Energy: Renewable Energy Revolution of Intelligent EVs

On March 3, 2023, we attended the Ideal Automobile 2023 Spring Media Communication Conference at the Ideal Automobile R&D headquarters.

During the conference, Ideal Automobile Chairman and CEO Li Xiang, Ideal Automobile President and Chief Engineer Ma Donghui, Ideal Automobile CFO Li Tie, and Ideal Automobile CTO Xie Yan shared the journey of building Ideal from 0 to 1, the thinking and judgment from 1 to 10, and the challenges and problems that Li Xiang faces as Ideal grows from billions to tens of billions in revenue.

The following is a summary of the important content of this communication conference, delivered by Li Xiang.

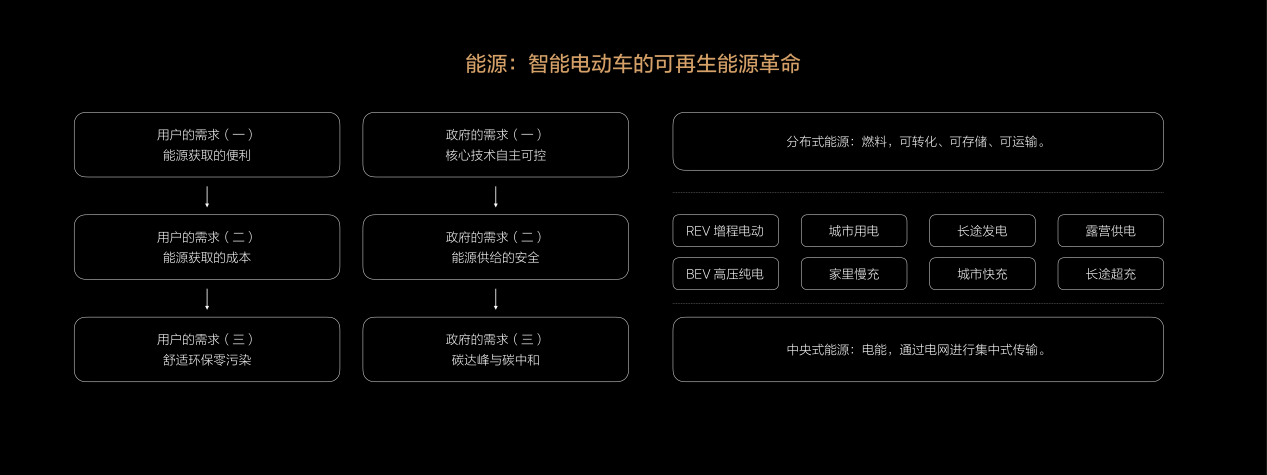

Energy: Renewable Energy Revolution of Intelligent EVs

Li Xiang believes that the primary influence on human development over the past several thousand years can be divided into two main aspects. The first aspect is energy.

From the use of firewood for ignition, to the use of fossil energy, to the use of electricity, and then to the vast application of renewable energy in recent decades, this is a process of human civilization advancement.

The other aspect is information technology, which contributes to the progress of human civilization. From the human ability to communicate using language, to the invention of measurement tools and the printing press, and to the development of computers and artificial intelligence, the information technology industry is developing rapidly.

Intelligent electric vehicles are a rare industry that bridges these two areas. They involve both energy and cutting-edge information technology, making it an important opportunity for Ideal.

From the perspective of users, the demand for energy can be divided into three levels.

The first level is the convenience of energy acquisition. Many electric vehicle users have given completely different evaluations based on whether or not they have access to charging stations. Those who have access to charging stations typically express their satisfaction with electric cars and find it difficult to go back to traditional gasoline vehicles. However, for many users who do not have access to charging stations or frequently travel long distances, they regret their decision to purchase an electric car. This is because their usage convenience is different. Users who have access to charging stations have a completely different way of thinking, which leads to this difference in opinions.

The second point is the cost of energy acquisition, which includes battery prices and usage costs. The cost of using an electric car is very low.Li Xiang believes that in the current economic environment, more and more consumers will choose electric cars because the money saved each year can be used to buy an additional iPhone or a new iPad, which is critical for slowing down the overall economic growth. This is the second user demand.

The third demand comes from users. The demand of users is for comfort, environmental protection, and zero pollution, which is different from what the government advocates, such as carbon neutrality and carbon emissions reduction. For example, when driving in daily traffic jams, the comfort of electric cars without gearboxes is universally recognized. What do users think about environmental protection? For example, in summer, if one drives a car to pick up their child from school and uses air conditioning, it will create a bad smell and pollution. However, using an electric car with air conditioning will be much better.

Li Xiang mentioned that some users buy multiple cars, but they are more willing to use their ideal car. The comfort and smell of air conditioning in gasoline cars and electric cars are completely different, so these demands of users are authentic. The better these demands are met, the higher the popularity of electric cars will be.

On the other hand, there are three demands from the government. The first is the independent and controllable core technology. As our country rapidly becomes stronger and becomes the second largest GDP in the world, we will face external constraints. Therefore, independent and controllable technology is crucial in competition between major countries.

The second point is the security of energy supply. Our oil and lithium carbonate production are different from our actual shipping and usage. We produce over 60% of the world’s fuel cells but less than 10% of our lithium carbonate storage. We use more than 20% of the world’s oil, but our reserves are probably less than 2-3%, so energy supply security is the issue behind it.

The third is the government’s demand. Just as Xi Jinping said, green mountains are better than gold and silver. This actually refers to carbon peaking and carbon neutrality. Therefore, China’s entire electric vehicle industry, the entire industry chain, including motors, electronic controls, third-generation semiconductors, batteries, new battery technology, and the entire industry chain such as photovoltaics, have reached a leading position in the world. This is based on the government’s core vision.If we look at an automaker, when Ideal made the decision to launch the Ideal ONE in 2016, there were two main challenges. The first challenge was the difficulty of charging. “Difficulty” is the standard for replacing fuel vehicles to carry out charging because consumers have no obligation to experience, travel radius and efficiency drop compared to fuel vehicles after buying an electric vehicle. Therefore, Ideal considered the charging challenge from the perspective of completely replacing fuel vehicles.

The second challenge is the high cost of batteries. As batteries are composed of core precious metals, they present a phenomenon where the better electric vehicles sell-such as the much stronger explosive growth seen from the second half of last year onwards, the more expensive they become.

Regarding battery cost, Li Xiang believes that almost every company has only achieved 4%-5% of the full-year target commonly set after two months. At this point, the price of lithium carbonate has obviously dropped from 550,000 yuan to 390,000 yuan per ton.

Li Xiang judges that the overall cost will certainly not drop to the original 4-5 yuan per ton, and a long-term stable price of 200,000 to 300,000 yuan per ton is expected. In this way, the cost of the battery will still not be able to decrease significantly, and even today’s battery cost is much higher than that in 2018.

Therefore, there are actually two solutions Ideal can offer. We first analyzed three paths we thought could solve this problem at the outset.

The first path was battery swapping, which Ideal’s founder also implemented as NIO’s CEO. Li Xiang believes that battery swapping is actually a very good solution because firstly, the experience of a battery swap can be infinitely close to a fuel refill. Second, many of the issues that users are concerned about can be resolved in this method. Additionally, battery swapping can even make the cost of buying an electric vehicle lower than that of a fuel vehicle. The whole experience would completely change, which is why I think that battery swapping is a part of it. Of course, battery swapping will also require more batteries to be prepared for the swapping station, including incurring the risk of large fluctuations in battery prices, which is why Ideal’s funding was limited at the time. As a result, we wondered whether it could be put directly into the product side rather than relying on the service side, so we developed a range-extended electric vehicle.

At that time, the most important choice Ideal made was to make a large battery (starting at 40 degrees). Today we sell all cars with a range of over 200 miles of NEDC, allowing you to use electricity in the city without looking for a charging station when traveling with your family.

About Charging Piles

The core of a charging pile is speed. The waiting time cost for users when charging is very high, leading to an average of only 2 to 3 charges per day. If the time can be shortened to within 20 minutes, users will not leave the car, and if it is shortened to 10 minutes for a fully usable range of a charge, the user experience will be basically consistent with that of a gasoline car.

Li Xiang believes that there are two key factors to achieving this. The first is to use a high-voltage platform, which is the only way to achieve the required charging speed. At the same time, the second benefit of a high-voltage platform is that when combined with silicon carbide and optimized aerodynamic drag, the battery cost can be significantly reduced, and efficiency can be significantly improved.

