Author: LYNX

As the saying goes, it’s not about the wealthy having money, but the wealthy also working hard.

Elon Musk, the CEO of Tesla, just attended the “Giga-Fest” public event at the Tesla Berlin mega factory on Friday, just after holding a shareholders’ meeting in the United States.

Regarding the Tesla shareholders’ meeting a few days ago, the Supercharger station summarized it as “tasteless but regrettable to give up”. Relevant information can be reviewed by clicking here, so I will not go into details.

As for the shareholders’ meeting, our editorial department unanimously recognized that the most interesting part was not about how much achievement Tesla has made and how many cars they plan to sell in the future, but the following live question:

Q: When will Tesla manufacture cars outside of Earth?

Musk: “Extraterrestrial factory? That’s a cool idea. I like your way of thinking. Of course, it will be many years before we build a factory outside of Earth. But from my own perspective, it may take about 40 years, and hopefully I can achieve it before I die.

In fact, as Tesla has been selling better and better in recent years, Musk’s “obsession” with factories has also deepened. After launching the “SEXY” product line which includes the Model S, Model X, Model 3, and Model Y, he has repeatedly stated in interviews that “factories are a sexier product than cars.”

Compared with the extraterrestrial factories still in good fantasy, Musk probably has more complex feelings towards the Berlin factory, which is different from the Shanghai super factory that received strong support from the Chinese government and had a rapid construction. The process of Tesla building the Berlin factory has been full of twists and turns, including but not limited to:

The impact of the COVID-19 pandemic. This is easy to understand. Tesla announced the Berlin factory in 2019 and officially started construction in 2020. However, what happened later was felt by everyone. The global spread of the COVID-19 epidemic has made delayed work a common phenomenon in daily life, and the construction of the Tesla Berlin factory has not been spared.

Complaints from local residents and environmental organizations about the construction of the factory. Several German environmental organizations have sued Tesla multiple times, citing reasons ranging from pollution of drinking water due to factory construction to deforestation, noise issues, and disturbance of ant colonies in the soil and hibernation of bats and snakes in the forest.

Although Tesla later won the lawsuit, the flattening and excavation work on the factory land still encountered a lot of obstacles.

Lengthy government administrative approval process. Compared with the regulatory authorities in China giving Tesla’s Shanghai factory construction a green light, the approval process for the construction of the Berlin factory fully demonstrates the “thoroughness” of the Germans. Even today, Tesla still has not completely obtained all the government approvals required for factory construction and production.

Of course, Germany is the “hinterland” of the global automotive manufacturing industry, and how much jockeying between local car companies and government departments is behind this is unknown to outsiders.

In the end, the planned Berlin factory, which was supposed to start production in July of this year, has not yet been completely built today, but it is close enough. Therefore, at the beginning of the article, Musk hurriedly flew from the United States to Germany to attend the factory’s completion ceremony.

Compared with the serious and tense atmosphere of the shareholder meeting, the Berlin factory completion ceremony was packaged as a big party by Tesla. The company invited more than 9,000 residents and their children from the local area to enter the factory and feel the roar of the machines.

The site was arranged like a lively market, with flashing lights, noisy electronic music, and a towering Ferris wheel rising from the ground. At first glance, one might think that Tesla built a Universal Studios in Berlin instead of a factory.

After all, this is a car company event, and it is not just about eating and drinking; test drives are also a must.

## On the Construction Completion of the Shanghai Factory

## On the Construction Completion of the Shanghai Factory

During the kick-off ceremony of the Shanghai factory, Elon Musk excitedly danced. However, during the event in Berlin, perhaps because the progress of the factory was not that thrilling, he didn’t demonstrate the same enthusiasm for colors, but chose a more difficult performance – delivering a speech in German.

In front of the live audience, Elon stutteringly delivered various information about the Model Y product highlights and future plans for the factory in his broken German. Occasionally, a sentence or two of English word “whatever” slipped out between his German speech.

Whenever he finished a complete sentence in German, the audience cheered and applauded. They constantly cheered Musk on, shouting “You can do it!”

Anyway, the day-long ceremony ended amidst the joyful noise. As for the content of concern, it was pretty scattered like at the shareholders’ meeting a few days ago.

From Elon Musk’s stuttering German speech and the pictures shown on the spot, the following summary can be roughly drawn:

Currently, the production of parts has started in the Berlin factory, but it will take some time before the first Tesla model can be produced due to the lack of official approval from the government… But once the approval is obtained, the factory can start the vehicle production within two hours.

