On January 3, 2022, Mercedes-Benz unveiled its VISION EQXX concept car, touted as the “most energy-efficient car in Mercedes’ history,” in Central European Time.

According to Mercedes’ official blog on EQXX, the first sentence reads: “Range and efficiency are set to define the electric era.”

Just from this sentence alone, the EQXX’s impressive 1,000 km range and 10 kWh/100km energy efficiency are undoubtedly successful.

I know what you’re thinking: “What’s the point of talking about concept cars and their specs?”

While that may be true for most concept cars, Markus Schäfer, the director of research and procurement at Mercedes, says the technology behind the Vision EQXX will define and support future Mercedes-Benz models and features. Additionally, many of the functions and research on the EQXX have already been integrated into mass production projects, including the next generation of Mercedes-Benz’s MMA platform.

Therefore, the EQXX is not your typical concept car, as it allows us to directly see the details of Mercedes’ future technology.

What we care most about is how the EQXX’s design compares to that of previously produced electric cars.

The aerodynamic design affects the shape of the car first and foremost.

The tail end of the car looks a bit familiar, doesn’t it?

Indeed, as early as 2015 at the Frankfurt Motor Show, Mercedes unveiled the Concept IAA concept car, which was notable for having a record-low drag coefficient of 0.19.

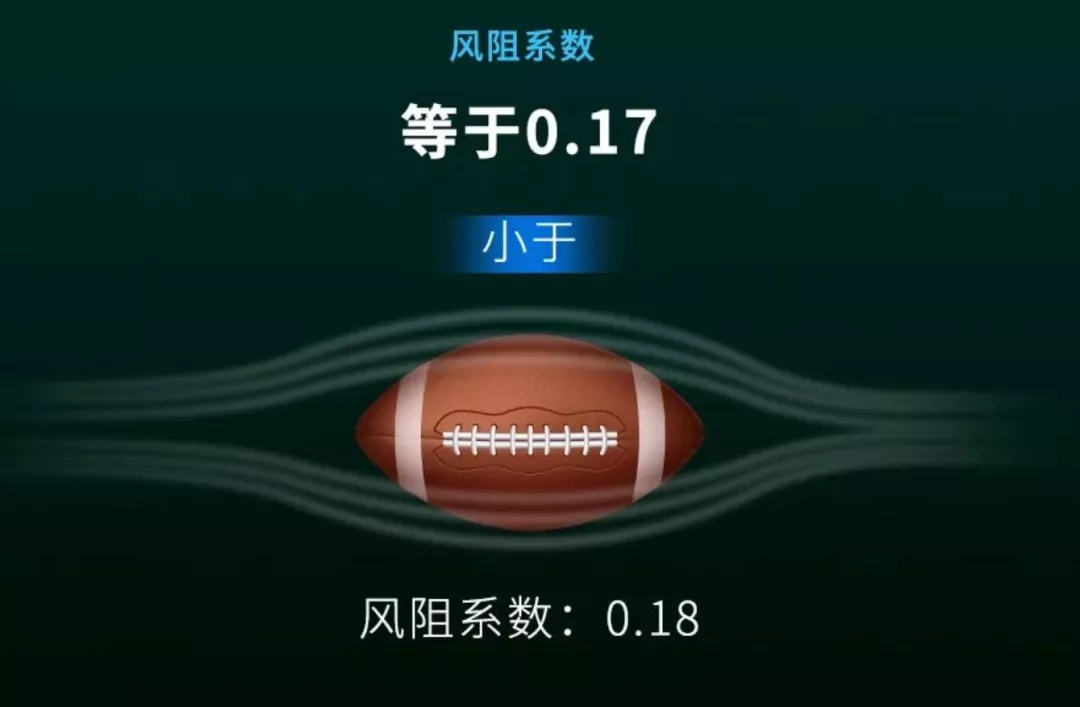

Now, with the focus on energy efficiency, the EQXX boasts an even lower drag coefficient of 0.17. Mercedes even used the drag coefficient of a rugby ball as a comparison.

