*This article is reproduced from the public account autocarweekly

Author: Aohu Hu

Blade battery, magazine battery, amber battery, Dayu battery, 811 battery, 523 battery, 4680 battery, NCM battery, NCA battery, large module battery, CTP battery, CTC battery, silicon-doped lithium battery, high-nickel battery, cobalt-free battery, sodium-ion battery, lithium-metal battery, solid-state battery, solid-liquid hybrid battery, CATL Power Energy Ring battery……

Please answer the origin of each battery name without using Baidu or seeking help, with no points awarded for the last one.

I don’t know when making batteries became like giving birth to a child: ten months of pregnancy doesn’t stop everyone, but choosing a name can be a headache. The specific performance of the product is not so important, but once the name is not chosen well, “Chu Zhongtian” can become “Lin Danda”.

This is an art as well as a technique.

There are those who follow the form-and-intent school, you see this battery is so flat and long, like that blade, so there is the “blade battery”; there are those who follow psychology, although “magazine” has never been related to “bulletproof” (that’s not the job of bulletproof vests), but it doesn’t affect the public’s impression that military-related things are all tough, so there is the “magazine battery”; and there are those who follow stream-of-consciousness, you see our directional explosion-proof design, like the way Dayu controlled floods without obstructing, so there is the “Dayu battery”…

To help you remember your own battery, the sciences, the arts, commerce, agriculture, medicine, and law are all included.

As for the purely technical naming conventions like 811/523, 4680, solid-state/half-solid-state, CTP/CTC, etc., they’re not something ordinary consumers can understand with just common sense. So when the technically objective “objective term” is mixed with the manufacturer’s subjective naming, consumers are not the only ones who feel overwhelmed, even industry professionals may have a hard time deciphering it.

Cell Packaging: Blade, 4680

Let’s start with the simplest, most familiar, and easiest to understand.# Bilingual Output

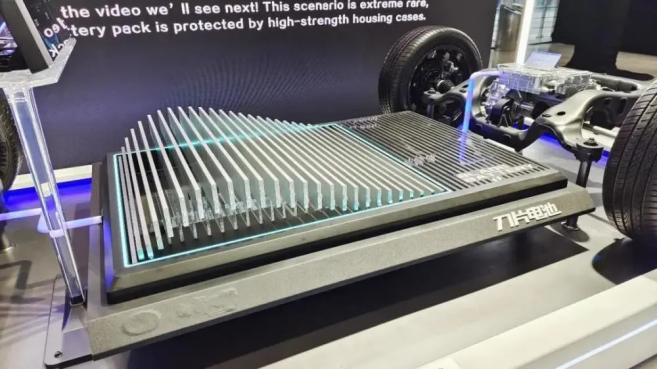

比亚迪的 「刀片电池」,实际上代表了三层含义:磷酸铁锂(电芯化学配方)、扁长形(电芯封装形态)、CTP(电芯成组方式)。而刀片这个名字,只是来自其中的电芯物理形态(长得像刀片)。理论上讲,倘若不是比亚迪使用在先(并绑定了更多含义),任何长条形电芯其实都可以叫 「刀片」。

