LEAPMOTOR, no longer merely being a sole car manufacturer.

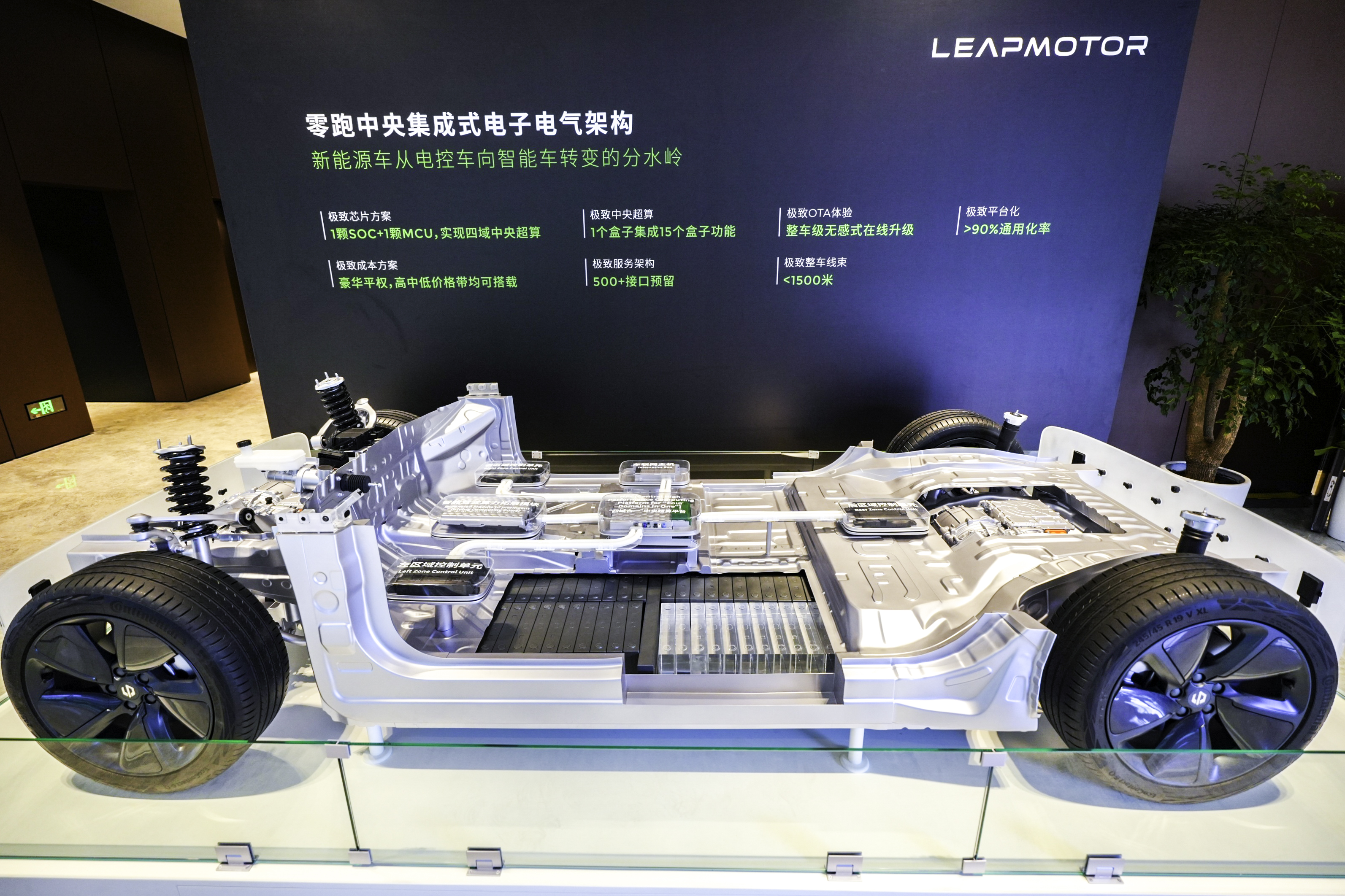

On July 31, LEAPMOTOR released a brand new generation of centralized integration electronic and electrical architecture, named “Four Leaf Clover.” According to the official announcement, the core electronic parts of the Four Leaf Clover system have been developed entirely in-house by LEAPMOTOR. The system is currently nearing mass production, and the first car model equipped with it will unveil at the Munich Auto Show in September this year.

Worth noting is that, following the release of the Four Leaf Clover structure, LEAPMOTOR has expanded its role beyond solely being a car manufacturer. It also aims to play the role of a provider of comprehensive intelligent electric vehicle solutions.