From the industry’s lowest wind resistance of 0.20 achieved by the already mass-produced EQS, it is obvious that Mercedes-Benz has a tradition of pursuing low wind resistance.

However, low-energy aerodynamics is not just about reducing the drag coefficient.

There are four factors that affect wind resistance: air density, vehicle speed, vehicle frontal surface area, and air resistance coefficient. The first two factors cannot be controlled by automotive companies, but Mercedes-Benz has pushed the limits in terms of the vehicle frontal surface area (wind-catching area) and drag coefficient.

The EQXX’s wind-catching area is even smaller than that of the Smart car model, and the overall appearance of the vehicle is also limited by wind resistance. The object with the lowest wind resistance coefficient in the world is a water droplet, with a wind resistance coefficient of only 0.05. This is why many car models are becoming more and more like “water droplets” to reduce their wind resistance coefficients.

Using this EQXX as an example, in order to pursue the ultimate drag coefficient, the Mercedes-Benz EQXX made the entire body of the car lower, including smaller rear-view mirrors, a lower front end, a streamlined body, and low-drag wheels, among others.

However, the influence of low wind resistance cannot be ignored. From the overall design of the EQXX, we can see that the headroom in the rear seats is very limited. Without the benefit of a panoramic sunroof, the passenger experience in the rear seats would be compromised.

There are also details such as the significantly elongated rear of the car and the low-resistance tires that are only 185 mm wide, which make it seem like Mercedes-Benz is trying too hard.

In contrast, outstanding representatives of current aerodynamics, including the Tesla Model S Plaid, Lucid Air, NIO ET7, and even Mercedes-Benz’s own EQS, achieve a better balance in terms of aerodynamics, design, and space.

One more detail: it seems somewhat unreasonable to reduce wind resistance by changing the size of the rear-view mirrors, as smaller mirrors can directly affect driving safety. If one must innovate with regard to rear-view mirrors, apart from electronic rear-view mirrors that are still restricted by regulations, the borderless rear-view mirrors from Polestar, which reduce the wind-catching area without affecting the driver’s visibility, are a reasonably balanced solution.

In terms of power, EQXX also fully implements energy efficiency. With a 900V high-voltage architecture and silicon carbide (SiC) power modules, the final vehicle drive efficiency of EQXX can reach up to 95%. However, if we further investigate, we may find some different conclusions.

In terms of actual power, EQXX is equipped with a 150 kW small electric motor, which limits the energy consumption of this car. This power definition conforms to the development logic mentioned at the beginning of the article, but from another perspective, the small motor will also have a direct impact on the vehicle’s power performance, including the simplest acceleration to 100 km/h.

As the world’s largest luxury brand, do you think Mercedes-Benz should launch a pure electric vehicle with acceleration to 100 km/h over 8 seconds? If I remember correctly, the small electric car P5 from Xpeng is equipped with a 155 kW electric motor.

Now let’s talk about the battery. The battery pack of EQXX is developed by Mercedes-AMG HPP (High Performance Powertrains) and the Mercedes-Benz Grand Prix race car laboratory specifically for EQXX.

This battery pack has an energy density of 400 Wh/L and 202 Wh/kg. Such high energy density is due to the high silicon content battery used by EQXX, which has the advantage of storing more energy than traditional batteries, and it also reduces the overall weight of the battery pack.

Therefore, compared with the mass-produced EQS, the volume of the EQXX battery pack is only 50% of the EQS, and the weight of the battery pack is reduced by 30%. This is also the reason why EQXX with only 2800 mm wheelbase can accommodate such a large battery pack.

Comparing with other brands, the energy density of EQXX battery pack is 202 Wh/kg, Red Flag’s E-HS9 has a battery energy density of 209 Wh/kg, and the battery density of GAC Aion LX also reaches 205Wh/kg.

