“I’ve never felt more optimistic about Tesla than I do today,” said Musk during Tesla’s Q3 earnings call, fueled by the company’s strongest financial report since its inception. In Q3, Tesla achieved record highs in its overall gross margin of 23.5% and vehicle gross margin of 27.7%, resulting in an automotive business profit of $2.105 billion. The quarter also saw significant breakthroughs in production and delivery, surpassing historical records.

Q3 Financial Report Overview: Blooming Everywhere

Let’s take a look at the key information from the report:

Financial Data: Double the Profit and Gross Margin

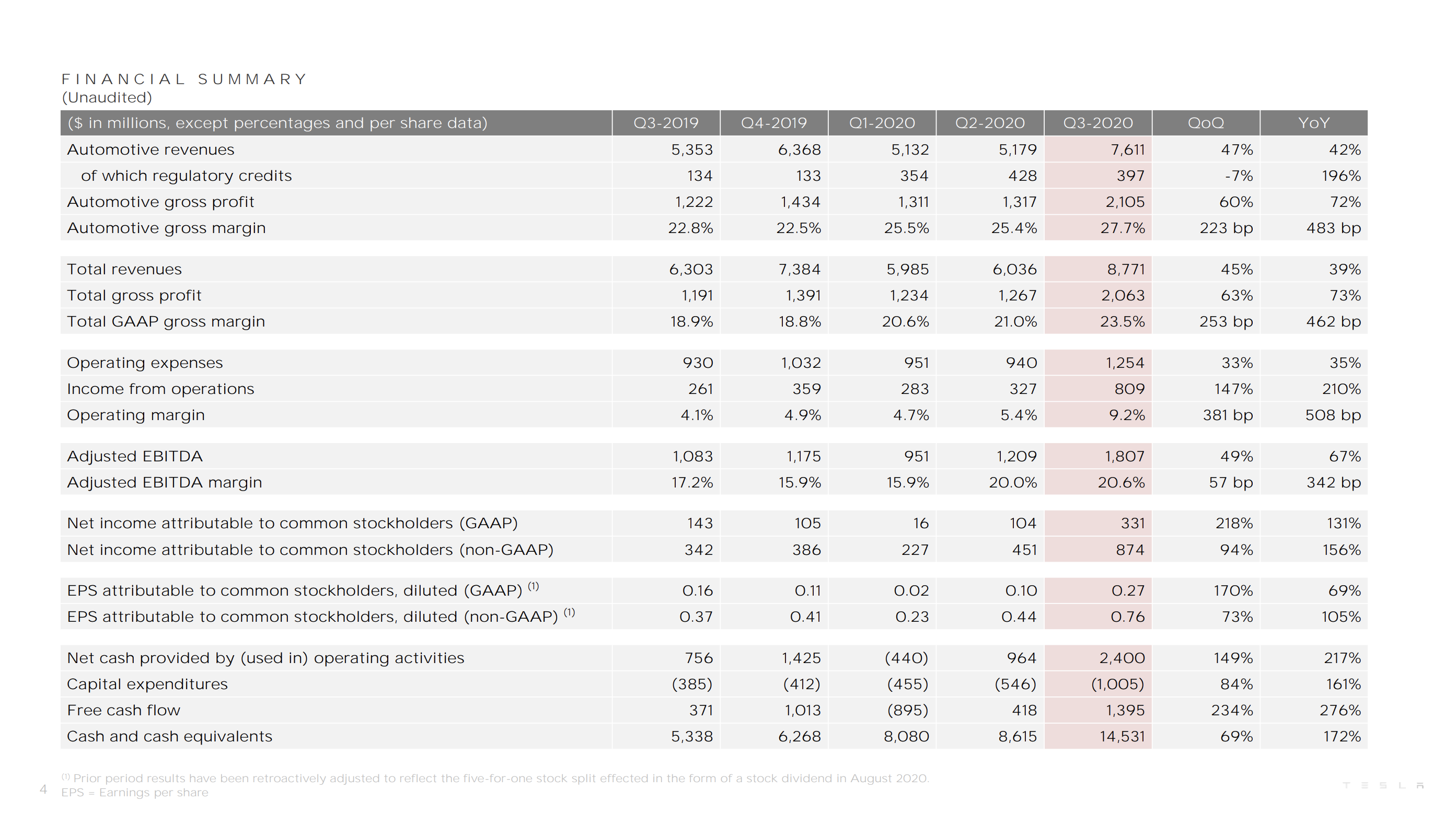

During Q3, Tesla’s total revenue was $8.771 billion, an increase of 45% QoQ and 39% YoY.

Automotive revenue was $7.611 billion ($397 million of which was from sales of regulatory credits), an increase of 47% QoQ and 42% YoY.

Automotive business profit was $2.105 billion, an increase of 60% QoQ and 72% YoY.

Overall gross margin was 23.5%, while vehicle gross margin was 27.7%.

Cash and cash equivalents increased by $5.916 billion to $14.531 billion.

Operating cash flow less capital expenditures (free cash flow) was $1.395 billion.

GAAP operating margin was 9.2%.

