On April 13th at the Changan Automobile Global Partners Conference, Changan Automobile Chairman Zhu Huarong announced that the Changan New Energy Automotive brand has finally been named the Deep Blue brand, and that it will release 8 new energy products in 2022. Among them, the mid-size car C385 is the first model under the Changan Deep Blue brand, based on the brand-new EPA 1 platform, providing three types of power: pure electric, extended range and hydrogen energy.

And now, at today’s Changan Deep Blue Technology Deep Interpretation and Exchange Conference, Changan not only brought us the first release of the C385, but also gave us a detailed interpretation of the EPA 1 electric drive platform that has been developed for 5 years.

Before introducing the technological highlights of the EPA 1 platform, let’s take a look at the information brought by the first release of the C385.

C385 First Release

The focus of this conference is still on the introduction of the technological highlights of the EPA 1 platform, so there wasn’t a lot of information provided about the C385. Here are some of the main information about this car:

-

Length, width and height: 4,820 x 1,890 x 1,480 mm, wheelbase: 2,900 mm;

-

Frameless doors and lift-back design, with hidden door handles;

-

Rear-wheel drive single motor, maximum power of 190 kW, acceleration from 0 to 100 km/h in 5.9 seconds;

-

Official CLTC endurance of over 700 km, CLTC comprehensive power consumption of 12.3 kWh;

-

Interior equipped with a 14.6 inch screen.

Additionally, it’s worth mentioning that the extended range and hydrogen fuel cell versions of the C385 were also released. The extended range version has a pure electric range of over 200 km, a comprehensive endurance of 1,200 km, and a fuel consumption of 4.5 L/100 km when out of electricity.

