On August 21, HOZON unveiled its “HOZON Strategy 2.0” in the Global Building just relocated next to Changfeng Park in Putuo.

It was assumed that the Brand Technology Day would be a grand event bustling with people. However, upon arrival, it was discovered that the somewhat frugal HOZON simply organized this “content-rich” Technology Day in a fairly spacious room in its own office building.

This precisely corroborates what HOZON’s CTO Dai Dalí stated – HOZON has always strived for high efficiency in company operations. Judging from the investment in research and development, HOZON does not seem to be “stingy” at all. A team of 500 people and a billion in funding; it is not something a “stingy” company can pull off.

Comprehensive from Architecture to Electric Drive

The conference featured five leading technology products at once: HOZON Super Computing, HOZON Skateboard Chassis, HOZON Electric Drive, HOZON Range Extension, and HOZON Thermal Control. They showcase the full spectrum of HOZON’s technical capabilities from Smart Cabin, Smart Drive to the complete EV suite.

Additionally, HOZON announced that these technologies are open to the entire industry. Given the frequent news of cooperation between foreign automakers and new power automakers recently, it seems that HOZON also hopes to use the technology it has to expand its revenue channels. And according to HOZON’s disclosure, it has been interacting with overseas car companies. Perhaps before long, we will hear good news about HOZON’s collaboration with others.