In this regard, the chairman of LEAPMOTOR, Zhu Jiangming, said:

LEAPMOTOR is very pleased to distribute the technology and has already licensed it to two complete vehicle manufacturers.

One integration, Four domains, elevating intelligent experience

As the new generation “centralized integration electronic and electrical architecture” developed by LEAPMOTOR, the Four Leaf Clover aims to provide users with a superior intelligent electric vehicle experience that stays innovative and updated.

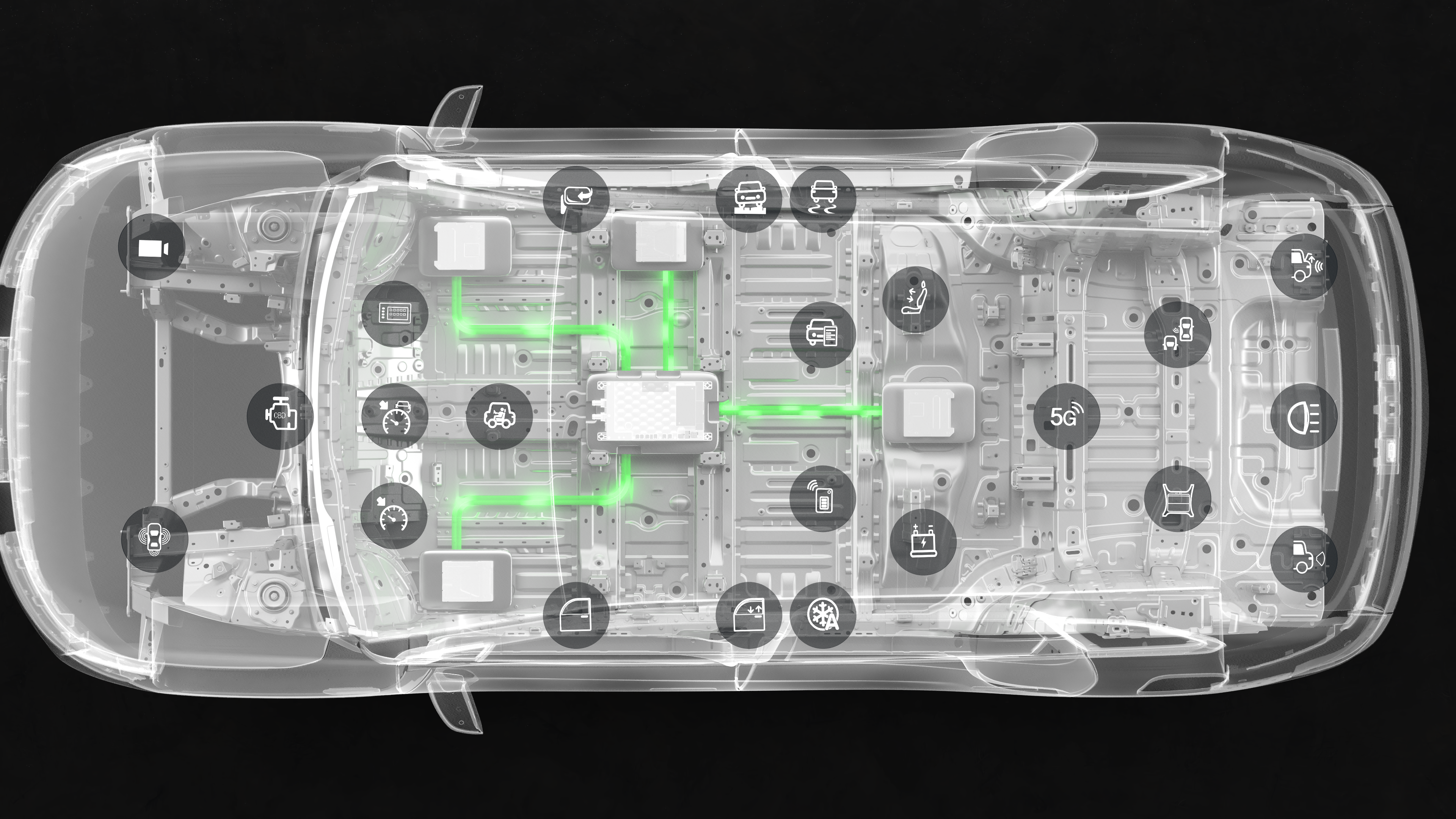

According to LEAPMOTOR, the Four Leaf Clover integrates the cabin domain, smart-driving domain, power domain, and car body domain into one, thus achieving high central supercomputing, efficiently synergizing the core parts of the intelligent electric vehicle. This is the only true centralized integrated electronic and electrical architecture to date.