Except for a 7% YoY decrease in income from regulatory credit sales, all other 19 financial metrics showed significant QoQ and YoY increases, 5 of which even exceeded three digits. Six of these metrics were at historical highs: total revenue, automotive revenue, automotive business profit, cash and cash equivalents, free cash flow, and GAAP operating margin. Despite a YoY decrease in the average selling price of Tesla’s vehicles, the Q3 report showcased an increase in overall gross margin and vehicle gross margin, indicating the company’s efforts in cost control.

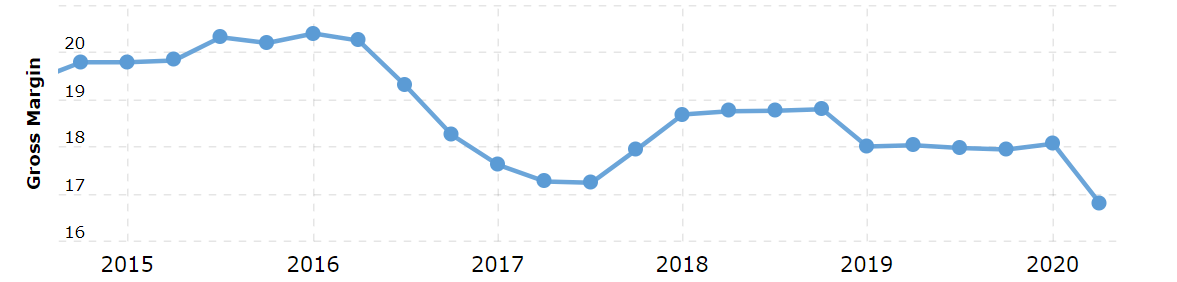

For comparison, Toyota’s average overall gross margin for the past four quarters was 18.6%. The chart below illustrates Toyota’s gross margin changes over the past five years:

### Selling the most cars in a quarter is not enough

### Selling the most cars in a quarter is not enough

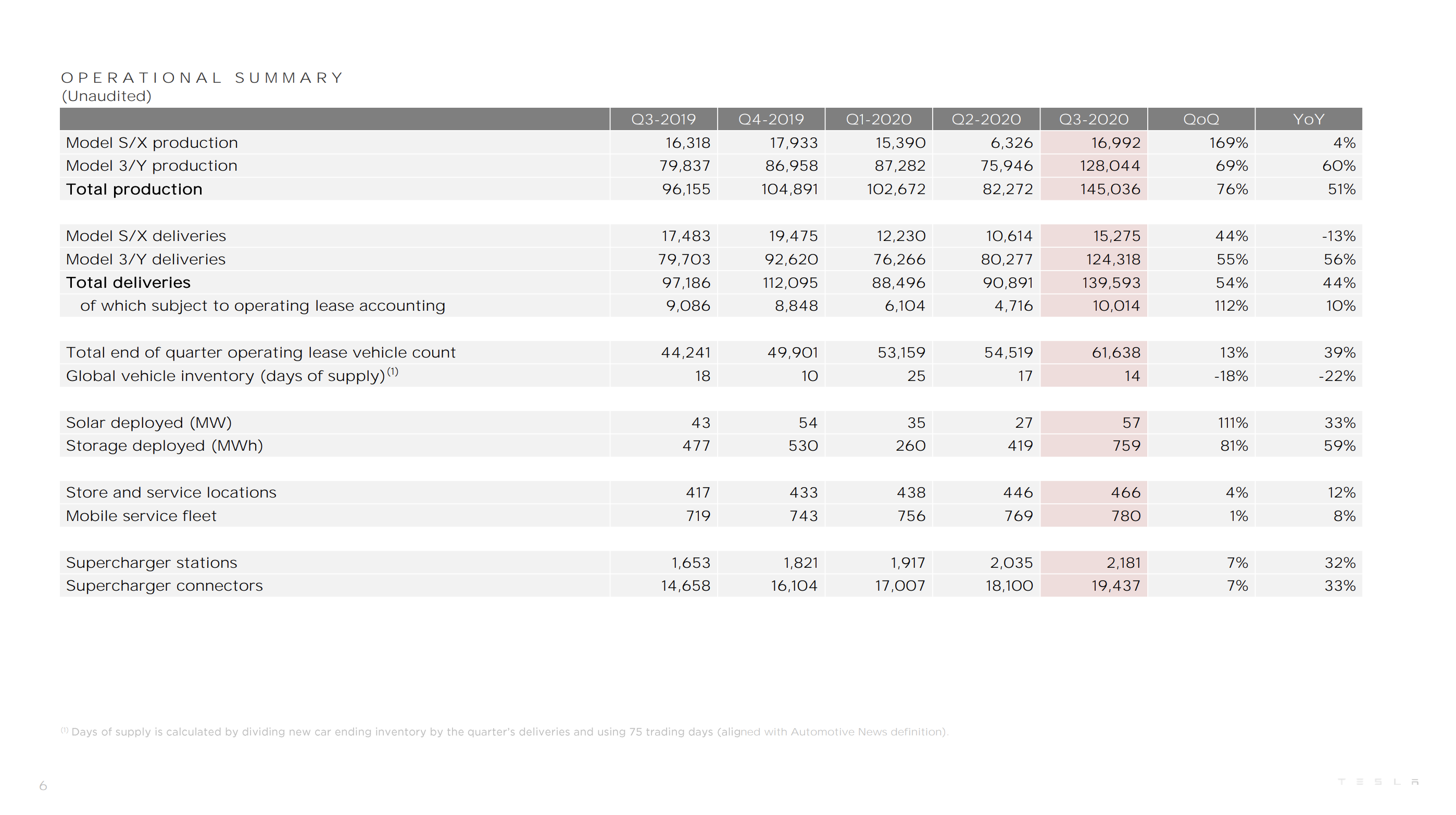

The following are vehicle production and sales data for Tesla’s Q3:

