Yesterday the news of the “explosion” of Volvo’s plug-in hybrid car spread throughout social media. Regarding the battery’s structure, capacity, and chemical composition, I hold both skeptical and negative attitudes towards whether the battery could generate such a powerful explosion.

However, there is indeed a problem with the safety of the next generation of high-nickel batteries that needs to be addressed. I would like to summarize some information based on a research report entitled “Analysis of Self-ignition Problems for New Energy Vehicles” written by Tianyi and Qianye.

Iteration of Heat Runaway Protection Technology

China is the country that places the strongest emphasis on heat runaway protection technology, and the core is the large number of domestic enterprises with a wide range of applications. Therefore, in this field, China is actually at the forefront of the world (when there are many incidents of battery combustion, it naturally becomes a prominent problem that needs to be overcome by everyone).

My understanding:

First-generation heat runaway protection scheme:

For a cylindrical battery, the simplest design is Tesla’s design structure, which is the most typical. The difficulty of a square design is higher but has been overcome. Soft pack implementation has the highest design difficulty. All three battery technologies focus on strengthening heat insulation and accelerating heat dissipation as the main technical methods. Quantitative analysis is carried out through multidimensional analysis of the energy released by a single unit, unit heat dissipation capability, and peripheral heat insulation capability during heat runaway propagation.

・Cylindrical battery

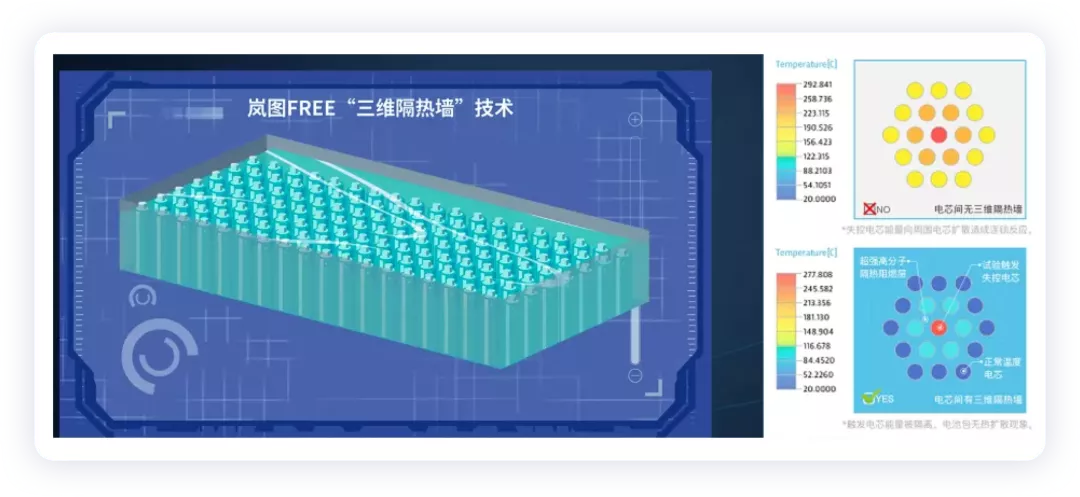

The principle of this design is to isolate the battery cells through a certain space and then use insulation materials to completely separate the heat emitted under the condition of heat runaway. Under the condition of heat runaway propagation, this material can prevent the release of energy from a single cell that exceeds 5Ah.

