Author: Zhu Yulong

After being split from Volkswagen Group, Porsche officially released the electric platform architecture PPE, and later it was reported that the Volkswagen Group’s SSP new platform may be delayed.

In my personal understanding, with the group’s spin-off, each brand has more freedom. For Audi and Porsche, the new PPE architecture can optimize layout and space performance for electric vehicles, to meet the needs of different types of vehicles with different driving forms and performance levels. Moreover, it is expected that by 2025, more than half of Porsche’s new cars will be pure electric or plug-in hybrid models, and PPE-based models will feature the pure electric Macan, which will have a large production volume. It is not appropriate to switch to SSP all at once, and there are some very important points to consider based on current information.

Regarding how the 800V platform charges, in the previous generation of products, Porsche used a DCDC, but in the new design, “combination charging” technology is now used, which automatically switches the corresponding high-voltage switch (gate) in the battery before the actual charging process begins. This effectively splits the 800V battery into two batteries, each with a rated voltage of 400V, which can be parallel charged at a 400V charging station. Currently, this technology is the opposite of GM’s technology, which means that a few companies are thinking about flexibly combining battery packs while charging.

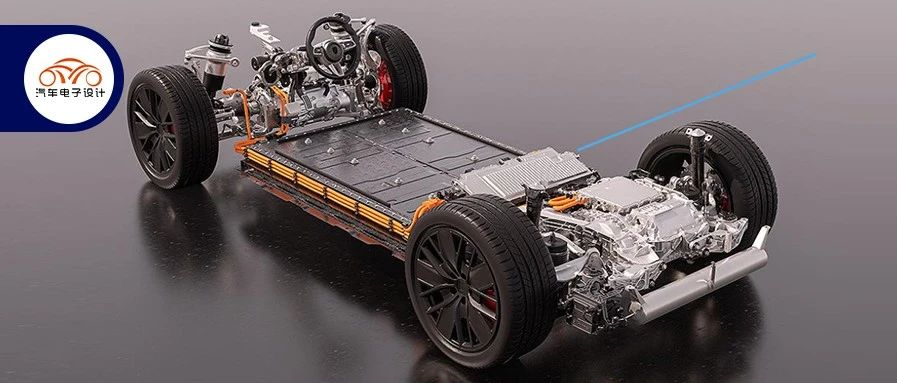

Overview of PPE powertrain technology

The PPE platform continues the 800V architecture, and adopts a new generation of motors, equipped with advanced batteries and charging management systems. Porsche and Audi jointly developed an architecture for high-end pure electric vehicles, which has multiple benefits, such as in layout and space. The PPE architecture provides a lot of operating space in terms of wheelbase, track width, and ground clearance and can meet the needs of various types of vehicles in different areas.The power output of the drive system can reach 450 kW, with a torque of over 1000 Nm, including various models of rear-wheel drive, four-wheel drive, and different performance levels demand. In the pure electric Macan, a new generation of permanent magnet synchronous motor with hairpin winding is used, and the water jacket cooling system is further optimized to maximize power density. An example of further comprehensive optimization is the double-V layer, which is the arrangement of magnets in the rotor. Here, due to the 800V system, silicon carbide (SiC) modules are used in the inverter on the rear axle.

There are actually two configurations in the battery system.

The batteries have been changed from soft pack to square shell cells with a capacity of only 67 AH per module, consisting of 34 cells.

◎The 12-module version is rated at 204s2p and the system voltage is 737V.

◎The 10-module version is rated at 170s2p, and the system voltage is 614V.

The most important design change here is the “combined charging” technology, which automatically switches the corresponding high-voltage switches (gates) in the battery before the actual charging process begins. The 800V battery is divided into two batteries with a rated voltage of 400V each, which can be charged in parallel at a 400V charging station.

This is actually similar to the system that Mercedes-Benz did for the EQC, dividing the battery pack into two parts, each with an independent battery distribution management and pre-charging system. Then use a group of combined contactors to switch between the serial and parallel connection of the two battery packs.

◎Serial connection: connect the positive and negative poles of the two battery packs with a set of relays.

◎Parallel connection: connect the positive and negative poles of the two battery packs separately with two sets of relays.

The difficulty of the design is to retain the existing set of positive and negative poles.

This is the basic logic of the design initially designed for individual enterprises and is now expanding to various car companies.

Protection of High-Voltage Components

From a design perspective, the 800V battery can be decomposed into two battery parts. If the states are inconsistent, they can be synchronized to a consistent charging state and then charged simultaneously. From the perspective of different enterprises, the combination of electrical components is used to replace the original with high-voltage contactors, mainly for efficiency. After all, from a cost perspective, after being divided into two parts, the current of a single contactor has not increased too much.

Currently, Porsche has applied for a patent for its integrated power box, which reduces the required cables and weight and lowers costs. This integrated power box combines the on-board AC charger, high-voltage heater, and DC/DC converter to save space.

I think it is regrettable that there are also discussions in this area in China. After all, good designs need to be realized.

Conclusion: This design is quite interesting, and we can continue to follow the landing of this plan.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.