Specifically, it has four major technological characteristics.

High level of cockpit integration

The Four Leaf Clover architecture is equipped with an SOC chip (Qualcomm Snapdragon 8295/8155) and an MCU chip (NXP S32G).

The Qualcomm Snapdragon 8295 chip has a computational power capacity of 30 TOPS, laying a solid foundation for the internal module synergy efficiency of the car. Meanwhile, the NXP S32G chip has strong security and communication capabilities endowed with the highest level of whole car information processing capability, supporting rapid responses to massive amounts of information.

These two chips constitute the “Central Supercomputing” of the car, much like the “left and right brain” of a vehicle. The SOC is the “right brain”, responsible for the intelligent cockpit and smart-driving, while the MCU is the “left brain” managing overall vehicle control and body regulation. With the teamwork of the “left and right brain”, a powerful intelligent driving capability and a smoother intelligent cockpit are achieved.

Integrated ECU Control Units

LEAPMOTOR has independently developed 15 modules, including whole vehicle control, body control, gateway management, thermal management, instrument information system, in-car entertainment system, 360° view, APA parking, fatigue monitoring, life monitoring, driving record, sentinel mode, sound warning, DSP amplifier, and video conference. These modules are highly integrated in one central supercomputing module, solving the problem of excessive ECUs in the distributed and domain-controlled electronic and electrical architecture.

To ensure the central supercomputing module works within the optimal performance and longest lifespan temperature range, LEAPMOTOR adopts a liquid cooling method to control the temperature, aiming to maintain the chip in an optimal working state, enhancing the car’s intelligent interaction capability and intelligent driving response speed.

To ensure the central supercomputing module works within the optimal performance and longest lifespan temperature range, LEAPMOTOR adopts a liquid cooling method to control the temperature, aiming to maintain the chip in an optimal working state, enhancing the car’s intelligent interaction capability and intelligent driving response speed.

Due to the huge reduction in ECU, the total vehicle harness has been shortened below 1.5 km in length, reducing the weight to 23 kg, conducive to vehicle lightweighting, making power consumption even more friendly. At the same time, with a shorter harness, the speed of interactive information transmission is also enhanced.