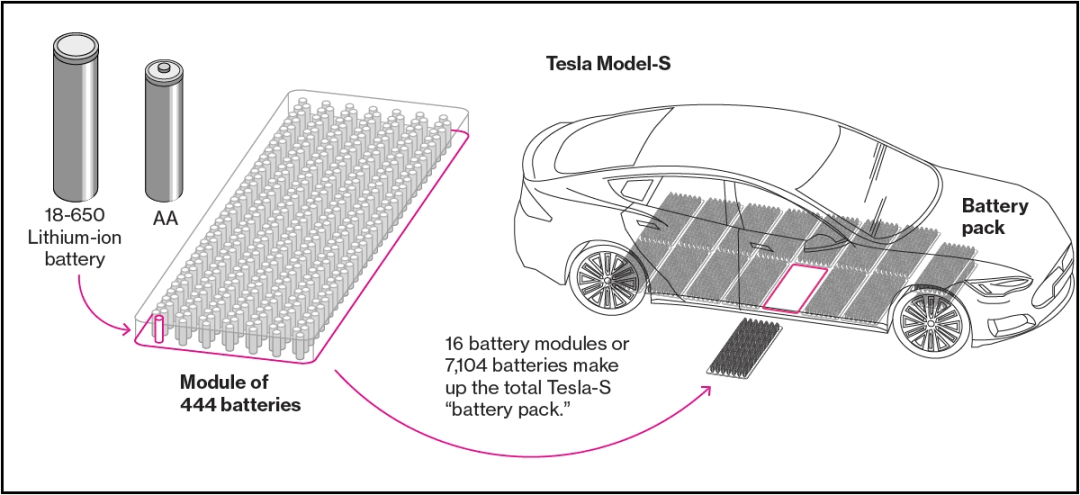

与(仅限定物理形态的)「刀片」 类似的,还有大家听了好多年的 18650、21700(2170)电池。比如 「18650」,代表 「直径 18mm、高度 65mm」 的圆柱形(最后一个 0)电芯。当你看到这样一串数字,就知道这个电芯长什么样。

所以互联网一度流传着 「特斯拉电池和充电宝一样」 的低智说法,其实 「一样」 的只是个物理规格而已。就好比我的脚是 42 码,梅西的脚也是,我也不好说我有一双和梅西 「一样」 的脚……

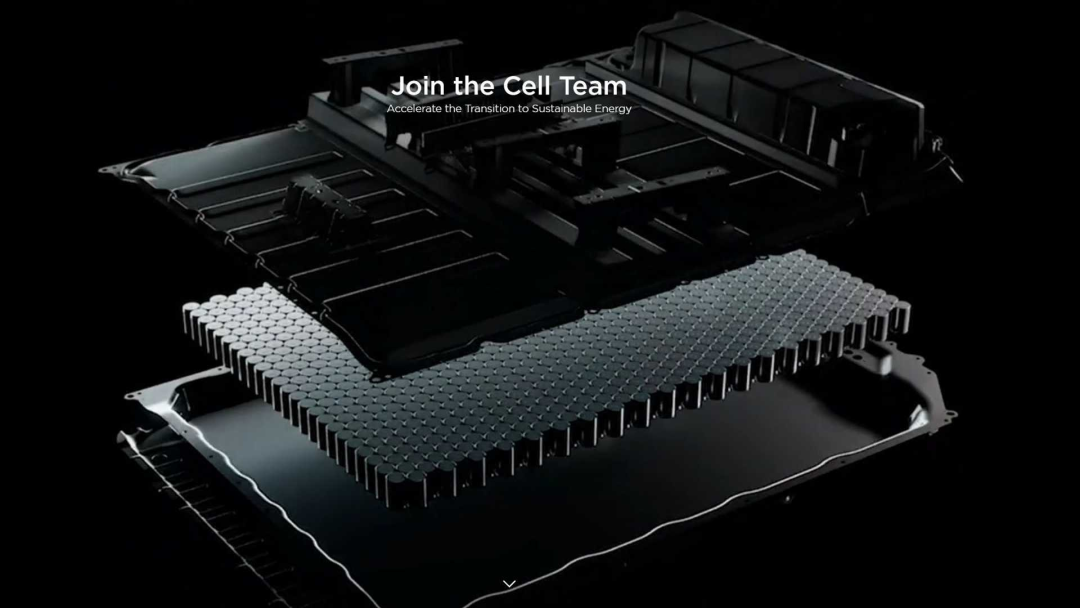

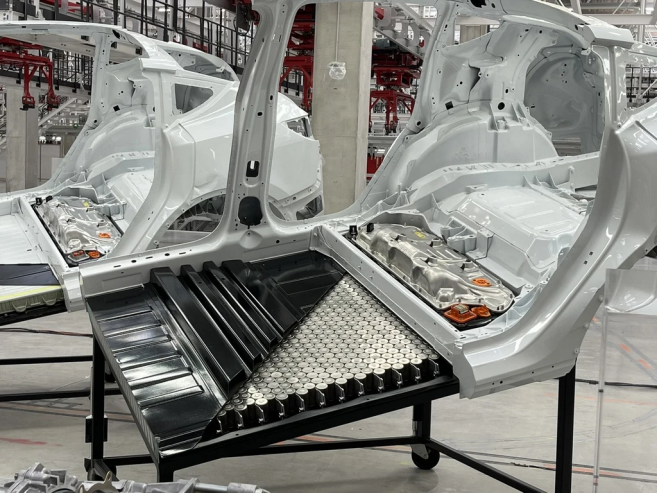

4680 是特斯拉最新一代电芯的物理规格:直径 46 mm、高度 80 mm、圆柱形。未来几年它会越来越频繁出现,直到实车上路。不难看出从 1865 到 2170 再到 4680,圆柱电芯的单体尺寸在变大。

