Rapid Expansion of Domestic Lithium Iron Phosphate (LFP) Market

Since the second half of 2020, private purchases have become the mainstream of EV development in China. Consumers demand higher mileage, faster charging speed, and safer batteries. Lithium iron phosphate batteries have been widely used in the middle- and low-end electric vehicle models due to their longer lifespan and lower cost, while ternary lithium batteries are mainly used in medium- to high-end electric vehicle models for their higher energy density and lower overall energy consumption.

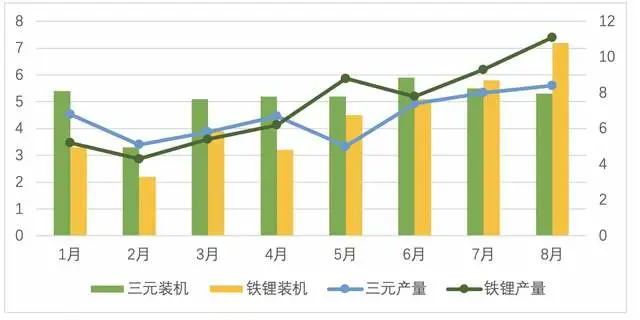

The debate over battery technology is still ongoing. However, as of 2021, for the first time in March, the production volume of lithium iron phosphate batteries exceeded that of ternary lithium batteries, and in July, the installed capacity of lithium iron phosphate batteries also surpassed that of ternary lithium batteries. Furthermore, the gap between the two technologies continues to widen in August. It is apparent that after the improvement of energy density, lithium iron phosphate batteries have gained a significant breakthrough in A00, A0, and A-class vehicle models due to their excellent cost-effectiveness and safety features.

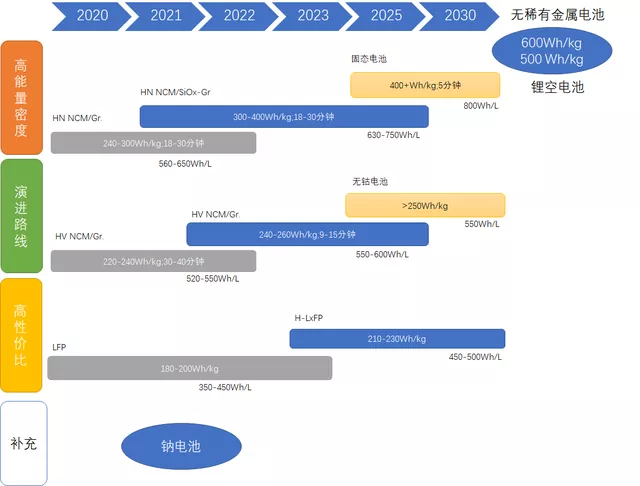

Domestic battery companies have made progress in promoting cost-effective electric vehicle batteries, equating them with lithium iron phosphate materials. Lithium iron phosphate has the advantage of requiring less metal and currently has an energy density range of 180-200Wh/kg (volume energy density 350Wh/L-450Wh/L).

Since 2017, due to the suppression of subsidy policies, the monopoly of ternary batteries in passenger EVs has been greatly challenged. For now, the energy density of middle-nickel battery cells at 240Wh/kg has not widened the gap with lithium iron phosphate batteries. The application of high-nickel battery cells has been restricted due to an increase in fires in recent years. Battery safety has become an essential consideration for consumers when purchasing electric cars. Safety concerns are mainly reflected in the battery technologies. “No fire” is the most critical and challenging problem for battery safety. The development of ternary batteries can bring more mileage, but how to solve the safety problem is yet to be solved.The industry’s design solutions include NIO’s non-flammable battery, GAC’s magazine-style battery, Great Wall’s DY battery, and Geely’s SEA platform battery. Recently, Voyah Motors released the Amber and Mica battery systems.

