Author: Bai Ge

During the time of the NIO “866” model, NIO’s suspension was mocked by car owners as “Schrodinger’s suspension.”

This is because NIO OS system updates affect the suspension experience, and different small versions of updates result in different performance and styles of the suspension.

This phenomenon has always been criticized by NIO’s old users.

When ET7 was delivered, some old users also worried that “Schrodinger’s suspension” would still appear.

But this time, ET7 did not disappoint its users.

“In comfort mode, ET7 still has a magical feeling, smooth and comfortable, but not loose, completely different from the feeling of the S-Class Maybach at home, let alone compared to the bouncy suspension of the ES8.”

“ET7’s suspension is much stronger than that of 866 and is at the same level as 56E in terms of chassis performance, which is the real feedback from the first batch of users of NIO ET7.”

Behind the positive feedback lies the credit to the independently developed suspension control system.

According to Xiao Bohong, NIO’s senior director of vehicle engineering, ET7’s intelligent chassis is mainly composed of two parts:

- The first is the Intelligent Chassis Controller (ICC), which is also the key to NIO’s intelligent chassis.

- The second is the independently integrated and developed chassis hardware system.

NIO ICC will be fully deployed in NIO’s NT2.0 platform products such as ET7, ET5, and ES7. ET7 started deliveries in March of this year, and ET5 and ES7 will also be delivered within this year.

With the continuous improvement of automobile intelligence, the role of the intelligent chassis domain controller in various stages of vehicle development has become particularly important, bearing the responsibility of software and hardware unbinding and software and hardware definition.

With the development trend and evolution of centralized electronic electrical architecture, the chassis domain controller has also become a must-win position for intelligent chassis development.

Breaking the international monopoly and independently developing the entire stack allows for more efficient vehicle development.

Fully self-developed products have always been the core weapons of new automakers.

From autonomous driving to intelligent cabins, and then to chips, batteries, and other components, new automakers insist on mastering the “soul” in their own hands.

For automakers, the benefits of full-stack self-development are the ability to obtain absolute autonomy, which brings about a comprehensive improvement in technology and product development efficiency.

The self-developed entire vehicle chassis domain controller is no exception.

In the past, international Tier 1 companies controlled the core of chassis control technology and provided “black box” solutions for automakers.Below Tier 1, Tier 2 and Tier 3 (second and third-tier suppliers) provide chassis-related parts such as shock absorbers, air suspension, EPB, and more than 100 major controllers related to them for the car maker. This means car makers need to match the development cycle of their partners during chassis control development. Meanwhile, development of the chassis domain controller has a high barrier and a long cycle, making it difficult to meet the needs of FOTA quickly.

After the full-stack self-research, what problems did NIO solve?

Take the adjustment of air suspension and dynamic suspension damping control parameters as an example. Traditional ASDM requires a reservation of debugging resources from suppliers half a year in advance, plus the release of integration from the supplier and validation release from the host factory which accumulates to at least 8 months.

According to William Li, NIO solved the air suspension data correction issue in just 1.5 months after independently developing ICC, enabling quick FOTA updates.

For the development of complex chassis functions, different departments such as first and second-tier suppliers need to be jointly debugged, and the entire development cycle takes at least 4-6 months.

After NIO self-researched, they could make more reasonable system designs according to their own needs, while developing algorithms and simultaneously coordinating joint debugging and validation which shortened the R&D cycle by half.

In traditional vehicle chassis development, the various components and subsystems control themselves relatively independently, which is the main pain point and restriction of traditional chassis development.

Many auto makers, especially domestic independent brands, lack deep-level chassis function integration and development capabilities, which limits the vehicle to simple basic driving experiences and fewer extended functions, making the driving experience relatively single.

With software on board, the chassis is no longer simply a mechanical integration. The vertical integration capability of software will make all components integrate seamlessly and improve the dynamic performance boundaries of the whole vehicle.

