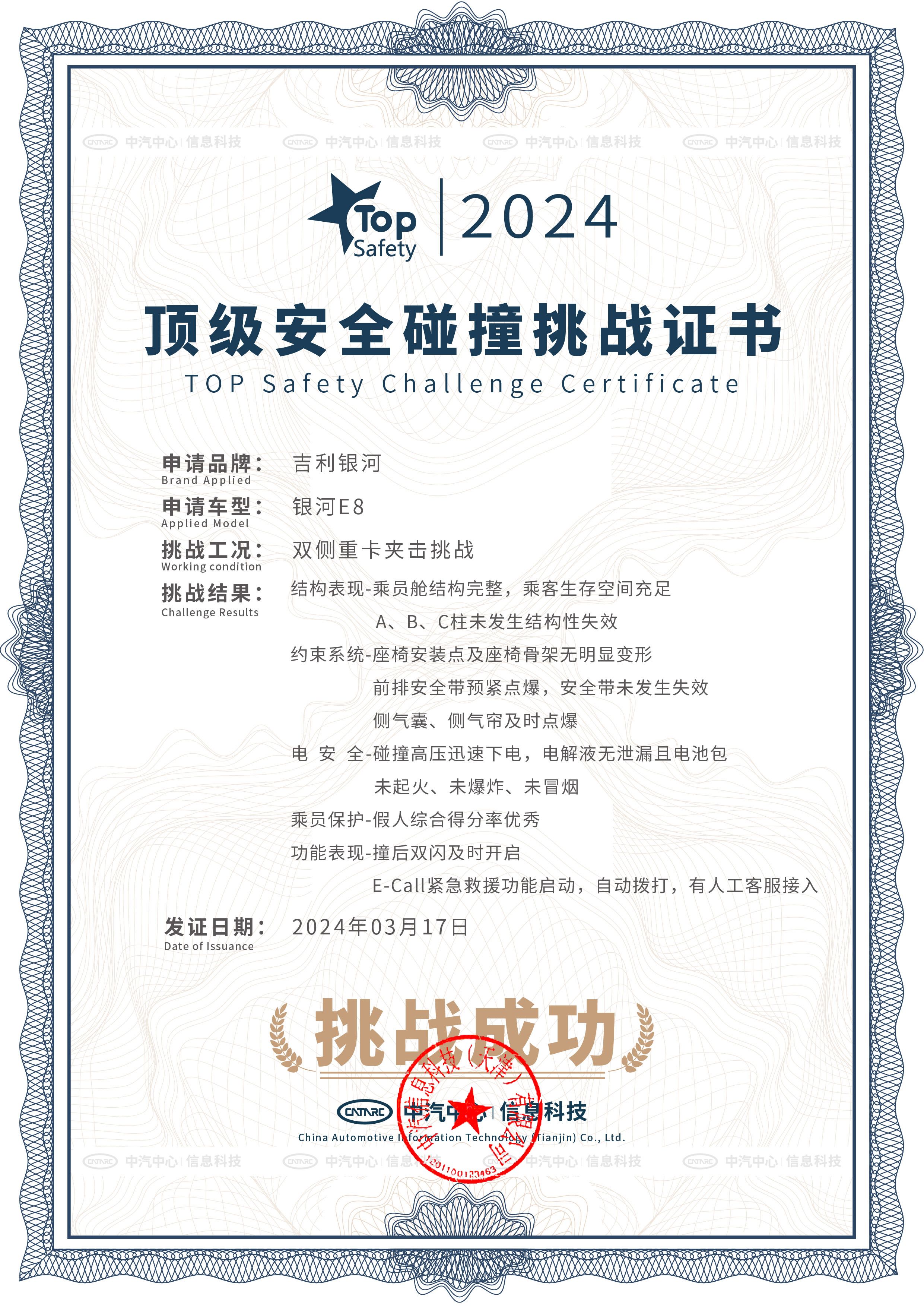

On March 25, the Geely Galaxy E8 underwent the industry’s first 20-tonne uncontrolled heavy truck pinch collision test at the China Automotive Technology and Research Centre in Tianjin. The Galaxy E8 test vehicle, stationary, was impacted at the center of gravity by a 10-tonne lorry at a right angle at a speed of 30 km/h from the left. After the impact, the Galaxy E8 test vehicle was displaced, side colliding with another stationary 10-ton heavy truck on the right, the energy impact being 3.3 times the national standard.