- Total production of 145,036 vehicles in Q3 2020, a 76% increase year-on-year, including 16,992 Model S/X and 128,044 Model 3/Y;

- Total deliveries of 139,593 vehicles in Q3 2020, a 54% increase year-on-year, including 15,275 Model S/X and 124,318 Model 3/Y;

- Inventory turnover was 14 days, a decrease of 18% month-on-month and 22% year-on-year.

Not only has Tesla sold more cars, but the vehicle inventory turnover is also shorter, which reflects Tesla’s current vehicle demand is not a problem.

In addition to vehicle delivery, Q3 was also accompanied by rapid growth in Tesla’s energy business, with 57 MW (megawatts) of solar power generation deployed, a year-on-year increase of 111%, and 759 MWh (megawatt-hours) of energy storage battery deployments, a year-on-year increase of 81%.

Here, I would like to elaborate a bit. Although Tesla’s business in this area in China has not made any stunning moves, in a country like Australia where electricity prices are high and the stability of the power grid is insufficient, Tesla’s “Virtual Power Plant” project, which is composed of individual rooftop solar power generation, jointly promoted by the government, has begun the third phase of deployment in Q3, adding 3,000 households with rooftop solar power generation. Local rooftop solar power generation project participants do not need to pay for power generation and energy storage equipment, and the photovoltaic generation electricity price used after the system is installed is equivalent to 80% of the Australian national power grid.

Following the solar energy storage network, there is also the stable growth of Tesla’s Supercharger network. In Q3, Tesla added 146 Supercharger stations and 1,337 Supercharger piles, both of which increased by 7% month-on-month.

Global Factory Updates

The information part also includes updates on Tesla’s manufacturing information. The content is as follows.