Based on this, compared with traditional chassis control of different components relatively independent in longitudinal, lateral and vertical vehicle dynamic control, NIO’s full-stack self-research ICC can improve the dynamic performance experience of the whole vehicle through intelligent coordination of hardware and software and fully exert the effectiveness of the entire system to meet more personalized demands.

NIO’s acceleration of R&D brought about by ICC is also reflected in the earlier stage before entering real vehicle debugging.According to reports, NIO has launched the first driving experience simulation platform for mass-produced vehicle development.

This platform consists of driver simulators, simulation systems, vision systems, and other auxiliary facilities, which can carry out virtual debugging of vehicles, performance evaluations, and verification of various onboard systems.

It integrates ICC modules, which enables the expansion of more functional tests under NAD scenarios and various working conditions, achieving a balance between agile vehicle development and research and development investment while shortening the design and iteration cycle.

Based on its self-developed ICC stack, NIO has broken the monopoly of foreign suspension control system “black box” solutions.

The full-stack self-developed ICC allows engineers to adjust the chassis at any time and is more flexible in upgrade.

The electronic of future chassis will become personalized for users after the control area is unlocked. ET7 can provide users with more interaction and greater possibilities.

With the evolution of the electronic and electrical architecture of the entire vehicle, domain controllers have gradually become mainstream. Compared with the traditional ECU unit mode, the domain controller mode has the following advantages:

- Multiple functions can be fused together, including high computing power and fully redundant functional safety systems, and vehicle motion control, etc.

- Domain controllers replaced the decision-making function of the original independent ECU.

- The domain controller has a powerful hardware computing capability and rich software interface support.

- The intelligent control core functions are centralized with high real-time performance, fast coordination processing speed, and high system functional integration.

- Standardized sensing components and executing components can be developed, with strong component compatibility and a wide range of applications.

In NIO’s self-developed suspension control system, the chassis control has also been formally upgraded to the “domain” concept.

The chassis domains of traditional Tier 1 manufacturers usually integrate functions such as transmission systems, driving systems, steering systems, and braking systems.

NIO’s self-developed chassis domain controller integrates traditional control functions such as redundant parking, air suspension, shock absorbers, and supports advanced autonomous driving scenarios and FOTA upgrades after cross-domain integration.

Equipped with ICC, NIO ET7’s system and components loaded on the chassis architecture have been further improved and optimized. Through the intelligent collaboration of the entire system, it can achieve fusion control and fast iteration.

NIO stated that ET7 achieved a completely self-developed forward development in China, from overall vehicle experience goal definition to embedded systems, components, software and hardware, and chassis domain controllers.

Specifically, based on ICC, ET7 has two major advantages in product function experience:

First, ICC can comprehensively design and tune the comfort and handling of the chassis.In the CDC (Continuous Damping Control) of the dynamic suspension, each damper hardware can change the damping by changing the current.

In the interaction between real-time vehicle signals and sensor signals, the car collects a large amount of real-time road information, and the CDC software calculates the current status of the vehicle.

The tuning engineer will, according to the actual situation, seek the optimal damping setting by decoupling the software parameters layer by layer between 1.8 amperes (minimum damping) and 0 amperes (maximum damping).

Through the arrangement and combination of softness and hardness between different structures, it is not inferior to playing a Rubik’s cube of several hundred by several hundred orders. The tuning engineer needs to find one optimal solution after another in this cube.

The use of ICC allows the ET7 suspension system to have higher activeness. The controller detects the vehicle’s state based on the signal received by the sensor and determines the optimal parameter instruction to adjust the spring stiffness and the damping status of the damper according to the algorithm or control strategy.

