Author: Zhu Yulong

Although Kirin Battery has been very popular recently, Ava 11 jointly developed by Changan, Huawei, and Ningde has also been officially launched. Ava 11 has three configurations, with a price range of 349,900 to 4.099 million yuan.

After attending Ava’s communication meeting today, I think there is still a lot to say about this power battery, which is mainly designed by Ningde Times.

-

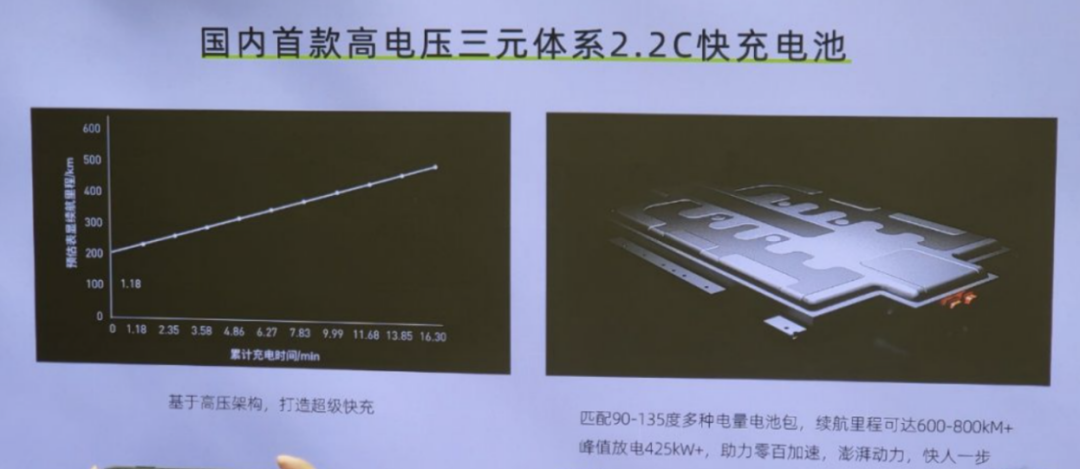

Fast Charging Design: The mainstream fast charging design in China is developed around 1.2C, taking about 40 minutes from 10% to 80% battery level. Ava 11 improves the battery charging speed to 2.2C, achieving about 25 minutes from 10% to 80% and about 15 minutes from 30% to 80% on the production models, supporting 750V high-voltage charging platform. It still ranks among the top in stable fast charging ability, and the maximum capacity of the battery has also reached 116kWh. The peak charging power is up to 240kW.

-

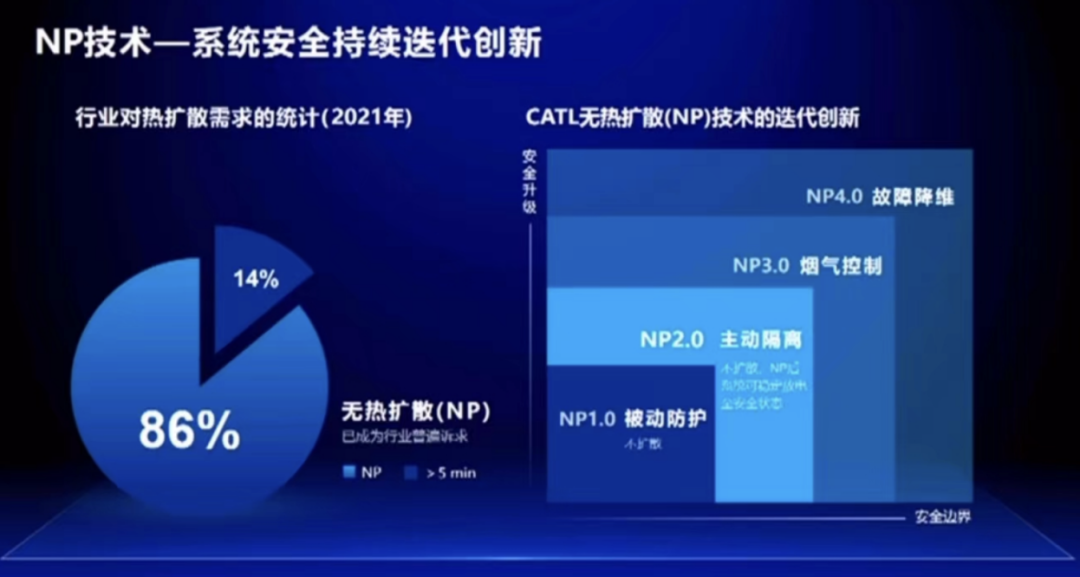

Safety Design: Due to the maximum energy of 116kWh, the energy density of the battery cell is 245Wh/kg. Ensuring the safety of the battery system is crucial. Ava 11 adopts NP non-thermal runaway design in this regard.