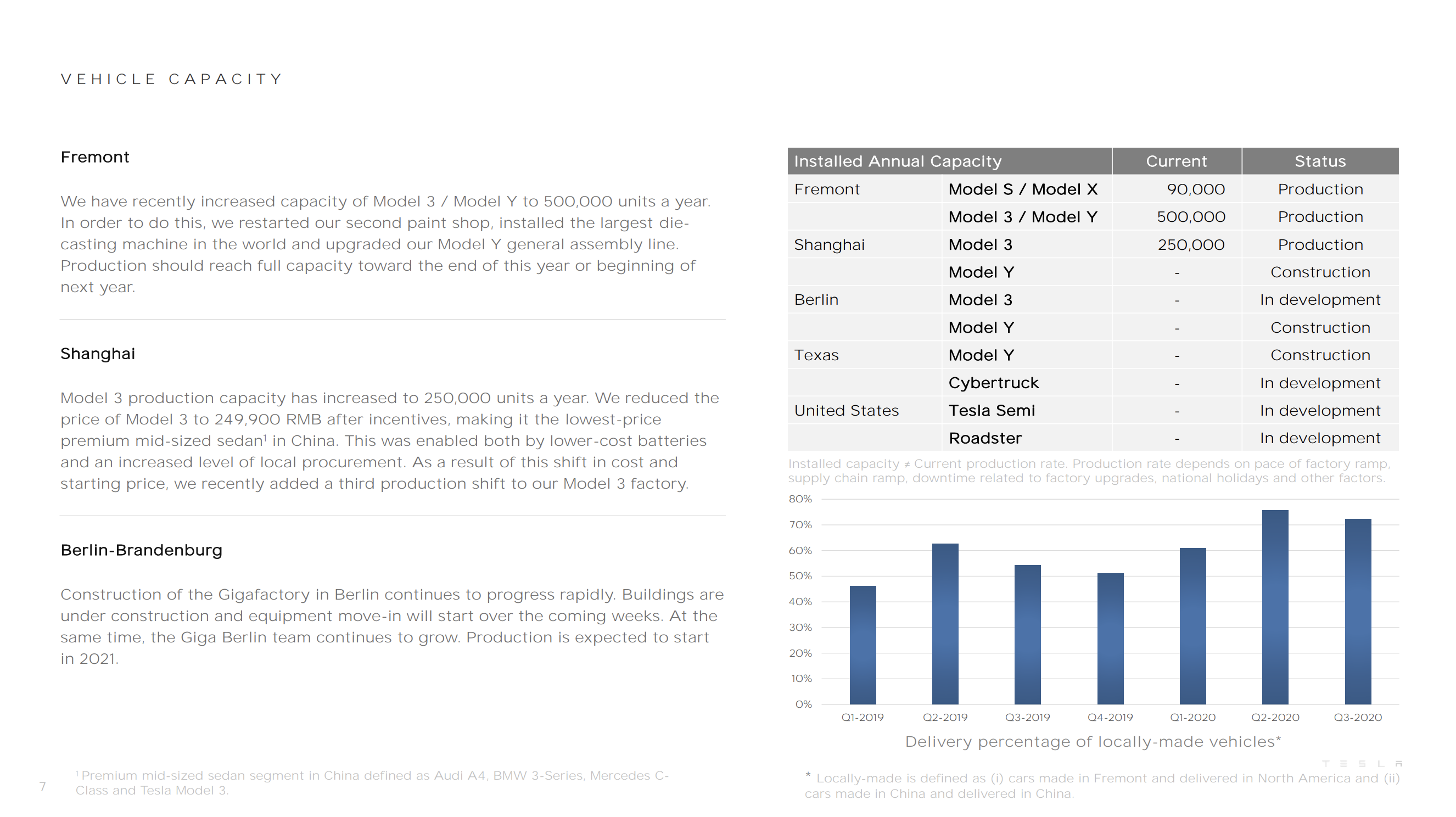

The Fremont factory has recently increased the theoretical production capacity of Model 3/Y to 500,000 vehicles per year, opened another paint production line, and used the world’s largest pressure casting equipment to upgrade the production and assembly of Model Y. The production capacity is expected to reach 100% by the end of this year or early next year.The production capacity of the Shanghai factory has now increased to 250,000 vehicles per year, and the factory is currently operating in three shifts. Large-scale die-casting equipment has also been introduced to the Model Y production line.

The Berlin factory is still under rapid construction and is expected to begin adding production equipment to the workshop within a few weeks. At the same time, the personnel team at the Berlin factory is still expanding, and the factory is expected to start mass production in 2021.