除了这些圆柱电芯,目前电动车更常用的是所谓方形电芯和软包电芯。由于直径 / 高度有固定的组合,圆柱电芯基本都是 「有名字的」。而后两者则多 「默默无闻」,像 「刀片电池」 就是方壳中的一个特例。

这一类名字,本身仅代表着物理形状、尺寸、规格。但因为其中某些名字是与其他技术相伴而生的,这才让它们有了更多其他含义。比如 「刀片电池」 与磷酸铁锂、CTP 绑定了,比如特斯拉的 4680 与 CTC(后面说)绑定了。

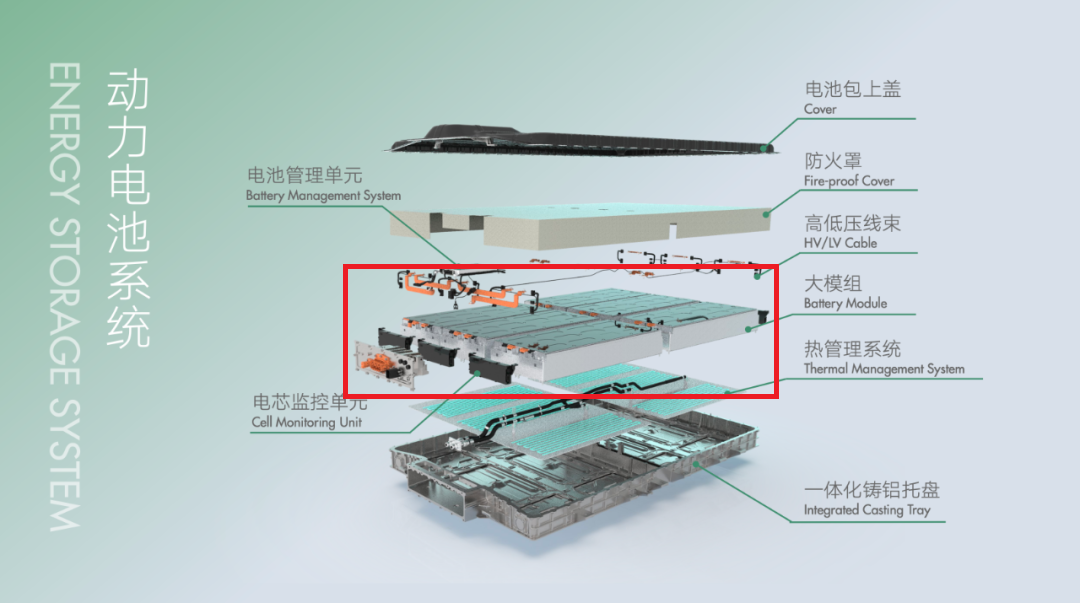

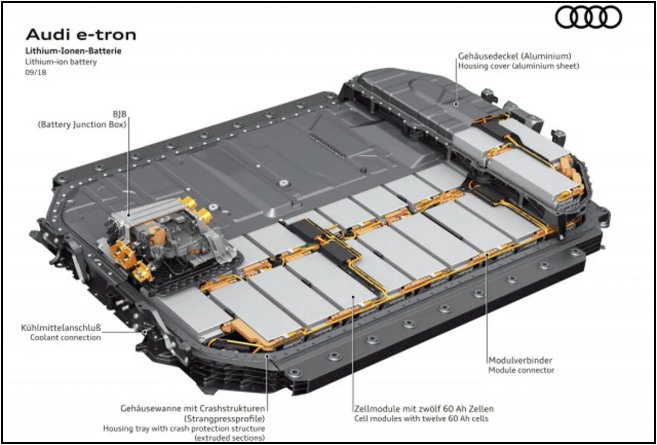

电芯成组:大模组、CTP

「大模组电池(电池包)」 和 「CTP 电池(电池包)」 是近来越来越常见的名字,它们已实现了实用化、装车、量产,正在逐渐走向主流的过程中。

As everyone knows, the cell is the smallest unit that makes up an entire battery pack. Previously, there was usually an intermediate level between the two, the module. The size of the module is a relative concept rather than an absolute one, and there is no “what size of module counts as a large module” question.