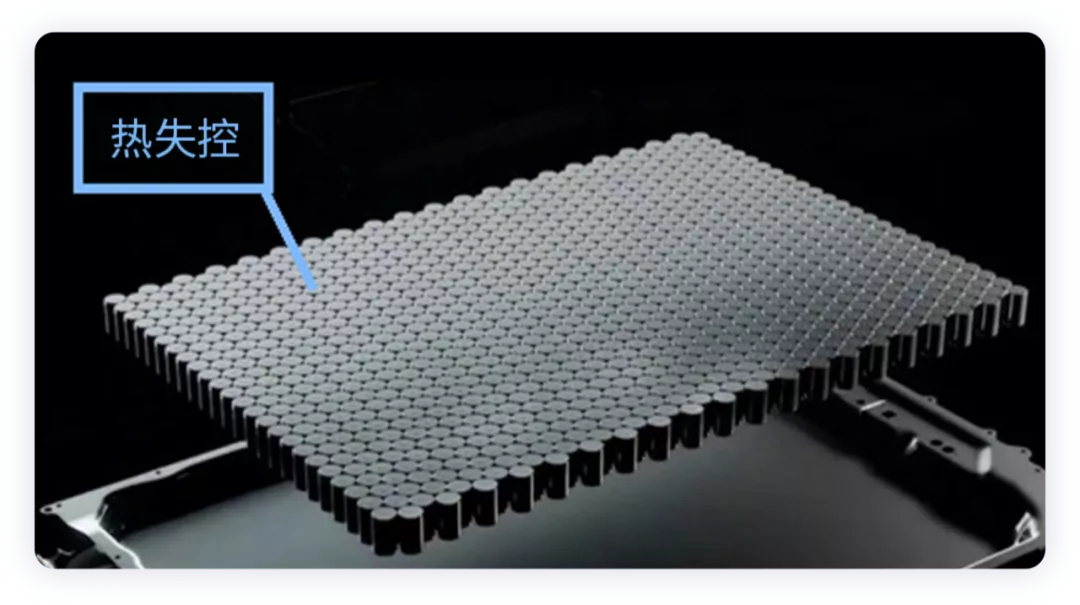

In the era of the 4680 battery, the design logic is also similar, but according to research, the direction of the valve opening of the cells is different from what we previously understood. It sprays downward and uses insulation materials to prevent users from panicking. In the CTC era, there is a layer of cells underfoot, so thermal insulation materials are needed for protection.

・Square Shell Design

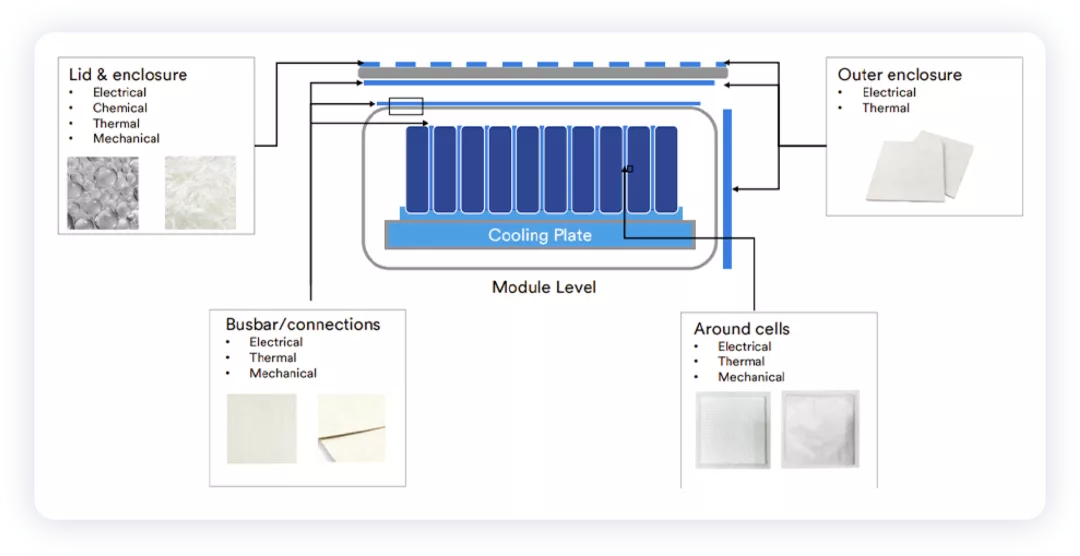

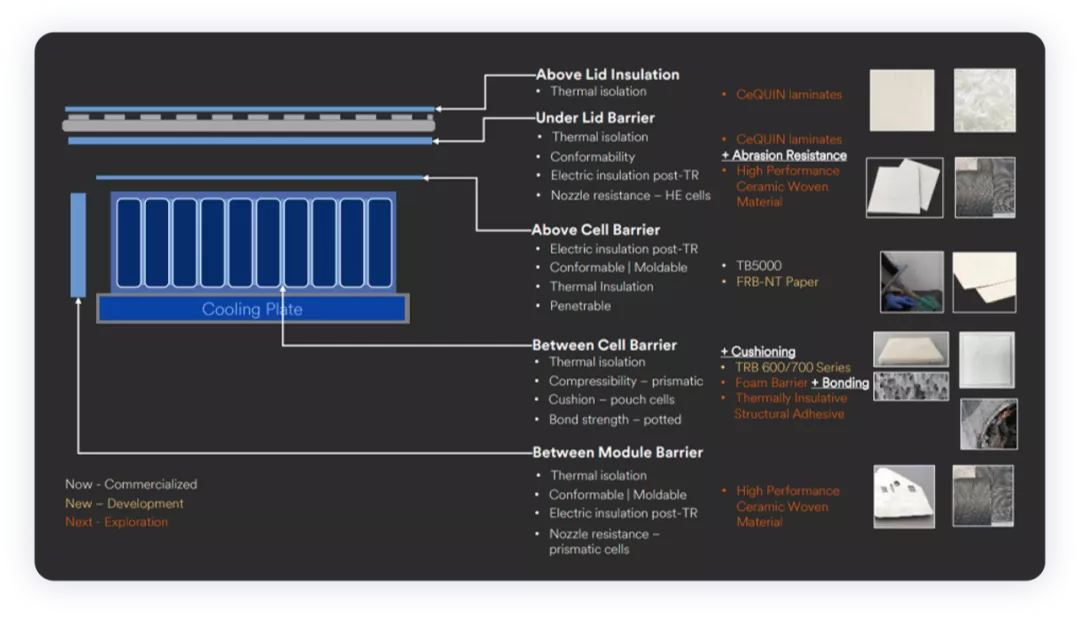

In fact, every company’s design is convergent and divided into cell-level insulation and electrical connection insulation.

