In existing power batteries, a single-structured, single-system battery cell is often configured in a battery pack, which has the advantage of facilitating mass production and unified control, but the disadvantage of difficulty in balancing performance and the overall cost of the battery pack.

The energy density of power batteries, as an important performance indicator, directly affects the range of electric vehicles. How to improve the energy density of power batteries is a hot and focal point of technical personnel in related fields.

In this process, NIO differs from other manufacturers in its use of an integration of ternary and iron lithium to solve the problem of performance and cost.

However, “ternary iron lithium” primarily solves the problem of SOC estimation in lithium iron batteries. Under NIO’s standardized battery pack volume, how to improve energy density is a new challenge for NIO.

Therefore, NIO has proposed a new patent.

Without further ado, let’s take a look.

NIO’s Cylindrical Version of “Ternary Iron Lithium”?

In May 2021, we exclusively interpreted the technical patent of NIO’s “Ternary Iron Lithium” battery pack on the entire network, and in October, NIO released a mass-produced 75-degree ternary iron lithium battery pack.

In March 2022, a technical patent for a battery pack appeared in the announcement of the State Intellectual Property Office, with the applicant shown as “WEILAI AUTOMOTIVE TECHNOLOGY (ANHUI) CO., LTD.” and the inventor being NIO’s vice president of power battery systems, Zeng Shizhe.

According to the patent, the purpose of this invention is to “improve the energy density of the battery pack.”

Based on past experience, the probability of mass production of this battery pack is very high. Therefore, let’s take a look at what black technology NIO has used to improve the energy density of its power batteries.

NIO excels in taking unconventional measures to solve problems, such as battery swapping and ternary iron lithium battery packs. To understand NIO’s new battery pack patent, we first need to clarify a few questions:

- The main way to improve energy density currently is to improve battery pack structure, with the core being to install more battery cells.

- NIO’s structural innovation in power batteries must be within the existing battery pack design specifications to meet the battery swapping needs of new and old models.

- The difficulty for NIO is to increase the energy density of both the iron lithium and ternary versions within the limited space of the battery pack.

Let’s see how NIO does it

According to the patent description:

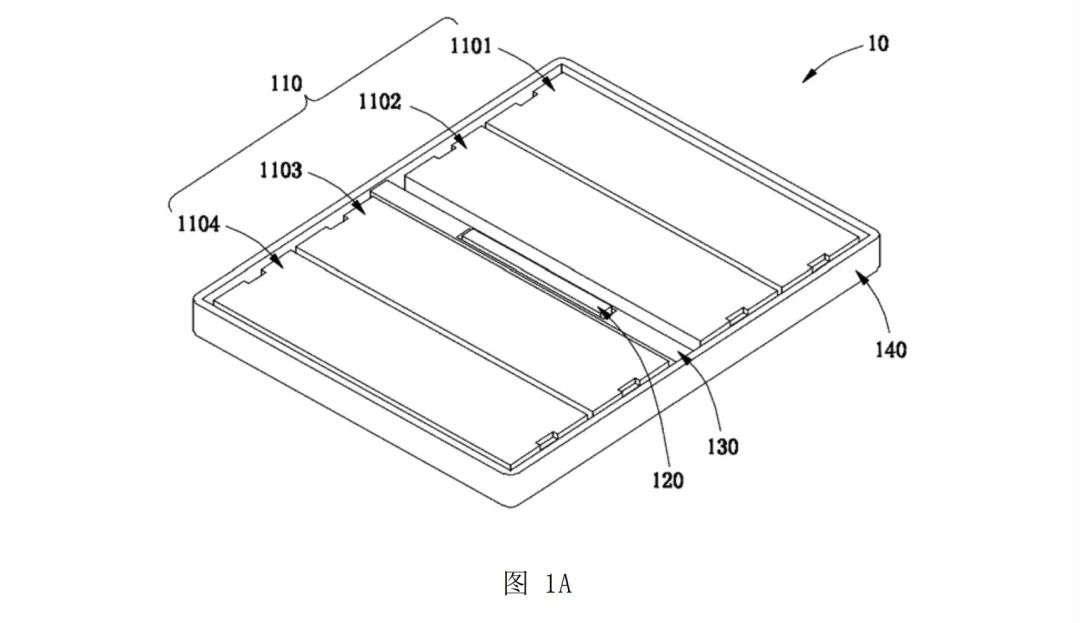

NIO provides a battery pack, which includes a supporting portion that provides structural support for the battery pack; and an electrode assembly, wherein part of the electrode assembly is located inside the support.

