Author: Turbocharged Fat Boy

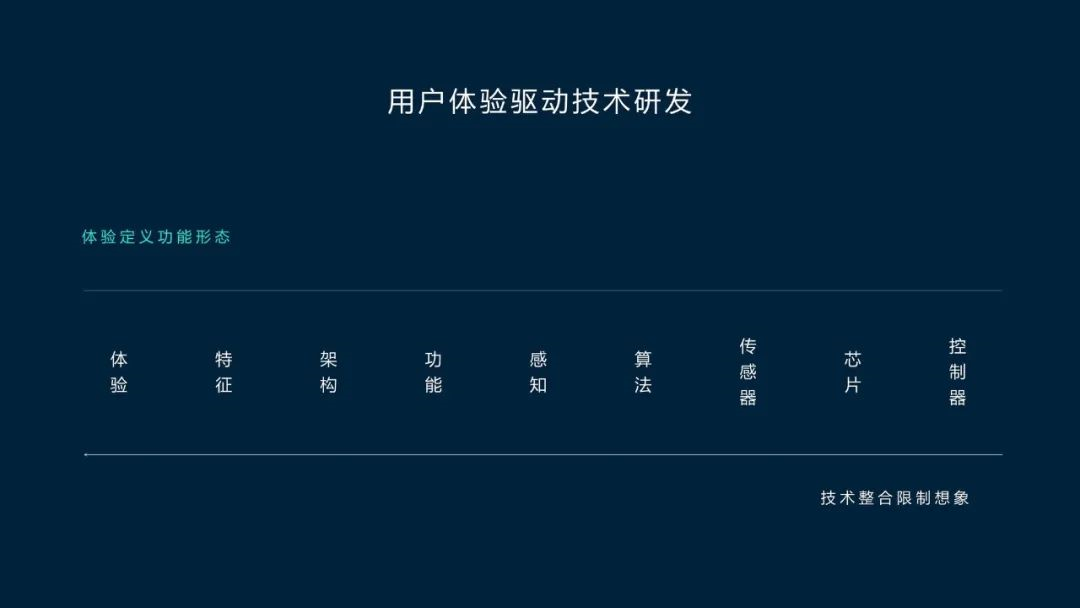

As cars enter the era of intelligence, our understanding of cars has undergone earth-shaking changes. We no longer debate which parts of a car should be intelligent and which should not, because we have begun to understand that every part of the car will enter the era of intelligence.

A few days ago, NIO held a “NIO Innovations’ online salon for the ET7 intelligent chassis technology and introduced NIO’s independently developed intelligent chassis domain controller (ICC).

So why did NIO choose to independently develop this intelligent chassis? Let’s analyze together.

Independent research and development is control of core technology

According to the traditional model of car manufacturing, the core technologies in the hands of the automaker are mostly related to the power system. This was also the decisive factor in the fiercely competitive automotive market in the past. Other parts could almost be left to suppliers or developed in cooperation with suppliers. Automakers are responsible for the acceptance and implementation of technology and products.

However, when we enter the era of intelligent cars, the current model of car manufacturing is changing. More and more automakers are developing core technologies themselves and taking over things that would otherwise be done by suppliers.

The fundamental reason for these changes is still: core technology.

Core technology here does not only refer to a component, part, adaptation, calibration, etc., but also the introduction of more and newer ideas into the automotive industry, including the automotive system, automotive standards, intelligence, services, etc., which have become the “core technology” in the hands of automakers.