The post-impact performance of the Galaxy E8 was impressive. The passenger cabin structure was intact, ample passenger survival space was available, and there was no structural failure of the A, B, and C pillars; there was no noticeable deformation of the seat anchorage points and seat frames, the front seatbelt pre-tension points were triggered, the seatbelt did not fail, and the side airbag, side air curtain were set off promptly; after the collision, the voltage dropped rapidly, there was no leakage of electrolyte, and the battery pack did not catch fire, explode, or smoke; an excellent composite score was achieved by the dummy in the car; after the collision, emergency hazard lights were switched on immediately, the door handle popped out automatically, the E-Call emergency rescue function was activated, automatically dialled, and a human customer service representative was connected.

SEA Architecture Fully Enables Galaxy E8 Body Structure Safety

For Geely, there is no distinction between ‘safety’, ‘luxury’, and ‘mainstream’. The Geely Galaxy E8, forged on the SEA architecture, is the safest new generation pure electric flagship in China. A new generation of shield battery safety systems has forged a four-level ‘blind-free’ safety protection system for the Galaxy E8, from battery to architecture, vehicle, smart control, and cloud, reshaping the safety standards for new energy vehicles.

The SEA architecture fully enables the Galaxy E8 body structural safety. This dedicated intelligent pure electric architecture, developed by Geely’s Chinese, Swedish, British, and German R&D centers over 5 years with an investment of 20 billion yuan, establishes the ‘comprehensive safety concept’ as the safety benchmark, safeguarding life, health, asset, and privacy domains across 9 large systems (passive safety, active safety, functional safety, information safety, high voltage safety, fire safety, health safety, user safety, and theft safety).

