Author: Zhu Yulong

At CES2023, BMW’s new platform, Neue Klasse, also held a technical workshop with the title “GEN6 BATTERY CELL TECHNOLOGY&PURCHASING AND SUPPLIER NETWORK”. As BMW’s most important milestone, Neue Klasse is a future electric vehicle-exclusive platform that’s characterized by the use of cylindrical batteries, the sixth generation dynamic lithium battery, which significantly increases BMW’s battery density by 20%, increases its range by 30%, and improves charging speed by 30%. Here, we first discuss why BMW doesn’t invest in battery factories.

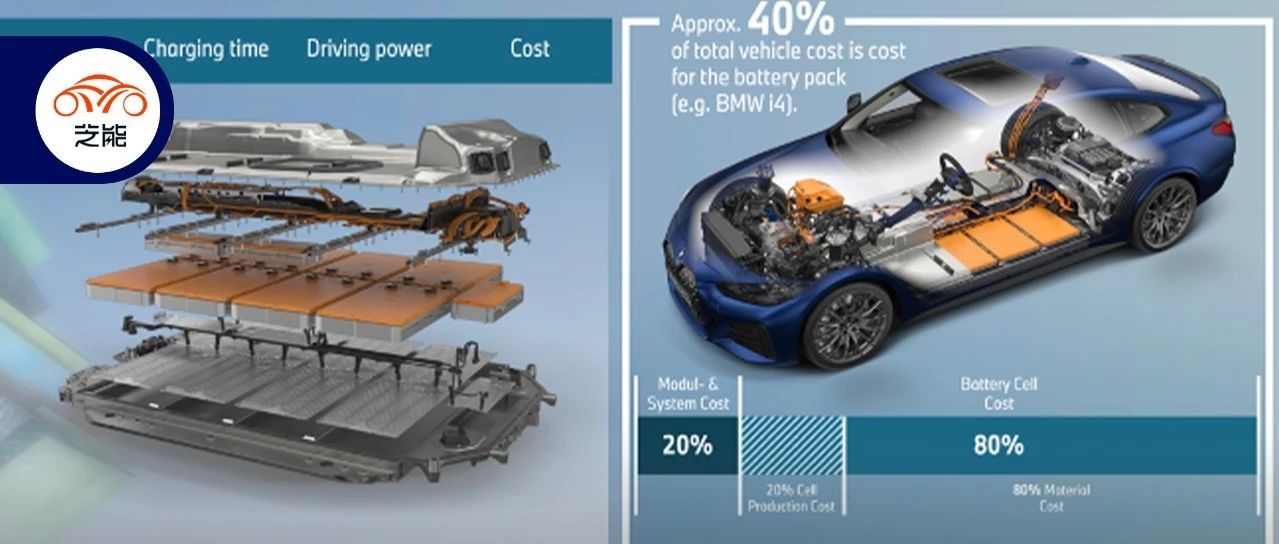

For BMW, researching and developing batteries is important, but with overcapacity, in the future, the manufacturing cost of batteries will only account for 20% of the total battery cost. This is a fact that BMW is certain of. For luxury car companies like BMW that have a production capacity of 2 million units, during the evolution process, as long as their products are strong enough, they can pull global battery companies to produce batteries for them, and they don’t need to build their own battery factories. This is the fundamental difference between BMW and VW, two German automakers.

For BMW, from battery selection, battery core research, the establishment of a battery core technology center, to battery core testing and solid-state battery pilot testing lines, BMW is very serious about mastering battery technology knowledge. Only by understanding core knowledge can you make the best choice and let suppliers invest in production lines for you.

BMW’s Development

I have always been unclear as to why BMW has determined that large cylindrical batteries are a strategic direction. For a company like BMW, making a huge turn is not easy, especially after mastering the entire set of technologies from battery core characteristics to battery core manufacturing on a small scale.“`

At this point in time, BMW confirms that from the fifth-generation prismatic battery to the sixth-generation cylindrical battery:

◎ Positive electrode material: an increase in capacity of over 10%, and a reduction of over 50% in cobalt usage.

◎ Negative electrode material: an increase in capacity of over 15%.

◎ Copper foil: a reduction of 40% in copper usage.

Battery cell casing: a steel casing is used to reduce CO2 emissions by 3g per Wh.

Looking at the current situation, all attempts are based on calculations and trials, aiming to achieve capacity increase, faster speed, cost reduction, and carbon emission reduction. Under the guidance of Tesla and BMW, the path of large cylindrical batteries seems to have become a promising and bright road.

In the design process, BMW has also caught up with Tesla in terms of research and optimization, focusing on large cylindrical pack design. There are not many patent barriers in this field, so battery companies researching CTC technology do not necessarily fully occupy this technological field. This is also an important advantage for large cylindrical batteries. It is a playing field that all global battery companies can participate in, and cannot be monopolized by patents or other factors.

Probability for Success

With Tesla’s price reduction stirring up the global automotive industry, there are several aspects that all car manufacturers need to consider:

◎ Performance: range and fast charging compatibility. Can they have a compatible way forward in these two mutually exclusive elements?

“`◎Cost Aspect: With the price reduction, how low can the cost of the battery go?

◎Space Aspect: Will there be a fundamental difference in the energy density of the entire vehicle?

If the mastery is not good, it will be difficult to concentrate on various competitive fronts. From the current point of view, the large cylindrical route still has a certain robustness in compatibility with different chemical system schemes.

This time, BMW held a beauty pageant, starting from 26 battery companies in the first stage, including soft packs, square shells, and cylindrical battery companies. The second stage had 9 companies, the third stage had 6 companies, and finally three designated companies were screened (EVE, CATL, and Faraday Future).

The Gen5 to Gen6 production capacity climb started from 50GWh to 200GWh, and this number is exaggerated, covering the three regions of China, Europe, and North America respectively. Although it is not yet known whether this long-term goal can be achieved, this consideration is very serious.

Conclusion: From the current point of view, it is impossible to determine the advantage of the large cylindrical battery at present, but the injection of resources has also made this route full of vitality. We look forward to this route achieving more standardized battery design and becoming a battery standard that can be universally used in the industry in the next generation.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.