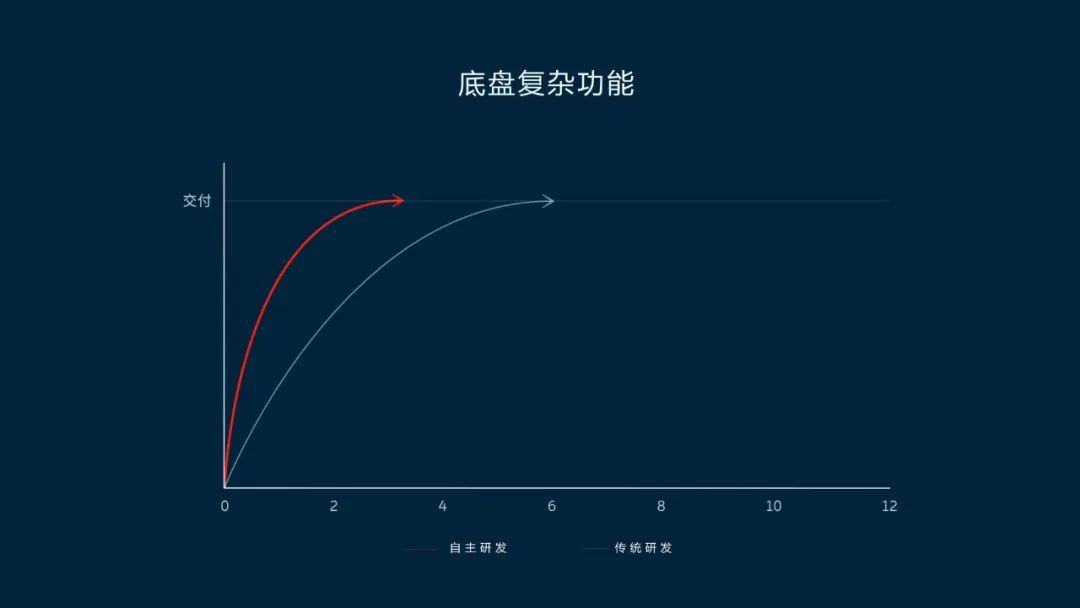

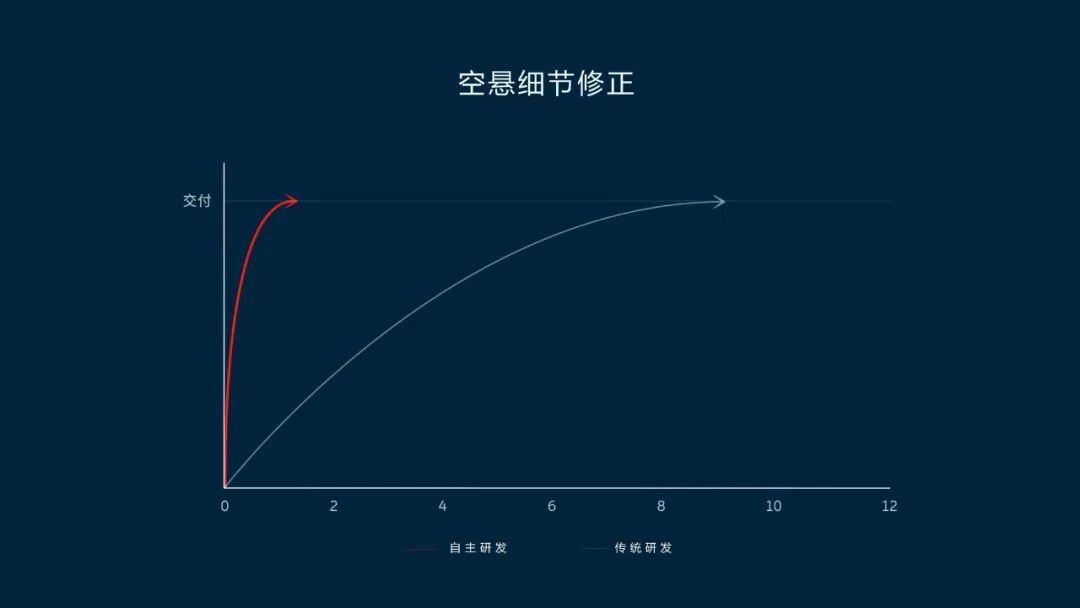

For a long time, automakers have been highly dependent on supplier support, resulting in automakers lacking the ability to integrate and develop the functions of each part of the vehicle, which greatly affects the expansion capability of functions and experiences. If automakers can develop the core technology independently, they can not only break free from the dependence and constraints of suppliers, but also further improve the expansion and integration capabilities of the various functions of the vehicle.

NIO and the future both need intelligent chassis

This time, the self-developed technology introduced to us by NIO is the intelligent chassis.Nowadays, the chassis is no longer a pure mechanical integration, and with the addition of software, the vertical integration ability of chassis development has been greatly improved. The integration of components has improved the dynamic performance boundary of the entire vehicle. The electronic and intelligent chassis can also meet a more diverse range of personalized user needs, providing users with more interaction.

NIO’s Intelligent Chassis Control (ICC) domain controller was first featured on NIO’s first sedan model, the ET7. Combined with the independently integrated hardware system of the chassis, ICC can comprehensively design and tune the comfort, handling, and driving characteristics of the chassis. It has integrated redundant parking, air suspension, shock absorber control functions, and also supports advanced autonomous driving scenarios with cross-domain fusion. It can also be upgraded iteratively through FOTA.

Why do I say: NIO needs an intelligent chassis?