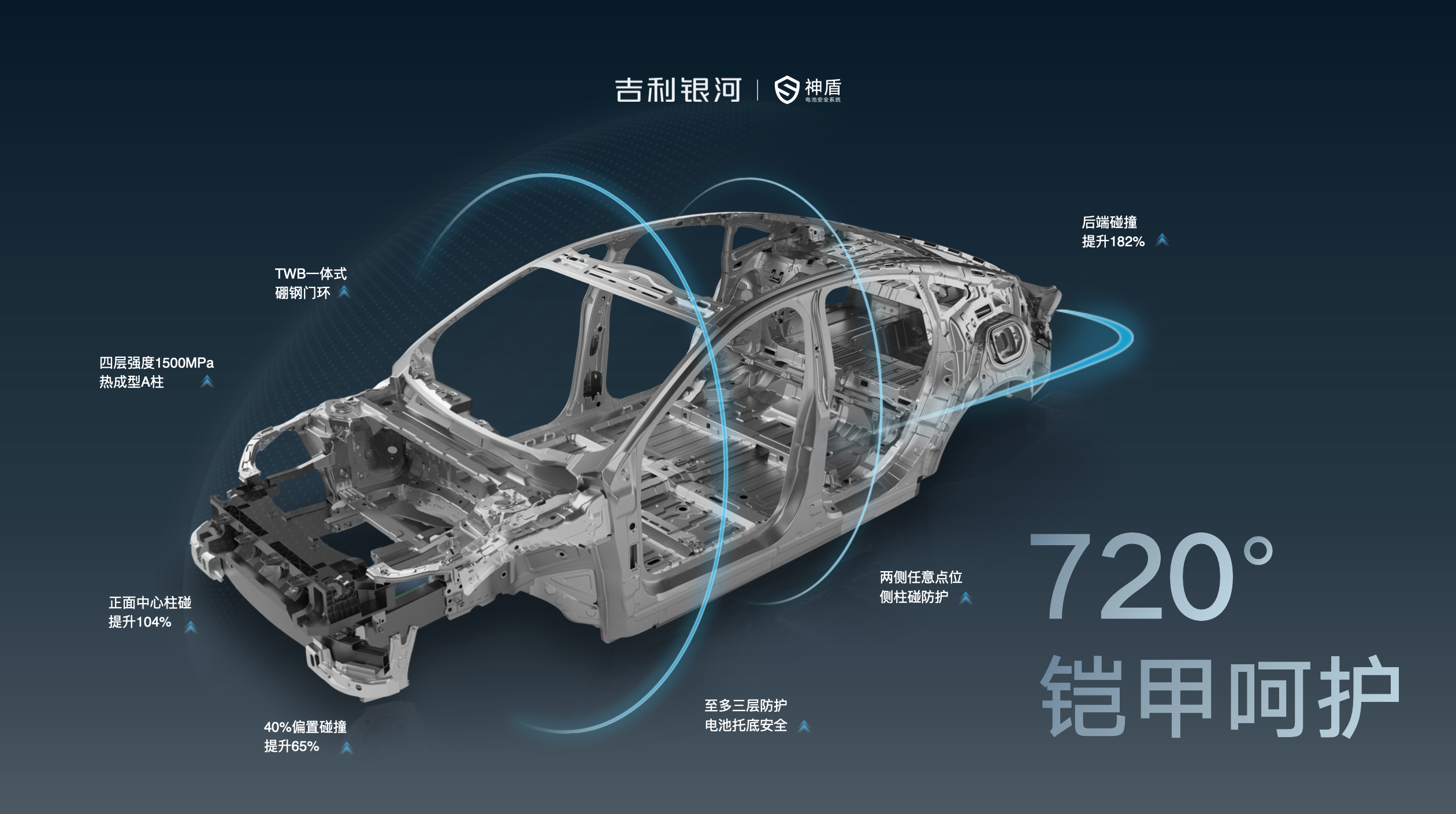

All products developed based on the SEA architecture can achieve a global five-star safety standard. Galaxy E8’s head-on collision safety protection use a star-like cage body. The white body of the phenomenal Geely Galaxy E8’s lightweight coefficient is as low as 1.74, the use of high-strength steel and aluminum alloy amounts to 80.3%, 54.1% of the key safety parts use ultra-high-strength steel and hot-formed steel, the body torsional stiffness has reached 41000 Nm/deg, leading in its class. In the event of a collision, the cage-like body structure can distribute force to the entire body, avoiding localized extreme stresses leading to structural damage and thus rendering potential danger to oblivion. Additionally, there is a space-grade 7 series aluminum alloy “Omega” front anti-collision beam. The front anti-collision beam uses a “目” cross-sectional design, with internal ribs innovatively adopting an Omega structural design. This ensures the strength and stiffness at low speeds, and the deformation energy absorption at high speeds, maximizing material utilization, and maintaining subtle structure.The GEELY Galaxy E8 has a crash beam length exceeding 1370 mm, with a main body thickness of 4 mm, accounting for over 72% of the vehicle width, which is considerably greater than the conventional 60% in most models. This provides more protection against collisions. It also incorporates an ultra-long aluminum alloy energy absorption box measuring 460 mm / 140 mm in height, made from 6061 aluminum alloy. This extends from the front anti-collision beam position all the way to the front wheel suspension position, and is bolted for easy replacement. This design significantly aids energy absorption and accident repairs. Additionally, between the front collision beam and the bumper, there is a thick pedestrian protection foam measuring 130 mm in thickness, among the best in its class.

To enhance forward collision capability, the GEELY Galaxy E8’S front-end frame utilizes PP + LGF30 long glass fiber composite material, making for a lighter frame. The frame includes motor sinking technology, lowering intrusion by 50 mm. The standard for front center column collision of the Galaxy E8 can reach up to 50 km/h, the toughest and highest global standard. Even with twice the industry standard impact energy, the Galaxy E8 can contain frontal impact within the front guard.

The side-impact protection on the GEELY Galaxy E8 has also been optimally designed, with a ‘grid’ design inside the door sill collision beam, consisting of three layers of irregular 10 anti-collision compartments made of aviation aluminum alloy, with a thickness that reaches 163 mm — the highest in its class. A pioneering industry-first achieving five invention patents, it equips the battery with an ‘energy-absorbing armor’. Meeting comprehensive pillar-side collision safety tests, with a maximum intrusion amount of 12.5 mm, it guarantees the safety of both the battery and passengers. Its three-layer anti-collision energy absorption structure allows the vehicle to withstand a side-pillar collision instantaneous impact force of 65 tons.