Amber and Mica Battery Systems

(1) Amber Battery

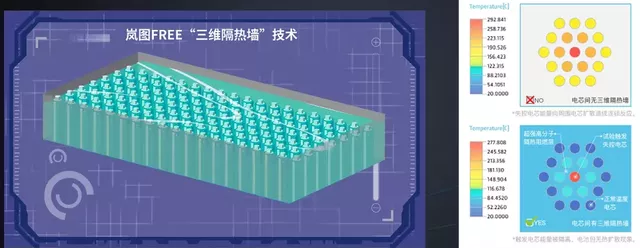

According to the official statement, the “Amber” battery system’s 3D insulation wall technology fills the battery pack with special organic silicon composite materials, combined with organic silicon polymers, low-density insulation materials, and flame retardants to form an efficient insulation and flame-retardant insulation layer, so that each battery cell unit is fully packaged like “amber”.

In layman’s terms, according to the materials released by Voyah Motors, the design structure of the module is to use high-energy-density ternary batteries, isolate them according to a certain space, and fully separate the heat generated by the battery cells under thermal runaway conditions by filling them with insulation materials. This material can block the energy emitted by a single 5Ah or above (NCA + silicon-carbon, with a high energy density) battery cell under thermal runaway propagation conditions, but the heat generated during fast charging will also be blocked. In the schematic diagram below, we did not see the cooling structure inside the module.

It can be said that Voyah Motors is the first among all mainstream domestic automakers to choose cylindrical batteries. With the future upgrade of 21700 to 4680, Voyah’s 21700 Amber battery can be upgraded to the 4680 large Amber battery, while the overall design can remain almost unchanged.

In Amber’s solution, the main way to achieve thermal runaway protection is through module design, which has been fully proven in Tesla’s millions of electric vehicles. I believe that the cylindrical technology route is still rarely used in China.

The Voyah FREE electric version model uses this cylindrical Amber battery, and also uses Samsung SDI’s NCA high nickel 8 series battery cells, which is also a rare differentiated choice among domestic pure electric BEVs.

(2) Mica Battery

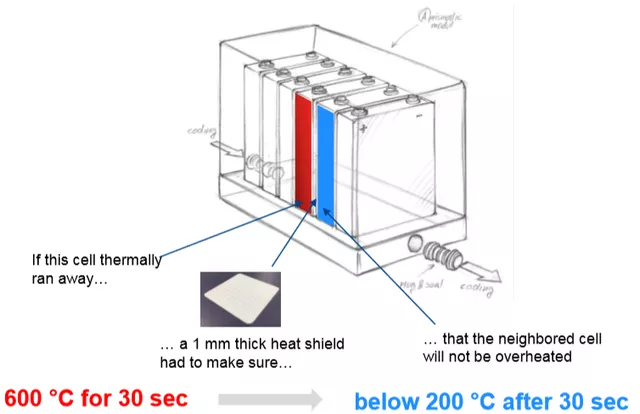

The mica battery system is applied to the Voyah FREE extended-range version. The term “mica” refers to the addition of layered Al-Si mica and aerogels between the square shell battery cores.

This approach is actually quite common, as shown in the following figure:

In my personal opinion, ternary batteries actually need to be combined with DC fast charging. As high-end electric vehicles require both longer range and faster charging speed, ternary batteries are actually more suitable for fast charging than lithium iron phosphate. In the long run, the strategy for high-end electric vehicles is to reduce the weight of the battery and improve the charging speed, with safety being the guarantee to fully tap into the boundaries of fast charging current.

Summary: Voyah chose cylinders as its strategic direction in pure electric vehicles, which I think is still very interesting. It can still achieve differentiation through the upgrade path of the 4680. In the extended-range version, it has implemented thermal runaway protection and introduced mica batteries, which is also a very interesting design. Normally, PHEV batteries with low energy density do not need such protection, but there are still certain risks if protections are not implemented for the PHEV cells in the 8 series.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.