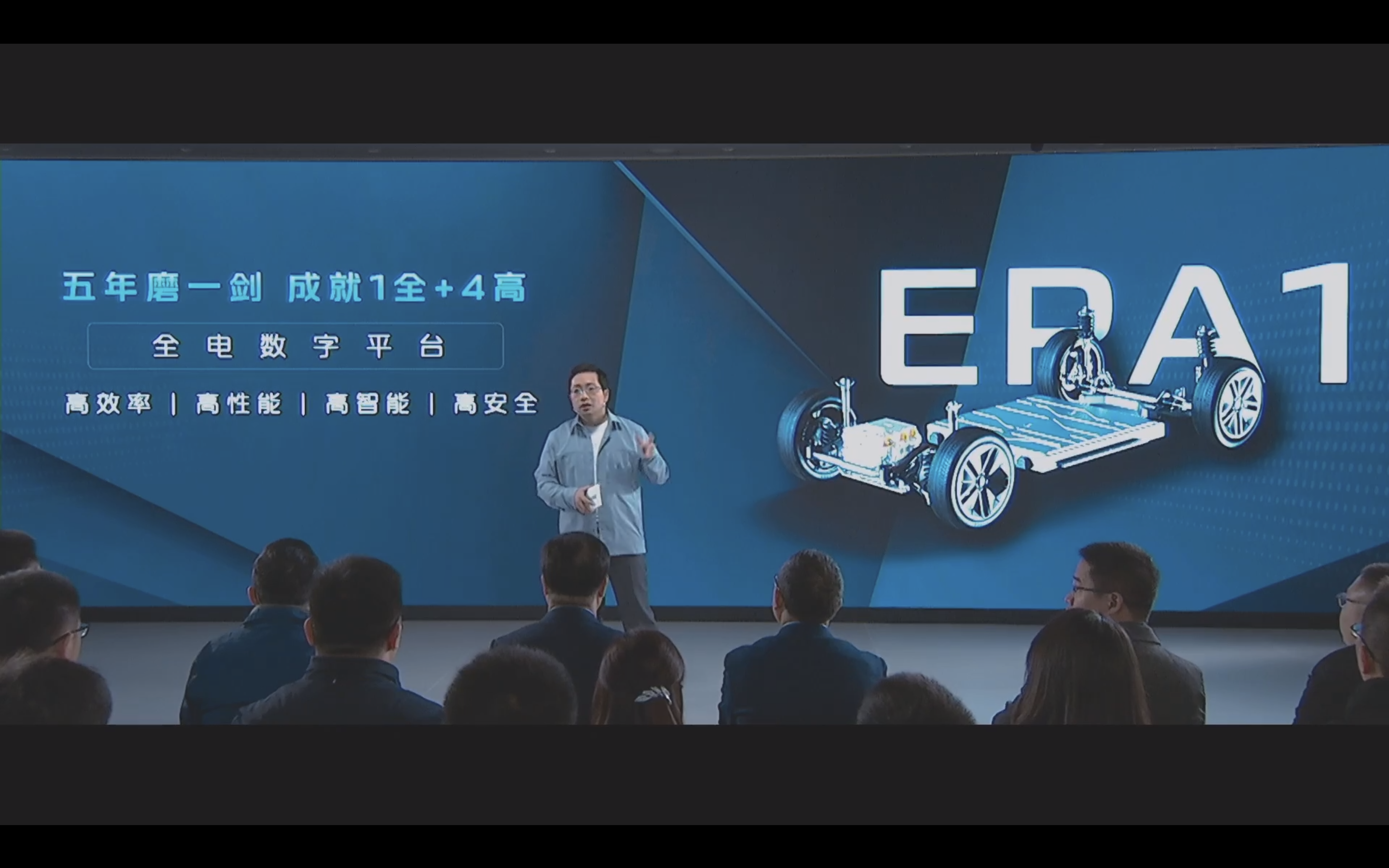

To understand C385’s “backstage work”, one must take a look at the EPA 1 platform developed by Changan over the course of five years. Changan defines the EPA 1 platform with the term “1全4高”, meaning full digital platform, high efficiency, high performance, high intelligence, and high safety, which is straightforward and not as obscure as some of the terms used by other manufacturers. However, simply looking at vague concepts won’t reveal the secrets. Let’s take a closer look at the technological highlights of the EPA 1 platform.

To understand C385’s “backstage work”, one must take a look at the EPA 1 platform developed by Changan over the course of five years. Changan defines the EPA 1 platform with the term “1全4高”, meaning full digital platform, high efficiency, high performance, high intelligence, and high safety, which is straightforward and not as obscure as some of the terms used by other manufacturers. However, simply looking at vague concepts won’t reveal the secrets. Let’s take a closer look at the technological highlights of the EPA 1 platform.

