Weekly Index

Weekly News

Tesla Shanghai Factory Expands Production Again

On November 26th, Caixin learned from the Shanghai enterprise and institution environmental information disclosure platform that the second phase of the production line optimization project for the Tesla Shanghai factory (Phase 1) is undergoing environmental impact assessment public notice, indicating that Tesla Shanghai factory is officially preparing to expand production capacity.

Quick Comment:

Currently, Tesla Shanghai factory is burdened with a backlog of orders due to the impact of the delayed launch of the Berlin factory, which has been supplying Europe for several months. This has also led to a serious backlog of orders in the Chinese market, with the earliest delivery of Model 3/Y only possible in the first quarter of next year. However, the longer the backlog of orders, the greater the risk of cancelled orders for users. Therefore, this expansion of production capacity can not only reduce the backlog of orders and speed up users’ delivery, but also partially make up for Europe’s supply problem.

Model Y Performance Officially Delivers in China

Recently, Tesla’s Model Y Performance high-performance version has officially started delivery in China. In terms of power, the maximum power is 357 kW, the maximum torque is 659 N·m, and the official 0-100 km/h acceleration time is 3.7 seconds.

In terms of endurance, the NEDC range is 566 km, which is slightly less than the 640 km range of the Model Y long-endurance four-wheel drive version.

Quick Comment:In September, Model Y Performance had a price increase of 10,000 RMB in China, but its current price of 387,900 yuan is still one of the highest-performance and cost-effective SUV products on the market.

Momenta and BYD establish a joint venture company

BYD and Momenta have established a joint venture company for intelligent driving, named Shenzhen DP Intelligent Driving Technology Co., Ltd. Its registered capital is 100 million yuan, with BYD investing 60% and Momenta investing 40%.

The legal representative of the company is Yang Dongsheng, who has also served as a supervisor of BYD Co., Ltd., the vice president of BYD Co., Ltd., the director of Product Planning and the Institute of Automotive New Technology, and the chief designer of DM Technology. The business scope of the company includes IoT application services, AI public data platform, and AI basic resources and technology platforms.

Comments:

In the C-round financing of Momenta in March this year, it received a $500 million investment from investors such as SAIC, Toyota, Bosch, Temasek and Yunfeng Fund. In September of this year, General Motors also invested $300 million in Momenta, and GM stated that it will also use Momenta’s assisted driving solution in the future.

Within a short period of six months, Momenta has received more than $800 million in investment. Perhaps Momenta’s participation will make up for BYD’s shortcomings in the field of assisted driving. Previously, we have been able to see from real-life cases in Suzhou City that the Jing Ji vehicle using the Momenta solution is using assisted driving.

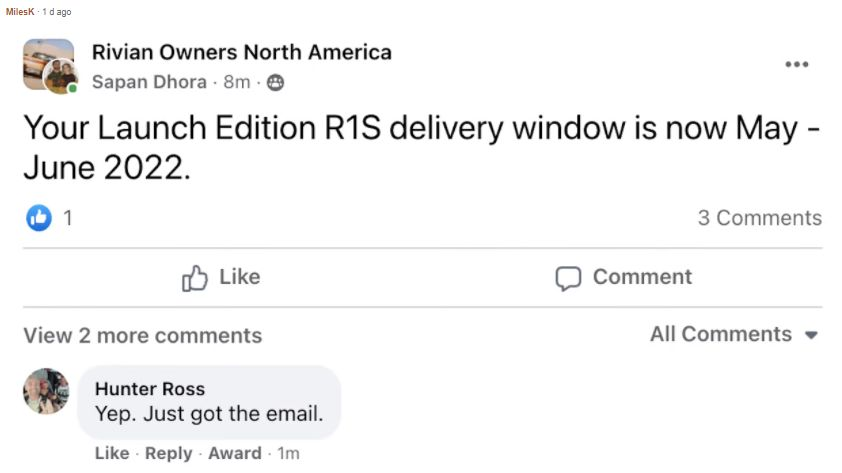

Rivian delays delivery again to 2022

According to foreign media reports on November 25th, Rivian had originally informed customers that it would start production of R1S in December and deliver to pre-order customers in January next year. But the company has notified customers that the earliest delivery of vehicles will be between May and July next year.

Comments:On November 10th, Rivian had its first public offering. Just two days after it went public, its market value quickly surpassed that of traditional automakers such as Ford and GM. Despite some price corrections in recent days, Rivian’s market value is still at the top of the $100 billion mountain as a new force in the car manufacturing industry.

Although Rivian’s market value is high, as a new force in the car manufacturing industry, it must also bear the hardships it experiences. As Elon Musk commented on Rivian’s first IPO, “the real challenge is to improve production capacity and balance cash flow”.