Recap of Battery Day information

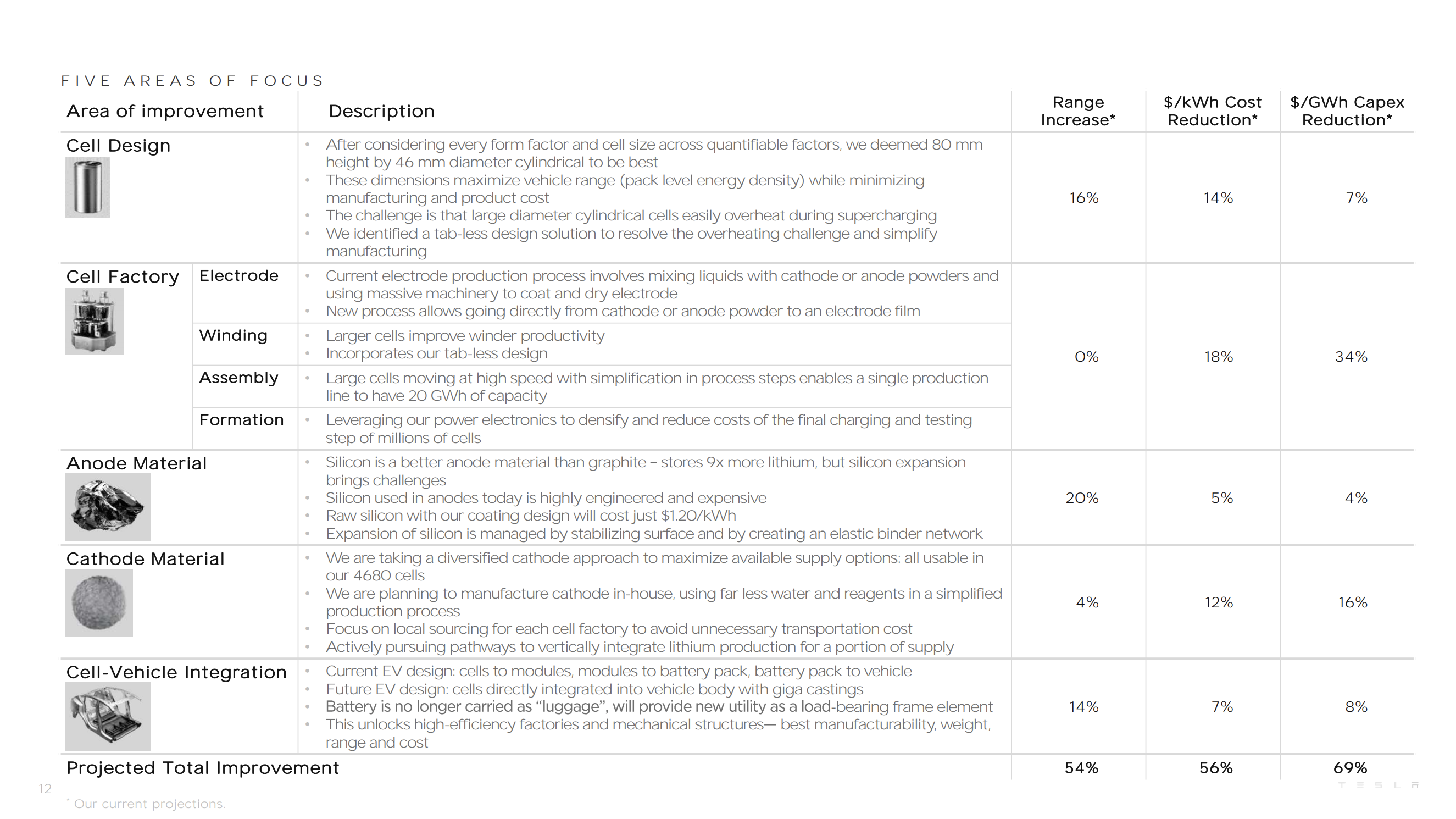

The financial report also includes a summary of Battery Day information, the main content of which is that Tesla plans to improve vehicle range by 54% and reduce the cost of power battery packs by 56% through five major optimization innovations in the next few years. The production cost of each MWh battery will also be reduced by 69%. There is a featured article on this topic, so I won’t go into further detail here.

Now that we’ve summarized the main information, let’s move on to a few hot topics.

Will Tesla deliver 500,000 cars this year?

As of Q3, Tesla has delivered a total of 318,350 vehicles, which is far from the target of 500,000 vehicles.

Why mention this number of 500,000? Because on October 8th, Elon Musk sent an email to all Tesla employees, urging them to roll up their sleeves and work hard to achieve the goal of delivering 500,000 vehicles by the end of the year. This number is also mentioned in this report.

So how much effort is needed to achieve this goal?

Tesla’s global delivery volume in the first three quarters is:

- Q1: 88,400 vehicles

- Q2: 90,650 vehicles

- Q3: 139,300 vehicles

To achieve the delivery of 500,000 vehicles, Tesla needs to deliver 181,650 vehicles in the fourth quarter alone, more than the total of Q1 and Q2 combined.

Bottlenecks for delivering 500,000 vehicles

As we mentioned in our previous article on the Model 3 price reduction, Model 3 is currently in short supply in all international markets except China and the United States, where there are factories. For Model Y, which has not yet completed mass production, the situation is even worse.

Therefore, if Tesla wants to achieve the goal of delivering 500,000 vehicles, the top priority is to increase production. Unfinished factories such as Berlin and Phase 2 of Shanghai are not expected to contribute much this year, so the feasible approach is to “squeeze” the production capacity of existing factories. The financial report naturally also mentions the measures taken by Tesla.### Induction, induction, or induction

Let’s start with the Shanghai factory. You may have heard the news that the domestic Model 3 in China will be exported to Europe recently. In fact, the supply and demand for Model 3 in the European market have been in short supply for some time. Previously, Fremont factory which was producing Model 3 for Europe has already put in a lot of effort, so there is not much room for improvement in the short term.

By comparison, the Shanghai factory still has some potential to tap. The original planned production capacity of the Shanghai factory was 200,000 vehicles per year. Now with the implementation of three shifts, the production capacity has been increased to 250,000 vehicles per year. Therefore, in the three months of Q4, the Shanghai factory may produce nearly 60,000 Model 3 vehicles.

However, this is only one-third of the 180,000 vehicles. The remaining 120,000 vehicles still depend on the United States and Fremont.

In the financial report, it was mentioned that the maximum production capacity of Model 3/Y in the Fremont factory has been increased to 500,000 vehicles per year, and the time to achieve this production capacity will be at the end of this year or early next year. The financial report also separately mentioned the measures to increase the production capacity of Model Y, including the addition of a second paint production line, and the use of the “world’s largest die-casting equipment” previously mentioned in the factory. This equipment will be used to produce battery the before-mentioned battery castings for the body.

According to the production capacity efficiency of 500,000 Model 3/Y vehicles in Fremont and 250,000 vehicles in Shanghai factory, the theoretical production capacity limit of Tesla in Q4 is about 187,500. However, since it is the theoretical production capacity limit, it is probably difficult to achieve.

But one thing should not be forgotten. Although the production capacity of Model 3/Y is constrained, the production capacity of Model S/X in the Fremont factory is surplus. Therefore, if they could sell more Model S/X in Q4, it would also be helpful to achieve the goal of 500,000 deliveries.

Able to produce, but also able to deliver

The Q4 delivery plan is 30% higher than Q3. This means that if the delivery volume of each product line in each country and region of Tesla does not increase by at least 30% on a month-by-month basis, it will hold back their progress.

China’s Model 3

Tesla, who takes quick actions, adjusted the prices of its products sold in China on the first day of Q4, the standard range plus with LFP battery pack dropped to CNY 249,900 (-8%), and long-range CNY 309,900 (-10%).

Meanwhile, Tesla launched 32 super charging stations in 20 cities in September, and promised to continue to build charging stations in 27 cities and establish experience centers and service centers in 20 cities in October and November, in preparation for the coming “delivery hell”.With the combination of price reductions and infrastructure construction, Tesla China team has prepared to surpass 30% quarter-on-quarter in delivery volume.

Q3 delivery volume in China was 36,402 vehicles, and the pass line for Q4 is 47,322 vehicles. The remaining production capacity at the Shanghai factory will be used to fill the demand in European countries.