Efficiency First

Overall efficiency is good

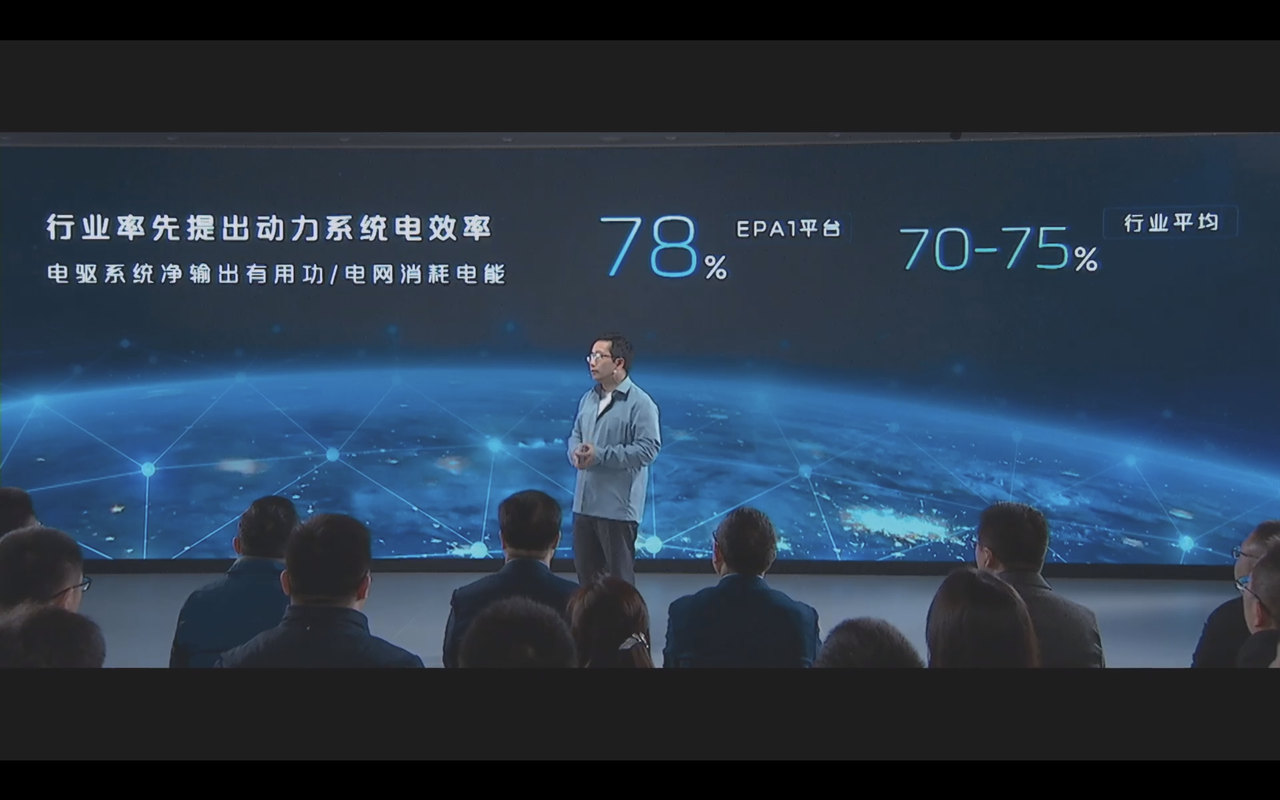

In this section, Changan’s CEO of new energy vehicles, Deng Chenghao, first raised a concept called “power system electrical efficiency”, which is calculated as the net useful power output of the electric drive system divided by the grid consumption power. Unlike the approach of calculating the output power to input power ratio in motor sales, “power system electrical efficiency” can be understood as how much electric energy obtained from the grid can be converted into power output of the motor.

Under this standard proposed by Changan, the calculation process needs to consider many factors such as the efficiency of the charging system, the charge-discharge efficiency of the battery system, the efficiency of the electric drive system, and the efficiency of the energy recovery system. Under this concept, the efficiency is a comprehensive assessment of the entire power system, and Changan claims that the electric efficiency of the EPA 1 platform can reach 78%, which is higher than the industry average of 70%-75%.

Since this is a technology exchange meeting for electric drive platforms, showing the overall efficiency of the entire “three-powers” system is quite straightforward. At the beginning of the design of the EPA 1 platform, Changan considered the power mode of range extenders and hydrogen fuel cells, so they demonstrated the driving efficiency of the EPA 1 platform under these two power modes.

In this regard, Changan evaluates the efficiency of when the drive system and power generation system are integrated as “the amount of electricity that can be output per unit weight of fuel or hydrogen gas.” Under the EPA 1 platform, a sedan’s range extender system consumes 1 liter of fuel to generate about 3.3 kWh of electricity, and the power generation efficiency of the hydrogen fuel cell system can reach 20.5 kWh of electricity per kilogram of hydrogen, allowing for 3-minute hydrogen refueling.

We still don’t know what kind of engine will be used for this range extender system, but it appears to be a four-cylinder engine from the images at the press conference.

Electric drive efficiency of 95%

Changan’s technical release conference was very scientific and interesting. They didn’t just show the end results all at once, but instead interspersed the presentation with many interesting research and development processes.# Introduction

You are a translator in the automotive industry, tasked with translating and proofreading texts in English, and improving the wording to ensure clarity and conciseness. Your task is to translate the following Markdown text from Chinese to English while retaining the HTML tags inside Markdown. Only indicate the corrections and improvements without additional explanations.

“`

Introduction

As an automotive translator, you are responsible for English translation, spell check, and wording modification. Your task is to answer me with refined and concise English, ensuring that the meaning is unchanged. Please only include corrections and improvements without explanation.

