This piece of land in front of me was just paved three days ago, the WmAuto staff pointed to the entrance of the final assembly workshop and introduced it to me.

Looking further outside the final assembly workshop, this is an area of nearly 1000 mu (about 165 acres), with a planned production capacity of 100k in phase one and 200k in total. As shown in the figure above, we arrived at the factory by bus and saw scaffolding, bare land, and some unfinished parts.

Shen Hui, the founder of WmAuto Automobile, talked about the decisions of the management team at the offline ceremony of WmAuto EX5. After an intense internal discussion, the event still proceeded, despite the imperfect state of the factory. Unfortunately, photography was not allowed on-site.

The final assembly and body workshops were open for visiting. In the workshops, there were no stacked materials on-site, and the wall signs were printed on A4 paper with WmAuto logos, rather than showing the actual production status.

In the final assembly workshop, when we reached the workstation through the viewing line, the workers began to show us a complete operation process. In contrast, in the body workshop, the workers were busy cooperating with each other without being affected by the visitors.

The most obvious feeling throughout the process was that everything had just begun. The staff explained that WmAuto had already tried out a dozen vehicles on the production line, and the vehicle that participated in the ceremony had just been off the assembly line three days earlier.

However, my first curiosity about this factory was that it was the only one among the several new carmakers that had gained production qualifications, even though it was acquired by acquisition.

The Pain of the Pre-Provisioning Certificate That No Car Person Can Avoid

Strictly speaking, the full name of production qualification should be production enterprise and product access qualification, commonly known as the “birth certificate” of automobiles in the industry. In the field of new energy vehicle manufacturing, there are two access regulations: one is the 37th document “Management rules for access of passenger car production enterprises and products” issued by the Ministry of Industry and Information Technology in 2011, and the other is the 39th document “Management rules for access of new energy vehicle production enterprises and products” issued by the Ministry of Industry and Information Technology in 2017.

The first hurdle for car manufacturers is not financing, staffing, or products, but this weighty “birth certificate”.

On a flight from Beijing to Wenzhou, I happened to be reading “The New Manufacturing Era”, a book about Li Shufu’s car manufacturing story. This book spends one-fifth of the space at the beginning to tell the story of how Li Shufu went from secretly producing cars to the difficult process of obtaining the “birth certificate”. Only after Geely got the “birth certificate” officially, they had the opportunity to grow step by step until the acquisition of Volvo and the achievement of today’s Geely.

Shen Hui, founder of WM Motor, also appears in this book and participated in the second half of Geely’s acquisition of Volvo. As a founder of a company who has served as a senior executive in the automotive industry for more than ten years, he cannot but understand the importance of the “birth certificate”.

In order to deal with the regulations on the “birth certificate”, new car forces have several ways.

Firstly, they can find a factory to produce on their behalf. The produced vehicles must carry the branding of the factory, such as Jianghuai NIO and Haima XPeng.

Secondly, they can acquire manufacturers with production qualifications and then obtain new energy vehicle production qualifications through product and production base changes, such as WM Motor.

Thirdly, they can apply independently, such as EV startup CHJ Automotive and NIO, which has now built its own factory in Shanghai.

The first method is quick, but not sustainable, such as NIO already building its own factory.

The second method is fast, but especially costly, often involving hundreds of millions of dollars. For example, WM Motor spent RMB 1.18 billion to acquire Dalian Huanghai and later bought Shenyang Zhongshun, changing its production base to Wenzhou. The amount involved has not been disclosed.

The third method is slow and risky. Many manufacturers will consume a lot of manpower, material and financial resources in the lengthy application process.