For example, a large SUV with a range of about 100 kWh and a distance of 600 kilometers can achieve the same range with only 80 kWh by using an 800-volt high-voltage platform with better aerodynamic drag and optimized efficiency, and the vehicle will be lighter, allowing for a reduction in the use of aluminum and a cost reduction of about RMB 30,000 to 40,000. This is related to our own silicon carbide model and three-in-one motor.

When these things are done well, compared to today’s traditional 400V mainstream EVs, in the same size and drive format, a car can reduce the cost of components by about RMB 30,000 to 40,000. You may soon see our 800V high-voltage platform EVs, as 4C still has some selectivity, which can achieve the same price as an extended-range EV. This may be different from what everyone imagines, as people generally believe 800V silicon carbide is a more expensive technology, but in fact, it can save a lot of costs.

Therefore, I think these are our two core routes. Whether we are doing extended-range EVs or high-voltage pure EVs, the first core purpose is to solve the problem of charging. When we use 4C batteries, we can charge 400 kilometers in 10 minutes. When we use 2C batteries, we can charge 400 kilometers in 20 minutes. This is the core of it.

On the other hand, after we reach this scale, we always believe that charging stations are a product, not a service, and a charging station is a product in itself. If we provide 4C, but don’t have a comprehensive 4C charging network, it’s like buying a 4G phone, but only having 2G network coverage. Therefore, we believe that it is a product itself, and everyone should not worry about the speed and determination of our charging station deployment, because it is not as expensive as everyone imagines.In 2030 and beyond, we will continue to pursue two paths forward, and strive to improve efficiency and performance. On the other hand, we aim to excel in the area of high-voltage pure electric vehicles, providing customers with two choices based on their preferences. Therefore, this is a consideration in the energy sector.

In the past, during the phase of going from 0 to 1, range extension technology helped us to gain a foothold and achieve substantial revenue. In recent months, the IDEAL brand has been among the top three new energy vehicle brands in China, behind only BYD and Tesla. This revenue scale and growth rate can support our full efforts to excel in pure electric vehicles. Our investment in the development, production of components, and supply chain for pure electric vehicles is deeper and greater than people may imagine. The above pertains to the energy sector.

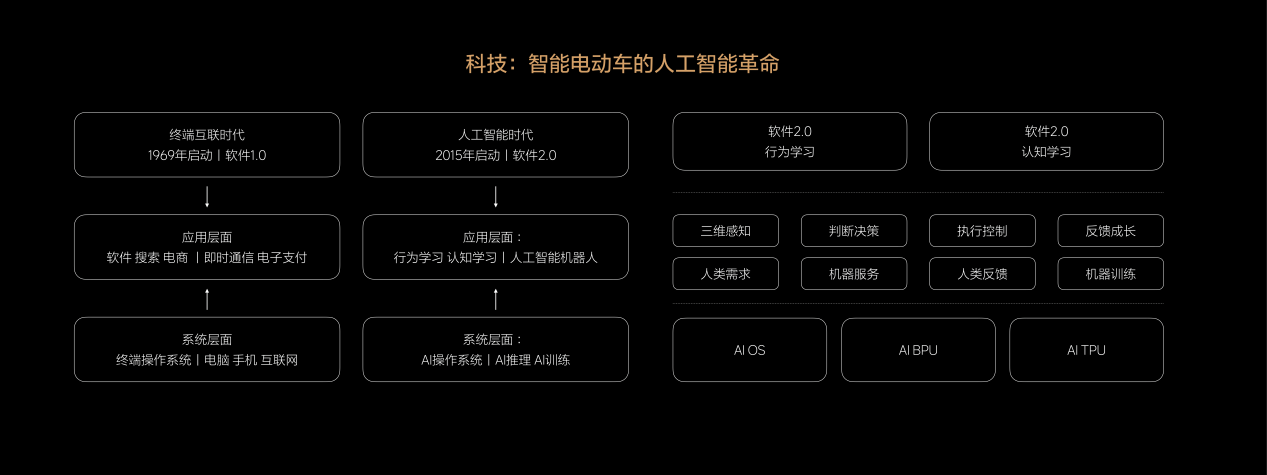

Technology: The AI Revolution of Smart Electric Cars

Another aspect is the entire realm of information technology, namely artificial intelligence. Many people don’t understand why we attach so much importance to it. Let me elaborate. At Ideal, we have four artificial intelligence algorithm teams, each solving problems in four different areas: 1. The multimodal algorithm team established last year for intelligent cabins, 2. Intelligent driving, 3. Intelligent factories, and 4. Intelligent retail.

Regarding the third “Intelligent Factory,” we use artificial intelligence algorithms to replace hundreds of inspection personnel performing every step of the production process on the production line every day. Our algorithm can also help us solve quality problems. From a quantitative perspective, the proportion of quality cost per car is approximately 50% less than Mercedes-Benz, BMW, and Audi with similar selling prices.

Therefore, if quality conditions are measured by money, our quality is significantly better than luxury car brands such as BBA. In addition, this algorithmic system can also help us decompose various accidents. If you ask a friend who owns an IDEAL ONE, they will give you an important feedback – our insurance is the cheapest among peers, even cheaper than a fuel-efficient car. The insurance for general electric vehicles is higher than that for fuel-efficient cars.

As a car costing over 300,000 RMB, the second year’s commercial insurance premium for the IDEAL ONE is only 3,300 RMB. With the mandatory traffic accident insurance and other costs, the total is only 4,300 RMB. This price is even comparable to that of many new energy vehicles priced around 100,000 RMB. This is all thanks to our entire algorithmic system.# Back to Why We Need Such a System

It’s actually related to my previous work experience in Autohome. In Autohome, almost all of our products were successful except for one: the car e-commerce platform. Not only did we fail, but other big players in auto e-commerce such as Yiche, Taobao, JD.com, and many start-ups in the same industry also failed miserably. This was not just happening in China, but also in the US over the past few years. For example, Carvana, a used car e-commerce platform with a valuation of 50–60 billion USD, lost millions and billions of dollars and now is only worth tens of billions. True Car, which we tried to learn from, also failed.

When we reflected on why we encountered such a problem, there was an important point to consider. 90% or even 95% of the entire business chain of auto e-commerce happened offline. We didn’t make any improvements in the entire offline experience chain such as warehousing, inventory, logistics, and delivery. The cost was even higher than traditional auto dealers, apart from the additional 5000 to 15,000 yuan CPS cost that we spent online. In other words, we didn’t create any value except spending some extra money within the measurement of money balance efficiency and business chain.

Similar problems also occurred in new retail, which was previously considered a hot industry, such as group buying and ride-hailing apps. Both Uber in the US and Didi in China have far lower market values than their initial valuations when they received funding. The core problem was that they were using “Software 1.0,” which couldn’t solve problems in the physical world.

So what is “Software 1.0” as we define it? It’s where humans establish the rules by themselves, write code by themselves, and then use it by themselves. Whether we use the Internet, apps, or other terminals, they all follow the same principle that runs in a digital world. However, we can’t change anything that happens in the physical world. We can use Uber to order a car very quickly in the US, but the total cost of ownership between point A and B hasn’t decreased. Instead, it is even higher than taking a taxi due to a higher vacancy rate. Therefore, the platform companies will face a dilemma: they will lose money when they need to gain high growth and market share, and the only way they can make money is to exploit drivers. For example, Uber takes 30% in the US and Didi takes 25% in China, while traditional taxi companies only took 20% before. So they are now charging more fees to drivers than traditional taxi companies did.Retail e-commerce, on the other hand, is different. With e-commerce, you can sell expensive department store merchandise from a warehouse, resulting in a 35% to 40% overall cost reduction. However, this cost reduction is split three ways within the industry. First, consumers take a portion, which makes goods more affordable. Second, platforms take a portion, creating trillion-dollar enterprises like Alibaba and Amazon. Third, these brands – those who use new retail methods to conduct e-commerce – take a portion.

Therefore, we were considering a question at the time: what can change the physical world? Is there any way to change the physical world? We found the answer to be AI! AI can change the physical world because its core is learning, not programming or logic – it depends on imitation and learning from humans.