The implication of a large module is that there are fewer modules and more cells per module (conversely, smaller modules have fewer cells per module). Today, the main function of modules is to improve safety. With the same cells, larger modules mean fewer modules and less empty space between them, resulting in a higher volume energy density for the entire battery pack.

However, with large modules, there are more cells per module, and if a single cell has a problem, it may affect more cells. In essence, this is a question of “how many baskets can a given number of eggs be distributed into”.

Therefore, for large module batteries, the safety of individual cells needs to be higher, and the safety measures for the battery pack need to be tighter as a guarantee. Increasing the size of the module itself is not difficult, but maintaining the safety of large module battery packs is the key.

The ultimate development of large module batteries is to remove the intermediate module level. The entire battery pack becomes the sole module, with individual cells directly making up the battery pack, in other words, the Cell-to-Pack (CTP) technology.

As the extreme form of large module batteries, CTP battery packs require even higher safety standards. Therefore, earlier CTP battery packs used relatively safer Lithium Iron Phosphate cells, with the most typical being the BYD “blade battery”. NCM CTP battery packs from CATL have also been installed in cars, such as NIO’s 100 kWh battery pack and 75 kWh hybrid battery pack.

Tesla’s next-generation battery system, based on the 4680 cell, is also a CTP module-free battery pack, but this aspect is included in the more breakthrough CTC technology.

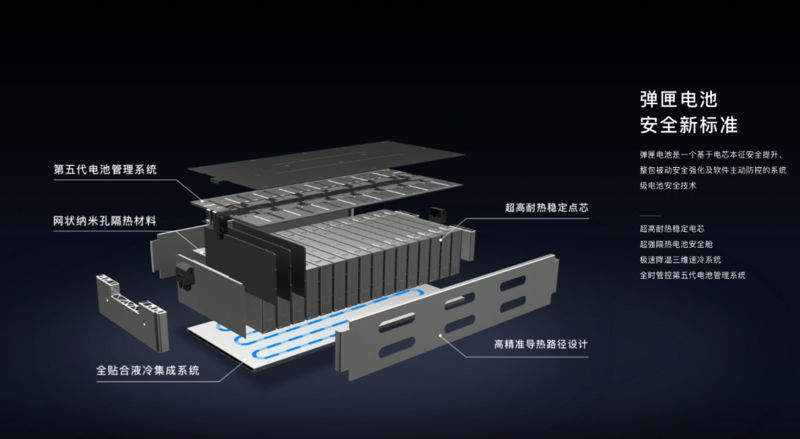

Integrated Package Technology: AmmoBox, Dayu, AmberAlthough “Magazine” and “Blade” are equally famous, or rather the most well-known battery systems closest to the blade, in fact, the naming of the two is completely different. “Blade” is directly named after an unprecedented physical shape (although it has more meanings after becoming a proprietary term), while “Magazine Battery” is obviously not “shaped like a magazine”.

This is a very conceptual naming. GAC Aion said “placing the battery in a safety cabin resembling a ‘magazine'”, but if the problem is explained in this way, which battery system does not “place the battery in a safety cabin”? Moreover, the main function of gun magazines is not to prevent the explosion of bullets inside. Can it be the same, for humans, the magazine doesn’t have this task.

Therefore, Magazine Battery is a more packaging-oriented naming. You can understand that GAC Aion has bundled a series of battery safety technologies and named them with an easy-to-understand and memorable name. Considering the effect of “surrounding” the battery core on its shape (like almost all batteries), the name of “Magazine”, which is similar in shape but different in spirit, was thought of – I guess there should be no military fans in this publicity team, otherwise they might not be able to bear the logical bug of “Magazine anti-explosion”.

The above evaluation only applies to its naming, and does not involve the performance of the battery.

For Great Wall’s Dayu Battery, the concept-based naming of “just naming” is even more obvious – obviously, batteries cannot be like Dayu (humans). Obviously, Great Wall does not hide this fact. The naming of Dayu Battery comes from its explosion-proof design concept of “turning blockages into smoothness”. The greatest feature of “Dayu” is the design of multiple directional explosion vent channels, which can lead the burning and explosion out of the battery when thermal runaway occurs.

