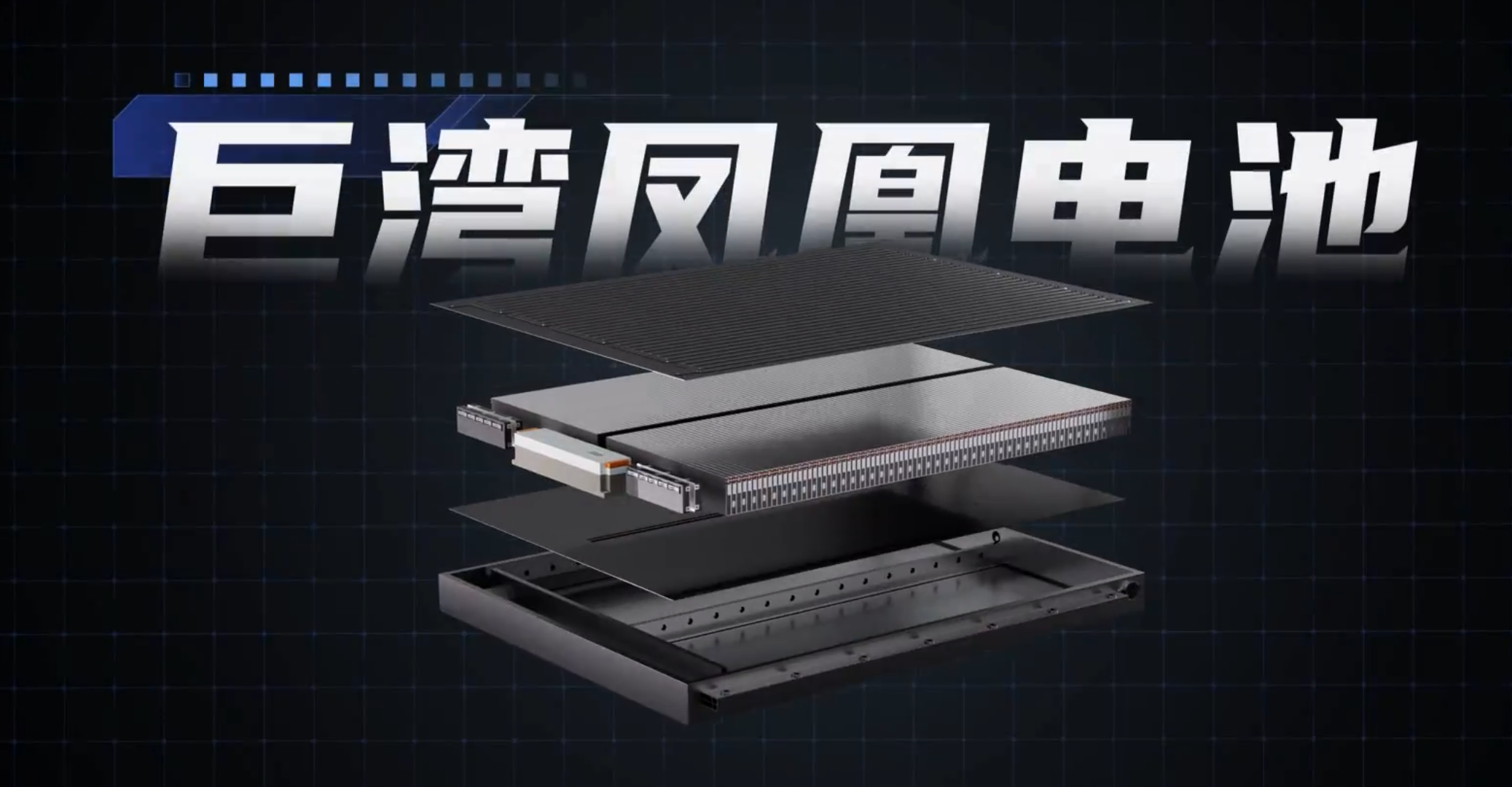

On June 6th, Giant Bay Tech officially released the new self-developed Giant Bay Phoenix battery with XFC technology.

The most impressive part of this short 7-minute launch event was when Giant Bay announced its goal to “make charging as convenient as refueling.”

