Perceived quality, a term perhaps not as flashy as “intelligent” or “electric”, yet it symbolizes something you can instantly feel with each touch and stroke.

Why does a car’s paint need to shine brighter, or why does every button need to be metallic? How should the scent of the leather seats be tailored, or how can the sound of a door closing be more pleasing to the ear? Enter the world of Perceived Quality.

This week, we ventured into the Beijing R&D headquarters of LI Auto, delving deep into LI Auto’s perceived quality evaluation system, and understanding how they perfect it.

What Impressed Me?

Let’s start with an ‘explosive’ statement: the safety of a car can be perceived.

Take seat belts for instance. A steel cable at the end of it meets the safety standard. During the trial phase of the LI L9, the seatbelt ended with a sheathed steel cable. But for most, this design did not ‘appear’ safe.

Therefore, in the production run, the seatbelts were made to have a unifying form, presenting a perceivable ‘safety’.

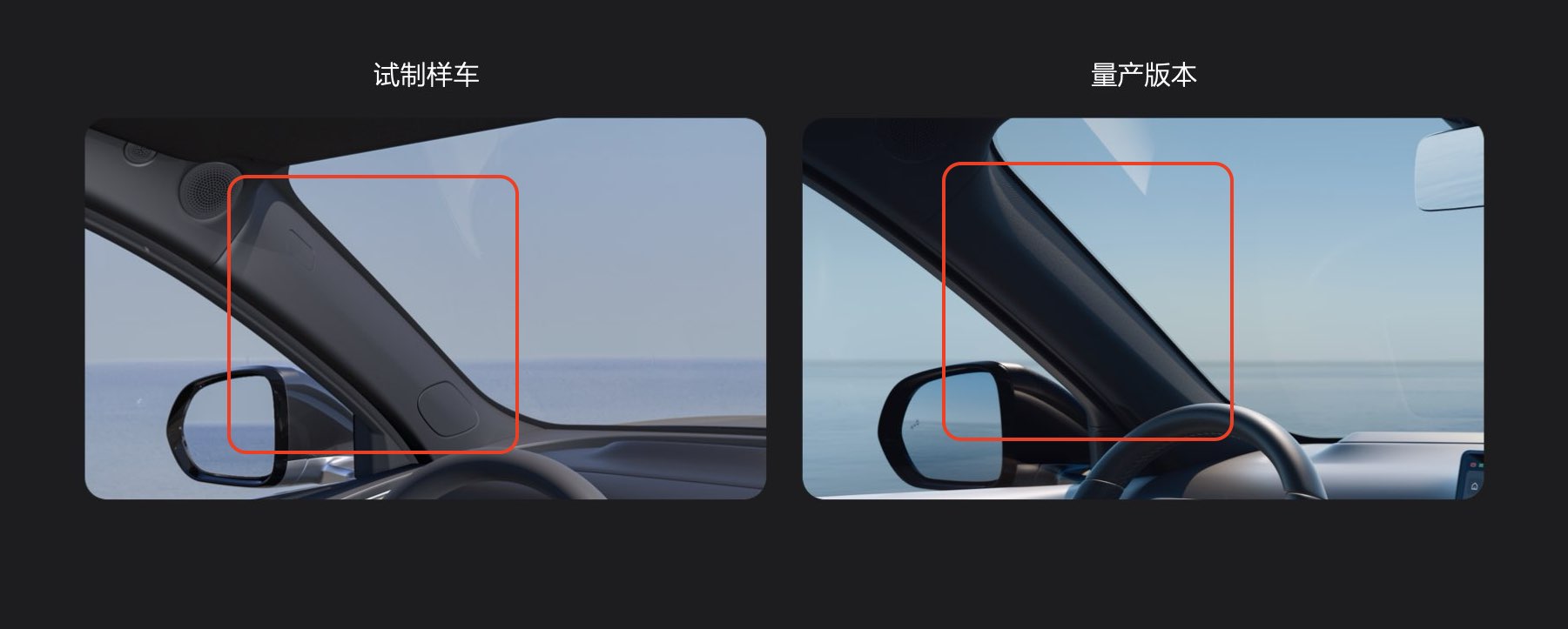

Then, there’s the A-pillar of the LI L9. In prototype vehicles, it’s noticeably more robust, whereas in the production car, the interior trim was optimized, resulting in a prism-shaped outer form. This allows the driver’s line of sight to extend perfectly outside the car. Even the robust A-pillar, supposedly, doesn’t seem to obstruct the view much.