We divided AI into two categories: the first category involves long-term analysis and observation to achieve a human-like state. In the physical world, there are two ways for humans to learn: one is behavior-based learning, with the cerebellum as the main focus and the brain as a secondary focus. We use the brain for thinking and self-training, but once training is successful, the cerebellum can perform tasks quickly, such as driving a car or performing inspections on a production line. In many cases, complete brain thinking is not necessary, resulting in the cerebellum taking the lead and the brain as a secondary focus.

The other category, which is currently popular, is based on Open AI, such as ChatGPT, as well as “Ideal Co-pilot” and “NOMI” in cars from NIO. Their working method is cognitive learning, with the brain as the main focus and the cerebellum as a secondary focus. When a complex command is given, it is processed in the cloud and executed with relative certainty after training. On the other hand, if it is placed in the car, it can produce results through GPU or BPU, which is two different ways of working. One advantage of Open AI is that it is difficult to train the brain, but you do not have to worry too much about it making mistakes. For example, ChatGPT may talk nonsense seriously, but you would not mind too much. However, if it is an AI in the first category, which is based on the cerebellum for the execution of actions, once it makes a mistake, it could lead to a traffic accident or an injury to a person, which would result in completely different consequences.

Let’s take driving as an example to understand how humans learn to drive and how they professionally work in the physical world. The first is three-dimensional perception: humans obtain and process information about the entire three-dimensional world through two eyes and two ears in conjunction with the brain. The imaging in the human eye is different from that of other animals because the results of each respective “sensor” and “processor” is different. This creates an interesting phenomenon that we joke about: the difference between living organisms is their ability to obtain and process information. Humans dominated the earth not because they had stronger reproductive abilities, but because they possessed the strongest information acquisition and processing abilities – making humans the earth’s overlords.And we look at cars with these eyes, trying to determine if what’s in front of us is a car or a rock, if it’s a moving car or a stationary one. First, we need the ability to perceive in three dimensions. Secondly, we need the car to make a judgment based on what it sees and its own state. For example, if it sees a car in front of it, it needs to hit the brakes and slow down. If it sees an accident ahead or a rock, it needs to judge how to avoid it. Thirdly, we need the cerebellum and nervous system to execute on this information. It needs to decide on the steering angle and speed, or how hard to hit the brakes. Fourthly, we need results and feedback, which equates to training. If everything went smoothly, and it was safe, then we gradually reinforce our intuition. But if, based on those first three steps, we end up rear-ending someone, it can take us years to recover from this mistake, because we adjust our behavior for next time. We may hit the brakes a little earlier or a little harder if we ever find ourselves in a similar situation.

In fact, when we learn to walk or play ball as children, it’s a similar learning process. Once we go through this problem-feedback-brain-training process, our cerebellum can handle it. For example, when we drive and become proficient, we may suddenly take a call and talk for half an hour or even a few hours. Whether we’re on the highway or stuck in traffic, our brain does not control the vehicle’s movement, but we still drive safely.

Returning to the subject of autonomous driving, it goes through two stages, the behavioral learning stage and the cognitive learning stage. In the first stage, due to the limited sensor and processing power, we used a Mobileye with only 2 TOPS of processing power and a forward-looking camera with only 2 million pixels. The original working principle was that it couldn’t do 3D perception. In this video, it actually just recognizes one 2D image at a time, so it can only do 2D perception, applying AI technology to recognize 2D images, without other capabilities.

In layman’s terms, in this image, you draw a box around something that looks like a car or draw a box around something that looks like a person. At the same time, we also use “2D ranging,” where the wider the image, the closer it is to us, and the narrower the image, the farther it is from us. However, the car will shake during the driving process, causing recognition errors. Our solution was to use a low-cost method, to add a millimeter-wave radar, which measures the distance between objects and people for each image. Basically, this is how the majority (up to 99%) of vehicles on Chinese roads operate, including Tesla’s AP and FSD in China which use this method, even though they have upgraded to the Orin computing platform. We jokingly call this a “2.5D working method.” This means, like a bat, we use radar to measure the distance between various obstacles and target objects as a prerequisite for the next step.Therefore, today, all mass-produced cars on the road have no connection to AI in terms of decision-making. They are all rule-based, even if they have algorithms, they are white-box algorithms, transparent rules written by humans. This means that, based on my speed, when I encounter a car trying to cut in my lane, how should I deal with it, and how should I react when I think it is leaving my lane, and how should I react when it gets closer to me or far away from me, etc. All of these things rely on a large number of people to debug and rely on human programming to achieve. So, the quality of experience today depends on who writes more rules rather than AI algorithms. This first stage requires more testing scenarios and more rules written by humans. The definitive conclusion is that problems can be solved within the rules, but cannot be solved outside them. If accidents occur, it is the responsibility of the consumer because I am only an assisted driver.

The third part is the same in terms of the entire execution control, and it is completely rule-based. Therefore, when encountering a traffic jam, if you follow the car in front of you very closely, you will feel a bit dizzy because its braking is faster and starts faster to prevent other cars from slipping in. Cars that are more comfortable to ride in have a more stable acceleration but are easily inserted by other cars in traffic jams. Major car companies are constantly adjusting to find a balance between the two.

The fourth part is feedback and growth. This area is divided into two major parts. First, because I have collected more videos, I hire a calibration team behind the scenes. For example, Tesla’s calibration team is located in India. In the past year, people have been saying that Tesla’s autopilot team has laid off people, but in fact, they are all calibration teams. Also, calibration teams for Chinese brands are all outsourced, and a large number of calibration teams are in Guizhou. Returning to the work of this stage, artificial calibration is carried out based on videos. For example, people recognize that this is a pole – when it is standing, it is still a pole when it falls down, and the same box is drawn for both upright and fallen poles. Then the car can “recognize” that it is a pole. A object with wheels and two wheels can be recognized as a car, and later it was discovered that a road roller has only one wheel, and after we completed the calibration, it could also be recognized, and it says it is a car, so it won’t go straight into it. If there is no calibration, it may think that there is no object in front of it, and the strategy will be to continue driving and lead to a direct collision. Therefore, at this stage, whether it is doing visual AI or speech AI in this industry, our internal joking phrase is – the more artificial it is, the more intelligent it is.The above is one part of the training. Another part is that we can adjust rules, whether they are decision rules or execution rules, to make them more comfortable and safer, allowing more people to adjust them in more scenarios.

So the current stage is essentially unrelated to “autonomous driving”. It is just assisted driving, and even L2’s “point-something” is still only L2. The essential change in this stage comes from Tesla’s FSD and its senior director of autonomous driving algorithm, AK, who was recruited by Musk from Open AI after he left Tesla, bringing about an essential change in Tesla’s intelligent driving. Prior to that, AK was studying 3D vision with Fei-Fei Li at Stanford.

At the same time, the efficiency of the FSD chip is actually very high, because the FSD is a dedicated BPU with only 144 TOPS. However, its effective computing power is basically the same as that of two Orins. Its effective computing power is about three times that of GPU, so two FSDs with 144 TOPS are basically equivalent to two Orin X with 508 TOPS. At the same time, Tesla has upgraded to 360-degree cameras, and it begins to do BEV 3D using “large models”, becoming a three-dimensional vision. The process of pixel occupancy and pixel movement of the entire three-dimensional vision, including the network behind it, is similar. The benefit of this is that the car begins to observe the world in a way similar to humans.

It still has some differences from humans, with its pixel count currently only at 2 million, while the car behind it can reach 8 million, and the human eye is basically 150 million to 200 million pixels. Its advantage is that you don’t need to look back, and you are always 360 degrees, so it is actually more effective than humans in the entire observation range, but its efficiency in looking forward is lower than that of humans because people can see about 400-500 meters away without any problems, while today’s cameras can only see about 100 meters, especially at night. This is the problem encountered at present. Of course, we believe that whether it is visual sensors or other sensors, and computing power will continue to develop rapidly, and these problems can be solved over time.After having such three-dimensional perception, the judgment and decision making process is different. In fact, the process can be divided into two layers: one layer is the white box, which is programmed to follow traffic rules and laws. The other layer is called “end-to-end” which integrates perception, decision making, and execution control. It can clearly see how humans observe, judge, and execute decisions when they see certain things. The entire process can be recorded.

I believe this is a fundamental change that we call “shadow learning”. It is a learning process that requires a closed-loop capability from your terminal, including today’s GPUs or specialized BPUs, to capture the entire process.