“Magazine” and “Dayu” are very similar in naming style. Although GAC Aion has a shape explanation for Magazine Battery, this explanation is somewhat far-fetched, while the conceptual meaning of Dayu Battery is closer. As a battery system with conceptual naming, the main features of both are at the level of the entire battery pack: designing insulation materials, improving cooling systems, and setting explosion-proof valves, etc.

Alternatively, we can understand that if the Magazine/Dayu Battery is equipped with “Blade” battery cells, it becomes “Magazine/Dayu Battery using ‘Blade’ battery cells”.Not all technologies at the whole package level can only be named conceptually. The LanTu Amber Battery is named for its use of insulation material inside the battery pack, which provides individual protection for each cylindrical cell to prevent heat diffusion. This “named after its shape” approach is more like “blade” than “magazine”, even though the two have completely different technical focuses: Amber is like the insulating gel inside the battery pack, while “blade” is like the cell.

CTC stands for Cell-to-Chassis and is classified as a battery package technology. This is somewhat far-fetched because CTC no longer has an independent “battery pack”, and the battery housing is integrated with the vehicle chassis/underbody. This has extended beyond the battery system and involved changes to the vehicle body structure, so it can be considered a part of electric vehicle body design.

The next-generation batteries Tesla uses with its 4680 cells use a CTC structure meaning Cell-to-Chassis rather than Cell-to-Module-to-Chassis, meaning that the CTP concept is included in CTC. CTC reduces the layer between the cell and the body significantly and can significantly reduce vehicle weight and improve performance and increase endurance.

Tesla recently demonstrated its CTC battery pack in Germany, and production is expected to begin in the next year or two. Volkswagen has also announced its intention to use CTC technology in the next-generation electric platform. CATL has also announced a CTC development plan, but as CTC involves white-body integration, it may be challenging for battery suppliers.

Electrode Materials: High-Nickel, Cobalt-Free, Silicon-Doped Lithium

For those familiar with electric cars, you are probably familiar with lithium iron phosphate and ternary lithium. You should also know the two main formulations of ternary lithium, NCM cobalt-free manganese and NCA cobalt-free aluminum. You may also be familiar with the “classic ratio” of NCM, 5:2:3 and 8:1:1, the former being more conservative and the latter more aggressive.

Here, lithium iron phosphate, NCM, and NCA refer to the materials used in the positive electrode of the battery. Currently, the negative electrode materials are mostly graphite, and the electrolyte (electrolyte) is an organic solvent containing lithium salt.Developing three-element lithium with stronger potential, the current trend is to increase the nickel content and decrease the cobalt content (as seen by the development from 523 to 811). Therefore, high-nickel batteries, low-cobalt batteries, and even cobalt-free batteries have emerged, all of which describe the cathode material of the battery, but are not as specific as “523” and “811”.

Nickel is the key to increasing energy density, but too high nickel content can bring challenges to stability and cycle life. Conversely, cobalt’s role is to suppress the confusion caused by nickel ions, thereby improving stability and prolonging the life of the battery. At the same time, cobalt is a toxic rare metal, with expensive prices, limited production, and human rights issues in mining being a global challenge.

The difficulty of high-nickel batteries is the stability of the battery after increasing the nickel content, while cobalt-free batteries require finding other means, such as nano-level microstructures, to replace cobalt and perform the role of improving stability and prolonging life.

Tesla has been committed to reducing and even eliminating cobalt, with the goal of reducing cobalt content to only 3% in the next generation of products. Currently, the true cobalt-free battery is being mass-produced and installed in vehicles by a company under Great Wall Motors, called Beijing EFC energy Co., Ltd.

As for the negative electrode material, the recent trend is to add silicon, yes, the silicon used to “supplement lithium”. Because the currently used carbon negative electrode is close to its capacity limit, it has become the bottleneck for lithium batteries to increase energy density, while the coulomb capacity of silicon is more than ten times that of carbon. However, there is a problem with the large volume change of silicon during charging and discharging, so the current practice is to gradually increase the silicon content in the carbon-silicon negative electrode.

A more radical measure is to replace the graphite negative electrode with lithium metal, which is a future battery technology that has not yet been put into mass production.