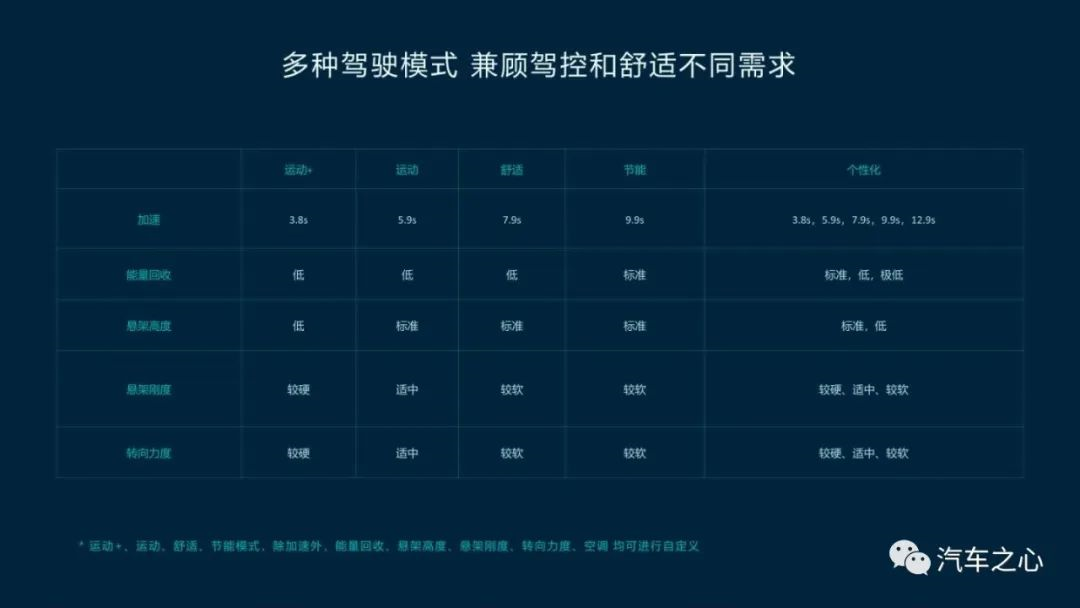

With the help of ICC, after tuning a large number of key components such as tires, air suspension, and steering systems, the NIO ET7 has four driving modes: Sport+, Sport, Comfort, and Eco.

In comfort mode, the suspension will give the vehicle more “breathing feeling”, while in sport mode, it will increase the correction of pitch and roll and enhance the control of the body.

This allows users to have a better driving experience.