Another dominant aspect is the perception of value. Value here isn’t just about specifications, but also about elements that are hard to express in listings.

If you scrutinize closely, you’ll realize that seatbelts are often embedded within the C-pillars in many five-seater SUVs, and their height cannot be adjusted. This approach ensures matured design at a low cost. However, it brings a problem, for short passengers, the seatbelt could choke them.

LI L7 considered this during development, and positioned the seatbelts behind the seatback instead.

Then, consider the door handle storage. The development mantra at LI is for everyone to feel as though they are handling a broad and silky palm, and not just something expansive.

The third strong perception is the quality of manufacturing and sound. Can it evoke a strong ‘longing’ in the user?

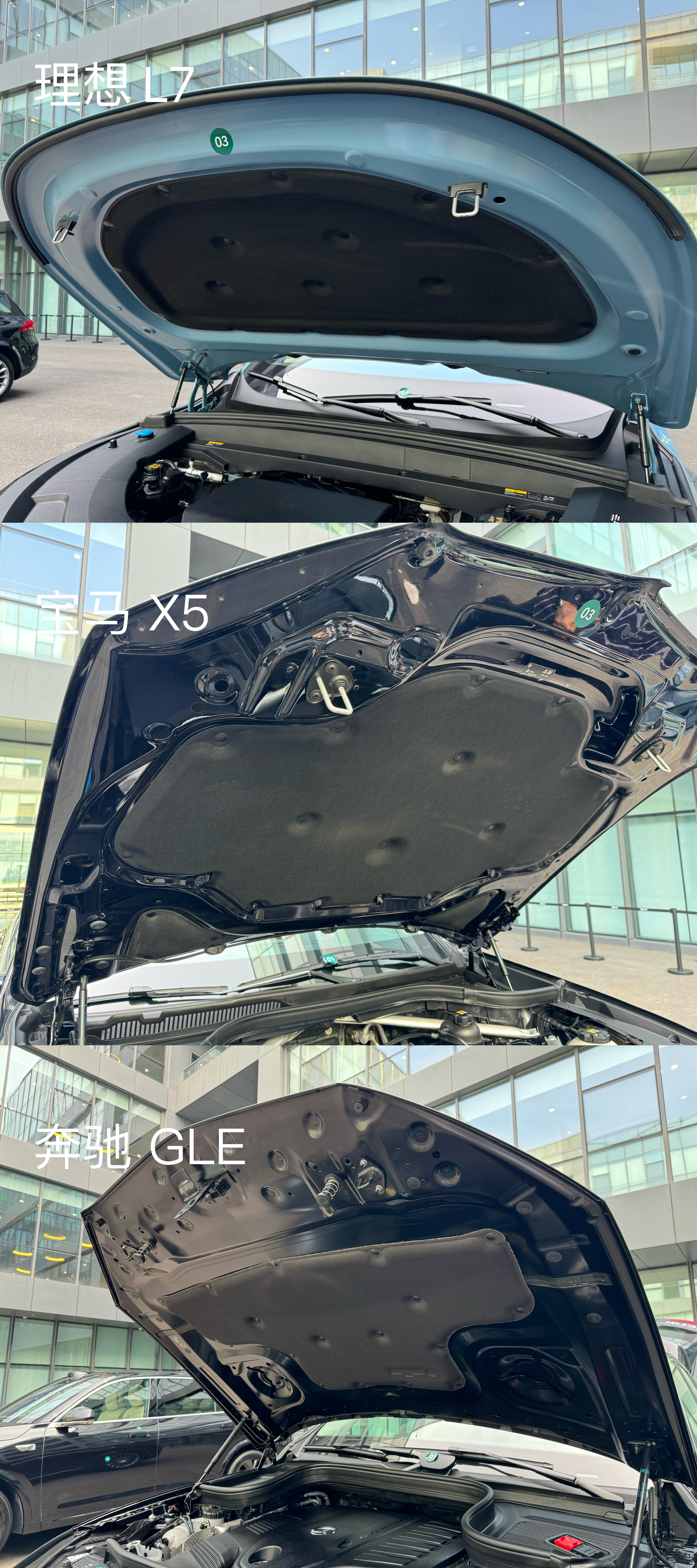

This is evident once you step into the car. LI presented three cars at the exhibit: LI L7, BMW X5, and Benz GLE.