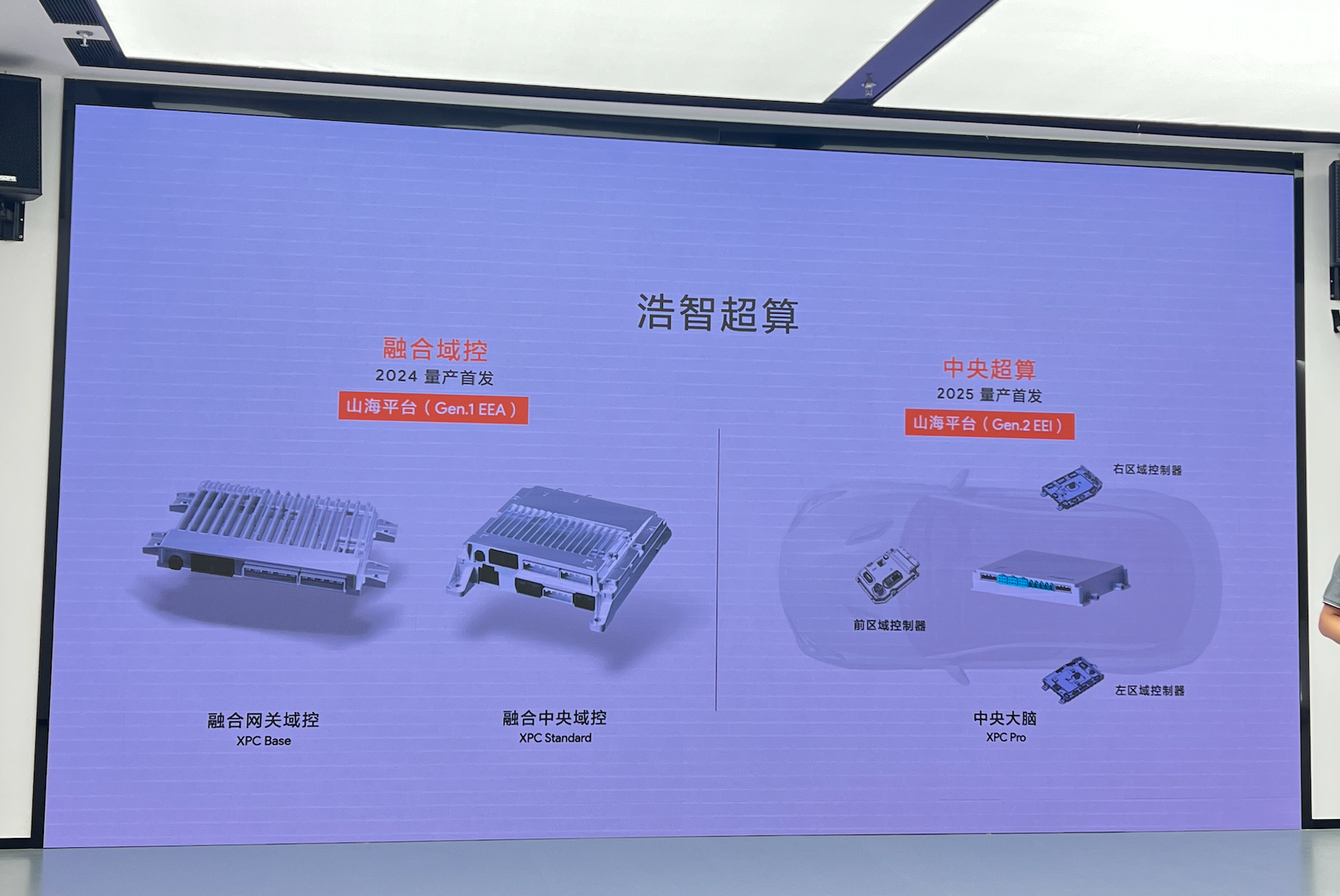

HOZON Supercomputing Central Computing Architecture

The HOZON supercomputing platform released by HOZON this time primarily consists of three products: the Fusion Gateway Domain Control, Fusion Central Domain Control, and Central Super-Computing Platform. The Gateway Domain Control and Central Domain Control components will be initially installed in the “Gen.1 EEA” of the Shanhai Platform mass-produced for the first time in 2024.

Fusion Gateway Domain Control: Rich in interface extensions, with 14 CAN channels and 9 Ethernet channels, conducive to adapt to the entire vehicle, capable to achieve smart gateway, power domain control, heat management, body control.

Fusion Central Domain Control: The smart drive domain and the control domain blend together, S32G3 chip for smart cabin, 1~2 Orin-X chips for smart drive, where each chip has its own role, enhancing the quality of contingency handling. Maximum computing power is 508 TOPS, 400+ KDMIPS, capable to meet the smart cockpit requirement and realize high-speed pilotage, memory parking, and city pilotage.The integrated gateway domain controller and integrated central domain controller will follow the new car SOP in May 2024. It is most likely to be integrated into the updated HOZON S model.

Central Supercomputing Platform: Consisting of central supercomputing with over 1000+ TOPS computing power, and controllers for the front compartment and left and right areas. The regional controllers use Infineon’s high-security multicore Aurix-TC3xx series processor. All vehicle sensor data will preprocessed by the regional controllers before key data are uploaded to the central computing platform for flexible processing and major data computation.

Under the central-regional architecture, the vehicle wiring harness is reduced by 1.5 km and the weight is reduced by 10 kg, increasing the cruising range by 5%. This plan has completed the conceptual design and plan demonstration, and will be mass-produced and delivered in 2025.

In addition, this central computing architecture will incorporate large AI models to achieve high-level autonomous driving. Also, the HOZON S is currently preparing to connect to the cloud’s large model, and there will also be a local large model that’s been pruned on the car side. The smart driving system, built on the central computing architecture, will also introduce BEV and Transformer. We are looking forward to seeing HOZON’s performance in smart driving.

