The busiest exhibitor at this year’s Shanghai Auto Show is Ningde Times.

On the evening of April 16th, Ningde Times announced that their sodium-ion battery will debut in Chery cars. On April 18th, Ideal Automotive signed a comprehensive strategic agreement with Ningde Times, and Ideal Automotive’s first pure electric vehicle will become the first car in the world equipped with a 4C Kirin battery.

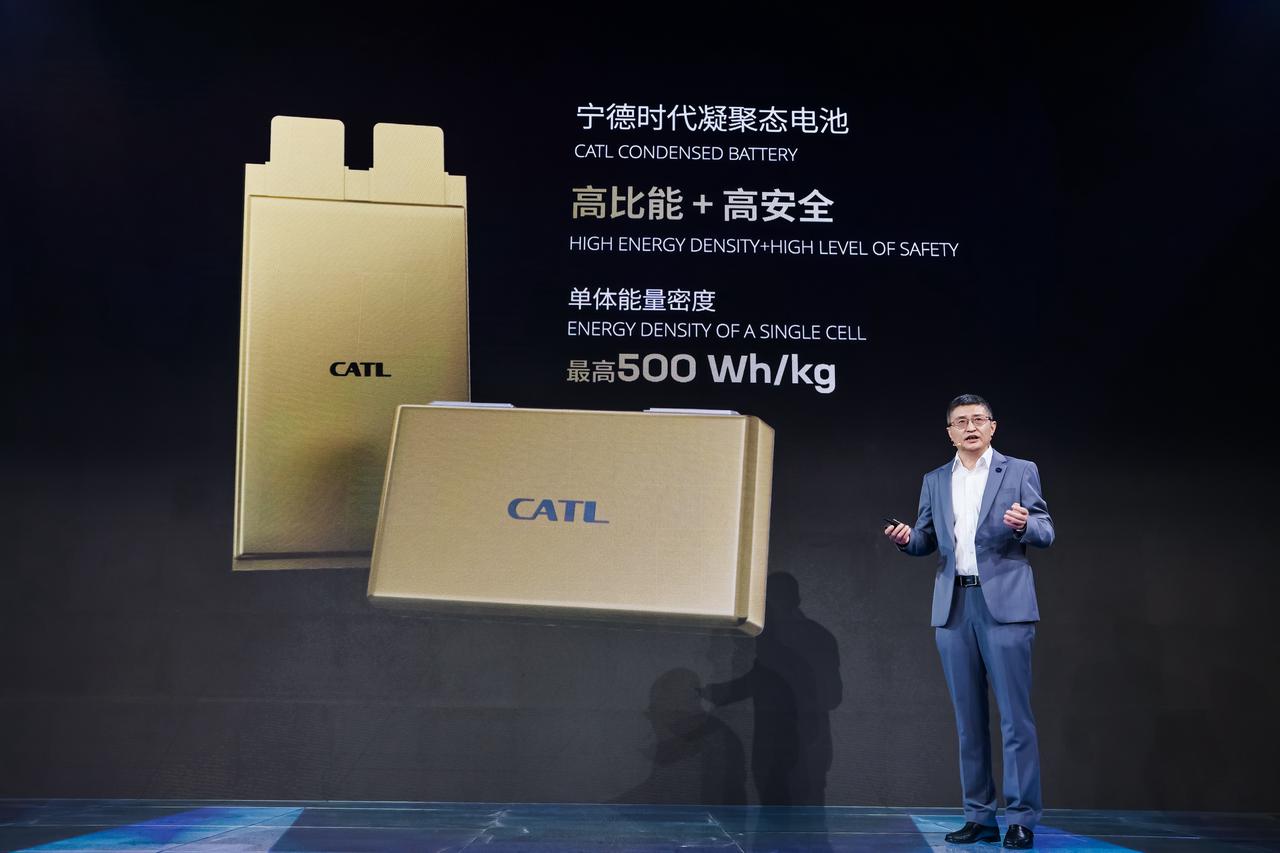

However, what has attracted the most attention from the outside world is Ningde Times’ “Condensed State Battery” unveiled on April 19th at the Shanghai Auto Show. This is not a branch of “semi-solid-state battery” or “solid-state battery,” as Ningde puts it, “the condensed state battery is a completely new category.”

For such a term, you may be a little unfamiliar, so I’ll highlight a few key points for you: 500 Wh/kg for single-cell energy density, manned aviation electrification, mass production capability within this year, and the launch of a vehicular-grade application version.