The first comparison was the front-face designs. LI L7 and BMW X5 displayed excellence, whereas the Benz GLE had multiple breakpoints on the front-face strips, significantly impacting its appearance.

The second comparison is focused on the B-side of the bonnet. The manufacturing process here is barely noticeable, but the stark differences between the three cars were immediate.

The B-side of the bonnet of the “LI Auto L7” is neat and orderly, a small clutter is the “Benz GLE”, and the “BMW X5” is wildly unconfined.

But this doesn’t imply that the Benz and BMW are below par, but instead, it’s a matter of preference; perhaps, some customers fancy the mechanical look of the bonnet.

Another detail is the gas cap twisting knob; pictured below, the three cars also differ.

One can clearly see that the cap of the “BMW X5” leans significantly to one side, during rotation, the fingers easily scrape the plastic cover, while the more centered “Benz GLE” and “LI Auto L7” allow for a smoother operation of the gas cap.

There’s a backstory why it’s not centered, to accommodate the addition of a urea filler port for diesel models. As a result, gasoline models had to compromise.

The final comparison is the way the second row of seats is folded. Both the “LI Auto L7” and the “Benz GLE” are electrically foldable, but the power button of the Benze GLE is noticeably hard to press, requiring a 90-degree outward rotation of the right hand to press both buttons. The button logic of the “LI Auto L7” is significantly superior; just reach out and push.

Do hundred-year-old manufacturers really lag behind?

Perhaps some friends will question why in all comparisons, “LI Auto” appears superior. Does this mean that the hundred-year-old manufacturers are lagging, and we’re far ahead?

Not quite. On one hand, different cars serve different user groups, each with its edge. Judging Benz by “LI Auto” standards may not be fair; on the other hand, some designs do not necessarily have pros and cons, it still depends on the product definition.

Inevitably the sound performance of these three models have to be mentioned. After considering my subjective preference, the “LI Auto L7” has the quietest car door opening and closing sounds, while the “Benz GLE” has the most pleasing sound. Among the three cars, the “BMW X5” has the most pleasing hood closing sound.

There are no clear winners or losers in terms of sound; the product’s definition determines the sound quality. For instance, “LI Auto L7” caters more to household users, the opening and closing of doors should be as quiet as possible to not disturb family members, having a softer sound with an auto door is the product development goal.

Another aspect is the design of the vehicle lights. Perhaps attentive friends will notice a ‘step’ between the “LI Auto L7” taillight and the body of the car, which does not align. This is due to manufacturing tolerances that can’t satisfy a perfect alignment, enforcing direct alignment could potentially cause the edge to warp.The Benz GLE has chosen another approach, its headlights are flush with the body, providing a more visually pleasing effect. However, the edges of the taillights are rather sharp, and may pose a risk of cutting your hand.

Therefore, this project demonstrates no better or worse approaches – even for consumers, it might be challenging to make a choice between a flawless exterior that might scratch the hand or a slightly less appealing one that won’t.

So what areas have the Benz GLE and BMW X5 clearly excelled in?

For instance, the interior atmosphere of the Benz GLE is supreme among these three vehicles, with the combination of leather, wood grain and metal giving an instant luxurious feel. This could, perhaps, be a significant part of Benz’s PQ system.

The seats of the BMW are notably more supportive, giving passengers the sense of being ‘enveloped’. The sports accent possibly counts for a substantial portion of the BMW’s PQ system.

Finally, when I asked the supervisor what scores would the X5 and GLE receive in the LI PQ evaluation system? The rough estimate was that the X5 would achieve 80 points, with an assessment of being excellent, and GLE slightly lower, still gaining 75 points.

What is LI’s PQ System?

Targeting family users. That’s the shared objective of the three models in LI’s L series. Thus, LI Auto’s PQ is custom-made for family user groups, with six principal dimensions.

Exterior quality, seat comfort, operational comfort, light quality, audio quality, and human-machine efficiency make up LI Auto’s PQ system, along with functional logic.

What makes an excellent PQ system? LI’s answer is to have PQ engineers become PQ product managers, using standard data integration to all aspects of development, and constantly iterating PQ systems based on manufacturing and user feedback.

Most auto manufacturers have PQ engineers acting much like pre-production quality inspectors. Different engineering departments have separate PQ engineers, implying they have absolute say and the PQ engineer ultimately serves the engineering department.