At the current pace, the Berlin factory will officially start production in November and December, and the first German-made Tesla will be delivered in December.

The degree of automation in the factory is very high, with 445 robots just on the white body production line. On the notice board on site it is written: “Robots can perform welding, riveting and bonding of car parts and other tasks. With their high accuracy and fast movements, these robots can produce one Model Y body every 45 seconds.”

Tesla fans have calculated based on this data that the Berlin factory can produce 700,000 cars per year at full capacity. Even if 10% of the time is deducted for robot maintenance, at least 600,000 cars can be produced each year.According to Musk’s reply, “Berlin factory is expected to achieve 45 seconds of continuous production cycle. It can maintain normal operation for an average of 75% of the time each week. If running 24/7, it can produce about 10,000 cars per week.”

By this statement, the Berlin factory can produce up to 520,000 cars per year, which is consistent with Tesla’s previous estimate of 500,000 peak capacity for the Berlin factory.

However, Musk also stated that “It is easy to produce the first car at the factory, but the difficult part is mass production.” He estimated that it would take at least a year for the Berlin factory to reach peak production, which would be at the end of 2022.

For comparison, the annual capacity of Tesla’s Shanghai factory is currently 450,000, and it has been almost two years since its official production.

After the Berlin factory’s peak capacity of 500,000, its production capacity will exceed Tesla’s annual delivery volume in Europe last year, and Europe will no longer need to import Tesla from China.

However, at present, all parts of the Berlin factory are imported from China, and for a considerable period of time in the future, parts will need support from Tesla China.

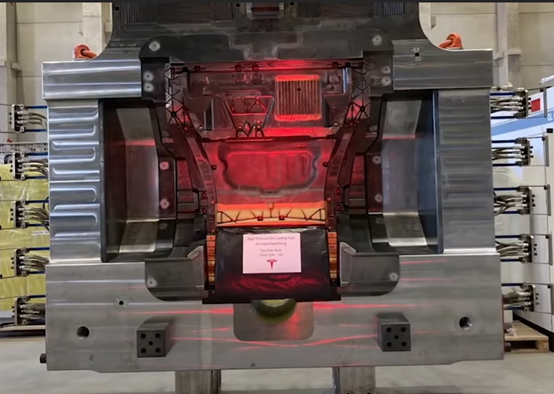

In addition to the robots on the production line, another device that people are generally concerned about in Tesla’s factory is the large-scale die-casting machine.

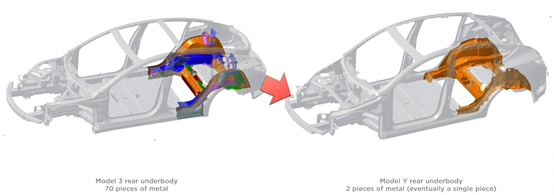

In 2020, Tesla announced that it would use innovative car-making methods and use single-casting to directly cast more than 70 components in the lower half of the car’s rear into one piece to improve production efficiency. To achieve this goal, Tesla designed the world’s largest die-casting machine, which is equipped in both California and Shanghai factories.

The Berlin factory will also use this casting process. At the same time, Musk stated that the front components of the Model Y will also “soon” use the same process to further improve production efficiency.