Creating Thousand Faces for Thousand Users Car Experience

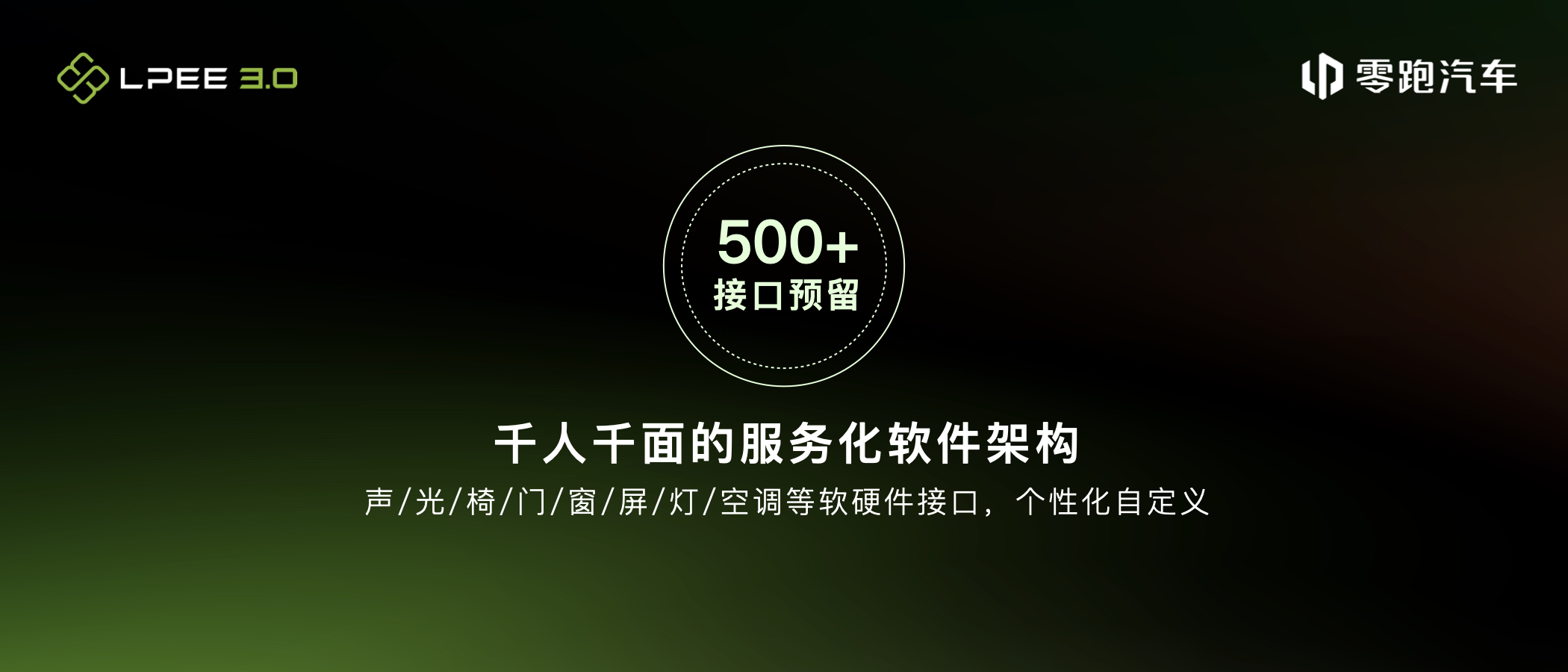

The four-leaf clover architecture reserves more than 500 interfaces, which can realize different combinations of functions for the cockpit, intelligent driving, power, and vehicle body modules, giving users more customization authority.

On the software level, the four-leaf clover architecture has one SOC code library and one MCU code library configuration, addressing the issue that traditional domain control architecture code libraries are independent, unified communication protocol is hard, and the system cannot run efficiently. Eventually, it makes every system operate with greater compatibility.

Seamless Online OTA

With the high central integration of the four-leaf clover architecture, a LEAPMOTOR OTA upgrade of a supercomputing platform software can complete the whole vehicle’s evolution. Moreover, it supports automatic background upgrades during the upgrade. After the upgrade, the car will prompt the user whether to switch to the latest system. If the user needs, they can immediately switch to the latest system, making OTA more timely in the intuitive experience.

Overall, the appearance of the four-leaf clover architecture is LEAPMOTOR’s inevitable result of chasing intelligent car waves.

After all, as the degree of car intelligence is deepening, users driving intelligent cars will inevitably demand higher efficiency in data transmission, processing, and decision-making. But the past distributed and domain control electronics and electrical architecture can no longer significantly break through the car’s intelligence.

And the higher degree of central integration, harness intensive, and computational power centralization of the central integration electronic architecture can achieve unified decisions through central supercomputing. Regional connections only take charge of the execution. Its high computational power, high synergism, and low latency are more suitable for the current intelligent requirements for cars — and LEAPMOTOR’s “four-leaf clover” architecture cooperates well with this trend.

Three Solutions, Two-Year Iteration Cycle

According to reports, from a product implementation perspective, the four-leaf clover architecture will be applied to all LEAPMOTOR models in the future, paired with three solutions. Specifically:

Standard solution: Qualcomm 8155 + NXP S32G (3-core)

- Support 6 ~ 12 speakers, 4 screens, AR-HUD;

- Support 4 surround view cameras, 1 facial camera, 12 ultrasonic radars.

Medium configuration solution: Qualcomm 8295 + NXP S32G (7-core), possessing 30 TOPS computing power* Maximum support for 20+ speakers (external power amplifier), 4 channels with 2.5K resolution, 1 channel with 1080P, 2 channels with 720P;

- Support for 4 surround view cameras to achieve L2/L2+ level intelligent assisted driving.

High configuration solution: Qualcomm 8295 + NXP S32G (7 cores) + NVIDIA Orin X, the whole vehicle possesses 284 TOPS computing power.

- Maximum support for 20+ speakers (external power amplifier), 4 channels with 2.5K resolution, 1 channel 1080P, 2 channels 720P;

- Support for Lidar, precision map, 4 surround view cameras, 4 blind spot cameras, 4 radar for blind spot corners to realize L2++ high level intelligent assisted driving.

It’s evident that even the standard solution under the Clover architecture isn’t budgeting on crafting an intelligent experience.

In the latter half of the new energy vehicle led by intelligence, the electronic and electrical architecture often determines the upper limit of a car’s intelligence – evidently, through the layout of the Clover architecture, LEAPMOTOR hopes to promote a comprehensive upgrade of the intelligent experience of its various products, enhancing the competitive strength of LEAPMOTOR.