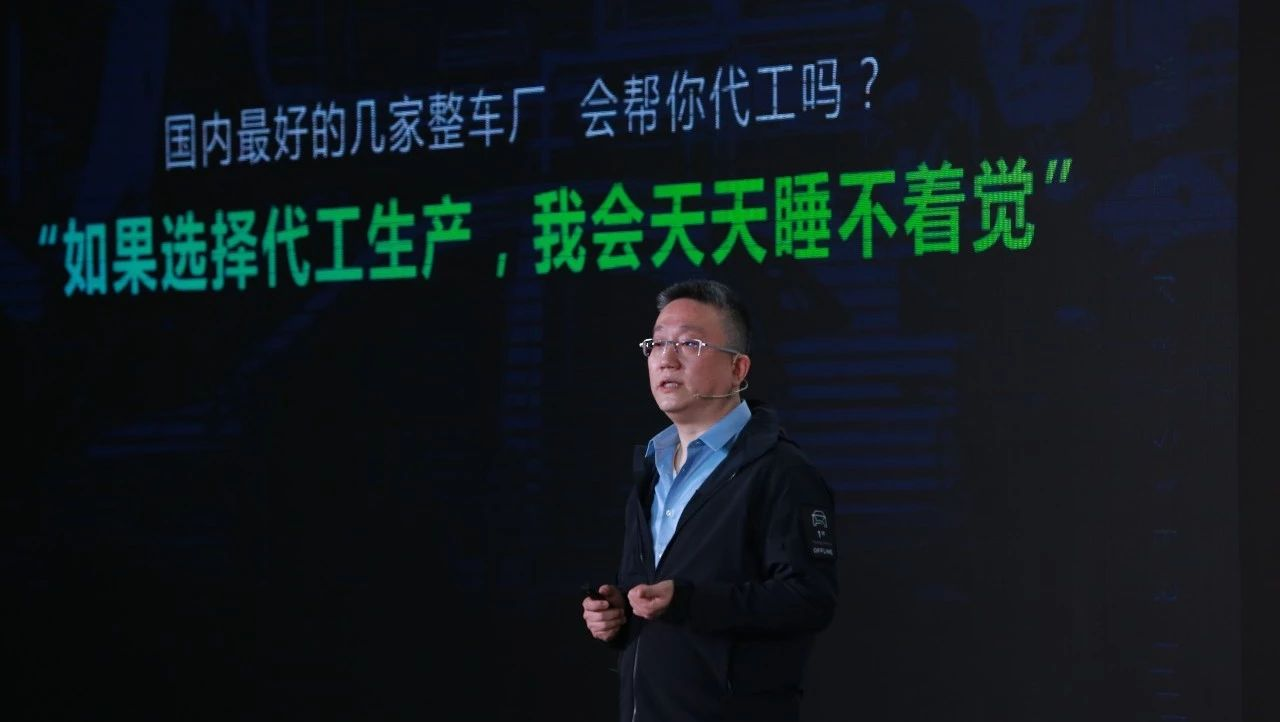

At the event, Shen Hui directly mentioned the OEM model, saying that the OEM model has developed for more than 30 years abroad, and it has been proven to be a relatively failed model, just like surrogacy, with many uncontrollable risks.

The choice of the three methods seems to imply the direction of different enterprise styles. If the OEM model is regarded as a low-risk preference, WM Motor should be considered as medium-risk preference, not radical, nor conservative. Applying for qualification independently seems to have the highest risk in the short term.Use a word to describe WM, it would probably be astute, a kind of sharp astuteness from the predecessors.

The first step is not the intelligence of the vehicle, but the intelligence of the factory

When describing WM’s strategic plan, Lu Bin, VP of WM Strategic Planning, mentioned that WM’s first-stage strategic positioning is high-end intelligent manufacturing. About this, you can see in many media reports of WM’s offline ceremony that WM has spent a lot of space emphasizing the automation and intelligence of the factory, and also mentioned that WM’s goal is to create a benchmark for the new energy vehicle industry 4.0 park.

For example, WM’s automated production line in the body workshop reached 100%, and WM launched an artificial intelligence quality inspection system, as well as the application of RFID wireless radio frequency technology, etc. These are actually issues of machine automation rate. More importantly, WM mentioned that it is reconstructing the order and manufacturing system from scratch.

The reconstruction of software and hardware constitutes the industrial 4.0 system. The goal of implementing industrial 4.0 is to improve production efficiency and achieve the most efficient C2M customization production.