North American Model Y

Recent news suggests that there are signs of an increase in Model Y production. In Q2 this year, about 9,800 Model Ys were registered in California. This number increased to 16,200 in Q3. According to Tesla analyst Troy Teslike, the corresponding global delivery volume for Model Y in Q2 was 16,484 vehicles, and in Q3 it was 29,482 vehicles, showing significant growth. In addition, 7-seat and cheaper rear-wheel drive versions will also begin delivery in Q4. Model Y will become the core force to improve delivery data in North America.

European and American Model 3

Compared to the improvement in delivery data for Model Y, the delivery volume of Model 3 in California decreased by 13% in Q3. However, on October 16th, the redesigned Model 3 was launched on Tesla’s US and European websites, with improved range and optimized interior and exterior design. We have reason to believe that the redesigned Model 3 will once again boost delivery volume in Europe and America.

Global Model S/X

The Model S/X product line, which is facing a comprehensive redesign, is doomed to not achieve a 30% quarter-on-quarter increase. On October 16th, Tesla announced on its official website that the range of Model S/X had been slightly upgraded, and the Model S had also been slightly discounted in China and the United States. After this round of adjustments, Q4 is likely to be higher than the 15,275 deliveries in Q3. However, overall, maintaining the current delivery volume is considered a victory.

In summary, I personally predict that Tesla’s achievement of 500,000 vehicles this year is very likely. Even if it is not achieved, the gap should be within 10,000 vehicles.

Next, let’s talk about the big news – the rewritten version of FSD.

FSD Rewrite Will Bring “Autonomous Driving Futures”: Will it Be Realized Soon?

In the financial report, there is a section that introduces AP, mainly that the Autopilot team is currently focusing on deep neural network and control algorithm rewriting of the software, allowing the “City Street Autonomous Driving” function in FSD to be launched. In October, the rewritten FSD will be gradually released to users with “early experience privileges”. The capability of street autonomous driving will also be improved with future data collection.In the presentation by an external Tesla leaker, the rewritten Full Self-Driving (FSD) software can construct a complete “God’s-eye view” of the surrounding roads using algorithms and predict traffic flow in all directions. With this and a series of other improvements, FSD can automatically recognize and stop at traffic lights and navigate complex intersections without human intervention.

As of the time of publishing, some users have received the updated FSD with a new UI that is more developer-focused and contains multiple marking colors. The update prompt indicates that the beta version of FSD can automatically change lanes, exit highways, overtake other objects or vehicles, and complete left and right turns in autonomous driving mode. However, the prompt also stresses the need for drivers to continuously pay attention to the road situation, especially in challenging environments such as visual blind spots or narrow roads.

Since its launch in October 2014, Autopilot has developed for six years, and the expectation for the Full Self-Driving function is enormous. However, the long wait for the core function to be launched also means that FSD is known as a “futures” product.

Today, this “futures” product has taken a new milestone step and is presented to the public with great anticipation.

Musk on FSD

Musk spoke in detail about FSD during a conference call. Here is a summary of his statement:

The FSD rollout after the rewrite will be very cautious and gradual because the real-world situation is extremely complex. Therefore, we will implement a small-scale rollout first and then gradually expand the scope of the rollout. If the situation is good, we may perform large-scale rollouts by the end of the year.

With more data collected by the system, its capabilities will become stronger. This is somewhat similar to Google’s search engine. The more you search for something, the smarter its recommendation algorithm becomes because everyone is “training” the algorithm, so it keeps evolving and becomes a very efficient search engine. The same applies to autonomous driving.

Tesla currently has one million cars serving as terminals to provide various driving data feedback, some of which contain valuable special scenarios that you cannot consider when designing the system. While regular scenarios can be simulated, many rare special scenarios exist only in the real world. Therefore, we will collect and record these scenarios and use them to perform specialized case training for algorithms to improve the system’s ability to handle these scenarios.In this system, which belongs to the domain of intelligent bicycles and is based on a powerful general algorithm network, you can achieve automatic driving even if your car has no communication with the outside world, and has never been to the road you are about to travel on. It is like a human driver. This is the system we are developing and planning to release this year.

In the reminders pushed by FSD and Elon Musk’s remarks, it can be seen that Tesla is cautious and considers “safety first” in the promotion of FSD automatic driving. Even after the financial report, Musk replied to TESLARATI’s statement that “the rewrite of FSD will be pushed on a large scale by the end of this year”: “This will depend on whether this FSD can prove its high safety in practice.”

However, after the excitement, I have to pour some cold water on you. The aforementioned time points are all for the US market. Considering multiple factors such as data and policies, the promotion in China may not happen until at least next year, in my conservative estimate.

Highlights of the Conference Call

In addition to the FSD that has already been discussed, there are several topics worth noting in the conference call after the financial report, which we have recorded below.