However, LI Auto assigns product manager roles to PQ engineers, who then participate in product definition. This elevation of PQ product managers’ power of discourse would enhance PQ performance.

LI Auto has also established its own PQ evaluation system, with more than 10,000 individual assessment criteria throughout the vehicle, each criterion serving as a ‘mathematical question’.For instance, the standard for the charging port includes the pressure for opening it, the force required to close it, and its R angle. After establishing the standard, engineers are able to produce products in line with the PQ standard.

Lastly, there is consistent iteration of the PQ standard, with data sources from both the manufacturing and customer ends.

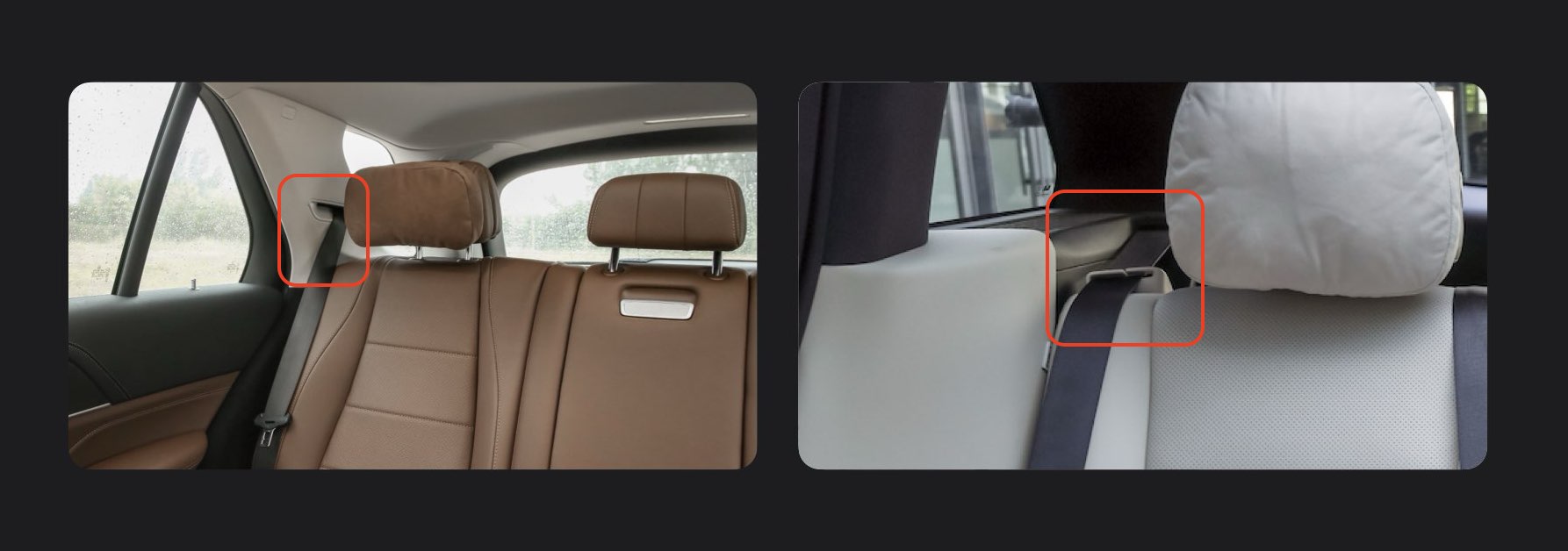

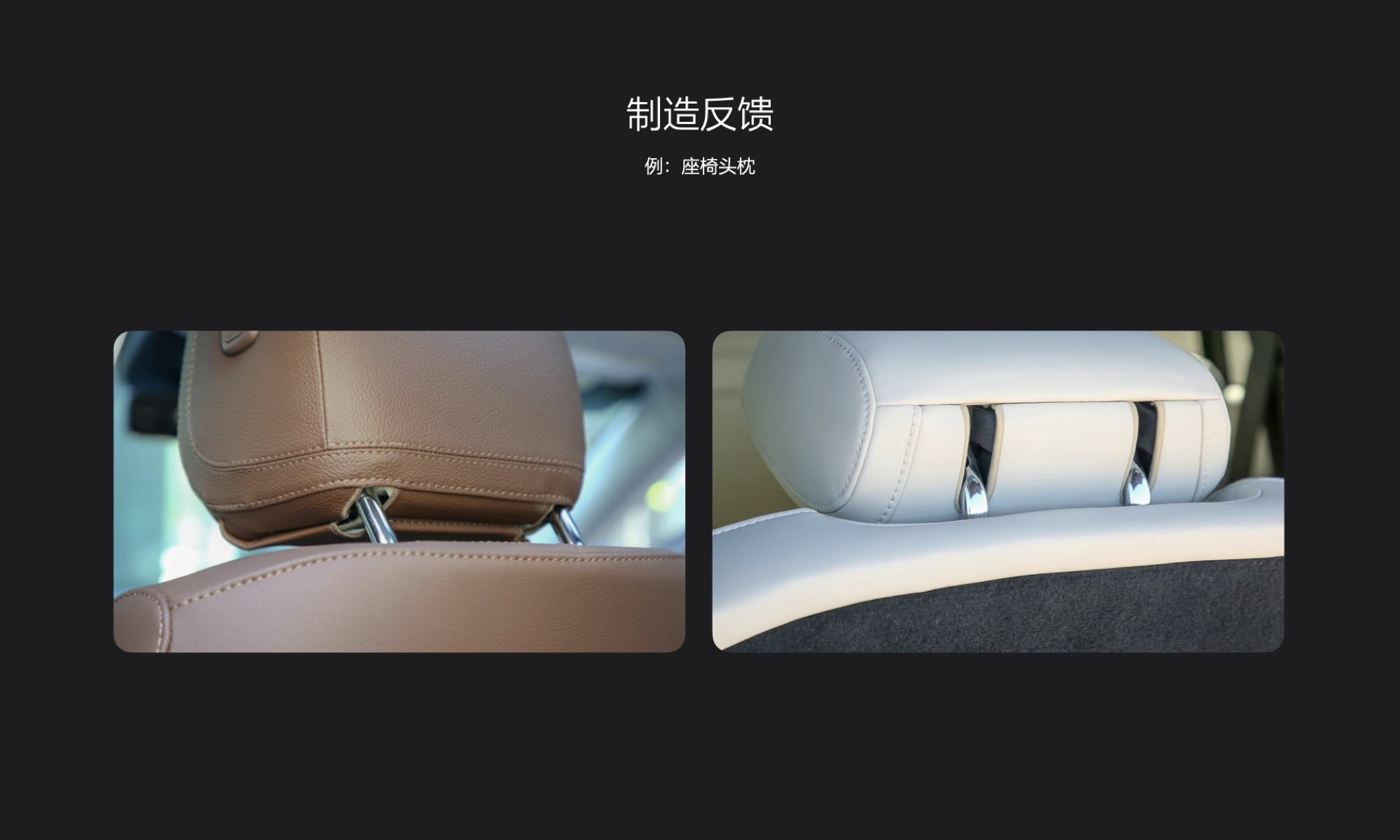

There are two little stories here, one about the headrest, and the other about the car door.

During the trial production stage of the LI Auto L9, the manufacturing end discovered a problem. Rear passengers could see the sponge inside the front headrest through the gap, which slightly detracted from the customer experience. To address this issue, LI Auto promptly updated the design and iterated the standard for the second time.

Similarly, seven months prior to the mass production of the LI Auto L9, user feedback revealed that semi-enclosed doors were prone to scraping against one’s pant legs, attracting some criticism. Additionally, the mold costs for the semi-enclosed doors had already reached 60 million.

Should they update the design, this would mean a loss of 60 million, in addition to the challenge of completing a process that typically took 18 months within 7 months.

To the contrary, they could opt not to make any changes, enduring customer complaints; after all, both the Benz GLS and BMW X7 featured semi-enclosed doors.

In the end, LI Auto chose to overhaul the design, transforming the semi-enclosed doors into fully-enclosed ones over seven months.

Final Thoughts

After static comparison of three different vehicles, one can clearly sense the dedication of LI Auto towards the PQ system. Not only are visible areas meticulously attended to, but the same attention is extended to areas unseen.

Moreover, as auto manufacturers continue to develop and evolve, catering to diverse customer needs will always entail on-going enhancement of the PQ system, even to the point of completely re-engineering it to suit individual customer needs. Similar to the current BBA luxury brands, different products are defined to target specific user groups.

This article is a translation by AI of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.