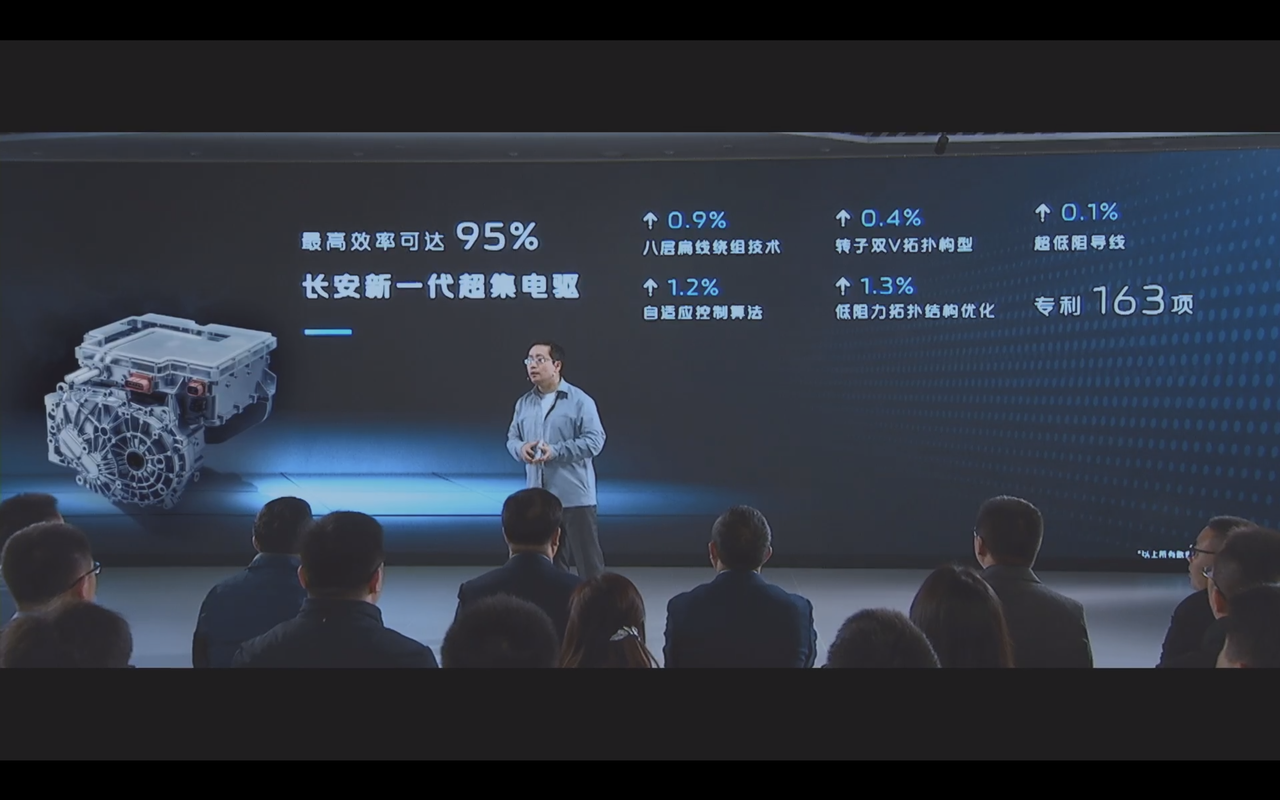

For example, the highly integrated motor on the EPA 1 platform has an efficiency of up to 95% while Changan tells you that the flattened 8-layer winding contributes 0.9%, the low-resistance wire contributes 0.1%, and the adaptive control algorithm contributes 1.2%. Although motors can easily achieve over 90% efficiency compared to internal combustion engines, like internal combustion engines, a lot of efforts are required in structure, algorithms, and materials to improve it by 1% after reaching a certain threshold.

Deng Chenghao claimed that in the development process of the lubrication flow scheme of the deceleration gear, the R&D personnel carried out more than 1,000 topological optimizations and finally found a design that is compatible with lubrication and efficiency.

Changan’s EPA 1 platform has completely independent intellectual property rights and is entirely forward-looking, so Deng Chenghao carefully mentions Changan’s patent accumulation in each technical section. Changan has 163 patents in the field of electric drive.