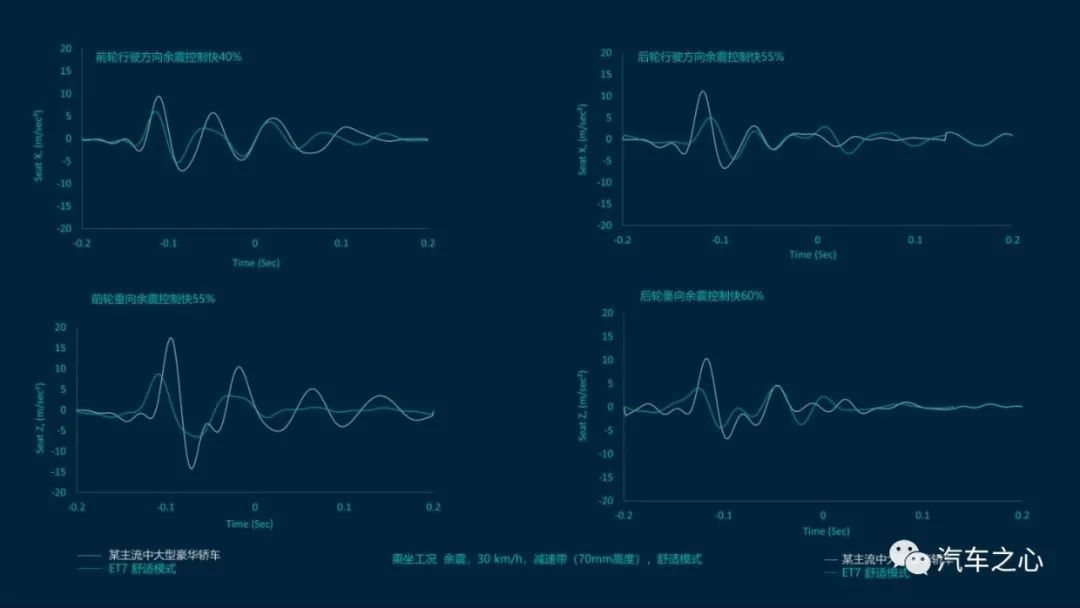

According to data provided by NIO, in comparison with a certain large luxury sedan:

In Comfort mode, the ET7 equipped with intelligent chassis control has 40%-60% faster damping control in the vertical and horizontal directions than the benchmark model.

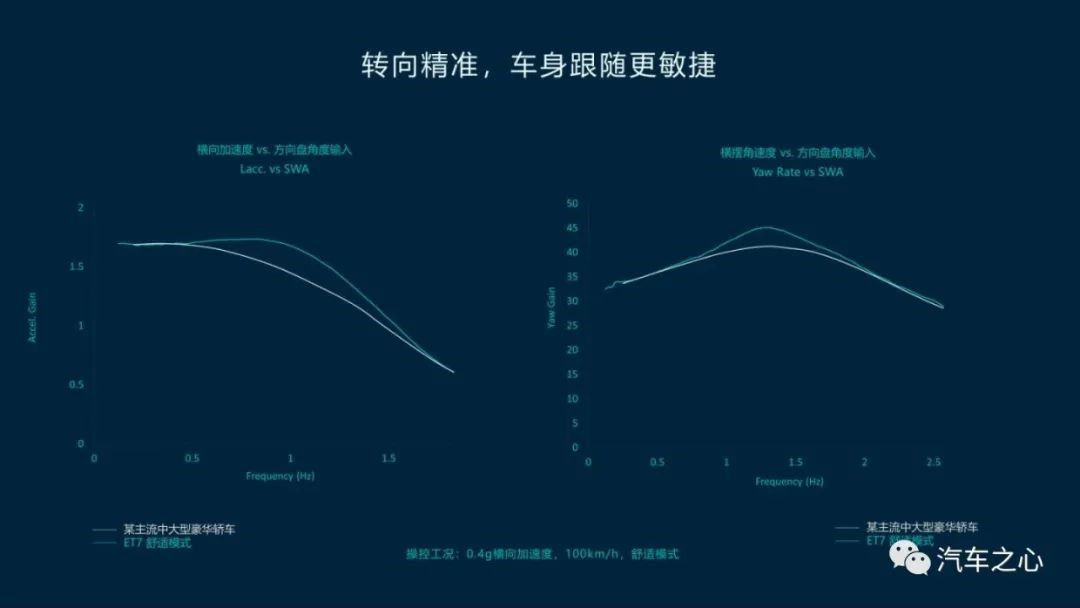

At a speed of 100 km/h, the comparison between the steering wheel angle speed input SWA and the lateral acceleration LACC and yaw rate is better in the ET7 than the benchmark model, which means that the turning of the ET7 is more accurate in this comparison.

Secondly, ICC can drive the automatic driving scene and achieve multi-degree-of-freedom fusion control.

Generally, in order to meet the richer functional experience in the NAD automatic driving scene, the chassis needs to provide a carrying platform for the automatic driving system, cockpit system, and power system.This is also a more critical goal of the self-developed intelligent chassis of NIO – Design for AD (design for autonomous driving).

In the NIO NAD autonomous driving scenario, the intelligent domain fusion control system can control the vehicle’s four-wheel drive distribution, line control movement, variable suspension, and other functions, making the whole vehicle more intelligent and realizing the driver’s expectations to the maximum extent, thus continuously expanding the boundaries of future functions.