About the Integrated “Skateboard” Chassis

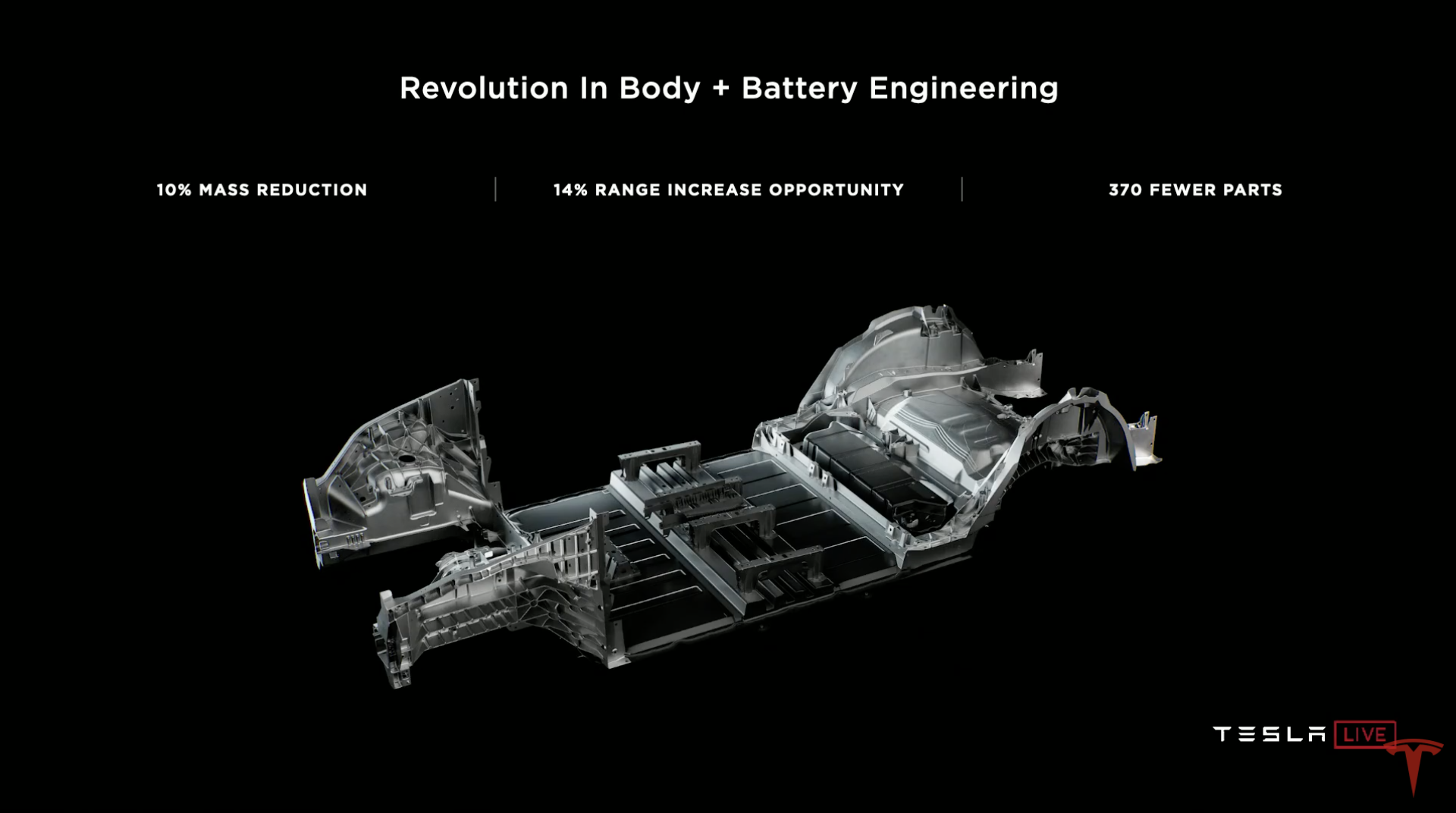

One of the key technologies mentioned in Battery Day is that Tesla plans to integrate the chassis and battery pack into a “battery pack chassis”, while installing front and rear single-piece cast car bodies.

This new structure is more like the combination of a skateboard and its wheels. When asked about it, Musk believes that in the long run, this is the inevitable trend of electric vehicle design. He said Tesla is seeking to manufacture electric cars like electric toy cars, reducing the number of vehicle parts by using a large amount of cast parts, and making the battery pack a part of the overall structure of the vehicle body.

