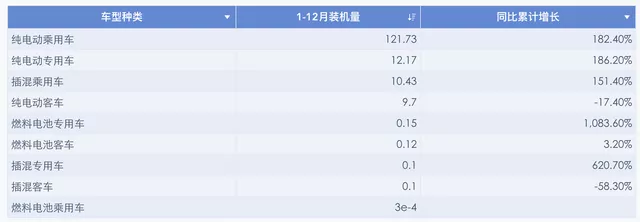

The Automotive Market in 2021

The 2021 automotive market can be seen from several directions, including passenger cars, coaches, and special-purpose vehicles. The coach market has always been relatively stable (or has nearly exhausted its potential). In 2021, special-purpose vehicles have shown remarkable combat effectiveness.

At present, in terms of installed capacity, pure electric special-purpose vehicles occupy the second largest market for automotive power batteries in China, and in 2022, the electrification of heavy-duty trucks has huge potential in energy conservation and emission reduction.

The electrification of heavy-duty trucks differs essentially from that of passenger cars. It is a production tool for heavy-duty trucks, and the existence of the oil-electric price difference makes electrification have a very good economic basis. However, there are still some unfavorable factors in this industry from traditional perceptions:

-

The cost of pure electric heavy-duty trucks is high: it is expensive, more than 100,000 yuan per unit, which is 2-3 times more expensive than a traditional heavy-duty truck relying on an engine (30,000 yuan).

-

The operating efficiency of pure electric heavy-duty trucks is low: Heavy-duty trucks are relatively heavy. After being equipped with batteries, they are even heavier than traditional ones (more than 2 tons). This decrease in effective capacity of pure electric heavy-duty trucks will reduce revenue; even worse, recharging is slow (the fastest takes an hour), and if charging stations cannot be found, it could delay operation for two to three hours, greatly occupying operating time. Therefore, the benefits brought by pure electric heavy-duty trucks are greatly reduced, and economic viability has not been reflected.

-

The difficulty in building supporting facilities: Since pure electric heavy-duty trucks have large volumes and require high charging power, building charging stations is difficult.

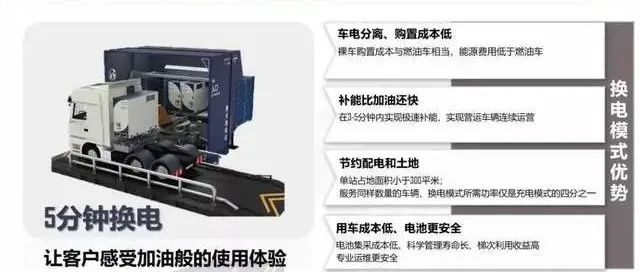

The above reasons make electric battery exchange a highly possible solution for heavy-duty trucks.

As seen in practice from 2021, battery exchange has become a good breakthrough point for heavy-duty trucks, depending mainly on the combination of the commercial model of vehicle-electric separation and the technology of battery exchange:

Firstly, a company is set up through financial means to have the battery bank buy heavy-duty truck batteries and then lease them to users, charging battery rent to users (which can be divided into monthly payment and payment based on mileage, etc.), and battery exchange operators provide charging and replacement services, while the vehicle manufacturers sell cars directly.

The Present Situation of Battery Exchange Technology

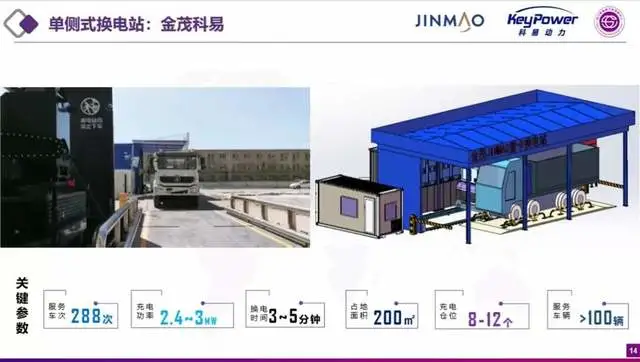

According to the classification speech made by Liguo, there are mainly three types of heavy-duty truck battery exchange technology in China: overhead suspension battery exchange, single-side integrated battery exchange, and double-side integrated battery exchange.