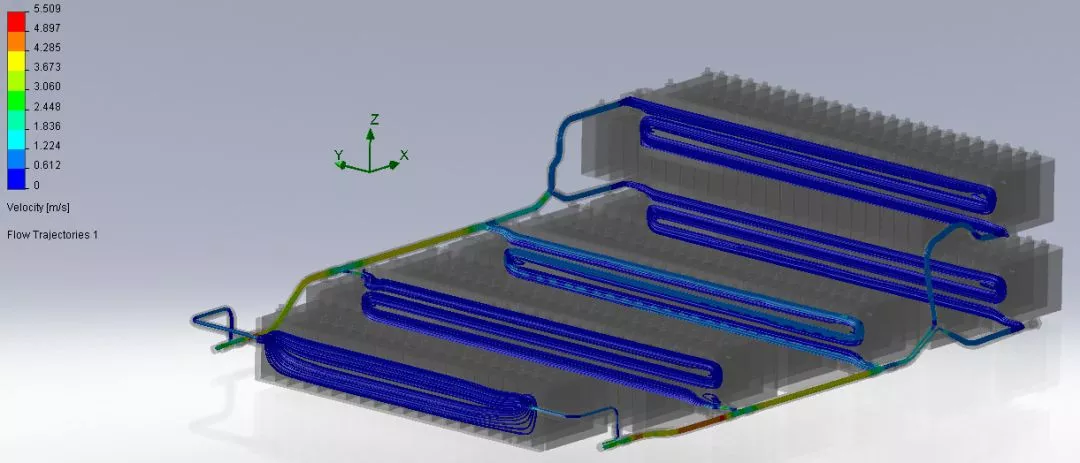

More importantly, both E-HS9 and Aion LX have complete liquid cooling and thermal management systems, which can take away heat in time during fast charging and intense driving conditions, providing better battery performance. However, the battery pack of EQXX sacrifices thermal management and adopts an air-cooled battery solution.

This means that in conditions of fast charging and intense driving, if the battery temperature rises rapidly, the input and output power of the vehicle will be limited to some extent.

Considering that both E-HS9 and Aion LX are already in production, the EQXX battery should not be considered too “conceptual”.

Compared with EQS, the 900 V high-voltage platform and SiC are indeed a good breakthrough.

However, from the industry perspective, the Tesla Model 3 began using SiC in 2017. In China, the already in-production BYD Han, next year’s NIO ET7, and XPeng G9 will all be equipped with SiC. Even in terms of positioning, except for the ET7, the Model 3, G9 and Mercedes-Benz MMA products should all be in the same price range.

The BYD Han is even more entry-level. In this regard, it is more appropriate to say that EQXX is “flattening the gap” more than “widening the gap”.

Due to the air-cooled battery, EQXX is equipped with “on-demand cooling”. Simply put, during normal driving, EQXX only cools down through the cooling plate at the bottom of the vehicle body using wind. During intense driving, the active air intake grille at the front of the vehicle will open to dissipate heat. When the vehicle is stationary and needs to dissipate heat, the backup cooling fan will be activated.