Lithium metal batteries are not a new term, but previous lithium metal batteries were disposable batteries, not rechargeable batteries. This is because during charging, metallic lithium will deposit irregular dendrites on the negative electrode, and the growth of the dendrite can pose a risk of puncturing the battery shell, leaking, and short circuiting.On the other hand, using lithium metal instead of graphite as the negative electrode greatly increases the amount of lithium ions that the negative electrode can provide during discharge (after all, the entire electrode is made of lithium), which has a significant effect on improving energy density. Under this temptation, some people still invest in lithium metal batteries, such as SES, which uses a special mixed electrolyte to solve the problem of dendrites, transforming the growth of sharp dendrites into dense deposition.

The lithium-metal battery sample just demonstrated by SES has a single-cell energy density of an astonishing 417Wh/kg, which has already reached the target energy density of future solid-state batteries. Moreover, the only thing that the lithium metal battery has changed is the negative electrode and electrolyte; there is still room for improvement in the solid-liquid state of the positive electrode material and electrolyte.

Electrolytes: Solid-state and Semi-solid-state

Solid-state batteries, which sound like science fiction, are probably the most common category of “future batteries.” Even Toyota’s Akio Toyoda, who is always dissing electric cars, has said that he is not pessimistic about electric cars but about lithium-ion batteries with liquid electrolytes; he needs to wait for solid-state batteries to come into position.

The electric cars we can buy now, whether lithium iron phosphate or ternary lithium, no matter whether it’s a blade or a magazine, NCM811 or cobalt-free, cylinder or square, 2170 or 4680… all without exception, their electrolytes are purely liquid (electrolytes).

Liquid electrolytes have many troubles – most things are more troublesome in liquid form than in solid form, such as rocket fuel. As long as it is a liquid, there is a risk of leakage, and the risk of short-circuit caused by electrolyte leakage has always been a key consideration in developing battery systems by major manufacturers.

The organic solvents used in liquid electrolytes are usually flammable, and solid-state electrolytes are much safer (and less prone to leakage), which provides a prerequisite for improving energy density. The development of batteries has always been wavering between energy density and safety and stability. In addition, the volume of solid-state batteries is more compact, allowing the use of lithium metal electrodes (SES lithium-metal batteries are solid-liquid mixed electrolytes), further pushing up energy density.

However, solid-state batteries are still far from practical, and the main challenges are the conductivity, fast charging capability, and production costs of solid-state electrolytes, etc. The current mainstream view is that solid-state batteries will not truly mature until after 2025. Before that, only semi-solid-state batteries that are a mixture of solid and liquid may be commercialized earlier.

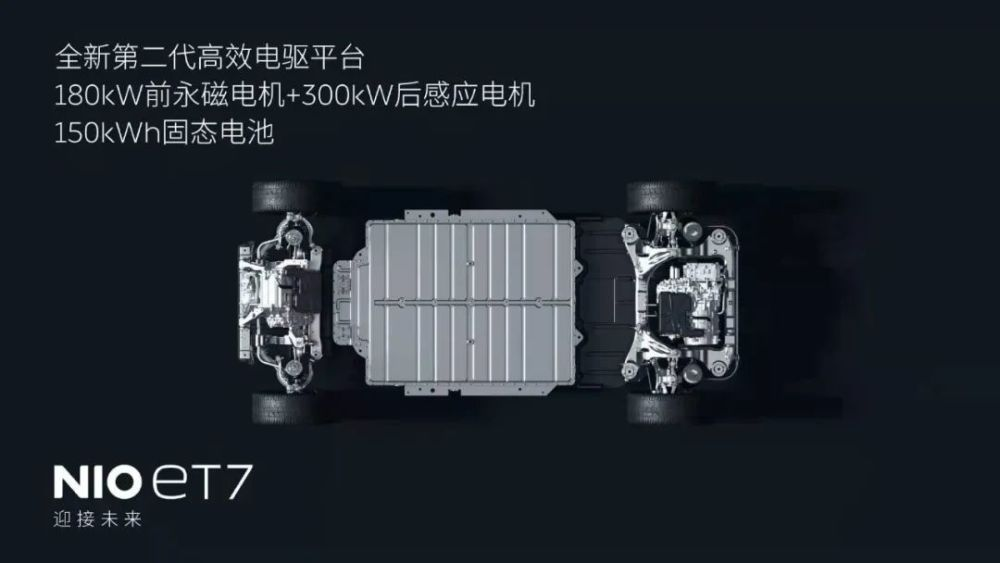

NIO’s solid-state battery is not entirely solid.# Introduction

The so-called solid-state battery that NIO claimed to launch with ET7 and announced to be put into production by the fourth quarter of 2022, later proved to be a semi-solid-state battery with some liquid electrolyte present, rather than a fully solid-state battery. Similarly, the “silicon doping” proposed by the IM Auto also incorporates some features of a semi-solid-state battery.