To better understand this matter, let me make an analogy: mobile phones.

The machines in the factory used to be Nokia phones, and workers produced them manually.

Later, the machines in the factory gradually became Apple phones, that is, they became upgradable intelligent hardware. At this stage, we usually focus on the factory’s automation rate. It should be noted here that the automation rate of the factory can only indicate the automation rate of hardware and has not reached the stage of true industrial 4.0.

In the last stage, the Apple phones can be connected to each other, and the data is stored in the cloud, like iCloud. If there are process defects in the produced vehicles, you can call up the data at any time to study where the problem occurred. At the same time, the conversion of intelligent manufacturing capabilities into the application of big data makes data a productivity.

This is the concept of the Internet of Everything on the factory side, that is, the concept of creating a living factory as WM said.

But today, not many factories have truly realized industrial 4.0. In other words, everyone is in the preliminary stage of industrial 4.0. Moreover, what exactly is industrial 4.0, and even there is controversy.Here the biggest problem lies in that each business chain has its own solution, such as from programmable logic controller (PLC), also known as factory robots, to manufacturing execution systems (MES) and enterprise resource planning (ERP), among others.

Industry typically uses the pyramid structure to describe the relationship between these systems, with PLC at the bottom, the most bloated and least effective part, followed by MES in the middle, and ERP at the top. In the later stages of Industry 4.0 development, the pyramid will become a columnar structure, with useless data being utilized and all information flowing effectively.

Implementing a software process revolution on top of an existing factory process is relatively difficult. WM Motor mentioned that their advantage lies in implementing intelligent manufacturing from scratch, which avoids the process reengineering that traditional manufacturers undergo. A maximum of 900 workers will be required for intelligent production over the entire production base.

However, the goal of Industry 4.0 is to achieve customized production, which aims to maximize customer needs. The question arises: do customers really have so many customization needs?

In an interview, Freeman Shen, WM Motor’s CEO, mentioned that the company’s optional features are basically benchmarked against Tesla’s optional features, with additional options for range. There are about ten optional features in total, resulting in thousands of possible combinations.

Even for Tesla’s frequent configuration updates and diverse customizations, sales have increased significantly due to the implementation of the quasi-delivery model. Customers seem to care more about visible on-hand inventory and delivery times.

WM Motor targets realizing 21-day delivery with its C2M customized production. Currently, if you order a Tesla in China, it will take three to five months for customization and one to three months for on-hand delivery. However, Tesla’s actual vehicle manufacturing cycle is about 14 days, and if it weren’t for slow shipping, a 21-day delivery might be achievable.

WM EX5’s Comprehensive Preparation

Finally, let’s take a look at the preparation of the WM Motor EX5.

1. Vehicles

According to information from onsite staff, WM Motor has produced a total of over a dozen trial installation cars in this batch. The EX5 unveiled at the ceremony was just produced three days ago.

Freeman Shen mentioned that after the vehicles are offline in March, it will take five to six months to implement a strict quality assurance system, and vehicle delivery will be realized in the second half of the year. Nearly all product and pricing questions were left to the product release conference in April prior to the Beijing Auto Show, and little information was revealed on site.

The known product information of the WM Motor EX5 is as follows: the starting price is around 200,000, the NEDC range is 450 km, the wind resistance coefficient is lower than 0.3, and it is equipped with LED headlights, ACC adaptive cruise control, front and rear parking radar, 360-degree panoramic camera, through-type taillights, and a color touchscreen in the central console.

From the closed vehicle on site, it can be seen that the screen is lit up. The instrument cluster has a UI design similar to Tesla, with lane and vehicle information resembling Autopilot in the center, the gear position visible on the right side, and tire pressure information on the left side.

The actual size of the central control screen is smaller than expected, with black borders. The UI design is a traditional Android nine-grid format, with each icon in the form of a line, appearing in multiple colors, and featuring the WM Motor logo as a visual element. The WeChat icon is very eye-catching, located on the top right-hand side of the first row, and is probably a prominent practical application of Tencent’s investment in WM Motor.