Now, let’s focus on what’s important: How exaggerated is the single-cell 500 Wh/kg energy density?

Previously, foreign media dismantled Tesla’s 4680 battery and found that the energy density of a single 4680 battery from the Texas super factory was 244 Wh/kg, and the energy density of the system after being grouped was 230 Wh/kg.

In other words, the “condensed state battery” mentioned by Ningde has increased 51.2% in single-cell energy density compared to the 4680 battery. If this is applied to cars, it can theoretically achieve longer driving range with the same weight, and further meet the lightweight requirements of electric vehicles for the same range.

Excitingly, Ningde Times indeed announced that they will also launch a vehicular-grade application version of the condensed state battery that can be mass-produced within this year.

In addition to vehicular-grade application, Ningde Times stated that they are collaborating on the development of civilian electric passenger aircraft projects, executing aerospace-level standards and tests and meeting aerospace-level safety and quality requirements.

Elon Musk once stated that the biggest obstacle to the electrification of manned aircraft is that the energy density of batteries is not high enough. If the energy density exceeds 400 Wh, the popularization of electric aircraft will be possible.“`

Without a doubt, the “Aggregate State Battery” of Ningde Times may become the first chapter of commercialized aviation electrification. So, technologically speaking, what exactly is the Aggregate State Battery? Is it the same type as the highly popular Solid State/Half-Solid State Battery?

Regarding the first question, Ningde Times responded as follows:

“Ningde Times targets the chemical material electrochemical reaction changes of highly specific energy, uses high-power bionic aggregate state electrolyte, constructs a micro-level adaptive network structure, adjusts chain interaction forces, while enhancing the stability of the microstructure, increases the battery’s dynamic performance and improves the efficiency of lithium-ion transportation.“

“The Aggregate State Battery also integrates a series of innovative technologies, including ultra-high specific energy positive electrodes, new negative electrodes, insulating membranes, and processes, to have excellent charge and discharge performance, as well as high security performance.”

The Aggregate State Battery is neither a Half-Solid State Battery nor a transitional product from Half-Solid State to full Solid State Battery. Ningde Times stated that the Aggregate State Battery is a “brand-new type.” In fact, an internal memo from Ningde Times circulated online earlier, proving the company has a cautious attitude towards Half-Solid State Batteries and comparing them more with Solid State Batteries. Half-Solid State Batteries are more speculative products.

Answering the second question, except for the full Solid State Lithium Metal Battery, which is still difficult to be mass-produced, the electrolyte of either a Half-Solid State Lithium Metal Battery or an ordinary Lithium-ion Battery is still a moving liquid.

According to Ningde Times, “improving the efficiency of lithium-ion transportation” also demonstrates that the Aggregate State Battery will have higher conductivity.

Most importantly, Ningde Times stated that the “bionic Aggregate State Electrolyte” can “adjust chain interaction forces, enhance the stability of the microstructure,” which also means that the safety and stability of the battery will be improved compared to batteries using traditional liquid electrolytes.

For the commercial development of batteries, two core indicators are crucial: one is the ability for mass production, and the other is cost control. The popular Solid State/Half-Solid State Batteries still have an insurmountable gap in these two aspects.

At the NIO Day in January 2021, NIO attracted much attention to its Solid State Battery. Still, after two years, the delayed 150 kWh battery pack has yet to emerge. Earlier, Qin Lihong, co-founder and president of NIO, said that the NIO 150 kWh battery pack is expected to be launched this summer, but its cost is high, equivalent to a NIO ET5 vehicle.

“`And the partner of NIO’s solid-state battery, Wei Lian New Energy, has previously stated that the current goal for the 150 kWh solid-state battery is to produce 1,000 battery packs by 2023. Obviously, this cannot satisfy the large-scale demand of the market.

Therefore, Wu Kai, the chief scientist of CATL, undoubtedly provides a confidence booster with his speech at this year’s Shanghai Auto Show:

“At present, we are cooperating with the civilian electric passenger aircraft project, conforming to aviation-level standards and tests, and meeting aviation-level safety and quality requirements. Meanwhile, we will also launch a vehicle-grade application version of the solid-state battery, which will have the ability to mass-produce within this year.”

Technology needs to be practical

How much hidden aces CATL still has in its hand is a common curiosity in the industry. For CATL, what is terrifying is not only its strong research and development capabilities on the forefront of technology but also its speed to quickly implement technology into actual use.