Afterward, the entire “feedback and growth” level is different. It will return structured data to the supercomputing platform for training, which is a black box process. Although there are algorithms, some of which are white boxes, and we consider them to be 1.0 or 1.5 stages, fully black-boxed algorithms, which we consider to be 2.0, are a fundamental change. Learning on the vehicle and deploying enough samples to the cloud for training will automate annotations, classification, and training. This eliminates the need for many people, and Tesla’s algorithm team is very small, as is OpenAI’s algorithm team. This is a huge contrast to most of the Chinese AI companies who require many people, because automation after “big models” is completely different.

Meanwhile, since it is a black box, the entire training observes not just right or wrong, but the extent of improvement in the quality of training. When the machine starts to learn, it is not only observing right or wrong, programming can observe that, but its core is to observe the change in quality. This is when training is conducted on the entire supercomputing side. After training, it will not be directly deployed on the vehicle, there is a simulation system which will deploy to another type of simulation to validate with a large number of human operation behaviors to see if the quality of my algorithm has improved. After significant improvement in the algorithm’s quality is validated, it will be deployed to the vehicle because it is only safe to do so.

At this point, the comparison of the intelligent driving capabilities of a car company is actually in three parts: the first part is how to reduce the cost of the vehicle computing platform and sensors, so as to make it possible to achieve a standard configuration for each car. Only having a camera cannot achieve training, so the entire vehicle-side capability is necessary.Actually, the cost of Tesla today is very low, which includes sensors (radar, camera) + computing platform for our intelligent driving. The cost for Tesla is $1,500 and $4,000 for our ideal. The second part is who has more “end-to-end” closed-loop data, it is useless to only get a part of the data; thirdly, the higher cost and greater challenge will be the training of the whole large model. Today, whether we use GPU on the car end or GPGPU in the cloud, it is not the most efficient way for the large model. It only has about 20% efficiency, which means that theoretically, the remaining 80% cost is wasted.

Therefore, companies like Tesla actually need to do their own BPU and training chip D1 to do large model training in a data flow manner. After the entire system is built, the cost of an entire computing cluster can be reduced to about 1/6 of NVIDIA A100, and its scalability becomes higher. I think this may be the part that companies that really want to do artificial intelligence have to face, solve, and invest in research and development. This is the progress we see in the development of artificial intelligence.

In fact, in addition to truly making good products, platforms, algorithms, and applications, we believe that the real competition in the future will appear in the bottom layer, the AI operating system. At that time, the entire system chain will be a real-time operating system, and the efficiency of such an operating system when running various new large model algorithms will become critical.

On the other hand, there is the BPU on the car end, which is a typical working mode where the small brain is the main and the big brain is auxiliary. Going back to the training end, there is the TPU, a dedicated cloud training chip, which will be the future super central brain. This is the fundamental of the entire AI development that we see.

Many people say that we are relatively cautious in artificial intelligence, but in fact, we have been deepening our perception in this regard for a long time. After confirming that this route is feasible, we will be All-in to do it. Our truly core investment in self-developed intelligent driving began after we roughly established a logical model for Tesla. When we were doing this, including why our L-series began, the car would do multimodal, we would have ToF and array microphones, the reason is that we started to open our own algorithm in the car and gradually gave up the algorithms we used before, used large models for training in our own car, because only large models can achieve what we want, real artificial intelligence 2.0.I believe that the true era of intelligent electric vehicles starts from the true 2.0 that can run. I predict that this time point, especially for mid-to-high-end cars, will appear in 2024. It will be a real NOA for the city based on large models and BEV technology. Now, Ideal Motors is doing relatively well, with a usage rate of more than 13% for the entire ADAS. Although the usage rate of our ADAS has exceeded 50% in high-speed scenarios, it is impossible to use in urban areas. I think a technology will only become indispensable when the user’s daily usage and mileage usage rate exceed 60% and are stable.

What about the results of urban NOA? Actually, it doesn’t need to become fully autonomous, it just needs to help the driver improve the driving experience when commuting in traffic every day. More than 60% or even 80% of cars in the city will be equipped with this feature, which is safe and can avoid most accidents except for some violations or minor scratches. At this point, a huge change will occur, just like consumers buying a 20-30 floor building, having an elevator or not is a fundamental difference.

I think this year, companies that use Orin computing platforms will basically deliver the first NOA for testing in the fourth quarter of this year, based on large models. It requires extensive training and cannot simply be put on the computing platform. Personally, I think that by the end of this year, most leading companies will be able to achieve Tesla’s level at the end of 2021. By 2024, everyone can achieve Tesla’s level in North America at the end of 2022 or early 2023. I think that if mid-to-high-end cars cannot provide urban NOA, it will affect consumers’ purchasing decisions. At this point, starting with mid-to-high-end cars, we will completely enter the era of intelligent electric vehicles based on software 2.0 and the era of smart and electric mobility. This is our prediction, otherwise we can only sell non-intelligent electric vehicles.

This is our simple little prediction. We will not provide city NOA based on the previous way of landmarking different cities one by one. When we provide urban NOA, it will provide this kind of NOA function that covers all cities based on large models.

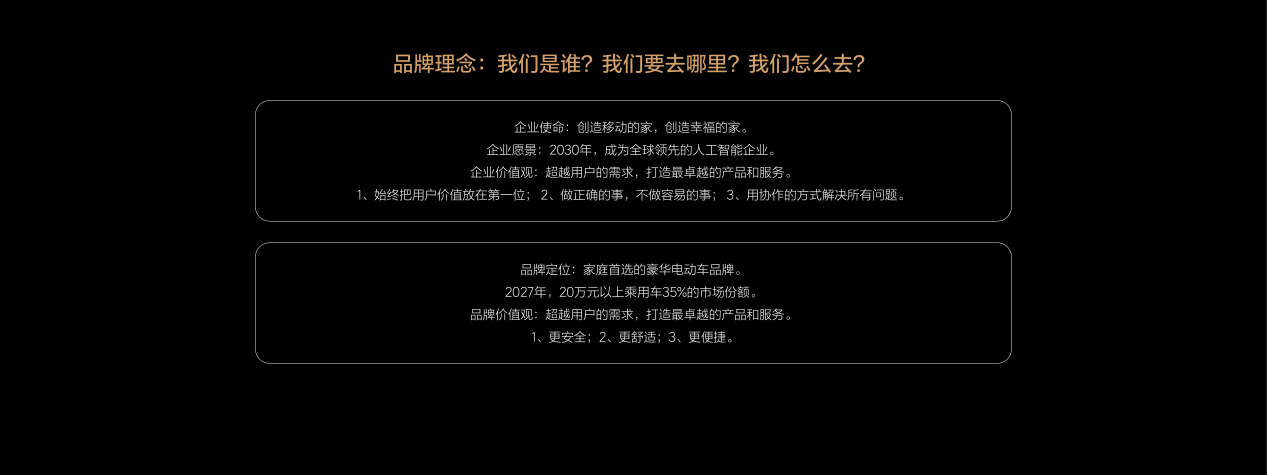

Brand Concept: Who Are We? Where Are We Going? How Do We Get There?

The first two questions answer why we founded this company. As a 0 to 1 enterprise, the most important thing is our brand, because our brand needs to answer questions both internally and externally. First, we need to answer internally because we haven’t yet taught consumers who we are, where we’re going, and how we’re getting there. On the other hand, we must also clearly answer consumers, who we are and what value we provide. This is, in my opinion, the most important thing for a brand.

Because when I was at Autohome, this was what we did after Qinzi joined our company in 2007. The last time I started a business, I didn’t know how to do these things. Qinzi provided us with a great deal of help and was an excellent teacher who taught us these things. Because he decided the efficiency of the company, whether or not everyone believes in what you’re doing, and whether everyone has a common goal.

What is the mission of Ideal Automobile at the enterprise level? Why did we start this company? Actually, it started from the moment of registration. Our company is called “Chehejia.” We hope to change the two most important spaces, the car and the home, through AI and renewable energy technologies. Therefore, our mission is to “create a mobile home and create a happy home.”

Second, what is the company’s vision? The company’s vision is what kind of enterprise we hope to grow into in the medium to long term. We formulated a plan 15 years later in 2015, and by 2030, we are committed to becoming a leading artificial intelligence company in the world, whether there are three or five head enterprises, we hope that we will definitely be one of them. Whether it is the product level, platform application level, or underlying system level, we must have the same ability as Tesla and Apple in order to establish ourselves.