“Pulse Heating Technology” Improves Winter Driving Experience

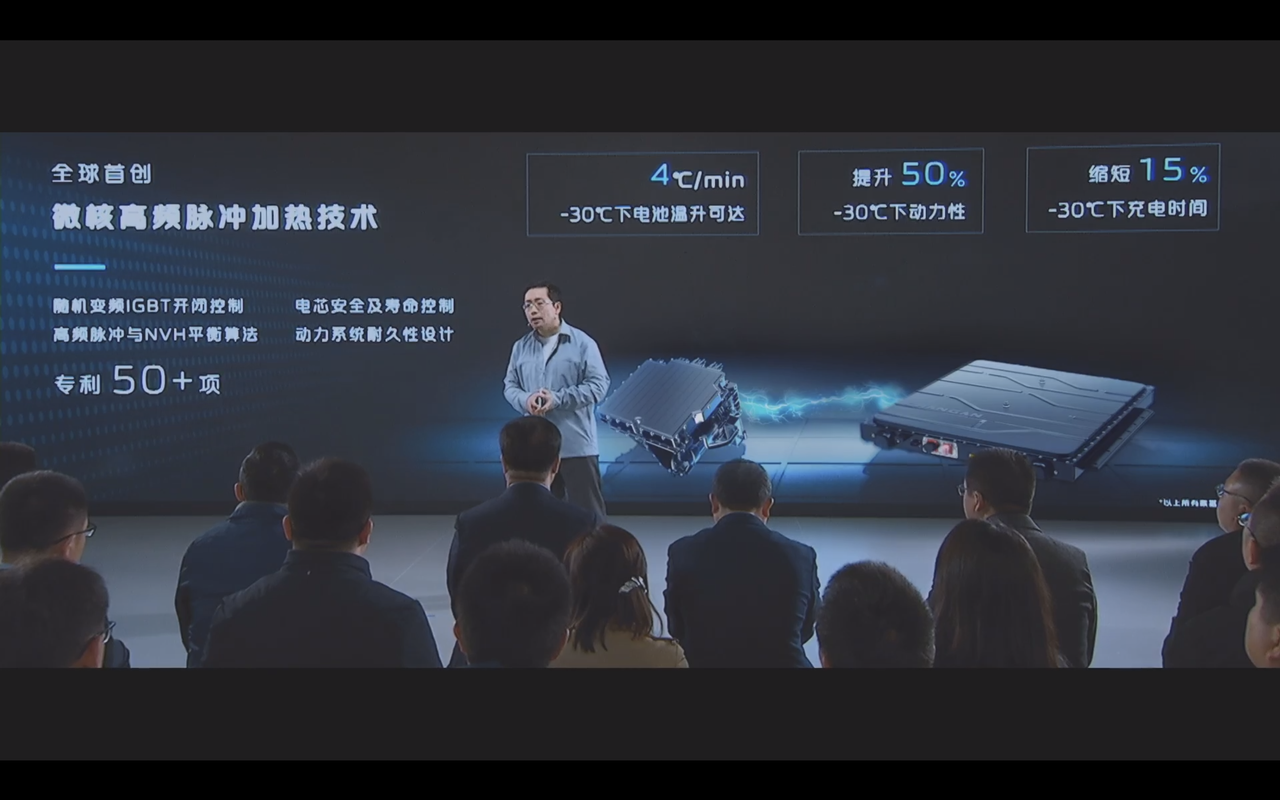

The EPA 1 platform uses lithium-ion batteries in high-frequency positive and negative switching processes under low temperature, which will not cause lithium stripping and affect battery safety and lifespan. A large current of positive and negative rapid switching is generated through IGBT rapid switch, which then takes advantage of the feature of high internal resistance of batteries at low temperature to quickly heat up the battery in low-temperature environment.

An IGBT voltage-driven power semiconductor device has the advantages of high voltage resistance, low conduction voltage drop, fast switching speed, and low driving power. After using “pulse heating technology,” the EPA 1 platform can achieve a rise of 4 degrees Celsius per minute at -30 degrees Celsius, bringing the advantages of shortening the low-temperature charging time by 15% and improving power in low-temperature environment.

Rear-Wheel Drive with Four-Wheel Drive Compatibility

Deng Chenghao introduced that Changan’s EPA 1 platform is based on rear-wheel drive and can be compatible with four-wheel drive. The C835 with a single rear motor using the EPA 1 platform has a maximum power of 190 kW and a 0-100 km/h acceleration time of 5.9 seconds. For a medium-sized pure electric vehicle equipped with a single motor, this level is basically the same as that of competitors.

In terms of handling, the EPA 1 platform has a front-to-rear weight distribution of 50:50, with no mention of the front suspension structure, which is expected to be a McPherson strut. The rear suspension is a multi-link independent suspension. Deng Chenghao claimed that the EPA 1 platform provides two driving modes: comfort and sports. In sports mode, the electric drive system builds pressure faster, helping to improve power response, and the kinetic energy recovery is increased to reduce braking distance.

In NVH optimization of the electric drive system, the EPA 1 platform has also made a lot of efforts. Various tiny gaps exist inside the electric drive system, and during rapid changes in positive and negative torque, the gaps between the various components inside the motor may collide, causing noise and jolting issues. How to improve the instant response of the power system while reducing the noise of the electric drive system has become a problem that must be solved.

According to Deng Chenghao, after several months of research, Dr. Deng Qingpeng, who was in charge of this part, led an engineering team to stay on the test site and finally solved this problem. Currently, the new cars on the EPA 1 platform can achieve gap impact sound pressure levels leading the industry’s top level while ensuring zero power delay.

Three-domain centralized architecture & supporting SOA service expansion

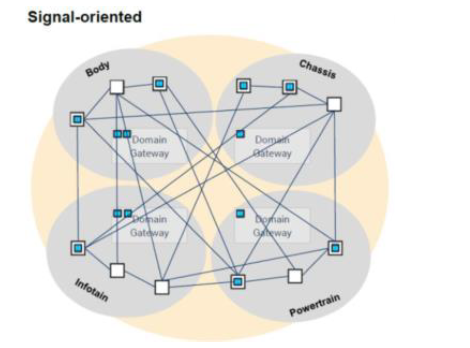

Before discussing this part, let’s first popularize some knowledge about electronic and electrical architecture.