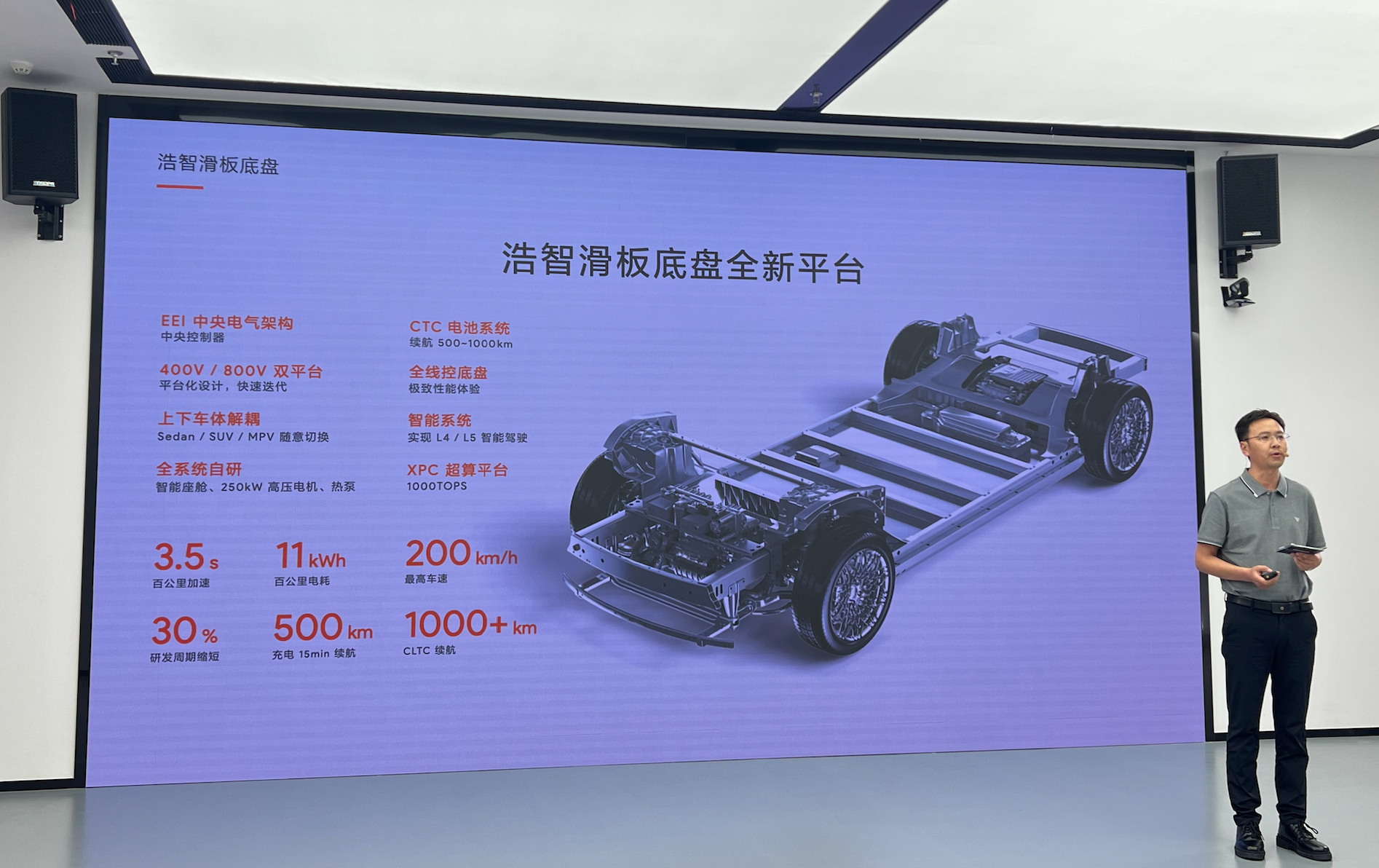

HOZON’s Skateboard Chassis – The Complete Combination of HOZON’s Five Major Technologies

At the beginning of this article, it was said that HOZON’s technologies are open. For a more complete integration of these technologies, the skateboarding chassis released this time would be a great choice.

The skateboard chassis had a moment in 2021. Unexpectedly, HOZON continues exploring this route, having completed the internal project setup. A prototype may be seen at the end of this year or the beginning of next year.