This slogan is not new – both electric vehicle companies and other power battery companies have claimed to make charging as convenient as refueling. However, no company, not even NIO, has truly achieved this yet.

How to enable ultra-fast charging for 400V vehicles?

As the electric vehicle industry rapidly develops and the number of electric cars increases, consumers are more accepting of electric vehicles. However, “charging issues” remain the primary factor that affects our purchasing decisions. Everyone has a strong demand for quick charging and hopes that electric vehicles can achieve “5-minute fast charging, as convenient and quick as refueling.”

However, slow charging and inconvenient charging locations, especially during long trips, make it difficult to guarantee charging facilities on the road. Particularly when charging power is low, it takes a significant amount of time to recharge. This not only reduces travel efficiency but also causes one to consider whether to drive an electric or gasoline vehicle for the next long trip. Therefore, developing ultra-fast charging is essential.

Speaking of ultra-fast charging, we must discuss XFC ultra-fast charging technology, proposed by the United States. This technology allows for charging a battery to 80% capacity within 10 minutes. Globally, ultra-fast charging technology is considered key to improving charging efficiency. We often hear about 800V high-voltage fast charging, which is currently the most promising technology for achieving ultra-fast charging.

As a result, mainstream electric vehicle companies, such as XPeng, LI Auto, and NIO, are developing 800V products. As more 800V high-voltage platform models emerge, the number of charging stations that support high-voltage fast charging will undoubtedly increase. Both automakers and third-party charging service providers are actively deploying high-voltage charging stations. It is expected that the number of 1000V high-voltage DC stations will increase to approximately 980,000 between 2023 and 2026.

The advantages of 800V are evident, and high-power, high-voltage fast charging will be the trend in the future.

However, the widespread deployment of 800V charging stations will bring new challenges. One issue is that a large number of current 400V platform electric vehicles cannot enjoy high-voltage fast charging due to hardware limitations. Imagine the frustration when your 400V vehicle is at an 800V charging station, and you have to wait half an hour or more while others with 800V vehicles charge for only 10 minutes and leave with a full battery.Translate the following Chinese Markdown text into English Markdown text in a professional manner, retaining the HTML tags in the Markdown, and outputting only the results:

Additionally, the R&D difficulty of 800V systems requires automakers to upgrade or redesign all high-voltage components, including electric drive, battery, charging, and thermal management systems, and re-optimize the entire vehicle. Developing a new platform inevitably leads to higher costs, which are reflected in the vehicle price for consumers. Currently, the lowest-priced 800V pure electric vehicle is XPeng G6, with a pre-sale price of 228,000 yuan, and most others are priced above 300,000 yuan, which is beyond the mainstream price range for Chinese car buyers.

So, is there any way for these 400V EVs to enjoy the advantages of 800V high-voltage fast charging without changing their voltage platform?

The recently released Giant Bay Phoenix battery may solve this problem.

This company may sound unfamiliar to some. It’s a battery company focused on fast charging technologies and next-generation energy storage technology development, incubated by GAC and jointly funded by GAC and external capital. Its products have already been used in GAC AION V Plus. The Phoenix battery is their latest product.

Three major technological innovations to solve the core pain points of fast charging for power batteries