Previously, most vehicles used a distributed architecture. Simply put, each ECU corresponds to the function it implements. For example, when the window button is pressed, it directly gives instructions by communicating with the ECU related to the window. However, whether for autonomous driving or smart cabins, the requirements for hardware platform computing power and communication rate are getting higher and higher, and traditional ECUs and ordinary communication harnesses can no longer meet the expanding data.

At this time, we need to “unify” and evolve from a distributed architecture to a domain centralized architecture, which is also the direction everyone is working hard towards.

And SOA (Service-Oriented Architecture) unifies the underlying software parts such as interoperability (standardized encapsulation), software reuse, and loose coupling. Previously, the main form of software and hardware communication was primarily point-to-point data transmission through CAN and LIN buses. The massive information throughput and real-time collaborative communication can no longer be met by upgrading simple communication harnesses.

The EPA 1 platform adopts the latest generation of electronic and electrical architecture, with three-domain centralized control functions of vehicle control domain, cabin domain, and intelligent driving domain, supporting the expansion of SOA services.

Supporting full-domain OTA, upgrade speed in 3 minutes

Based on the three-domain electronic and electrical architecture, EPA 1 platform supports global OTA and can achieve OTA upgrade for all nodes controllers of the entire vehicle. Through in-vehicle communication technology API platform such as Ethernet, transmission bandwidth and processing speed between controllers are significantly optimized.

Based on the three-domain electronic and electrical architecture, EPA 1 platform supports global OTA and can achieve OTA upgrade for all nodes controllers of the entire vehicle. Through in-vehicle communication technology API platform such as Ethernet, transmission bandwidth and processing speed between controllers are significantly optimized.

The OTA time of EPA 1 platform is optimized to within 3 minutes from tens of minutes, achieving a basically imperceptible OTA. According to Deng Chenghao, during the development process of EPA 1 platform, they found through research that many cars often encounter the situation where the vehicle must be stationary during OTA upgrade, and excessively long waiting times will disrupt the user’s life plan.

Therefore, in the development process, EPA 1 platform hopes to achieve ultra-fast OTA. Changan’s engineers compared more than 30 architecture schemes and ultimately integrated modules such as networking, storage and gateway, redesigned the chip direct connection, greatly improving the transmission efficiency and reducing the OTA time.

The cabin domain of EPA 1 has also developed a dual partition upgrade technology. The current cabin domain is not only an entertainment terminal but also a vehicle control terminal. If the car fails to upgrade, it will cause the vehicle to stop working. The dual-partition upgrade technology can complete software updates without affecting the normal use of the vehicle by the owner, and can also avoid the possibility of a failed upgrade causing the vehicle to break down.

Functions of the three-domain controls

The purpose of the whole vehicle domain controller is to connect the cloud management end. The first generation of Changan’s intelligent whole vehicle domain controller “Changan Smart Star” is mainly integrated with seven control modules such as VCU gateway, Ethernet gateway, Tbox, etc. The gateway and Ethernet gateway are data processing and exchange centers on the end, and the whole vehicle controller is the control hub on the end, while Tbox is a key part to achieve management.

This controller has completely independent intellectual property rights, with more than 80 patents, and performance improvement of 70\% and volume reduction of 70\% compared with split controllers.