Specifically, aside from the solid-state battery, CATL will also implement the following technologies this year: high-energy density/4C Kirin battery, sodium-ion AB battery, M3P battery.

Among them, the Kirin battery system can achieve an energy density of 255 Wh/kg and a volume utilization rate of 72\%. With CTP3.0 technology, it can significantly increase the endurance of the vehicles equipped with it. We have already seen a version of the Kirin 009 equipped with a 140 kWh battery pack, and the endurance of the Kirin 009 version has reached 822 km (CLTC condition).

In addition, during this year’s Shanghai Auto Show, CATL and Ideal Automobile officially announced that they will launch comprehensive strategic cooperation. Ideal Automobile’s first pure electric vehicle will become the world’s first vehicle equipped with the 4C Kirin battery.

The 4C Kirin battery is capable of fast charging at up to 4C or even 5C, thanks to the use of high-deintercalation graphite negative electrodes, low-impedance surface-coated positive electrodes, high-conductivity electrolytes, high-current collectors, and other technologies.

The 4C Kirin battery also adopts a dual-side large-area cooling technology, which can increase the heat exchange area by five times compared with the traditional bottom cooling scheme, reduce the thermal resistance by 75\%, achieve a maximum heat exchange power of 16 kW under the high-temperature cooling condition, and raise the temperature of the battery cell by 1.6 °C every minute under the low-temperature heating condition.According to previously released data, CATL’s 4C Kirin battery can achieve a more optimal charging path across the full temperature range, with a maximum charging power of 480 kW at room temperature, and a maximum charging power of 220 kW at low temperatures. Ideally, with the 4C Kirin battery paired with a 4C ultra-fast charging station, a replenishment speed of 400 km of range per 10-minute charge can be achieved.

It can also be seen from the cooperation between CATL, NIO, and Xpeng that both the long-range Kirin battery and the 4C version are currently targeting the mid-to-high-end market. Although the price of lithium carbonate raw materials is currently falling, battery costs still account for the bulk of vehicle costs for cheaper EV models.

On the evening of April 16th, CATL announced that its sodium-ion battery will debut in Chery models. The energy density of CATL’s first-generation sodium-ion battery cell can reach 160 Wh/kg, which is almost the same as traditional lithium iron phosphate batteries. CATL’s sodium-ion battery is superior to lithium iron phosphate batteries in terms of charging speed, safety, low-temperature performance, and system integration efficiency.

According to CATL’s data, vehicles equipped with sodium-ion batteries can reach over 80% charge in 15 minutes at room temperature and over 90% discharge retention rate in a low-temperature environment of minus 20 degrees Celsius. The system integration efficiency can also reach over 80%.

Huang Qisen, deputy director of CATL Research Institute, said:

“In passenger vehicle applications, sodium-ion batteries can generally meet the demand of EVs with a range of less than 400 kilometers. In addition, by combining CATL’s innovative AB battery system integration technology, sodium-lithium hybrid can be achieved, and sodium-ion batteries are expected to extend to EVs with a 500 km range. This range of EVs will target 65% of the market, with a very broad application prospect, and also provide conditions for the industrialization of sodium-ion battery products.”

Although there was no revolutionary difference between sodium-ion batteries and lithium-ion batteries, from the perspective of cost reduction and resource reserves, the significance of sodium-ion batteries is significant. The reserve of sodium element is much larger than that of lithium, and the material cost of sodium-ion batteries will be reduced by 30% to 40% compared with that of lithium-ion batteries.“`

According to the news from “LatePost”, CATL has built a sodium-ion battery pilot line in Ningde, and the pilot line is generally used for validation before large-scale production, which proves that CATL is rapidly advancing towards scaled development.

For A00-class cars, two-wheelers and energy storage markets, the maturity of sodium-ion batteries will effectively reduce the overall cost. From the perspective of the automotive market, sodium-ion batteries will be an important power source for pure electric small cars.

Lastly, it’s the M3P battery. At the performance briefing meeting for 2022 held by CATL earlier, Zeng Yuqun expressed that M3P battery is expected to be mass-produced this year.

The outside world previously speculated that the M3P battery is a lithium iron manganese phosphate battery, but according to CATL’s statement in the investor survey activities last year, the M3P battery cannot be strictly called a lithium iron manganese phosphate battery. The positive electrode material of the battery also contains other metal elements, and “ternary lithium-ion batteries with a phosphate system” is more appropriate.