Just the other day, I experienced the NIO ET7 for a few days. Compared to my previous experience with NIO’s “866” series of SUV models, the chassis of the NIO ET7 has a more obvious improvement in texture. Of course, there are several possibilities for this:

- The lower center of gravity of the sedan model makes it more stable to drive;

- The suspension and shock absorber compression stroke of the sedan model are shorter;

- The credit goes to the NIO’s self-developed intelligent chassis domain controller (ICC).

The above are my views, which may include some or all of these possibilities.

NIO’s ICC domain controller can uniformly adjust the height of air springs, damping of shock absorbers, and electronic parking function. Take the dynamic suspension damping control (CDC) as an example:

Each shock absorber can change damping by changing the current. Real-time onboard and sensor signals collect vast amounts of real-time road information. The software adjusts the damping settings between a minimum 1.8 ampere and a maximum 0 ampere based on the current posture of the vehicle.

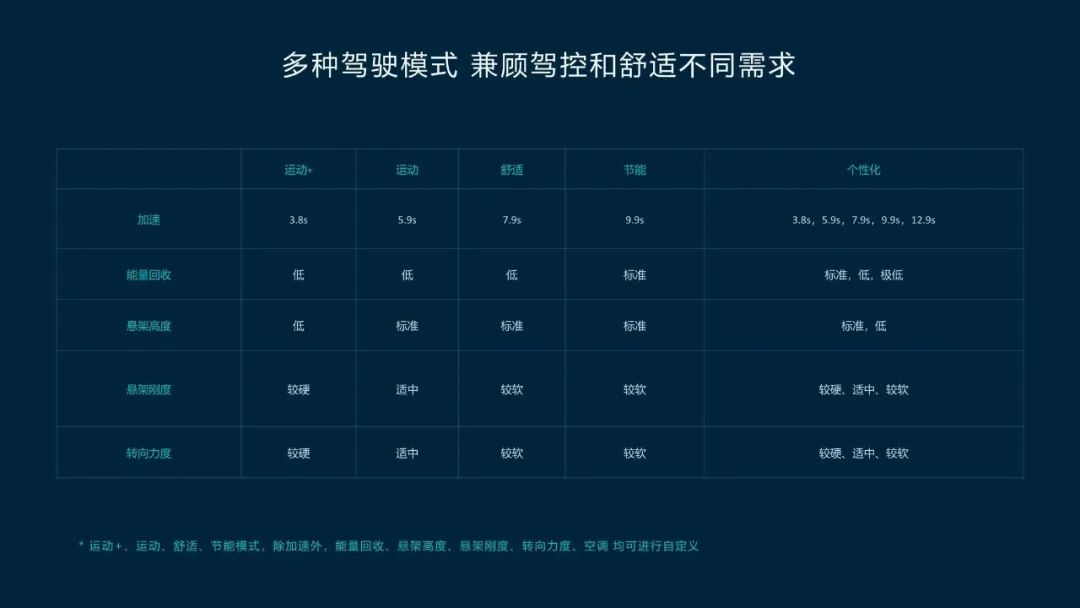

At present, the NIO ET7 has four driving modes preset by NIO Inhouse calibration experts based on Chinese road conditions and user driving habits, including: Energy-saving, Comfort, Sport, and Sport +. Each driving mode corresponds to different damping calibration.

For example, in Comfort mode, the suspension will filter out fine vibrations and reduce uncomfortable road feel, while in Sport mode, the suspension will increase correction around roll and pitch, improving control over the vehicle’s body…

However, after experiencing the NIO ET7, I found that there was some “excessive bouncing” in the suspension when passing through bumpy roads and speed bumps. Although it was not very obvious, there is still some room for optimization.

With support from this ICC domain controller, NIO can perform FOTA software calibration upgrades and adjustments to the suspension, providing a better driving and riding experience.

In the future, NIO ET7 will also introduce the 4D Dynamic function. This function will use cameras, LiDAR, high-precision maps, cloud big data and other information to predict and prepare for road bumps ahead of the vehicle, adjust suspension damping, and provide a more comfortable experience.

So why do I say that intelligent chassis is also needed in the future?

As we gradually move towards advanced autonomous driving, there is one technology that cannot be avoided in automobiles, and that is “line control chassis”.

The line control chassis can be divided into several parts, including: line control steering, line control throttle, line control braking and line control suspension. Nowadays, the vast majority of electric vehicle products already have line control throttle, some models have begun to try “mechanical structure redundancy” of line control braking, and many automakers are researching the most difficult line control steering.

The suspension system controlled by the domain controller is one type of line control suspension, which is now commonly applied to vehicle models equipped with air suspension.