The battery pack contains two groups of battery cells, including “the first group” and “the second group.” The first group of battery cells use “the first structure,” and the second group of battery cells use “the second structure,” which are located inside the supporting portion.

The first structure is different from the second structure.

Explanation:

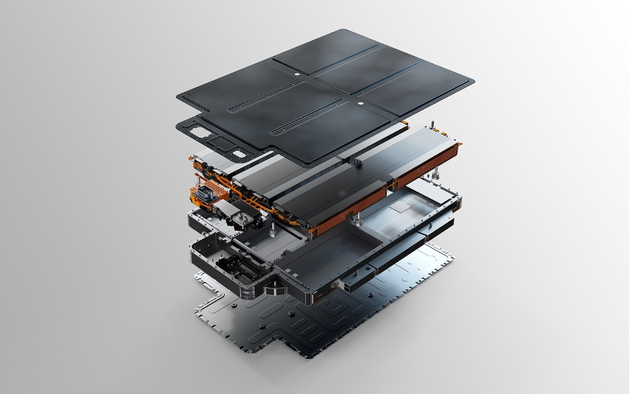

Looking at the existing battery pack of NIO, several important components can be seen after dismantling the entire battery pack. From the inside out, they are battery cells, modules, horizontal and vertical structural beams (used for structural support), upper and lower cover plates, and shell encapsulation components.

As we mentioned before, the difficulty of increasing the energy density of NIO’s battery pack is that the shape of the existing battery pack cannot be changed, so what NIO can do is to make improvements inside the battery pack.

According to the description of the patent mentioned above, NIO’s new battery pack will have two types of battery cell structures, which are also called modules, and the structures of the two modules are different.

The important thing is the first sentence, which indicates that some battery cells of this battery pack are encapsulated inside the “supporting part”.

It is important to note that the “supporting part” mentioned here actually refers to the structural beam inside the battery pack. Does this mean that NIO integrates battery cells into the structural beam?

Let’s keep reading.

In a traditional battery pack, the supporting part arranged in the battery pack for structural support reduces the space available in the battery pack for arranging battery cells, thus affecting the overall energy density of the battery pack.

In response to this problem, NIO arranged a set of battery cells inside the horizontal beam to optimize the spatial arrangement in the new battery pack, while maintaining sufficient structural strength of the new battery pack.