Third, what is the company’s values system? The company’s values system is what we possess, belongs to ourselves, and can sustainably help us achieve success. Generally, a good values system is not about what we’re lacking, but about what we already have after going through a certain verification cycle. When Qinzi joined in 2007, Autohome had made their product library number one in the industry, forum number two, and information number three. But Qinzi asked, why could we achieve such results in such a short period? What is the reason behind it? We then talked to all the veteran colleagues from the beginning and wrote on the blackboard why we could achieve these things, each with a profound story behind it. At that time, we decided that the first principle was to put consumers’ interests first; the second was to do the right thing, not the easy thing. And third, aim for 60 points before going for 100.Actually, it’s the same when we started to make Ideal ONE. At the beginning, many people raised questions like, why do we make a family car, why do we make a six-seater, why do we introduce OKR and why do we use Toyota Production System (TBP)? The thinking behind these questions is all embedded in our company’s core values. We have summarized that the core value of Ideal Automotive is to surpass the needs of our customers and provide the most outstanding products and services. We emphasize that we must exceed the needs of our customers because the automotive industry has a long life cycle. Only satisfying a customer’s needs can easily become outdated and replaced.

What does it mean to surpass our customers’ needs? In 2016, if we had conducted surveys to ask if users needed an extended-range electric vehicle, they would have said our choice was meaningless. If we asked users if they needed four screens, they would have said they need more buttons. If we asked users if they needed a six-seater car, they would have said why not buy a five-seater or a seven-seater and save money.

I think this is what we need to see- users themselves may not know, but they may have this kind of demand. Until users drive a six-seater SUV and find that getting in and out of the car is so convenient and the elderly can adjust the automatic seat by themselves, or when the co-driver uses multiple screens for long-distance travel, they will find that the driving experience has become very good, and users who use the extended-range will find that it is actually as convenient as a gasoline-powered car, but the whole driving experience is that of an electric car. Slowly, more and more people will follow, including any enterprise selling three-row seat SUVs, which will primarily be six-seaters. This is what we need to do. Of course, there are also some of our behavioral guidelines behind this, always putting user value first and, it’s not just about meeting needs.

Second, we need to do the right things, not just the easy ones. Why do we need to think before making many decisions? Because the life cycle of the automotive industry is too long, we must conduct in-depth insights and thinking before taking action at Ideal Automotive. Doing the right thing is more important than just jumping right into action. Many wrong choices are caused by too much eagerness.

Third, we need to solve all problems through collaboration. Why do we use OKR and why do we use IPD? It’s because collaboration is everything. We not only need to collaborate well with ourselves but also with all our partners, including product, technology, manufacturing, and services. Only by doing so can we effectively achieve our goals. This is our core value.On the other hand, who are our target customers? What value do we provide? Our core positioning is to be the preferred luxury electric vehicle brand for families, which includes two key elements. One is luxury, targeting customers with a budget of over 200,000 yuan, just like the BBA brands. What does “family” mean? 79% of customers with a budget of over 200,000 yuan are families. In fact, just like Mercedes-Benz is committed to luxury, BMW is committed to driving, and Volvo is committed to safety, we also need a distinct image to do this. Of course, I believe that focusing on families is something we are good at because the average number of children in the founding team of Ideal Automotive is three. So we have a deep understanding of scenarios that require six seats and multi-passenger travel because we have experienced it ourselves. Since there was no product that could meet our own needs, we chose to create one ourselves, and all partners believe in it.

The entire brand concept needs to be clarified both internally and externally on a daily basis. This will enable all resources and efforts to be unified, and everyone will know how to make the right choices because making choices is crucial in this industry. You need to know what you want and what you don’t want. If a company’s direction is unclear and its choices are unclear, you will find that various people are creating what they want instead of what users need or what is more valuable to the company. This is our brand concept. With this, whether we are going from zero to one or from one to ten, we use this diagram to diagnose the improvement, challenges, and competition we face as a smart electric vehicle company in every aspect because smart electric cars are a huge product. When we deliver products costing more than 300,000 or 400,000 yuan to users, we must ensure their safety, residual value, and good experience. This may be different from many fast-selling products. As a gem in the industry, it has particularly professional properties.

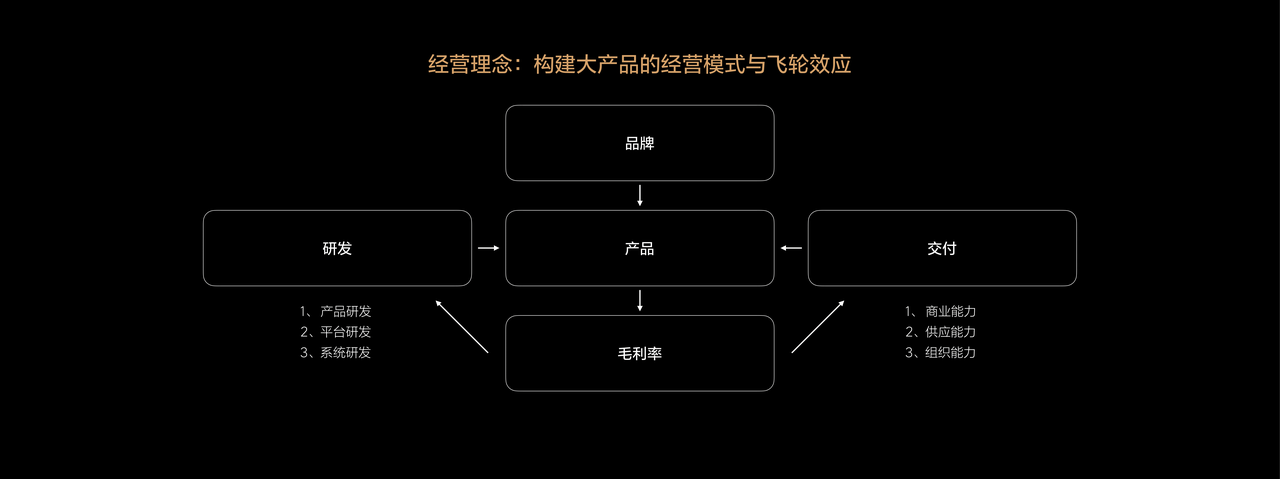

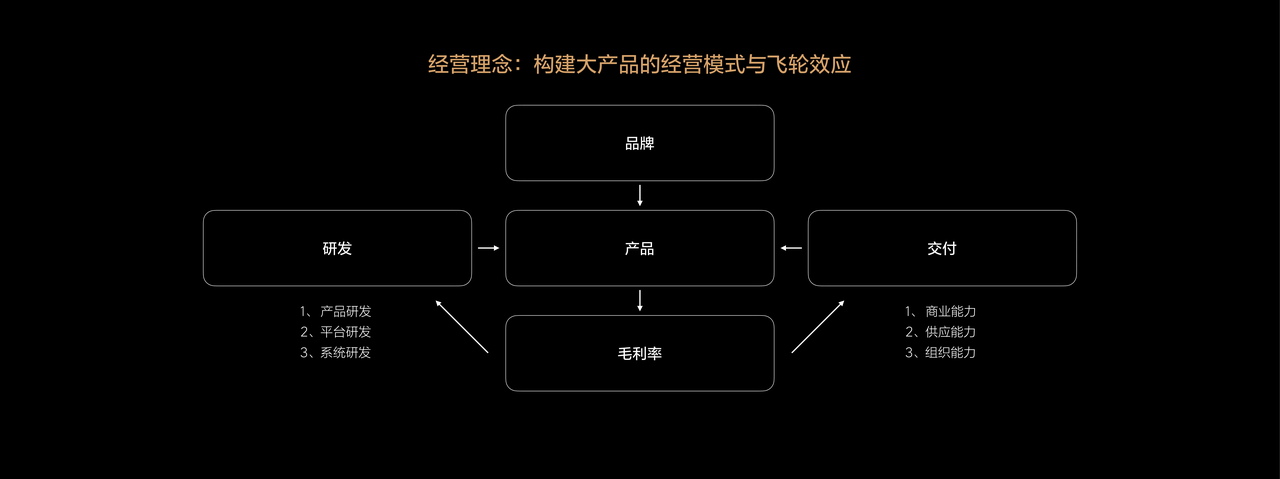

Business Concept: Building a Business Model and Flywheel Effect for Great Products

How do we observe and diagnose ourselves in this area? Sometimes we become too self-righteous, but we actually have serious problems. We have created a cross-shaped model, and the first aspect is the brand, as we all know that there are more than 300 new car makers, but only 1% of them have passed the brand test, let alone 5% or 10%. Most of the 300 new car makers do not even have basic knowledge. If they advertise being a family car today, they will advertise having a three-second acceleration the next day. All the logic is chaotic, which will affect all the products and the entire operation. Basically, all brands are ruined because of the brand aspect. You can see that basically the internal management of problematic companies is in a mess because everyone in every team has his or her own agenda. But we have achieved something that even the employees of the Starbucks in our plant know what our company is trying to do.The second point is about products. With a brand, there must be products. The brand is the brain, while the products are the body. As far as cars are concerned, they can be divided into three levels, which are common sense and not mysterious. However, many people do not respect common sense. The first level must be safety. Safety is the bottom line. As far as possible, we will do as much as we can to ensure safety. I can confidently tell others that L7, L8, and L9 are the safest cars in the world, exceeding all collision safety requirements.