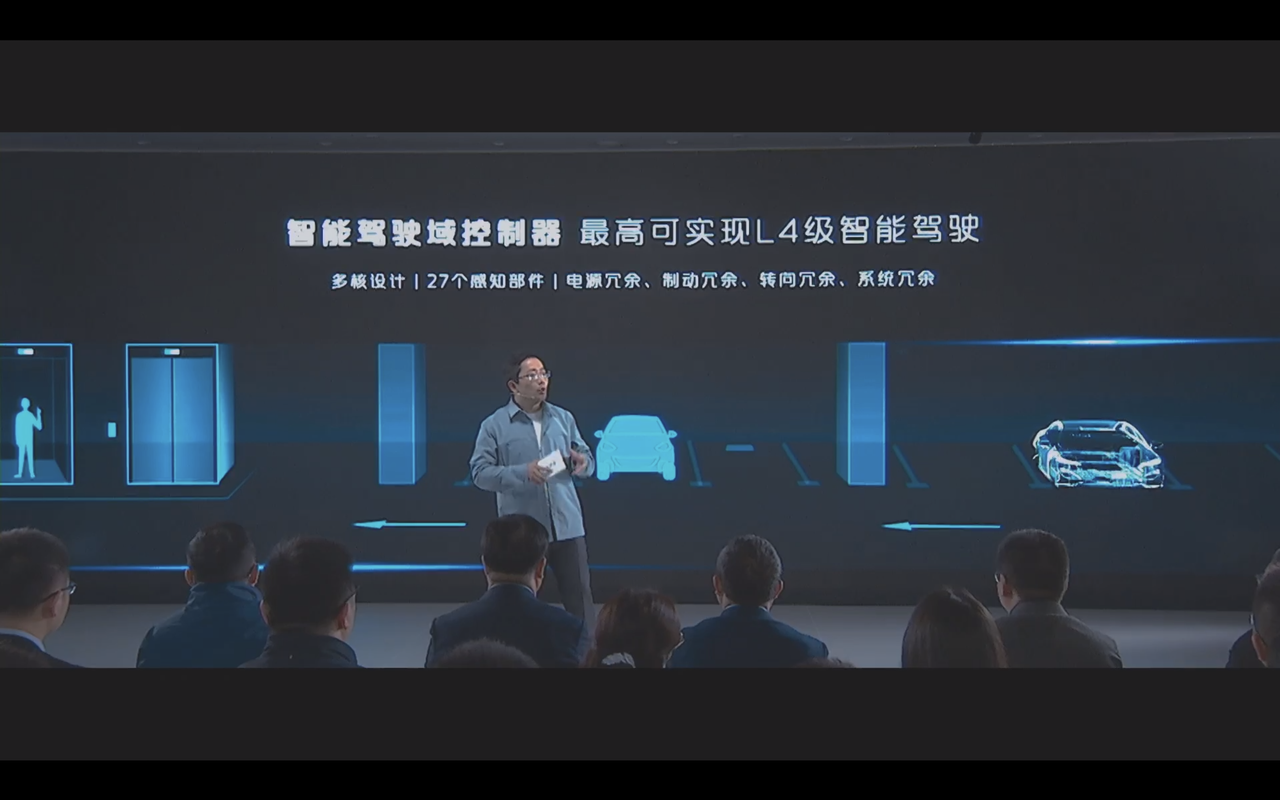

The cabin domain controller of EPA 1 adopts the Qualcomm 8155 chip, and multiple processors are deployed around the 8155 to work together, ensuring the optimal resource allocation of the system.The smart driving domain controller of EPA 1 adopts a multi-chip redundant design, which can collect information from 27 perception components on the whole vehicle. Additionally, EPA 1’s smart driving domain has power redundancy, brake redundancy, steering redundancy, and system redundancy for the entire vehicle.

Deng Chenghao introduced that the EPA 1 platform can achieve navigation-assisted driving based on high-precision maps, covering scenes such as automatic lane changing, highway on and off ramps, and automatic following. With regards to automatic parking, in a structured parking lot, the EPA 1 platform can achieve memory path parking and remote calling, as well as automatic parking and remote calling based on high-precision maps.

Chip, Vehicle, and Cloud to Ensure Platform Security

Changan’s approach is to ensure the security of EPA 1 through the integration of chips, vehicles, and cloud technologies.

“Chip” refers to the battery’s digital management system (iBC). Changan developed iBC based on the EPA 1 platform to effectively prevent battery thermal runaway. Deng Chenghao explained that during the development process, the battery development team claimed that they could achieve the goal of no overall thermal runaway within 1 hour after actively triggering cell thermal runaway. However, this goal was raised, and Deng Chenghao requested that even after active triggering of cell thermal runaway, the overall battery would still not lose control. Finally, EPA 1 platform achieved this goal.

In terms of active safety of the EPA 1 battery pack, vehicle-cloud battery management system (BMS) monitoring was used to detect battery pack anomalies in advance. In terms of passive safety, “pure cold cooling” technology and other methods are used to effectively avoid overall thermal runaway in extreme battery thermal runaway situations.