- High and low voltage switching technology

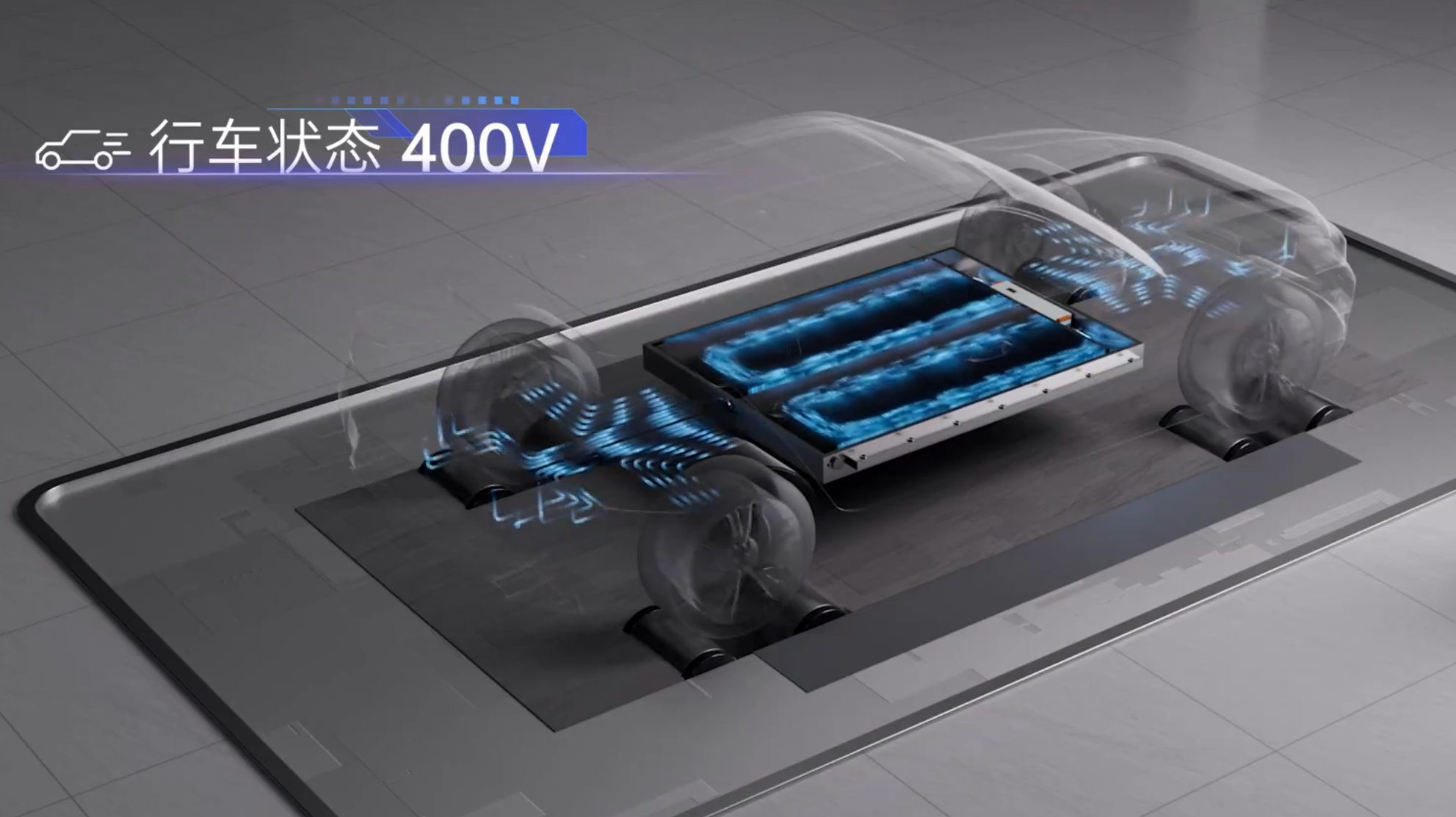

The Phoenix battery, released this time, has a very clever design strategy. Giant Bay R&D claims that without changing the whole vehicle’s low-voltage platform, the Phoenix battery can achieve fast charging at any voltage platform from 300V to 1000V by optimizing the electrical architecture, precise control of their self-developed switch matrix, and dynamic identification of the external supercharging network.

To put it simply, it charges at 800V, but it can output to the vehicle platform at a reduced voltage of 400V. This means that the existing 400V platform EVs can enjoy super-fast charging technology without changing their existing low-voltage platform architecture.

Some might argue that there are very few 800V charging piles on the market today. Even if the car can support 800V high-voltage charging, it may not hold much significance. However, people may overlook the fact that if the car supports 800V high-voltage charging, it will still charge faster than a 400V platform car on non-800V charging piles since it can operate at full power.

For example, an 800V car can achieve a maximum charging power of 480kW. When it encounters a 100kW charging pile, it can still maintain a power output of 100kW from 0-80%. Thus, the significance of an 800V platform goes beyond faster charging speeds when high-voltage fast-charging is more widely adopted – even now, it can bring faster charging speeds.