Of course, as time advances, the Clover architecture will continue to iterate – the iteration cycle is set to 2 years by Zhu Jiangming. He said:

I believe that by 2025, we will certainly iterate in terms of high-voltage platform capabilities, intelligent driving chip capabilities, and cockpit capabilities. This is certain, basically at a pace of once every 2 years.

Searching for the second growth curve through technology output

Intelligentization has drained a lot of capital from many car companies. Although LEAPMOTOR’s R&D fund is far less than the likes of ‘Wuxiaoli’, Zhu Jiangming believes, although LEAPMOTOR has invested less, its efficiency is high.

Through the Clover architecture, we can catch a glimpse of LEAPMOTOR’s ‘high efficiency’.

According to LEAPMOTOR, based on the Clover architecture, the number of car controllers has been reduced from 42 to 28, the length of the entire vehicle wiring harness is less than 1.5 km, and the weight is only 23 kg. Moreover, standard, medium and high configuration solutions are offered to cover more user groups, while the rate of platform generalization has reached more than 90%.

This indicates that, relative to the original A, B, C platforms, the production cost of the Clover architecture will be significantly reduced.

On this, Zhou Hongtao, LEAPMOTOR’s Senior Vice President in charge of car electronics, said:

We also hope to use these existing functions to the utmost, and make our products reach the highest cost-performance ratio. This is the direction of our efforts.

From a business perspective, the Clover Architecture not only fulfills the production needs of LEAPMOTOR, but also allows for technological sharing with its partners.

Currently, LEAPMOTOR has established four models of technological output for commercial cooperation:

Model 1: Technological sharing based on Clover electronic and electrical architecture and peripheral controllers (including car lights, cameras, radars, etc.).

Model 2: Technological sharing based on Clover electronic and electrical architecture, peripheral controllers, batteries, and electric drivetrains.

Model 3: Technological sharing based on complete delivery of the vehicle’s body (including electronic and electrical architecture, batteries, electric drivetrains).

Model 4: Cooperation and sharing at the vehicle level.

Hence, from this perspective, LEAPMOTOR aims to not only be a leading car manufacturer but also aspires to become a provider of comprehensive solutions for electric vehicles.

Zhu Jiangming states:

Through 8 years of global independent research, we in LEAPMOTOR have achieved capabilities in individual core components as well as overall vehicle architecture. From electronic and electrical architecture to vehicle construction, we are now also willing to externalize these abilities, establishing a new business model for LEAPMOTOR in the future.

Therefore, with the launch of the Clover Architecture, while showcasing its technological prowess, LEAPMOTOR is also hoping to find new growth points through business model innovation, identifying the “second growth curve”.

In Conclusion

Actually, the restructuring in the new energy vehicle market is intensifying. LEAPMOTOR is not having an easy time amid the pricing wars.

With regards to the market performance, LEAPMOTOR sold a total of 44,000 vehicles in the first half of the year, experiencing a 14.4% decrease YoY, only achieving 22% of the annual target. The pressure to boost sales in the second half is significant. On this score, Zhu Jiangming could only give a mark of 60-70 points.

When discussing the second half of the year, he stated that LEAPMOTOR would be aiming at a sales target of 20,000 vehicles per month—a target not easy to achieve in the currently turbulent market.

Due to this, Zhu Jiangming made it clear in the interview that in August, LEAPMOTOR’s high-end C-series models would undergo a full price adjustment, aiming to encourage customers to opt for higher-spec versions by increasing their investment slightly. Evidently, through the price reduction, LEAPMOTOR hopes to further boost sales.

This means that LEAPMOTOR is facing enormous market pressure.

In this situation, while the launch of the Clover Architecture signifies technological progression, it clearly serves other motives as well.

On one hand, LEAPMOTOR hopes to further amplify the cost advantages it gained through independent research, expanding profit margins. On the other hand, through technological output, it also hopes to diversify its income sources apart from vehicle businesses, thereby enlarging its room to survive. Of course, from a market perspective, LEAPMOTOR also intends to showcase its capabilities to instill confidence in the market.

However, it will take a significant amount of time for the Clover Architecture to truly bring value to LEAPMOTOR’s revenue.Hence, amidst the prevailing and intensifying market uncertainties, for emerging automotive firms like LEAPMOTOR, while future planning is essential, the more critical task at hand is boosting the sales of their current models through various means to achieve monthly sales targets of 20,000 or even more – after all, survival is the prerequisite for pursuing long-term development.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.