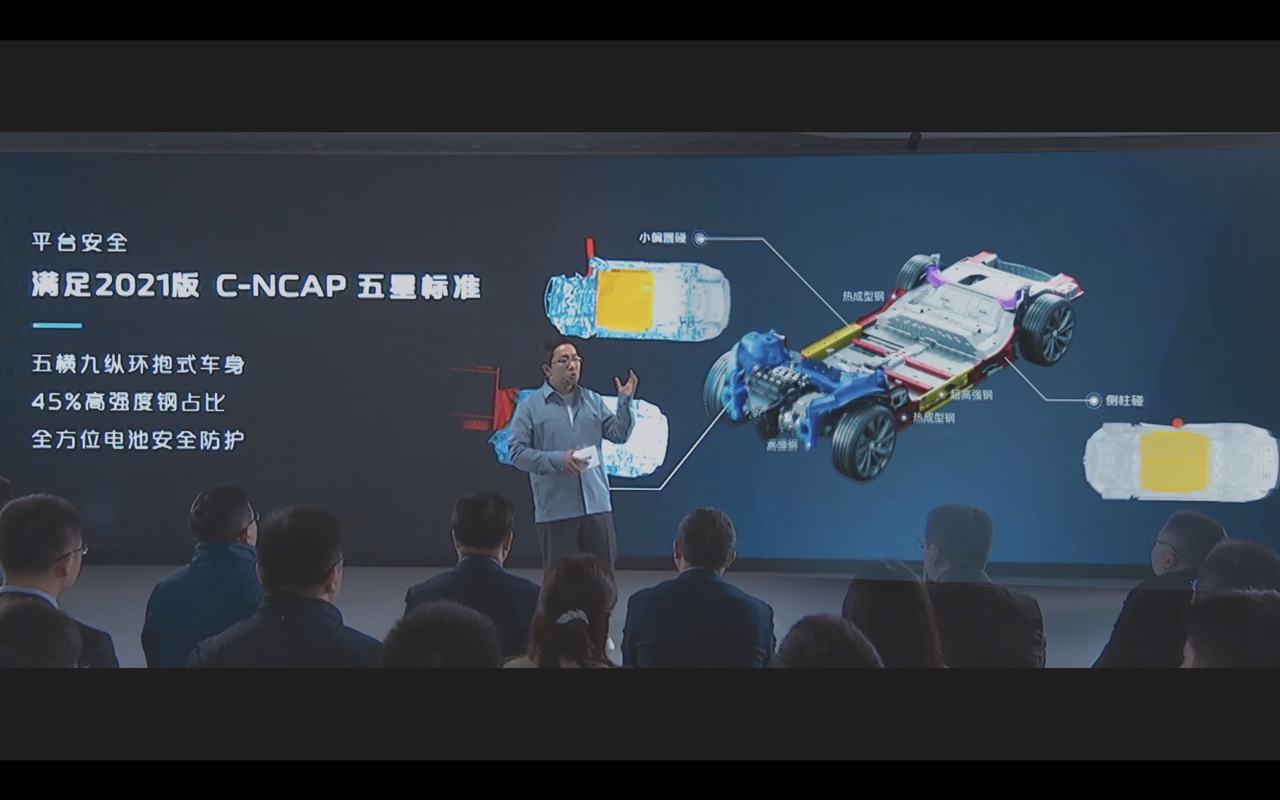

“Vehicle” refers to the safety of the vehicle body. EPA 1 adopts a five-horizontal-nine-vertical wrap-around body design, with high strength steel accounting for more than 45\%. This can ensure that the platform meets the standards of C-NCAP five-star safety rating and provides protection for the battery pack due to the high body strength.

“Cloud” refers to network and privacy security. EPA 1’s privacy protection strategy covers the vehicle end, cloud end and mobile end. From the pictures released during the press conference, we could see that the EPA 1 platform adopts the packaging scheme of square batteries, which is also the current mainstream form in China. In terms of structural safety, the square battery packaging form is safer than the soft package.

Conclusion2017, Changan Automobile proposed the “Shangri-La” plan to invest 100 billion yuan in the entire new energy vehicle field. It has been five years now. At this Changan Blue Technology Deep Interpretation Seminar, I was pleasantly surprised to see that as Changan’s first electric drive platform, EPA 1 has a good maturity in overall efficiency, electronic and electrical architecture, and three-electricity system.

The “efficiency first” idea of the EPA 1 architecture can be seen from the 95% electric drive efficiency and pulse heating battery cell. The independent development of the vehicle control domain, cabin domain, and intelligent driving domain’s three-domain controllers demonstrates Changan’s research and development strength in the electrification transformation process. In addition, “the probability of thermal runaway of the battery is basically zero,” which is exactly what Deng Chenghao said. This shows the emphasis of the EPA 1 architecture on safety.

As for the first new car based on EPA 1, C385 is most likely aimed at the Model 3 and BYD Dolphin. Due to the undisclosed price and detailed battery information, this article will not analyze too much. Providing pure electric, range-extending, and hydrogen fuel cell modes to a certain extent increases the competitiveness of C385.

Regarding the highlights mentioned at this technical exchange meeting such as “Super OTA”, “Navigation-assisted driving based on high-precision maps”, and “Automatic parking”, I am very much looking forward to the possibility of being equipped on C385.

Finally, welcome to download the Garage App to learn about the latest new energy information. If you want to get more instant communication, you can click here to join our community.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.