Once you truly experience 800V, it’s hard to go back, as stepping out to buy a bottle of water while charging can add 200km of range, significantly reducing anxiety about refueling. Although there’s still a way to go before reaching the speed of refueling with gasoline, the prospects of 800V are enticing.

For vehicles with lower market positioning, where the cost does not support 800V, the Phoenix battery is a great solution. Even if the cost is higher, it can be offset by achieving higher sales volume. Perhaps, in time, the benefits of 800V technology will be accessible to everyone, allowing everyone to enjoy a superior fast-charging experience.

- More efficient thermal management technology

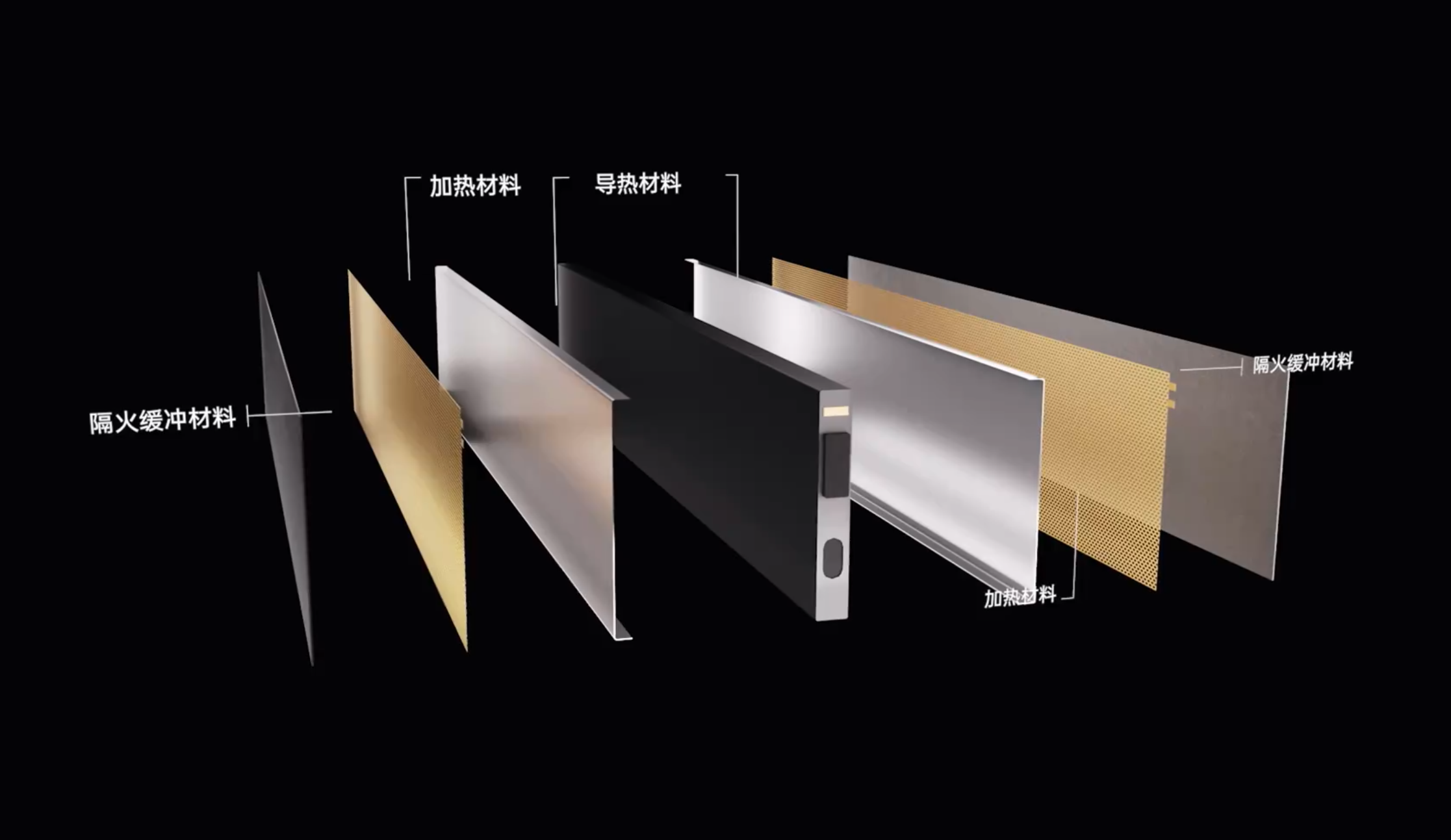

While 800V brings faster charging speeds, it also demands higher thermal management performance for batteries, both in terms of self-heating under high voltage and current and temperature regulation for external conditions.