Why? Because my family and all my friends ride in this car. How could I allow this car to be unsafe? Moreover, family users care about safety, not just individual safety but the safety of the entire family. The whole structural design involves many secrets behind the industry. For example, using high-strength and heat-formed steel on the A-pillar could cost only a few hundred dollars more. However, many companies insist on saving that few hundred dollars.

When the media dismantled our cars, they saw two anti-collision beams under the A-pillar and two anti-collision beams under the wheel eyebrow, as well as anti-collision beams at the rear. All these anti-collision beams use the best aluminum structure, which costs less than one thousand yuan. However, some companies put foam plastic on them because of fierce cost competition in the past. In addition, if you look at all our cars, the front seat belts are all pretensioned, explosion-proof type, which can firmly hold you under any circumstances. All our cars are fully equipped with safety airbags, including head and side airbags in the second row. The whole thing costs an extra 2,000 yuan, but most companies are not willing to spend this money. Safety is a huge issue once it fails. Safety is the bottom line. It will never be limited by any budget. We will just do it directly. We will not just satisfy the requirements of the collision test on the left side and ignore the right side. The left and right sides are the same because my wife sits on the right side, and she is just as important.

The second is product value, including space, comfort, and configuration, which are divided into two parts, hardware, and software. The core of the software part is that when we can independently research and develop the central domain controller, intelligent driving controller, and the entire software behind them, software is not a problem. Users’ needs can be met. We even let users act as product managers. We provide a task master. Apple’s shortcuts can only call APP software functions, but our task master can call hardware and software together. Is it self-developed? It depends on how many functions are available in the task master. Some functions are not opened by suppliers, only by independent research and development, so that all functions can be called and combined together.The most difficult part is the hardware, which is like 52 playing cards for a car. Adding one function means removing another. It’s not as simple as just increasing the cost. For example, many people ask why the L7 doesn’t have linked seats like the Mercedes S-Class and BMW 7 series. When I adjust the backrest, the seat cushion automatically extends forward because it has a different framework. To ensure safety while using linked seats, whether it’s the BMW 7 series, Audi A8, or Mercedes S-Class, the second-row seats cannot be folded down. It becomes very difficult for families who want to transport some things, so a choice must be made – do you serve the boss or the family user? This choice is easier to make.

If you want a car to accelerate in just over three seconds, you may have to sacrifice some other parts, such as energy consumption at low speeds or the size of the motor. It’s important to make these decisions based on your brand and your users, not just to create a sense of existence for your R&D team. You must make these choices for the value of your users and establish a complete verification system. At Ideal Auto, it’s impossible for just one person to make any changes to a product. It’s a rigorous process that involves PEA and demand analysis. Our demand analysis includes how long it will take to develop this product, how all competitors are doing it, what actual value it will create after launch, and how that value is calculated. Both software and hardware require complete PEA analysis. Many employees from traditional car manufacturers realize that their products cannot surpass ours because we do more thorough work – from demand analysis to verification of components to the system of record for parts, then to the verification of the entire vehicle. Our entire system is comprehensive, and no one can skip any steps. Without complete analysis, the project will not be approved, and R&D will not be conducted. During the process, the R&D team, including the supply chain, gets involved beforehand to ensure we get all the key details before moving forward. Knowing how to make these choices and establishing a complete verification system is crucial to creating a good product.### Three Levels of Product

Third, it’s about the special sense of brand aspiration. We want to make a mobile home, so we can’t just skim the surface in this aspect. We believe that if it’s like a home, it should have the largest and most comfortable space, and if we want to make it smart, we need to have more screens, because why can’t everyone have a screen in this space at home? On the other hand, if we want to make intelligent driving, we must use LiDAR and double Orin. We make NOA the standard for every car. This is the core. We must not just skim the surface, we must have excess investment and configuration. Otherwise, users won’t feel it, and you may think you’re good, but others won’t.

These are the three levels of the entire product: Safety level, product value level, and product aspiration level. Please believe me, consumers can fully feel these things, it’s not fake at all. It’s just that you can’t look at non-user groups, and your true consumers can understand and agree with this thing very well. This is how we deliver a good enough product to users.

The product is our body, and the third is gross margin. Why is gross margin so important? It’s still related to the automotive industry, because if you want to become a car company that stays on the table, basically you need tens of billions of dollars in revenue. If you want to become a world-class leading company, you need hundreds of billions in revenue.

How can you manage such a large revenue scale? This becomes very critical, you can’t rely on financing forever. When you’re small, you can rely on tens of billions or hundreds of billions of revenue from financing, but how can you rely on financing when you’re bigger?

And we can see from the development history of the automotive industry over the years, when cars are the hardest to sell, such as during an economic crisis, when cars are the hardest to sell and financing is absolutely unavailable, even large companies like GM and Chrysler bankrupted during the 2008 economic crisis, with car sales dropping by about 40%. Apart from revenue, what has been used too much is leverage, including later when companies like Delphi were split out and had to bear all the leverage themselves, so almost all the 40% decline in sales was borne by themselves.

What is gross margin? Gross margin is the sales price minus the cost of sales. The cost of sales includes the BOM cost of the car, the manufacturing cost of the car, the allocation of the car, the transportation cost of the car, the software cost of the car, and the taxes and fees are all the cost of sales of the car. The expenditure of personnel in the store is called selling expenses, which is beyond the gross margin. The part we leave for gross margin is to deal with selling expenses, so gross margin equals sales revenue minus cost of sales. Therefore, after subtracting the cost of sales from the sales revenue, what remains is the money that the company can invest, which is the part that enhances its own ability.From the perspective of the automobile industry, as an intelligent electric vehicle company, we believe that a healthy threshold is 20 points. Our R&D investment is basically above 10 points, and our sales and management expenses are also very good at 7 to 8 points, while still bearing a certain degree of risk and capital investment, such as building factories. We believe that 20 points are relatively healthy, and currently Tesla is over 20 points. BYD is also stable above 20 points.

BYD’s sales network is not direct, but if the dealer cost is calculated together, the gross profit margin of BYD cars is also over 20 points. We believe this is relatively healthy, otherwise how can we invest in R&D? We can’t just invest in R&D when the capital market is good and shrink R&D when the capital market is bad. This is not how the automotive industry works. Any plan in the automotive industry should be a period of five years or more. Therefore, gross profit margin is a key point here.

Of course, the higher the gross profit margin, the greater the difficulty for companies to operate, and the lower the gross profit margin, the easier it is, and negative gross profit margin is equivalent to giving away money, which is the easiest. What we see is that 20 points is the minimum gross profit margin for a company to achieve long-term healthy development. You can see that Tesla has been losing money for so many years, but from the Model S, Model X, and even from the Roadster, the gross profit margin has been stable at above 20%. I can spend a lot of money, but always insisting on a gross profit margin of over 20%. Tesla only dropped to 18 point something percent for one year, which should be in 2018, the year when Model 3 was plagued by production problems. Although Tesla has reduced prices on a large scale this year, at the annual report meeting, he said that he still maintains a gross profit margin of over 20 points this year, because only in this way can the company develop healthily. When a company makes any long-term investment, it can be fearless and firm in its investment.

After gross profit margin, how to spend money? This is two parts. Gross profit margin is our ability to generate blood, and the first important thing is to invest in R&D, and according to different stages, reference to intelligent mobile phones, and reference to Tesla are the same.