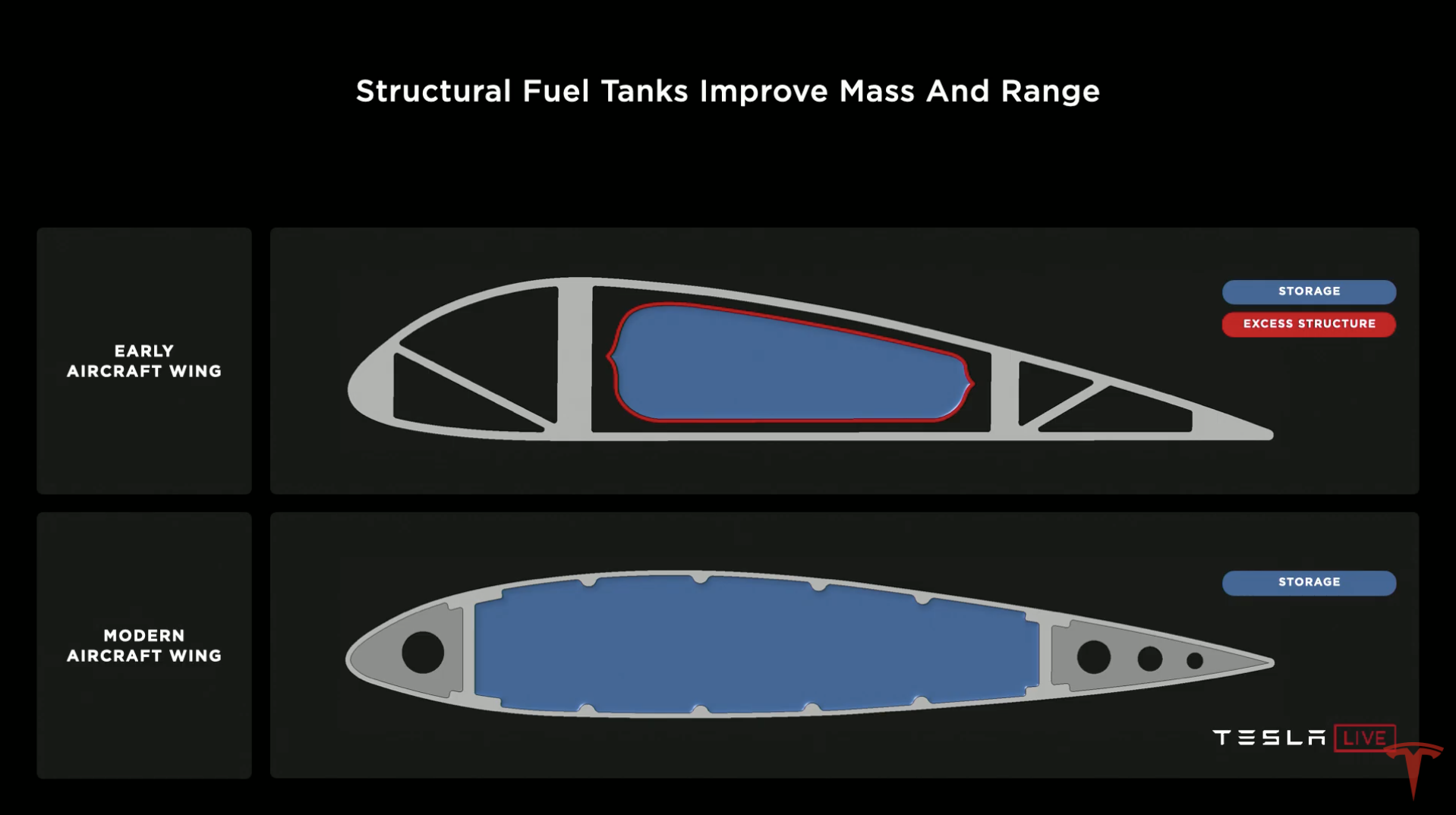

Musk said that the fuel tanks of the wings of airplanes and rockets are directly fused into the overall structure as structural components, and this is the inspiration behind Tesla’s design philosophy.

“There’s no need to put another box in the box,” Musk said. Although this “skateboard” style chassis revolution will not be completed overnight, it will happen in the future.

Cybertruck### Latest News about Cybertruck

According to Musk, Tesla team is still working hard on optimizing Cybertruck and their goal is to make it better than the prototype presented at the launch. Musk says this will involve a lot of detailed improvements and many have already been completed. He believes the final production vehicle will be even better than the Cybertruck showcased.

Furthermore, Musk mentioned that Cybertruck will be manufactured at Austin and a small number will be delivered by the end of 2021, with large-scale deliveries starting in 2022 and beyond.

Factory Upgrade and Renovation

In response to inquiries about improvements to Tesla’s equipment and manufacturing processes, Musk stated that Tesla has integrated and designed its own manufacturing equipment, or what Musk described as “the machine that made the machine that made the machine”. Musk hopes to minimize outsourcing to expand Tesla’s engineering capabilities. However, he acknowledges that he cannot determine whether such a radical change will be a wise move, but things look promising so far.

Will Berlin Use 4680 Batteries? FSD Account Transfer

Drew Baglino confirmed that Berlin will use the 4680 batteries, and Musk stated that he will consider FSD account transfer.

Conclusion

Although Tesla’s Q3 financial report was impressive, it was somewhat expected. The surge in sales, profits, and production capacity expansion was like a snowball gathering momentum as it rolled.

What interests me more are the technical challenges, including the FSD rewrite and Tesla’s manufacturing challenges. Despite Autopilot being the most capable driver assistance system on the market, it is still a long way from full self-driving. The fatal accident caused by Autopilot’s recognition failure a few years ago is still a black mark against Tesla.

There was also the Model 3 production hell that Tesla barely escaped from in 2018, due to Musk’s push for fully-automated factory production.

I believe these lessons were deeply ingrained in Tesla and Musk’s thoughts. Nevertheless, at this point, Tesla and Musk are challenging the industry and themselves once again.Although Tesla is now in its heyday, with top talents, various new skills, and healthy and abundant funds, no one can guarantee a 100% success in this revolutionary innovation.

As for why Tesla and Musk are still doing these things, I suddenly remembered a saying:

“Why climb Mount Everest?”

“Because it’s there.”

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.