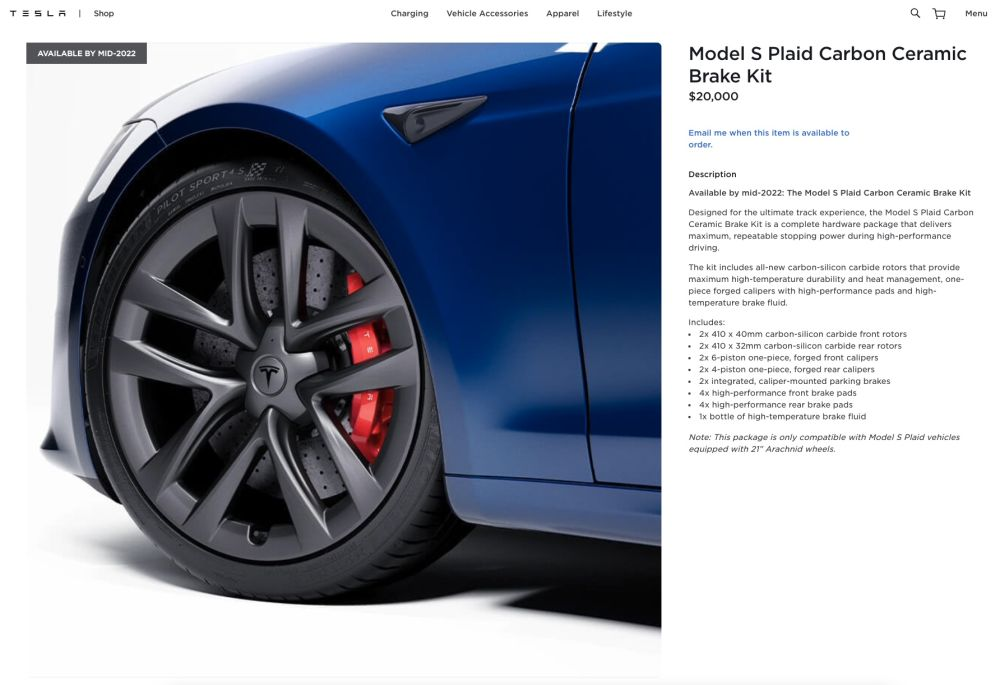

Tesla Launches Model S Plaid-Specific Carbon Ceramic Brake Kit

Recently, Tesla’s official website launched a $20,000 carbon-ceramic brake kit, which is exclusively for the Model S Plaid model and is expected to be launched in mid-2022.

The kit includes:

-

410mm carbon-ceramic brake discs for the front and rear;

-

Front 6-piston and rear 4-piston brake calipers;

-

High-performance brake pads and brake fluid.

Quick Review:

This kit priced at $20,000 is not too expensive. The 410mm carbon-ceramic brake discs are larger than the 401mm ones on the BMW M5. In addition, both front and rear calipers have single unit structures, which are more rigid. The brake discs are fixed through a full floating approach, which can eliminate the stress generated by thermal expansion and contraction, resist deformation, and optimize the initial brake feeling when the brake pads contact the discs.

Xpeng Unveils the Qualcomm Snapdragon 8295 Chips Using 5nm Production Process

Xpeng’s first mass-produced model will become the first product in China to use the 4th generation Snapdragon automotive digital cockpit platform. This SA8295 is equivalent to the Snapdragon 888 used in smartphones, and uses 5nm production process. The specific parameters of this platform have not been officially announced, but it is said that its NPU computing power reaches 30 TOPS, CPU computing power exceeds 200 K DMIPS, and the GPU computing power exceeds 3,000 GFLOPS.

The mass-produced Xpeng model equipped with the new digital cockpit is expected to be launched in 2023, and the concept car for this product is expected to be officially unveiled at the Beijing Auto Show in April next year.Quick Review:

The Snapdragon 8295 can support the fusion of multiple ECUs and domains, which can synchronously process multi-screen scene requirements such as instrument panel, cabin screen, AR-HUD, rear seat display, and electronic rearview mirror. The computing power of main computing units such as CPU and GPU has been increased by more than 50% compared to 8155, and the mainline capacity has achieved a super 100% improvement.

In addition to the performance improvement, the key is the benefits brought by the central processing centralization in the evolution of the regional system architecture. Multiple screens will become a trend in the future cabin, and the central processing center can use the lowest development cost to bridge the physical gaps between each screen. Cabin development does not need to constantly stack various “plug-in applications” between different development environments, and the performance requirements of each screen can also be uniformly scheduled.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.