The third is the development of the system. How to continue to reduce the cost of our platform. To delve deeper, it includes whether we are using other people’s or makeshift systems, or developing our own operating system, as well as the reasoning chip behind it. If we develop our own reasoning chip, we can achieve the same cost as Tesla, because the algorithm is in our own hands, including the entire training platform and training chips made by ourselves.After the research and development, what’s really important is our delivery capability. The whole chain of the automotive industry is too long, not only complicated but also having a long cycle. The cost of trial and error is extremely high, to an unbelievable degree. It is normal that the valuation of a company can drop by 80% if a product goes wrong. Everyone is playing the game under the same rules. Our goal is not just to develop the product, but to deliver it. There are many areas where we need to improve our capabilities to achieve this. Firstly, we need to improve our business capabilities, which include all services and sales related activities. Many people ask if marketing is important. Of course, marketing is important, because if you spend billions of dollars over three years with thousands of people working day and night to develop a product, marketing decides whether you will deliver 100% or just 30% of its value to the consumers. This money is not just for marketing, but for the entire development process. Unfortunately, many companies choose to sell the product with a 20%-30% discount without explaining the basic information clearly, which I think is a very serious problem that affects the entire user service process. For example, when we sell a product, we use a centralized management approach. Now that we are selling multiple products, we have introduced “provincial governors” to allocate critical resources. Our challenge is how to manage our salesforce effectively. Compared to traditional car manufacturers, we are not just covering large regions, but also provincial level. This way, we can avoid “big pot meals” and build a proper incentive model.

All of this requires us to constantly upgrade our capabilities and systems. In February, all of our store staff had an average sales capacity of almost 7 cars per person. If we exclude management, the average capacity is over 10 cars, which is about three times higher than the industry average. This way, our employees have the opportunity to do three people’s work and earn the pay of two. So now our employees are the hardest to recruit. The development also includes the supply capability. The reason why we can scale up quickly is that the most critical part of scaling up is the “three-electrics”: motor, battery, and electronic controls. We divide all the components into four parts. The first part is the traditional parts such as the rearview mirrors and bumpers. The automotive industry already has a production capacity for more than 20 million passenger cars a year, and there is no difference between electric and gasoline cars. Therefore, we do not need to produce these traditional parts ourselves, but can rely on suppliers.The second category is the new electronic and chip types, such as our domain controller. In the past, China had a very good OEM system, and China purchases about 40% of the world’s chips. The manufacturing efficiency of this system is very high. It is no problem for us to produce 200,000 or 300,000 sets of domain controllers, and enterprises like Foxconn can also do it. It is not complicated to solve.

Everyone is talking about the shortage of chips, but there has never been a shortage of Qualcomm chips and Qualcomm computing platforms, NVIDIA chips and NVIDIA computing platforms, or Horizon chips and Horizon computing platforms. The shortage is all about traditional small functional chips, which China is still very proficient at. China is the world’s strongest electronic OEM factory.

The third category of problems is related to the three electricity. For example, we develop the L series, and a car requires three motors, two drive motors and one generator. If we sell 300,000 cars in one year and place an order for 900,000 motors with any motor factory, they will not be able to accept it, because 900,000 motors mean that they have to build 10 factories. If we don’t need them after they have produced, they would have to bear all these things.

There is a very interesting phenomenon. When these suppliers are facing new forces, the amount we report to them and the amount they calculate are different. They have a set of analytical systems to analyze how much we can actually sell before they are willing to produce so much. When the car company used to sell only 10,000 units, but told the supplier that we needed to produce 30,000 units later, they would not believe it. At the end of last year, all suppliers believed that we could produce about 150,000 vehicles this year. It was not until we proved this volume that they adjusted it to 250,000 vehicles for us.

In addition, for the three electric parts, including range extenders, we produce them ourselves. Otherwise, our suppliers cannot keep up. Therefore, we have built our own range extender factory in Mianyang, and our L series’ front five-in-one motor is produced next to Changzhou. We will produce silicon carbide modules for ourselves at 800 volts, and we can also make our own silicon carbide motors. This is our supply capability. In addition to the factory in Changzhou, we will also build a factory in Beijing to produce pure electric vehicle products. Supply capacity requires 24 months of foresight, otherwise, there is no time. Including land acquisition, building factories, recruiting people, trial production, it takes about 24 months to be on time.

Cooperating with suppliers is also the same. If we find a European manufacturer who only produces 30,000 to 40,000 sets of air suspension for us in a year, we will chat with them for a year and may supply up to 60,000 sets at most. But we need hundreds of thousands of sets a year, at this time, we will discuss with Chinese suppliers together how to build production lines and factories to ensure that the second- and third-level parts are in place. The supply chain needs to be in place, we did not do it well last year, but some aspects of our advance layout still brought us great help.However, there is another issue in the supply chain, which is that the self-sufficiency rate should not be too high. All companies worldwide have experienced this, for example, like Toyota splitting off Aisin and Toyota Textile for shared use with others, or like General Motors splitting off Delphi. We know that many parts suppliers are split off. Because if you do everything yourself, it means that when sales decline by 40%, you have to bear all the leverage and costs in the 40%. At this time, it is particularly afraid to encounter major economic problems such as an economic crisis. Therefore, we believe that a self-sufficiency rate of 30% is relatively healthy, and we can work with suppliers. Even after our own R&D, we can let the supplier produce instead of producing it ourselves. This is part of the supply capacity.

The third biggest challenge is organizational capability. Because the car is too complicated, especially the intelligent electric car. We are an automobile company, but we are also an Internet company. We are a software company, an artificial intelligence company, a business retail company, and a manufacturing company. Therefore, the work scope of all the new forces of car making is broader than that of traditional auto manufacturers. For example, most new forces of car making have done their own direct sales system and also done the dealers’ work. Therefore, organization becomes the biggest challenge. It is also because after Qin IMa joined us in 2007, he brought very good organization to the automotive home, so we paid more attention to organization from the beginning. Organization will determine our efficiency and whether it can bring effective positive feedback.

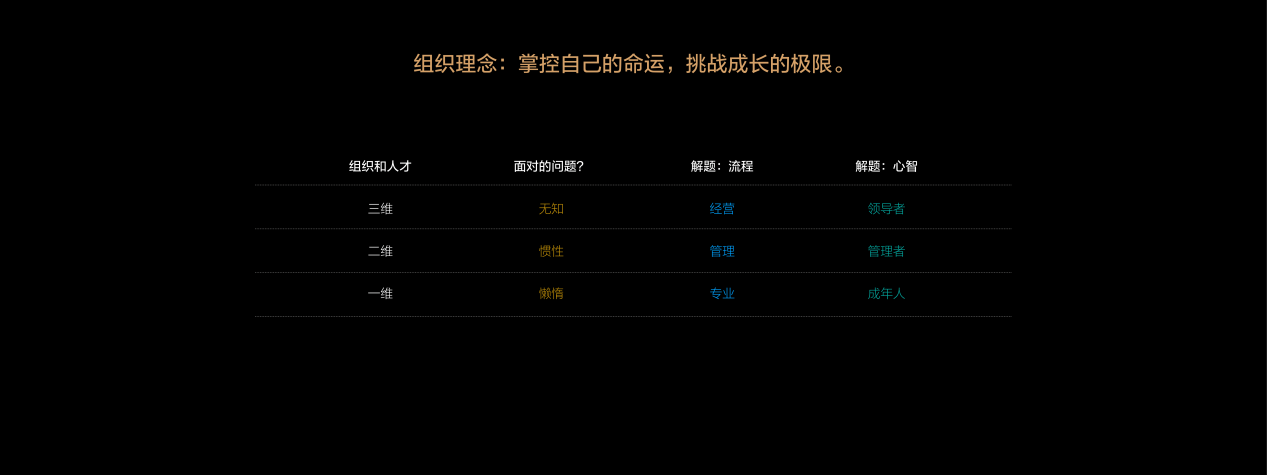

Organizational Philosophy: Take Control of Our Own Destiny, Challenge the Limits of Growth

We believe that organizations will encounter three different types of problems. The bottom-level problem is laziness, which is a personal problem. The problem seen from the management level is inertia: What I did when I made a gasoline car is what I’m doing now. For example, what kind of problem did we encounter at the time? Because the people we recruited at the beginning were all doing cars for 100,000 RMB, when we did cars for 300,000 RMB, we still did it the same way. How did we deal with it at that time? We bought a bunch of very good cars and let everyone drive them every day. Do not measure the car with a ruler and leave, like in the original factory. Every day you must drive the car for more than 3 months before discussing how to adjust the suspension.Don’t turn a full-sized or mid-sized SUV into a compact SUV’s driving experience for a 300,000 or 400,000 car. That’s not right. Try and test how the BMW X7 and the Mercedes-Benz GLS are calibrated. We need to break their inertia. Furthermore, if we want to solve the problem at the management level, the biggest challenge comes from ignorance, not knowing what we don’t know. This complexity becomes even higher.