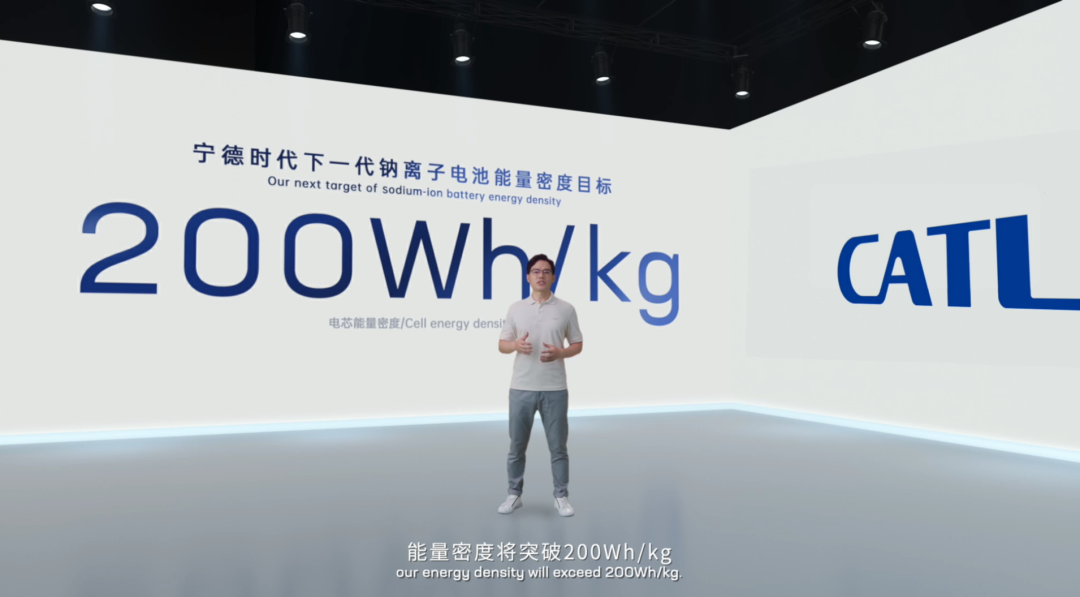

Compared with all other lithium-based batteries, the sodium-ion battery released by CATL this year is a completely different story. As a totally new charging battery, it is still in the early stage of development. Lithium is undoubtedly the best battery material as the metal with the lightest molecular weight, while sodium has a molecular weight that is only heavier than lithium.

The aim of the sodium-ion battery is not to replace the ternary lithium battery, but to compete with the lithium iron phosphate battery that has reached its peak in energy density and has an advantage in cost. Since both are pursuing cost-effectiveness, sodium, which has abundant reserves and low prices, may have advantages over lithium, whose prices are rising and mineral resources are imported, in the long run. However, currently, the sodium-ion battery is still in the early stage of development.

Conclusion

There are too many names for batteries, and I can hardly hold them all in my mind.

Some of them are objective facts, as new technologies naturally bring new names. Others are subjective wills, packaging and summarizing their selling points with simple and memorable names. Some names make people feel excited and curious, while others make people feel overwhelmed.

However, the market perception is that a good name is not everything, but not having a good name is a major drawback. Consumers always tend to summarize problems and hope to get a straightforward “A or B” answer, even if A and B are not comparable. Blade or magazine? Which one is better, Tesla 4680 or NIO solid-state battery? These are questions that cannot be answered and are not even meaningful.

Although there are some successful cases, following suit without careful consideration will not necessarily lead to good results. Conceptual naming is a double-edged sword. If it is well grasped, it can be easily understood at first glance and further strengthen memory retention. However, if it is awkwardly forced, it may only leave an impression of “Is that it?” after being seen through.

What is worse than not having a good name is to hollowly name something just for the sake of naming it.