Electric vehicle drivers may have noticed that during winter months, the range of the vehicle noticeably decreases, and energy consumption is significantly higher compared to summer. Part of this is due to heating systems requiring more energy, and another part is the impact of cold weather on batteries.

Batteries are sensitive to temperature, and their performance can be affected when it’s too hot or cold. For example, the optimal working temperature for lithium-ion batteries is around 25°C. When temperatures drop, battery capacity decreases significantly, reaching only about 60% of its capacity at -20°C. This is why electric vehicles are less common in colder regions; batteries degrade faster and charging speeds are considerably slower.

Most automakers currently use liquid cooling solutions for battery temperature control.

Liquid cooling systems commonly used in the industry are either bottom-mounted or vertical. These only provide single or double-sided heat dissipation, allowing only single-point cooling for batteries. This method also impacts the arrangement of battery cells, lowering the overall energy density of the battery pack. The Phoenix battery, with its innovative highly-conductive low-dimensional materials, offers three-sided heat conduction, resulting in better cooling and heating effects and improved energy density.

Relying on its unique highly-conductive low-dimensional materials, the three-dimensional thermal management system developed for the Giant Bay Phoenix battery can increase heat exchange surface area by 18 times. It allows rapid heating in just five minutes, changing temperatures from -20°C to 25°C.The Phoenix battery’s temperature control can effectively mitigate the impact of temperature on the battery, ensuring optimal performance and charging speed even in the cold northern regions through preheating technology. Based on this, models equipped with Phoenix batteries can adopt charging preheating, similar to Tesla, where the system preheats the battery when navigating to its own Superchargers, ensuring that charging power is not affected by low temperatures upon arrival.

With the help of this technology, super fast charging can be realized under various environments, significantly improving the user experience for electric vehicle owners in winter and northern regions. It also ensures that the battery capacity remains unaffected, resulting in better driving range.

- Increased safety protection

Apart from charging, safety is another reason why electric vehicles have not been fully embraced by everyone. Although some batteries on the market are advertised as resistant to spontaneous combustion, the reality is that such incidents still occur. Ensuring battery safety and changing people’s inherent perception of the dangers associated with electric vehicles is a difficult task.