So, how do we solve this problem? We talk about what professionalism is. We face the entire business on three levels. What is professionalism? I only need to manage myself to do things well. What is management? It means I can not only do things well, but also lead a team well, whether it is a project or a department. At this point, we see two things: how to do things well and how to use people well. It gets even harder at the level of management. To do things well, we need two resources: how to use people well and how to use money well. Because at the management level, we see expenses every day, so we fight for lower expenses. However, things are different at the level of management. We see resources, how to effectively utilize resources, and how to optimize our own resources by creating more revenue.

Therefore, I think the business management from 0 to 0.1 verification, from 0 to 1, and from 1 to 10 is constantly improving, and the problems faced are also different. What are our challenges? How do we turn laziness into initiative, inertia into necessity, and ignorance into cognition?

There are two ways—what the world’s best businesses do. The first way is the process. What is a process? It is the product that a company needs to run internally. In fact, all the processes in the world are designed to solve these three types of problems. When we solve specific businesses, we have a professional process, such as PEA, user needs analysis. If we use this tool well, we will become very professional.

Good processes don’t tell us how to do it. Instead, they tell us not to skip these things. When we need to analyze user requirements, we need to look outside and find out what the current function looks like and analyze the data. We then need to plan what the product should look like, what functions should it have, how long R&D will take, and how much it will cost.## To plan for operations, the key is to prevent the product from becoming a zombie after launch. It is important to consider the value it can generate, its activity level, usage rate, and review process. This is what builds up one’s own capabilities, the product’s capabilities and the team’s capabilities. The core of this planning is to not overlook these important aspects and focus solely on the easier tasks. Experience is helpful, but we need to use this planning so that we can be more professional. The foundation of this planning provides a continuous cycle where the product gets better, customers become more satisfied, and a strong market position can be achieved.

The most common problem for companies is offering lower-dimensional processes and tools. Only providing professional tools for employees to manage results or management tools to run a business is irresponsible. The necessary capabilities and dimensions have not been provided, hence the need for organizational upgrading. It is important to review the market to see what kind of organizational structure and staff other companies use to carry out similar business plans. What kind of compensation do these employees have? Next, according to the company’s business process to design suitable jobs that can meet the business plan, and HR’s work becomes much clearer. When candidates appear, it is easier to understand what their previous companies were like, what their compensation should be, and what kind of standards they should meet. This is important because it helps each manager improve their human resource management capabilities.

At the top level, the management level, we can learn from many large enterprises, for example, the first-level process of IPD, DSTE, IPD is integrated product development management, IPMS is integrated sales management, ISC is integrated supply chain management. These processes affect the business results, so how can we effectively allocate money and human resources and measure them? The goal of measurement is twofold. Firstly, to ensure that resources are really in place during implementation and not just temporarily requested. The second is effective retrospective analysis. This means comparing initial planning, resource allocation, goals and actual achievements, identifying and reinforcing good performance, and correcting deficiencies to meet the planned goals. These capabilities must be addressed before moving forward.Therefore, we find that behind all the most advanced processes in the world, there are identical pre-processed solutions that help us solve problems at every level – laziness, inertia, and ignorance – through the use of processes, tools, IT systems, and various methodologies. Whether it’s the tactical level we just talked about, the product requirements analysis we used for our own products, the Toyota work method we used, or the talent structure planning (LTP) we used at the next level, the talent structure planning, and the top-level processes like IPD and IPMS are all the same – they are just used to solve problems in different levels and different professional areas.

So, I told the team that the difference between one organization and another is like the difference between one organism and another, which lies in the differences in their ability to obtain and process information. I think the biggest difference between organizations is their ability to use tools. When using three-dimensional tools, it is easy to crush enterprises that only use two-dimensional tools – this is the core behind what we see.

Therefore, when we clarify this matter, everyone knows that process and organizational changes are not easy, but only when you sort out these things clearly can you discover the necessity behind them, and only when you do this can you solve my problem, only this way can we improve the efficiency of the supply chain, motivate the sales team, and turn every store manager into a business operator rather than a professional.

For example, when we started from zero to the first phase, we focused most on management.

Therefore, when we look at companies with tens or hundreds of billions of dollars in revenue, we look at them from a two-dimensional world to a three-dimensional world – what do we see? We see that they are both complex and rigid. But when we upgrade our abilities to the three-dimensional world, we discover that they are actually simple and rich, unlike what we see in the two-dimensional world.

Finally, one more thing to note: the processes mentioned above are like the products of the company, which need to be constantly upgraded and OTA’d as the scale grows to solve different problems, including human resources. The most important problem to solve for people is their mentality. Ideal Cars actually started with Autohome, where Qin Zhi introduced us to seven habits of highly effective people, which some of our colleagues were learning at the time. When we got to Ideal Cars, we further deepened this.

The second aspect is how we become qualified managers. Understanding others is our obligation, whether you lead a project or a team. As a manager, you cannot say that employees are not like me. It is precisely because they are different that they have value. If they were the same, the manager would do it himself. Therefore, understanding the team, every person in the team, and every person we cooperate with is our obligation, so that we can help everyone make the best use of his strengths and avoid weaknesses, and accomplish our common goals. Only then can you become a qualified manager.## Translation

At a higher level, when we come to solve business problems, the complexity becomes higher. I have talked about everything I am sharing with you today at every internal training because the world is too complicated, and it’s critical that everyone knows why, and we can all be on the same page.

The third aspect is about how to become a leader, how to make more people understand you, and how you can help everyone achieve victory. I think this is the requirement for a leader, so the most difficult thing is to make others understand you. Don’t complain that others don’t understand you. This is a serious problem.

When we have professional process tools as adults, we can definitely solve laziness when we have the corresponding ability. When we become a qualified manager, understand others and handle other people’s relationships well, we can do good management, solve the problem of inertia, and see the necessity. When we become a leader, make more people support and understand us, and create success together, we can become qualified managers, use management tools to solve various ignorant problems, continuously improve the team’s cognition, become the team’s ability and the team’s harvest. Therefore, this is the core concept of our organization.

Finally, let’s end today’s sharing by using this graph. We can not only diagnose ourselves with such a cross, but we can also see the advantages and mistakes of competitors to avoid them. We can learn from its advantages, including brand level, product level, gross profit level, R&D, and we can also see the gaps in our product R&D, platform R&D, system R&D compared to others. It also includes our entire delivery capability, our business capability compared to these advanced enterprises, our supply chain capability, and where our gaps are compared to Tesla and BYD.

As well as our organizational capability, there are gaps with these leading companies with revenues of tens of billions or even trillions. We just need to learn from them. Because the entire structure, in my three previous startups, I went through five stages, and now that we want to challenge the revenue of tens of billions, we have gone through five stages.

In the first stage, we always felt that we were different and never looked outside. We hid in a well.The second stage is when we cannot understand the complex processes and pre-research analysis from an external perspective. Therefore, the second stage is called looking outward but cannot understand and comprehend.

In the third stage, many companies would hire senior consultants or firms to help us understand the problem. So, we slowly begin to understand in the third stage.

In the fourth stage, the company immediately goes into action after understanding, but this causes problems. Why? Because it’s not something that can be done by just hiring a few employees. You may hire a few people from a good company to start the work, but later on, it turns out that they cannot complete it. This is because the most advanced processes are usually either performed by multinational companies or a group of people who are skilled in different stages. People who can plan, construct, and operate the road are different from those who only drive on it. Often, we find a group of drivers to repair the road for us or start repairing the road without any plan. Therefore, in the fourth stage, we will encounter many pitfalls.

In the fifth stage, we clearly know which consulting firms or even which teams of the company were involved in planning, constructing and operating the road when the company was on this road in the past. We will hire them and slowly learn how to plan, construct, and operate the road ourselves. At this time, the team will drive on the road from above, and the efficiency of value transportation will be improved.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.