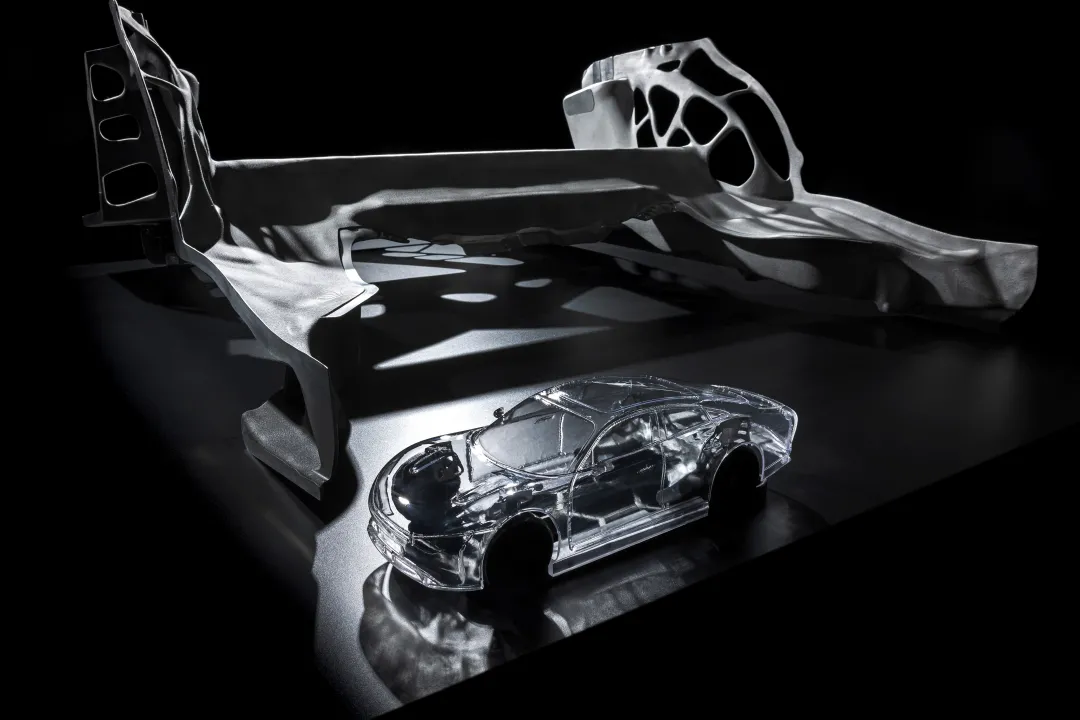

In order to achieve more extreme lightweighting, the white body of EQXX cannot escape. Mercedes-Benz uses an integrated aluminum casting on the EQXX rear window. The interface of the rear window casting is sealed with UBQ sheet material printed by 3D printing. By ensuring the rigidity and sound insulation, the weight can be reduced by 15% – 20% compared with traditional components. MS1500 ultra-high strength martensitic steel is also used in the body to achieve high strength while reducing weight.

In addition, the doors of EQXX are made of a mixture of carbon fiber-reinforced plastic, glass fiber-reinforced plastic, and aluminum, which ensures both strength and weight reduction.

EQXX has also made efforts on the wheels. Unlike mainstream electric vehicles that add low-drag wheel covers, EQXX uses lightweight magnesium material to directly create low-drag wheels. The brake discs are also made of aluminum alloy for weight reduction.

The shock absorbers on EQXX are 4 kg lighter than traditional ones. Even the wipers, springs and motor brackets have been designed to be lighter.

Unfortunately, Mercedes’ efforts were not reflected in the EQXX’s curb weight. Despite such crazy weight reduction, the EQXX’s curb weight still reached 1750 kg.

Comparing with others, the wheelbase of EQXX is only 2800 mm. The curb weight of BYD D1, which has the same wheelbase, is 1640 kg. The Tesla Model 3, which has a wheelbase 75 mm longer than Ta’s, has a curb weight of 1761 KG. Under such weight reduction, the EQXX’s curb weight did not really live up to people’s expectations.

In addition to weight reduction, EQXX will not give up the easiest way to obtain energy, solar energy. EQXX obtains energy from 117 solar panels on the roof, and under ideal conditions, it can increase the range by up to 25 km per day. However, these energies cannot drive the vehicle and can only be stored in a small low-voltage lithium iron phosphate battery to supply power to auxiliary equipment such as compressors, lights, and entertainment systems.

Mercedes is also working with its partners to further study how to use solar energy to charge the high-voltage system.

Under the conditions of ultra-low wind resistance, extreme compression of the three-electric system, ubiquitous weight reduction and solar panels, EQXX has achieved a single charge range of 1000 km.

Would you be willing to make these compromises for a 1000 km range?

More environmental protection

EQXX’s interior can be described as “environmentally friendly”. In addition to the basic principle of weight reduction, EQXX’s interior refuses to use any leather products.

The most commonly used door handles in the car have become “environmental sacrifices”. The door handles of the EQXX are made of Biosteel fibers produced by AMsilk, a degradable pure plant silk.