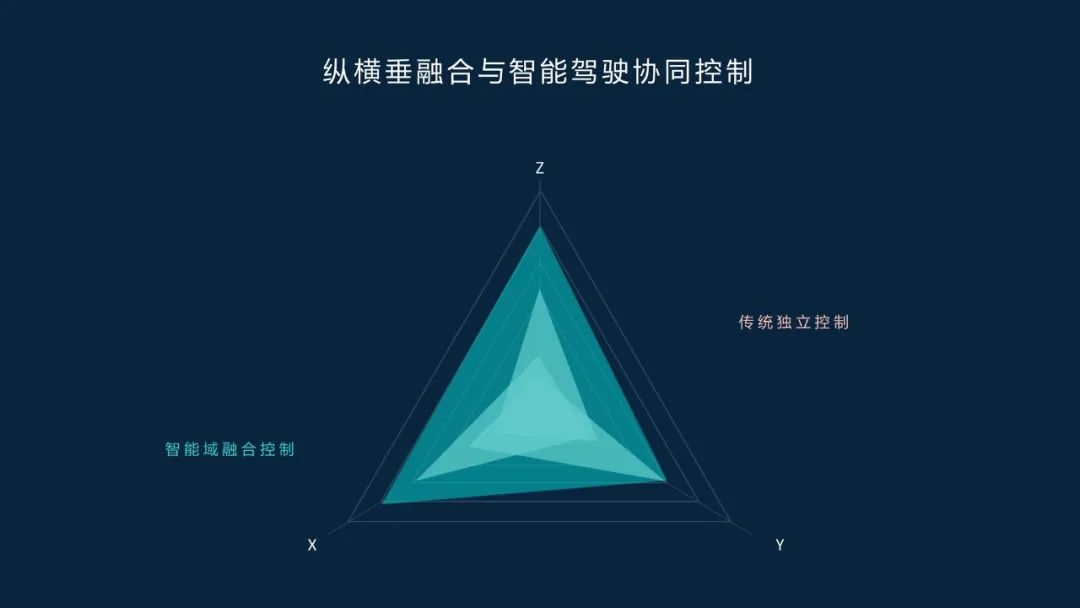

Taking the NIO ET7 as an example, the NIO ET7 is equipped with the NAD autonomous driving system. In order to achieve richer functional experiences, the chassis needs to provide a broad functional carrier platform for the autonomous driving system, cockpit system, and power system.

In the NIO NAD autonomous driving scenario, the intelligent domain fusion control system will be able to control the vehicle’s four-wheel drive distribution, line control braking, and variable suspension functions across domains. This allows the “brain” of autonomous driving to fully control and coordinate the vehicle, completing the autonomous driving function.

The wire-controlled chassis is the cornerstone of autonomous driving. Previously, main manufacturers including NIO, Geely, and Jidu jointly led the development and standardization of wire-controlled steering technology and the formulation of related national standards, which also confirms that NIO is developing wire-controlled steering technology. NIO’s “making the chassis more intelligent” is also accelerating its layout of wire-controlled chassis technology.

Independent brands need to have core technology

Returning to the topic of “core technology”, compared with those century-old car companies, in the past two years, with the promotion of electrification and intelligence in the domestic automobile market, the advantages of independent brands are obvious. However, returning to the essence of driving, the technological accumulation of independent brands is still insufficient.

To give a simple example, in the past, some self-owned brand promotions would mention terms like exclusive tuning by XXX team, XXX master-level tuning, XXX…, which would make many consumers think that the chassis tuning of this car model is very good. But think again, who has the core technology?

Anyway, it is not in the hands of these independent brands.

When the chassis enters the intelligent era, whether it is a century-old car company or an independent brand, we return to the same starting line. We may even be at the forefront.

Therefore, when independent brands have their own core technology, and finally get rid of dependency on others, we will not only walk faster, but also go further.

Finally

NIO’s self-developed intelligent chassis domain controller ICC will be installed on the NIO ET7, NIO ET5, the soon-to-be-released NIO ES7, and new products based on the NIO NT 2.0 platform in the future. The chassis domain controller gives new meaning to the intelligent electric vehicle chassis: defining the bottom, connecting the experience, and increasing the upper limit.

NIO’s intelligent chassis domain controller is like the cerebellum of the human body. The cerebellum controls our “sense of balance” and “coordination.” It is only a part of the brain but can complete human movements when combined with the cerebrum.

The same goes for intelligent vehicle chassis, which not only needs to be more comfortable and sporty but also more comprehensive. On the road to the future of autonomous driving, cross-domain integration is also a “must-pass route”.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.