This can gradually absorb energy to alleviate the impact force, providing protection for the battery and vehicle occupants. This is a globally pioneering ‘Dragonfly’ force transmission structure, which transfers the force generated from localized collision to the vehicle frame, further enhancing the strength and deformation capacity of the vehicle body. In the event of high-speed side and rear collisions, it can effectively resist harm to the passenger compartment and battery pack. TWB laser welding + patch one-piece hot-formed boron steel door ring allow for A-pillar 0 bending in small offset collisions.

The co-pilot leap-like safety airbag is exclusive to this class model. In the event of a frontal collision, the co-pilot airbag bounces towards the windshield and opens at an angle, jumping over the central control screen in a ‘leaping’ fashion to protect the driver and passengers. For arbitrary side pillar collision protection, every 127 mm along each side of the GEELY Galaxy E8 undergoes pillar collision testing, with 14 points tested on a single side, spanning the entire door sill beam from the A-pillar to the C-pillar. The industry standard is only to test one point on the vehicle’s sill beam.

The cross-sectional area of the A-pillar is 2598.6 mm², reducing the average industry cross-sectional area of 2778.76 mm² by 180.16 mm², greatly enhancing visibility safety. The A-pillar uses four layers of hot-formed boron steel, with a hot-formed stacked thickness of 7.5 mm for a super-strong A-pillar, superior to its class, making the visibility and collision safety performance of the GEELY Galaxy E8 A-pillar the optimal combination.Optimized hidden door handle and unlocking logic to minimize the failure rate of unlocking and popping out. The handle popping force is enhanced up to 15 kilograms, and the hidden handle must possess a physical pull wire on the outside. Even if the handle cannot pop out after a collision, it is possible to manually extract the handle to open the car door. All four doors must have emergency switches at conspicuous positions. These high-priority switches can immediately open the car door once pulled, ensuring that the car door can be opened in two ways (inside and outside) after a collision.

Empowerment by Shield Battery Safety System

The Galaxy E8 car model, with a newly launched shield battery safety system, ensures worry-free safety with eight-layer protection from the areas of the battery cell, PACK, structure, and safety test. Triple needle-puncture will not cause fire: at cell level, three steel needles simultaneously puncture the cell, causing no fire or explosion. At the PACK level, a single-time puncture through two cells causes no fire or explosion. At the level of the whole vehicle, piercing from the bottom of the battery pack through the battery, causes no fire or explosion.

Notably, the GEELY Galaxy E8 has been honored with the first 001 certificate of the six-dimensional electrical safety technology system for domestic new energy vehicles issued by China Automotive Technology and Research Center. It becomes the first new energy vehicle that has passed this certification, setting a new benchmark for the electrical safety technology system of new energy vehicles. Under the comprehensive prevention and protection of the shield battery safety system, GEELY Galaxy E8 has smoothly passed all the 16 sub-item tests in 6 aspects, including charging safety, electromagnetic safety, functional safety, high voltage safety, battery safety, and fire safety, exceeding the test standards.

Battery Safety: The basic safety test standard exceeds the national standard. GEELY made the safest battery cell for GEELY Galaxy E8. Through the improvement of electrolyte formula, it effectively reduces the heat generated from the reaction between solid-liquid interfaces, significantly enhancing the thermal safety of the battery. The composite anode material of multi-stage configuration offers a balance between fast charging and high-voltage capabilities, with a LiFePO4 battery energy density > 180 Wh/kg. Battery cell electrode coating gradient design possesses both high-ion diffusion rate and high electron conduction rate, providing exceptional fast charging and high power performance. Based on all-scenario limit conditions, the shield battery safety system has conducted more than 100 basic tests at the battery pack level, 80 more than the national standard, to ensure the solid basic safety performance of the “Shield Battery Safety System”. Among them, simulated collision, mechanical shock, water immersion safety, damp-heat cycle, salt spray, heat diffusion are higher than national standards. Bottom ball-hit, drop, IP6X, IPX9K, supplemented by GEELY, are added to define more GEELY-style safety guidelines into the standard “basic safety of power battery”.

This article is a translation by AI of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.