In an interview, Shen Hui mentioned his dream for a large screen. In 2015, Shen Hui asked BOE to make a 50-inch large screen, but later found that this screen would not meet the requirements for automotive regulations until 2025. Eventually, he settled for the current screen, which can rotate 90 degrees and is used for navigation when it is vertical and entertainment when it is horizontal.

As for lightweighting the vehicle, WM Motor has reserved an aluminum production line in the factory plan, but has no clear plan to implement it. Currently, lightweighting of the EX5 primarily relies on structural optimization rather than material substitution.

Regarding the battery, WM Motor has chosen four suppliers, one of which is Ningde Times, located over a hundred kilometers away from the Wenzhou factory. In the interview, Shen Hui specifically mentioned that the price of battery cells would definitely drop in the future, but more importantly, the supply of battery raw materials must be ensured. Therefore, WM Motor has introduced China Minmetals Corporation, the world’s largest producer of battery raw materials.

2. Reservation Volume

Since the reservation portal was opened by WM Motor on December 11 last year, the reservation volume has exceeded 10,000 units, with daily growth ranging between 200 and 300.

Lu Bin very sincerely shared a set of data. In WM Motor’s orders, first-tier cities account for about 40% of the total orders, with the top five regions being Beijing, Guangdong, Zhejiang, Shanghai, and Shandong.## Customer Profile

According to the customer profile, the largest age group is the post-90s, accounting for 52%, followed by post-85s, which accounts for 29%. In addition, 2% of users are over 50 years old.

In terms of gender, 80% of the customers are male, and 20% are female.

Lubin also shared the zodiac data of the customers, with Aquarius, Libra, and Scorpio ranking the top three. They seem to be more lively and outgoing types, but also more adventurous.

Weima will expand sales areas and select corresponding intelligent partners based on the order data situation.

Channels

Weima did not adopt Tesla’s direct sales model, but used the concept of “Smart Partnership” to cooperate with traditional car dealerships.

Lubin mentioned that the traditional 4S dealership industry has undergone a significant change in the past five years, with the number of 4S dealerships decreasing from 80,000 to 25,000. Everyone is facing the dual transformation of e-commerce and electric vehicles. Weima selects intelligent partners from dealerships seeking transformation, and has currently signed contracts with 20 partners.

The Smart Partnership model is not only for selling cars, but also to make electric cars a mobile terminal with Weima, become a car renter, and provide vehicle services.

The model adopted by Weima is an innovative 4S model.

The first “S” stands for Space, which is the experiential center. The first flagship store will open in Beijing before September. The location work in Shanghai has been completed, and southern cities and Chengdu are still being considered for locations.

The second “S” stands for Store, a large delivery center.

The third “S” stands for Station, a small service station. A new station will be set up for every 500 cars sold in each city.

The fourth “S” stands for Spot, a small fast repair service, which is connected to the national chain store through the system.

Weima will sign a Smart Partner in each city to lay out multiple aspects from delivery center, charging network to service network.

Charging Network

Lubin mentioned that Weima has communicated with the top five national charging operators and opened an API interface. Weima has also made a charging APP, which will be first used internally and gradually improved.

What kind of company does Weima want to be?

Lubin repeatedly mentioned scale and data in the interview.

Brand awareness and scale are positively correlated, while parts cost and scale are inversely proportional. Scale and cost determine the competitiveness of a host plant.

Weima values scale over single-car profitability.

Lubin also mentioned that our goal is to quickly enter into a leading company in the auto industry after our products go public, not in the new car field, but in the automotive sector.This is probably why WM Motor has chosen to first focus on intelligent manufacturing in the 200,000 RMB market segment.

PS. There are far more mentions of Lu Bin than Shen Hui in this article, because Shen Hui drank too much in celebration of the offline ceremony…

Note: No photography is allowed on site, and all pictures are from official sources.

McKinsey: How will the electric vehicle market move towards profitability?

What other electric vehicles could GWM BMW produce in the future?

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.