Fast Charging Design of the Battery System

First of all, the most important thing is the fast charging battery. This is the first high-voltage ternary system 2.2C fast-charged battery in China’s mass production. In the early stage of development, the goal was to increase the cruising range by 200 kilometers in 10 minutes. When planning the battery products, the design also considered 90 degrees and 116 degrees, and there may be configurations with higher electricity output in the future.

-

The energy density of the 116-degree battery pack is as high as 190Wh/kg, and the cruising range is as high as 680 kilometers.

-

The energy density of the 90-degree battery pack is as high as 180Wh/kg, and the cruising range can also reach 555 kilometers.

The next question is how to achieve fast charging. Ava 11 supports 750V high-voltage charging platform and can achieve super-fast charging capacity of 2.2C. The highest charging power can reach 240kW.

In terms of materials, this battery:

- Unique Modified Treatment to Solve Contradictions

To balance the contradictions between high energy density, fast charging, and long-life graphite technology, it is necessary to overcome the conflicts between fast charging speed and energy density, fast charging speed, and lifespan, super performance and supply chain. Therefore, in Avita’s battery cell scheme, through innovative material hierarchy and unique modified treatment, these conflicts have been resolved. The graphite particles adopt a core-shell design, and the surface of the porous coating layer of the anode material provides abundant lithium ion exchange, greatly improving the exchange speed of lithium ion charge and discharge and the rate of lithium ion insertion. The high-energy density nucleus matches the high dynamic surface (fast ion ring).

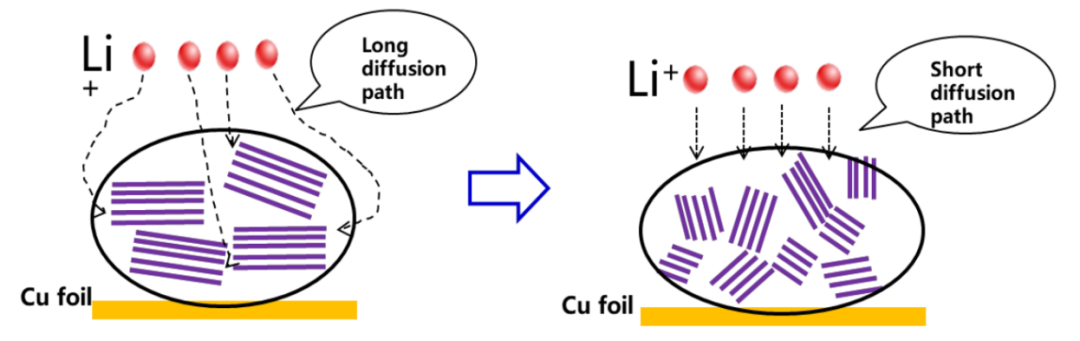

By importing isotropic technology and optimizing the lithium ion transmission path, lithium ions can be embedded in the graphite channel from 360 degrees, achieving a significant increase in charging speed. This is the most basic part of fast charging technology.

- Positive Electrode Material of Battery Cell

The positive electrode material has been optimized by using nano-riveting technology to connect the microstructure of the material together like rivets, ensuring the stability, high energy density and safety of the material. In Avita’s battery cell, a unique single-crystal particle growth technology is used in combination with surface passivation treatment technology, and high-voltage electrolyte is used to continuously widen the voltage upper limit of the material and the battery cell, balancing the improvement of energy density and long life, and enhancing cost-effectiveness.

In fact, surface-stabilized three-element positive electrode material with better energy density and stability can be obtained through intelligent screening and modification, which is also the most important method to achieve fast charging, energy density balance, and safety.

