HOZON Auto recently announced a collaboration with Everus Group to develop a cutting-edge, ultra-large tonnage integrated die casting machine. The initiative aims to refine the production process of new energy vehicles, heightening overall efficacy and performance. The ethos behind the machine is to fuse up to 100 components into a single piece in one casting, a technique yielding significant advantages in vehicle weight reduction and manufacturing complexity minimization.

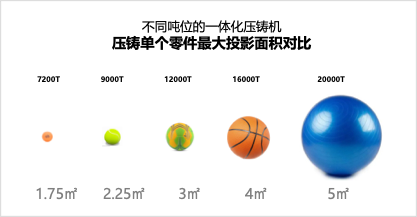

Contrary to the widely seen 6,000 to 12,000-tonne die-casting machines in the current market, the new machine developed by HOZON operates over 20,000 tonnes, capable of manufacturing parts up to 5 square meters under 40 MPa high pressure. This capacity deems it particularly suitable for large-sized component production, like B-class vehicles’ chassis, a crucial part in new energy vehicle manufacturing. By employing the battery-body integrated design, this technology is envisaged to enhance overall rigidity and safety of vehicles while significantly reducing about 3,000 connection points and near hundred procedures, thus accomplishing noticeable weight deduction.

As authoritative research indicates, each 100-kg weight reduction in new energy vehicles may add 10% to 11% to their driving range; a significant boost to new energy vehicles’ competitiveness in the market. This innovative technology from HOZON offers the industry a feasible solution to address the incessantly growing market demand and more stringent energy efficiency standards.

To propel practical application and further research of this technology, HOZON plans to construct a die casting demonstration manufacturing base in Anhui Province and commonly invested in a joint venture company and die-casting research institute with Everus Group. This collaboration is expected to optimize the production process, accelerating technological advancement in the new energy vehicle industry. As this technology matures and is implemented, it is anticipated to provide new energy vehicle manufacturers a higher efficient and more cost-effective production approach. At the same time, it will deliver lighter, more energy-efficient automotive products for consumers.

This article is a translation by AI of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.