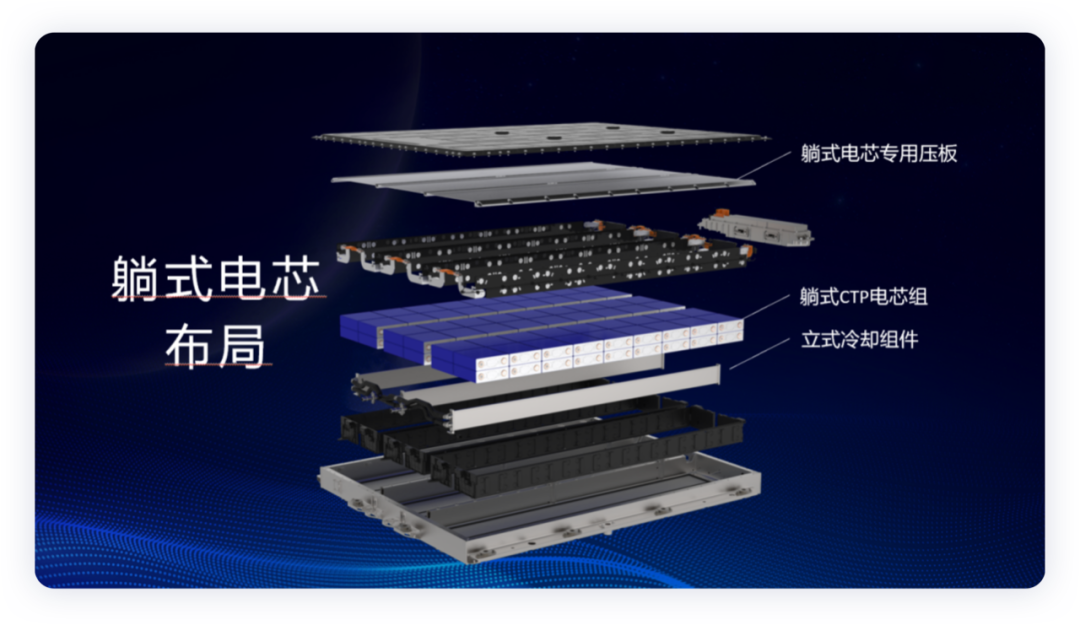

Design Interpretation

This is a typical CTP design with heat dissipation in the middle. The bottom of the battery cell is cooled through a long strip-shaped water-cooled plate similar to Tesla’s design. If high-power fast charging is required, a whole-water-cooled plate can be added to the upper and lower battery cells. However, as the battery cells belong to a larger size, the challenge of temperature uniformity exists.

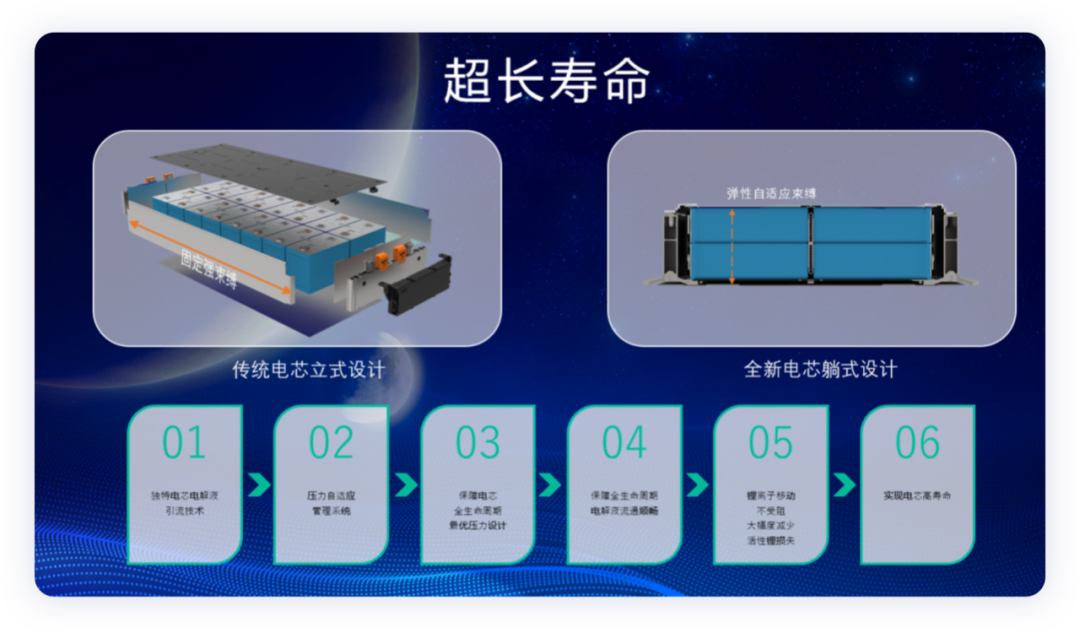

The core of the entire design is centered around not burning. Through the side insulation, at most two battery cells can be burned, which is the most basic consideration for the design of the entire battery. This is the biggest consideration for the design of this battery system.

Note: At present, all Chinese car companies are focusing on the lithium iron phosphate solution, and adding a certain thickness of insulation material is more suitable for thermal runaway protection.

If you compare it carefully, the large square shell is not a good solution to making a 110mm battery pack. Therefore, the only options are blade and 4680/4695. In our opinion, this is an inevitable choice.

The data on this page is mostly based on existing product comparisons. Looking at the comparison of data between the next generation of long and short blades, let’s compare them further.

Summary: After years of polishing, SAIC’s E2 battery platform is a very meaningful attempt based on the technology of square shell winding. Compared with all kinds of blade and 4680 produced by stacking square shells, there is no fundamental change in battery cells. The brothers who make packs have put in all their efforts, and now it’s all over.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.