This wave makes material manufacturers particularly happy. As shown in the figure below, taking 3M as an example, a series of spectra have been formed around this thermal insulation technology, and you can choose according to the material number.

Dupont, Dow, BASF, and others can play similar games. Personally, I think that this method of solving problems by piling up materials increases costs too much, and currently, it is necessary to compete with Tesla’s cost, and adding so many materials is calculated in thousands. Of course, soft-pack batteries are a different story.

Technologies that can be used in the future

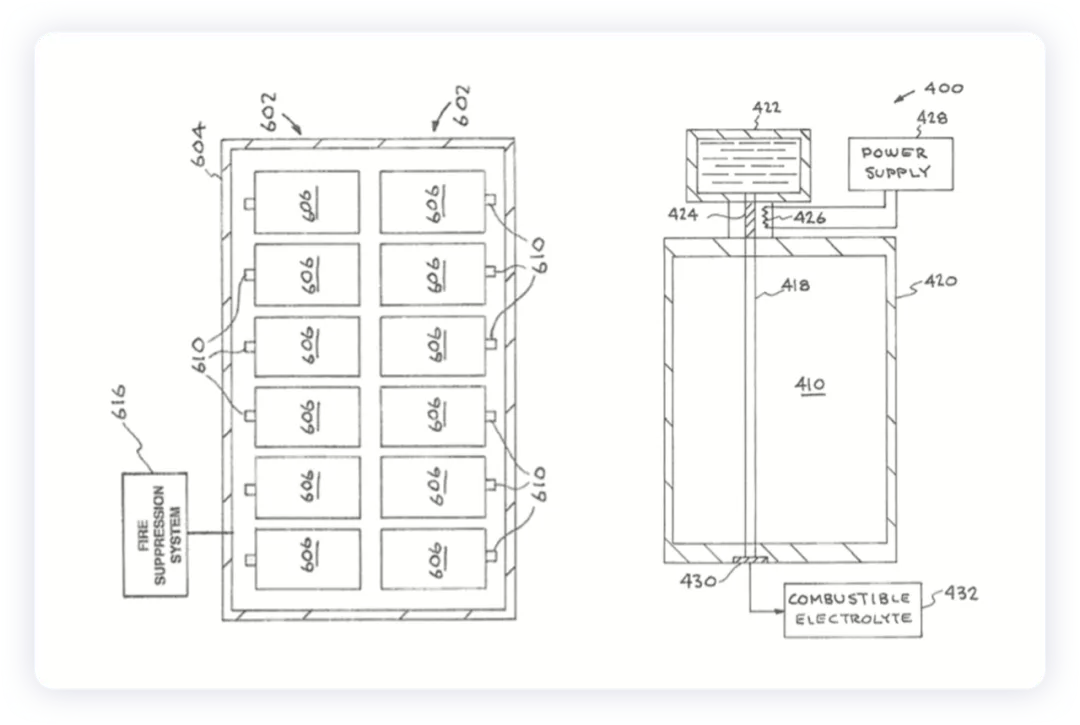

There are two directions here. The system-level thermal runaway protection plan is to extinguish the fire by pumping a large amount of cooling liquid. This technology is expected to be mass-produced by 2023. A large amount of flooding water is currently the only way to extinguish lithium-ion battery flames. In fact, this method was first proposed by firefighters in Europe and the United States, but by ingeniously designing a dedicated fire extinguishing pipeline for batteries, cooling liquid can be fully utilized in the battery pack to achieve directional injection of cooling liquid for fire extinguishing when a thermal runaway occurs.

This design is used in conjunction with the large shell electrode, and the effect of using the explosion-proof valve is better for the hard shell electrode above. For soft-packed electrodes, block injection is also a better solution.

At the same time, improvements at the cell level are also being developed, mainly focused on the key of ultra-high thermal stability materials. High-nickel electrodes can all be penetrated by acupuncture. From the current methods to solve the high nickel problem, the main methods are composite current collector fluids, solid-state dielectrics (semi-solid-state solutions also count), etc. Therefore, the latter two are in competition at this stage, and they can also make us see the feasibility of making 1000km electric vehicles.

Summary: I think that the existing protection technology is more beneficial to cylindrical batteries, so in the recent two years, it is actually difficult for the shell to suppress cylindrical high-nickel from the system cost, and lithium iron phosphate technology will become a “bargain” technology to evolve lithium-ion batteries towards standardized products.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.