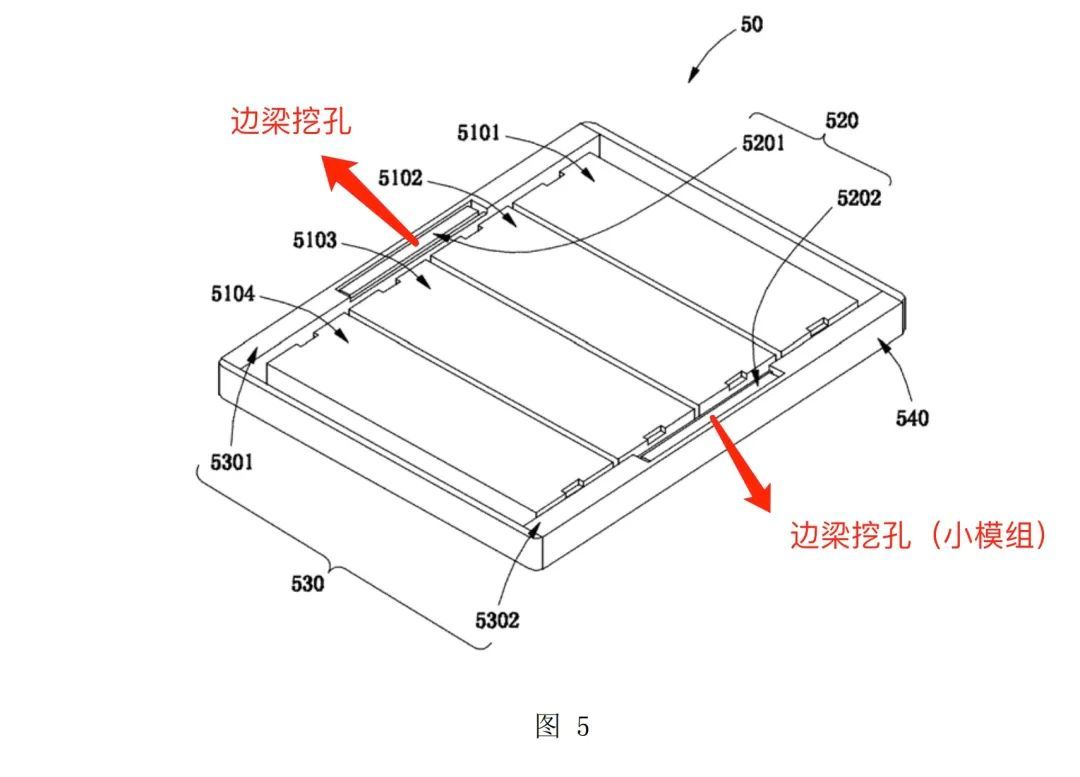

That is, as shown in the patent diagram, in addition to the traditional large module, NIO excavated the horizontal beam inside the battery pack to form a free space that can accommodate a set of battery cells. This controlled area is called the “supporting part”. Placing battery cells here can increase the overall energy density of the battery pack without changing the external structure of the battery pack.

In the patent, it only shows the arrangement of one type of battery cell module inside the supporting part, but in fact, multiple battery cell modules can be arranged in the excavation of the horizontal beam, depending on the size of the excavation. According to the size of the existing horizontal beam, arranging one set of battery cell modules is the optimal solution.

In the new battery pack, the supporting part is located on the central horizontal beam, but the patent indicates that the supporting part is limited to this structural design, and it could also be other suitable supporting parts such as vertical beams, edge beams, or their combinations.

So what does this mean?

In simple terms, NIO has used almost all the space available inside the battery pack. In addition to the conventional large module, NIO excavated the horizontal beam, vertical beam, edge beam, and other areas for battery cell placement to increase the overall energy density of the battery pack.

Regarding the connection method, the patent also discloses:

In the new battery pack, the battery cells of the large module and the battery cell modules inside the supporting part can be connected in series, in parallel, or in other mixed methods.The battery module packaging that supports the support part is fixed inside the crossbeam by the cylindrical cells through the opening using structural glue, bolts, clips, or any other appropriate means, in addition to the structural glue.

The entire content above explains the changes in the internal structure of the new battery pack, and the biggest feature of this new battery pack is that it is no longer a single structure single system cell battery pack, but it can be flexibly adjusted according to actual needs.

In the past, battery packs were all either ternary or lithium iron, single chemical system, except for NIO’s ternary lithium iron. The new NIO battery pack continues the concept of “ternary lithium iron”. The large module cells in the pack can be either ternary or lithium iron, and the support module cells can also be either of these two types, and all of these cells can adopt a square shell, blade, cylindrical, or soft pack structure.

For example, square shell structure can be used for large module cells, and cylindrical structure can be used for small module cells inside the crossbeam. The use of different structures is for the purpose of improving space utilization. Among them, the diameter of the cylindrical cells inside the crossbeam can be within 15-100 mm, and the height can be within 65-200 mm.

In other words, the use of cylindrical cells inside the crossbeam has the highest space utilization efficiency, and the space for digging holes can cover the mainstream 1865, 2170, and 4680 cylindrical cells. From the patent drawings, a single row of 4680 cylindrical cells may be the best choice.