In addition, EQXX also uses a material called MyloTM instead of pure vegan leather products in the car. it is made from mycelium (the root structure of mushrooms). The substitute for animal leather is composed of cactus powder fibers and a biopolyurethane matrix, and the cactus content will be increased in future versions. Don’t ask me, I don’t know what it is…The carpets in EQXX are made of 100% bamboo fiber, while the floor and door decorations are made from recycled PET bottles. In addition, designers have used Dinamica materials (including 38% recycled PET) on the ceiling, connecting the integrated screen with the doors and ceiling.

The interior of EQXX also features several UBQ materials made from garbage to replace plastic products. Overall, the EQXX interior design incorporates a large number of sustainable materials to create a luxurious feel that is difficult to achieve. However, environmental protection comes at a cost, and when it comes to mass production, cost becomes a major obstacle to using these materials.

In addition to environmentally friendly materials, there is a 47.5-inch screen seamlessly connecting two A-pillars in the EQXX interior, with a resolution of 7680 * 660 pixels. The Mercedes-Benz team has also collaborated with Nafis Automotive Systems to develop a 3D real-time navigation system that can enlarge satellite images up to 10 meters high in 3D city views.

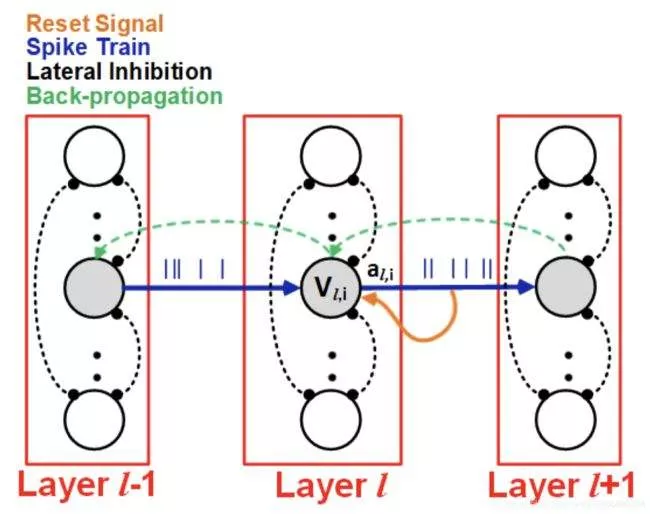

Behind the large screen is the Akida NSoC from artificial intelligence company BrainChip, responsible for the software and hardware system. Each Akida NSoC has 1.2 million neurons and 100 billion synapses, and the AI chip can implement the neural network architecture of pulse neural networks (SNN). SNNs are more like human brains, but their development is not as rapid as that of artificial neural networks (ANNs) at this stage. Mercedes-Benz only uses “Hey Mercedes” wake-up as an example, whose speed is 5-10 times that of traditional voice control functions.

SNNs may have greater potential in autonomous driving, but currently, the development of SNN neural networks is still in its infancy.

Of course, this large screen is not immune to the fate of energy conservation. The LED screen is composed of more than 3,000 local dimming zones that distribute electricity according to different screen areas. For example, when navigating in the city, a virtual view of the surrounding buildings will be displayed, while on the highway, the navigation will omit details and only show traffic information.

In terms of software, this EQXX is equipped with an energy efficiency assistant system, which can provide the most efficient driving style advice based on energy flow, terrain, power, wind direction, and even solar intensity.

ConclusionIn order to achieve excellent performance in endurance and energy efficiency, Mercedes-Benz has made every effort in both the selection of interior materials and the matching of software and hardware.

However, it must be pointed out that in the process of electrification in the compact car market, Mercedes-Benz’s technological and conceptual advantages seem to be not as comprehensive as they were in the era of fuel vehicles. This reminds people of October 6, 2020, when Ola Källenius, the newly appointed CEO of Mercedes-Benz, released his first “governing plan”, and the production pace of the compact car platform MMA was the latest among all products lines of Mercedes-Benz, indicating that Mercedes-Benz seems to be accumulating greater strength.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.