● Overhead Battery Swapping Solution: This approach uses steel cables to move the battery pack. When approaching the dock, the flexibility of the steel cables accommodates for positional errors. Its main advantage is its simplicity and relatively low cost, making it the earliest commercialized solution.

● Side-mounted Battery Swapping Solution: This approach uses a rigid grabbing mechanism operated by a robot, requiring high control accuracy. It is more suitable for public charging stations in cities, and the battery swapping robot needs a precise positioning device with visual and laser radar, making it more adaptive and easier to promote. Its biggest advantage is that the battery does not occupy the storage space of the cargo compartment, requiring two sets of robots and two sets of storage and charging compartments.

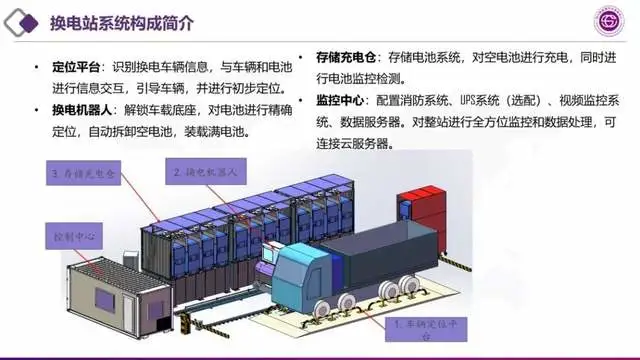

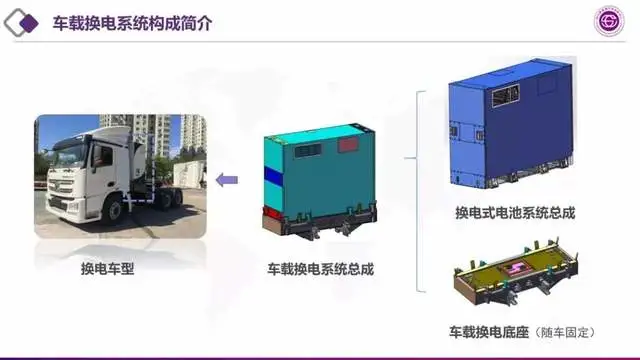

In terms of disassembly, the storage and charging compartment of the battery generally adopt on-site charging. In case of harsh environments, the entire set of storage and charging compartments at the back can be transported on the vehicle and installed in special areas. The core component is the battery swapping robot – a device that can move batteries, it can grab from the side (accurately located by laser radar or machine vision), or even grab from overhead (on a positioning platform). The vehicle-mounted battery swapping system generally consists of a vehicle-mounted battery swapping base fixed to the vehicle, and a replaceable battery swapping assembly that circulates between the vehicle and the battery swapping station.

CATL’s Standard Battery Swapping Solution

In fact, CATL and State Power Investment Corporation have done a lot of work for this.

Under State Power Investment Corporation, JiuHang Energy provides a complete set of battery swapping mechanisms, and JiuHang Energy can also build battery swapping stations. The chassis of the pure electric heavy-duty truck is equipped with a battery swapping base that can dock with the battery pack. Two charging connectors and two discharge connectors are installed on the base, and corresponding connectors are also installed on the battery pack. Due to frequent plugging and unplugging during battery swapping, the reliability and durability of the charging and discharging connectors have high requirements, and the number of pluggings and unpluggings is also extremely high.

This battery pack is designed with a parallel expansion scheme, extending from a maximum of 282kWh to 350kWh. My understanding is that while electric vehicle battery swapping has been implemented for passenger cars for some time, swapping for heavy-duty trucks and standard battery packs has also been in operation.

In summary, I am thinking that the difference between the swapping connection components and charging and swapping can be calculated for the overall capacity, and as battery swapping continues to be tried and promoted in various fields, the demand is still growing in an orderly manner.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.