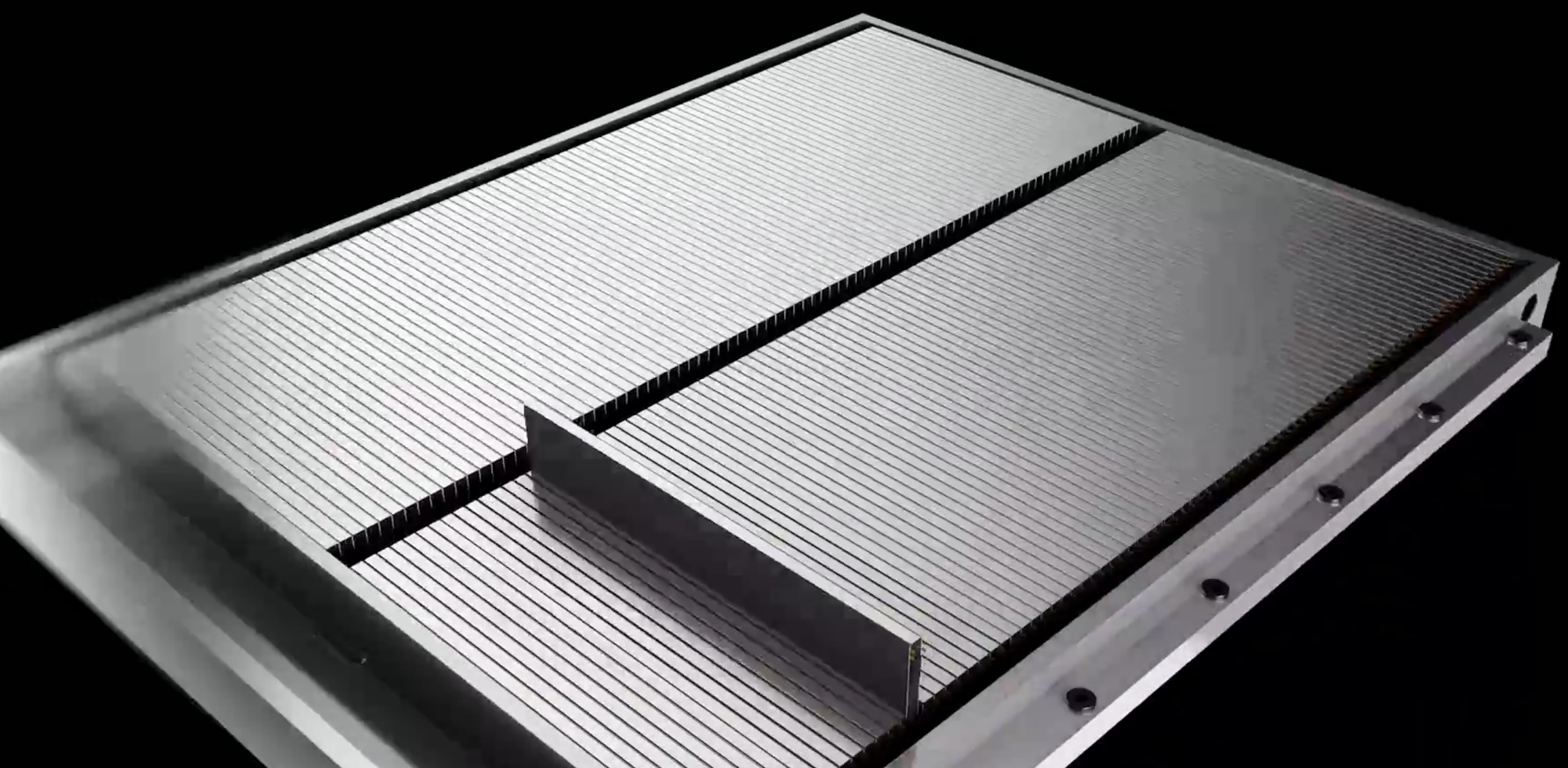

Phoenix battery utilizes a cartridge-style structural design, providing safety protection for individual cells through structural innovation, and greatly improving battery safety performance, including impact resistance and anti-penetration capabilities.

In common cell layouts, there is no physical isolation between cells other than structural adhesive. If a cell experiences thermal runaway, the adjacent cells are easily affected, exacerbating the combustion phenomenon. This is why many electric vehicle fires involve severe explosions.

Phoenix battery claims that with this cartridge design, even if a cell experiences thermal runaway, it will be contained within the “cartridge” and not spread, while the rapid cooling technology effectively dissipates the heat, preventing large-scale thermal runaway.

At the press conference, Phoenix battery stated that during battery system thermal runaway tests, it achieved 48 hours without fire, far exceeding national and industry safety standards. Moreover, structural optimization and the use of C2P solutions increase the integration of the entire battery pack, bringing the system integration rate to 75%.

Conclusion

Although the Giant Bay Technology’s Phoenix battery press conference was only 7 minutes long, it introduced many new solutions for China’s electric vehicle industry. XFC fast charging cells, the full-voltage platform solution, and safety protection all demonstrate great innovation. These technological capabilities give Phoenix batteries a wide range of application prospects, especially the full-voltage platform solution, which enables 400V platforms to enjoy 800V-equivalent fast charging experiences at minimal cost, essentially achieving a level of technology parity with 800V solutions.It is reported that the giant bay Phoenix battery will be mass-produced at the Giant Bay Technology Research (Nansha) Energy Storage Device and System Production Base next year and is expected to be installed on vehicles by the end of next year. By then, we will be able to see the performance of the Phoenix battery in practical applications.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.