Here are some key details of the HOZON skateboard chassis:

- Based on the EEI central electric architecture, with a single controller for the entire vehicle;

- XPC supercomputing platform, with a peak computing power of 1000+ TOPS;

- Whole-line controlled chassis, achieving decoupling of the vehicle body;

- 250kW high-voltage motor, supporting both 400V/800V platforms;

- Supports L4/L5 intelligent driving;

- CTC integrated battery and chassis, with a max range of 1000km.

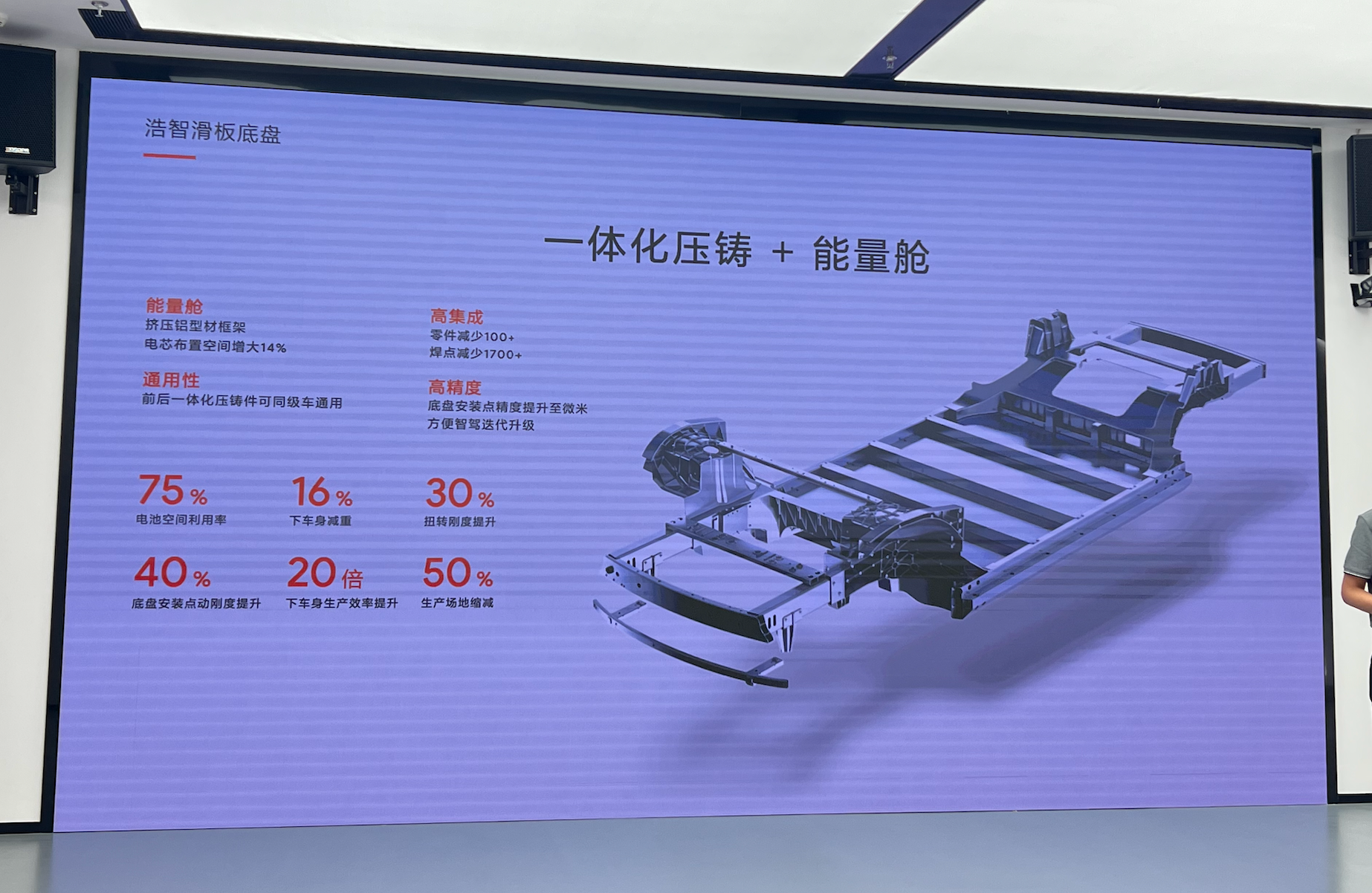

In addition, the front and rear of HOZON’s skateboard chassis will use an integrated die-casting design, reducing the weight of the lower body by 16% and improving vehicle rigidity by 10% and the mounting point dynamic rigidity of the chassis by 40%. This design also increases production efficiency by 20 times, shortens the R&D cycle by 30%, and reduces the production site area by 50%. It not only enhances vehicle performance and manufacturing efficiency but also greatly reduces production costs and resource waste.

With respect to the issue of maintenance, HOZON indicated that it was taken into consideration during the design process by trying to avoid areas of high collision rate in the integrated die-casting area. Furthermore, the die-cast parts will also have a certain degree of repairability. Regarding the problem of the connection between the skateboard chassis and car body, HOZON has performed a technical analysis stating the application of bolts and structural adhesive as the linking method. HOZON suggests that such a connection will make the whole vehicle operation differ slightly from the load-bearing differential.

In the area of tri-electricity, HOZON released new motors, range extenders, and thermal management systems today.

The motors include a 180kW medium voltage platform and a 250kW 800V High Voltage SiC electric driving system. With an output torque of 350N·m from the 180kW motor, maximum wheel-edge torque can reach up to 4850 N·m, highest motor speed is 20000 rpm, and the system’s maximum efficiency >95.5%, with a system NVH performance <77.5 dBA.

HOZON stated that the 400V or 800V SiC silicon carbide charging platform combined with the CTC (Battery and Chassis Integration) battery system could, under ideal conditions, extend the range by 200 kilometers after a 5-minute charge, potentially pushing the total vehicle range to exceed 1000 kilometers.