- Transmission Medium Electrolyte

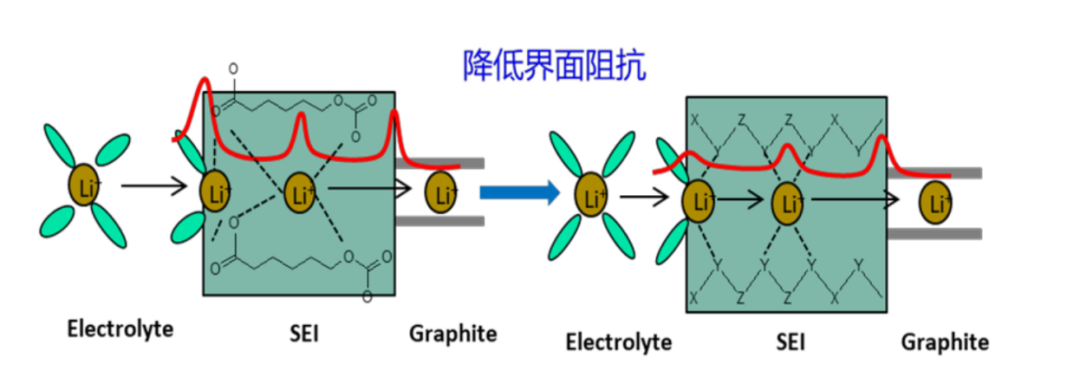

By using a special electrolyte, a highly efficient three-dimensional conductive network is built inside the electrode, reducing the internal resistance and heat generation of the battery cell, improving the rate performance of the material, making the material performance more stable, and allowing for rapid charging, high energy density, and safe material performance. In Avita’s battery cell, by optimizing the solvent and lithium salt composition, the viscosity of the electrolyte is reduced, ensuring the degree of solvation, and promoting lithium salt dissociation to obtain a higher conductivity. By developing and improving additives to reduce the interfacial impedance and enhance the ion transmission between the positive and negative electrodes, and by modifying the electrolyte genes to effectively reduce the reaction heat between the solid-liquid interface, the thermal temperature resistance and safety of the battery cell are significantly improved.

In fact, there are many things that need to be done on the box-shaped cell (245Wh/kg) to achieve stable fast charging. There are many modifications to the formulation of the cell, especially in controlling the cell’s impedance and heat generation.

Based on these technologies, the cell can achieve 2.2C fast charging with an energy density of up to 245Wh/kg, and 30%-80% SOC can be charged in as fast as 15 minutes. And this product can quickly replenish energy from zero to full in 60 minutes in a low temperature environment, with the usage environment being minus 10 degrees in the northern regions.

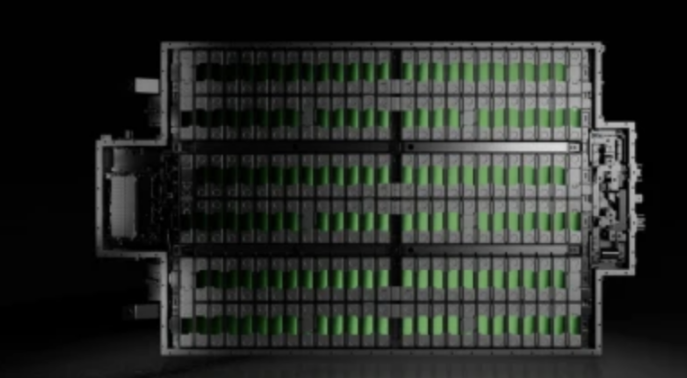

In addition, in terms of structure, the Avita 11 battery system adopts Ningde Times’ advanced CTP technology. Compared with traditional battery packs, the energy density increases by more than 10%, and the number of components is further simplified, and the assembly efficiency can be improved by 50%. This battery system is specially designed for fast charging capacity, with a special design for the cooling system and a smart distribution system for water flow to control the temperature difference within 3 degrees.

In fact, the CTP platform is a series of products, and the Avita platform will plan to use Ningde Times’ new generation Kirin battery technology to create products with higher fast charging performance and longer cruising range.

Safety design of battery system

The following safety design measures are implemented in this battery system:

-

Insulation design, using some aviation-grade insulation materials, can effectively protect the cell. Insulation materials can insulate the heat dissipation between cells on the premise of meeting the space requirements of different chemical systems, which can prevent the thermal runaway of cells.

-

For the battery pack system, the three-dimensional simulation is used to simulate the gas diffusion path when the cell fails, and optimize the exhaust channel and relief system design. Even in extreme cases where a few cells fail, after every certain number of cells, high-temperature insulation composite materials are used, and directional explosion outlet is designed with protective cover to discharge the high-temperature gas and flame.- Exhaust: By designing multiple flow channels, the heat source can be controlled to flow along a predetermined path, reducing thermal shock to adjacent battery cells. In addition, gas and flame emitted from a thermal runaway of a cell are evenly distributed in different structural channels, such as longitudinal channels (bottom flow channels), to avoid sudden thermal shock to adjacent cells and second thermal runaway.

-

Insulation design: High-voltage components inside the battery pack are insulated and protected, and high-voltage connections and safety zones inside the battery pack are designed with high-temperature insulation protection.

By simulating some extreme and low probability situations, the failure of a single cell can be limited to that particular cell at system level if it really happens, ensuring the safety of the battery system throughout its life cycle. At the Baidu World Conference, CATL’s 8th generation product has achieved NP (Non-Propagation), and is based on the medium-Ni ternary NCM523 chemistry system, which has many innovations, such as safety and stability.

Conclusion: The fast-charging battery developed around the 800V system will be a new blue ocean and a must-have for all car companies, and this Aveta battery is also very distinctive. Everyone is talking about Kirin batteries, including Aveta in the future, which may be more practical.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.