At the same time, cross-domain actuators can back up each other and systematically reduce the probability of critical function failure, thereby improving driving safety.

Xiao Baihong said that in the 866 era, NIO’s NP/NOP system had a relatively low diagnostic protection threshold. If there was a brake/steering error, the assisted driving would immediately exit. With the NT2.0 platform, including the next generation of models, NIO will use mutual calibration judgment between controllers to gradually extend the high-level assisted driving exit time caused by error reporting.

At the same time, the ICC will make vehicles highly personalized in the future, relying on continuous collection and recognition of user’s personalized driving data, and providing driving and riding experience that meets users’ psychological expectations through human-vehicle interaction and self-learning iteration.

In terms of traditional chassis design and tuning, ICC can provide ET7 with better performance.

Furthermore, ET7 realizes the “atomization of functions” on cars for the first time, which has a new meaning for the chassis based on software, and the electronic and intelligent chassis can bring more interaction and greater possibilities to users.

Behind the Integration of NIO’s Full Stack Development: Defining the Foundation, Connecting the Experience, and Increasing the Upper Limit

Currently, the traditional automotive industry chain has undergone changes.

The improvement of intelligent vehicle, the development of hardware-software collaboration, and the iterative upgrade of electronic and electrical architecture have made car companies unable to integrate various components into the whole car as before.

Chairman of SAIC, Chen Hong, once said that car companies need to grasp the “soul” in their own hands.

But what is the “soul”?

In the era of intelligent electric vehicles, the core triple-electric technology is the “soul”, and the autonomous driving technology capability is the “soul”.

However, in NIO’s view, the self-developed ability of cross-domain fusion control is the core ability that car companies need to have in the era of intelligent vehicles.

The full-stack self-development ability of car companies mainly embodies the high-integration of hardware and software. Car companies without fusion capabilities can only be called electric vehicle companies, not intelligent electric vehicle companies.

From the perspective of the supply chain, the traditional sequential mode has become a mode in which car companies are at the center and various suppliers are closely related. Car companies conduct software self-development and find suitable partners based on design definitions and functional requirements.

Only with the full-stack self-developed ability of cross-domain fusion, NIO can provide users with more personalized driving experience based on user’s high-perceived daily driving scene, focusing on user experience.

As Xiaobaihong pointed out, adopting supplier standards for solutions that use any materials will not only limit the expression of the final product during shaping, but also limit the team’s exploration of technical boundaries.

NIO insists on full-stack self-developed chassis domain controller, which mainly embodies the ability in software and hardware, which not only defines the functions of the car, but also endows intelligent electric vehicle chassis with new meaning:

Defining the Bottom Layer: Based on full-stack self-developed technology, NIO ET7 has four driving modes: Comfort, Eco, Sport, and Sport +, in which, besides acceleration, energy recovery, suspension height, suspension stiffness, steering force, and even air conditioning can be customized.

Experience Interoperability: Originally, various chassis components were not interoperable. Based on ICC and software capabilities, NIO ET7 has connected various scenarios from traditional control functions to automatic driving and OTA upgrades, so that it can realize rapid iteration and flexible upgrades.

Improving the Upper Limit: The length of NIO ET7’s body is 5101mm and its wheelbase is 3060mm, but its actual performance is not inferior to that of some mid-to-large luxury sedans. This means that based on ICC, NIO can continuously improve the overall performance experience of the vehicle.

Based on user experience self-development, NIO’s ICC will be fully deployed on the NIO’s second-generation technology platform products, which is an accelerator for whole-vehicle development and functional iteration.

In the past, the whole vehicle chassis has been controlled by international giants. NIO’s self-developed intelligent chassis system has broken the monopoly of international giants, representing the rise of China’s high-end automotive brands in the traditional field of whole vehicle engineering.

Self-developed intelligent chassis is just the beginning, which means that NIO will have more adequate preparations to bring better driving and riding experience to users in the future.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.