Further, considering the need for long-distance travel and the avoidance of charge anxiety, HOZON will continue providing plug-in hybrid models with range extension. The Hao Ran range extender launched at this release is an efficient Atkinson engine specially designed for range extension, a 1.5L naturally aspirated prime mover. It is teamed with a generator that covers the efficient zone between 2000-5000 revolutions, with an overlap rate of the efficient zone reaching over 93%, enabling a highly efficient range extender system.

The range extender’s flywheel and generator rotor connect directly for higher efficiency. The oil-electric conversion rate of 3.26 kWh/L for this range extension system, with NVH reaching 78.9 dBA, implies that if installed on HOZON S, a tank of fuel could theoretically generate 140 kWh of electricity.

Of course, for electric or electrically driven models, if you want to utilize the full performance of the hardware, the vehicle’s thermal management becomes exceedingly crucial. HOZON released Hao Zhi thermal control 1.0 and 2.0 in this launch. The 1.0 will start mass production this year, while the 2.0 will not be launched until 2024. The 2.0 will adopt a direct cold and heat framework, replacing coolant convection with refrigerant phase change for heat transmission, which enhances the heat transfer efficiency by an order of magnitude, supporting 4C or above fast charging.

Final Words

After witnessing numerous technology launches recently, HOZON’s technology day, based on the simplicity and modesty of its format, could be considered the most modest. Even the PPT content was concise yet meaningful, with the tech experts cutting straight to the chase during their presentations. Evidently, HOZON is eager to showcase to the public the technical innovations that have been in development for a long time.From tech research and development to self-built auto parts factories, it is evident that Nezha (HOZON), strives to seize more initiative in its own hands. Such actions not only enhance the user experience but also offer more competitive edges in the increasingly competitive new energy market.

With these technologies gradually materializing, Nezha (HOZON), will tread with even more robust steps in the journey ahead.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.