Wu Kai, the chief scientist of CATL, also said at the 2022 World Power Battery Conference last year:

“M3P battery can be tailored for mid-range models with a range of about 700 km. Previously, CATL used a medium-nickel and low-nickel ternary positive electrode material scheme for this range of models, which is relatively more expensive. Combined with the structure of Kirin battery pack, the new material of M3P battery can also meet the needs of such models.”

Although traditional lithium iron phosphate batteries have low prices, their energy density is close to the ceiling. By adding manganese elements based on lithium iron phosphate, the high-voltage platform and energy density of the battery will surpass lithium iron phosphate, and the cost is not much higher than that of traditional lithium iron phosphate, still lower than that of ternary lithium-ion batteries.

According to data released by China Automotive Power Battery Industry Innovation Alliance, the installed capacity of ternary batteries in February 2023 was 6.7 GWh, accounting for 30.6\% of the total installed capacity, and the installed capacity of lithium iron phosphate batteries was 15.2 GWh, accounting for 69.3\% of the total installed capacity. Lithium iron phosphate batteries have broad market prospects, and the proportion in February is close to 70\%.

```

**The M3P battery from CATL can be considered as an upgraded version of the lithium iron phosphate battery, and after entering mass production this year, it will undoubtedly launch a strong challenge to BYD's blade battery.**

## Conclusion

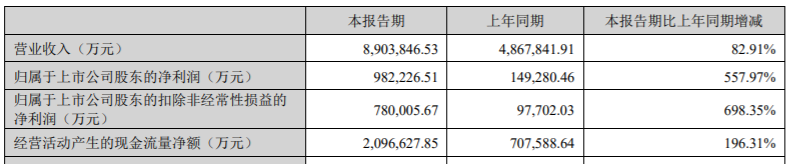

**In the first quarter of this year, CATL's net profit was 100 million yuan per day on average.**

On the evening of April 20th, CATL released its first quarter 2023 financial report. In this quarter, CATL achieved operating income of 89.04 billion yuan, a year-on-year increase of 82.91\% and a quarter-on-quarter decrease of 24.7\%. The net profit attributable to shareholders was 9.82 billion yuan, a year-on-year increase of 557.97\% and a quarter-on-quarter decrease of 25.2\%. The gross profit margin was 21.27\%, which was basically the same as the same period last year, and the net profit margin was 11.32\%, an increase of 7.26 percentage points year-on-year.

One counter-intuitive fact in this data is that the first quarter of each year is usually a low season due to the impact of the Spring Festival. In addition, in the first quarter of this year, domestic auto companies opened a price war to seize market share, further suppressing the demand for upstream batteries. In this context, CATL's profit growth rate in the first quarter still reached 558\%, which also set a record for CATL's quarterly growth rate.

**Matched with the increasing profits, CATL has also been increasing its research and development investment at a rapid pace.**

**In 2022, CATL's R&D expenditure reached 15.51 billion yuan, a year-on-year increase of 101.66\%, and R&D investment accounted for 4.72\% of the total revenue. From this financial report, CATL's first-quarter R&D expenses were 4.652 billion yuan, a year-on-year increase of 81.16\%.**

As of the end of 2022, CATL had 16,322 R&D personnel, including 264 with doctoral degrees and 2,852 with master's degrees. At the same time, the company owns 5,518 domestic patents and 1,065 foreign patents, with a total of 10,054 domestic and foreign patents that are currently applied for.

Believe it or not, after reading the above data, no one will doubt the strong R&D and technical implementation capabilities of CATL. From sodium-ion batteries, M3P batteries to Kirin batteries, while laying out the full range of products from the mid-to-low end to the high end, CATL has not forgotten its efforts in the R&D of new products. The solid-state battery is the best example this time.

Undoubtedly, the solid-state battery is a new “bomb” in the battery market. Similarly, the sentence “CATL is currently cooperating in the development of civilian electric aircraft projects, implementing aviation-level standards and testing, and meeting aviation-level safety and quality requirements” is worth exploring.

The Kirin battery has already enabled high-end new energy vehicles to achieve super-fast charging of 4C or even 5C and ultra-long range. The solid-state battery will further expand the space for the future development of new energy vehicles.

Alternatively, it may be that the prologue to the electrification of commercial flights is slowly being revealed by CATL.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.