What are the design advantages of this battery pack?

From the overall structure, if this battery pack is mass-produced, there will be several improvements compared to the existing battery packs:

1. Improve the energy density of the entire pack.

The increased utilization of space allows NIO to install more cells, which will inevitably improve the energy density of the entire pack.

2. The flexibility of cell selection inside the battery pack increases.

The patent states that in theory, both types of modules are not limited by material systems or module sizes, which means that large modules can choose large cylindrical cells, blades, short blades, and standard square shell cells. The benefit of this is that NIO can choose from more suppliers.

In addition, nickel content of the ternary lithium cells in the new battery pack is not restricted, and can be low-nickel cells, such as 30%, or high-nickel cells, such as 96%.

3. A win-win situation for cost, energy density, and performance.

We all know that automakers use lithium iron battery packs mainly because the cost of ternary cells is too high. However, although using lithium iron battery packs saves costs, performance and energy density are compromised.

Last year, NIO proposed the “ternary lithium iron” battery pack, which uses precise estimation of the SOC of ternary cells to solve the problem of SOC estimation accuracy of the entire pack, and the main cells use lithium iron to meet both performance and cost requirements, but it still does not solve the energy density problem.

The new battery pack not only fully utilizes conventional space, but also uses the limited positions of the horizontal, vertical, and side beams to arrange cells, which is the added cells, and can be used to arrange ternary cells.## English Version

The patent shows that “in the new battery pack, large modules can use lithium iron phosphate cells, while small modules can use ternary lithium cells. Due to the relative flatness of the voltage platform of lithium iron phosphate cells, the SOC estimation accuracy is relatively low, especially in low temperature environments. Combining ternary lithium cells with lithium iron phosphate cells in a new battery pack can improve the SOC estimation accuracy of the original lithium iron phosphate cells and improve the performance of the entire battery pack.”

Ternary batteries use a cylindrical structure because the size of the horizontal, vertical, and side beams and the size of the holes are limited. The cylindrical battery has the highest space utilization efficiency. Therefore, the entire battery pack can be regarded as an upgraded version of NIO cylindrical cells, the “ternary lithium” battery pack.

Cell Layout Scheme

Above, we talked about the innovative logic of this new battery pack, which essentially further squeezes the space. The patent specifies several cell layout scenarios:

- Hybrid configuration of large and small modules.

Compared with the four modules of large module cells mentioned above, the large module cells in the figure have a total of 32 modules. The patent does not limit the number of modules in the large module cells. The modules of the large component can be either a relatively large number of small modules or a relatively small number of large modules or a hybrid configuration of large and small modules.

- No restriction on the size, number, or position of the support part’s horizontal, vertical, and side beams.

Compared with the support part consisting of a single horizontal beam in the center of the new battery pack mentioned above, the support part in the new battery pack can also be the horizontal beam at the top or bottom of the battery pack.

It can be seen that this invention does not limit the number and position of the horizontal beams in the support part. It can be any number and position of horizontal beams at any appropriate position in the battery pack.

From this battery pack, it can be seen that NIO is running out of structural innovations to improve energy density after the new battery, but this new battery pack has brought new directions to automakers using large module solutions, which is to make full use of all available space.

Conclusion

According to the patent, in the new battery pack, by arranging some cells inside the support part, the space inside the support part is utilized, the space utilization rate inside the entire battery pack is improved, the energy density of the battery pack is increased, and the structural strength of the battery pack is maintained.

The cells and related components (such as structural adhesive used to fix the cells) inside the support part can maintain the structural strength of the battery pack. Therefore, this invention can improve the energy density of the battery pack without weakening its structural strength.

At the same time, different types of cells with different structural types can be arranged inside the support part of the battery pack, further improving the space utilization rate inside the support part and increasing the energy density of the battery pack.In addition, different chemical systems of battery cells can be arranged in different positions inside the battery pack to improve the overall performance by combining them. The biggest advantage lies in increasing the energy density of the “ternary lithium” battery pack.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.