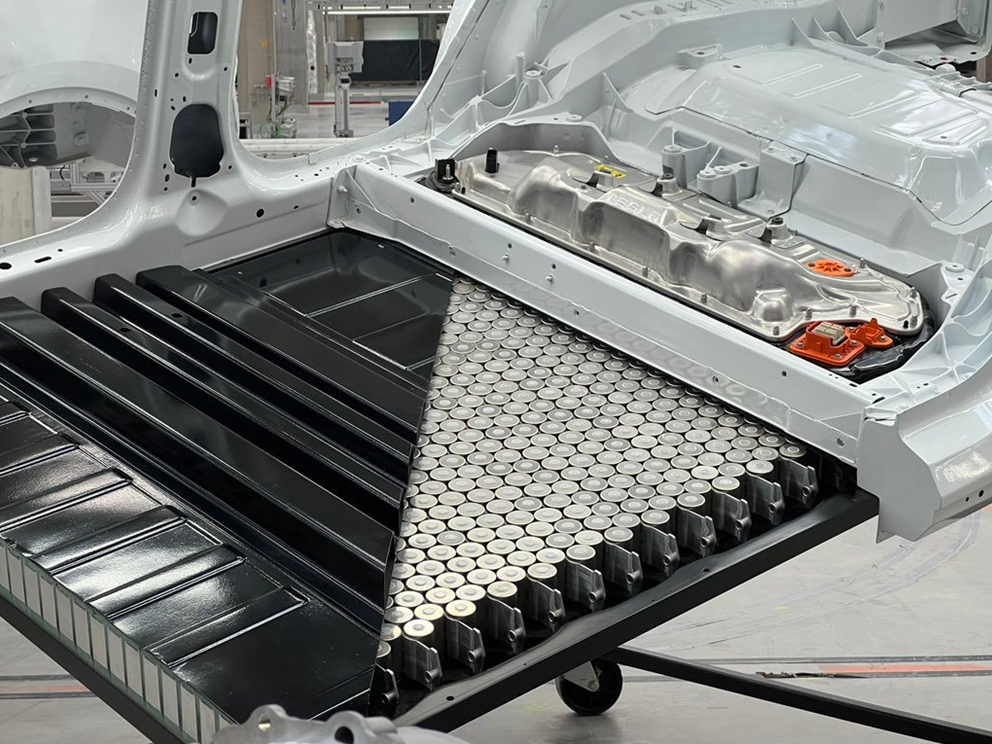

In addition to the body, the most critical component of an electric vehicle is the battery. At the Berlin factory site, Tesla also showcased a Model Y body equipped with a 2170 battery pack and a body equipped with a 4680 battery pack.“`

From the images, the most intuitive feeling of the 4680 battery pack is its “fatness”. According to the information released by Tesla during Battery Day in September last year, this battery pack has a longer lifespan, lower cost and more affordable price. For related information, please refer to our previous report: Tesla Battery Day: Musk’s Third Secret Master Plan.

Tesla’s goal is to equip the Model Y produced in Berlin with the 4680 battery pack. Currently, this battery pack is only being pilot-produced at the Fremont factory in the United States.

At the same time, Tesla has previously submitted a plan to invest 5 billion euros (approximately US$5.8 billion) to build a battery factory with a production capacity of 50GWh next to the Berlin factory, exceeding Volkswagen’s planned 40GWh production capacity factory in Salzgitter. Musk hopes that the battery factory will achieve mass production by the end of next year.

However, it is believed that European consumers will need quite some time to buy the Model Y with the 4680 battery pack. Because Musk said that the current battery supply for the Berlin factory still comes from China, which may also mean that the Model Y with the 2170 battery pack will be launched at the Berlin factory first.

I wonder if Europeans will choose to “buy early and enjoy early” or will they continue to wait?

Regarding new models, Musk stated that “the Berlin factory’s future plans will also produce the Cybertruck electric pickup”, but this is subject to regulatory approval and the availability of enough workers. In addition, “the Berlin factory may produce a smaller Tesla model” – whether it is called Model 2 or not, a smaller and cheaper Tesla is definitely a done deal.

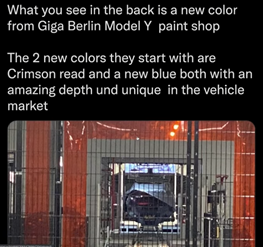

Compared with some vague electric pickup trucks and low-priced models, what is more certain is that the Model Y produced in the Berlin factory will have new colors.

“`Tesla stated that the Berlin factory has the most advanced painting production line worldwide, which can provide more stunning colors with subtle variations under the sunlight.

During the factory’s inauguration, we also saw a special color Model Y, but it is uncertain whether this flamboyant color will appear in mass-produced cars.

Finally, as it is Tesla, we cannot forget to talk about the autopilot.

Musk stated that FSD beta, the fully autonomous driving testing software currently being tested in the US, is likely to be equipped on Tesla models sold in Europe, and the current software is already “as perfect as possible and close to completion.”

These are all the main contents of the Tesla Berlin factory’s opening ceremony. After reading this, what do you think?

During the shareholders’ meeting a few days ago, Musk set a new goal for Tesla: to achieve an annual sales volume of over 20 million electric cars by 2030. After the Berlin factory is put into production, Tesla will have completed the puzzle of electric vehicle production in the US, China, and Europe, which undoubtedly provides strong support for this goal.

During the meeting, when asked if Tesla would build factories in other countries in the future, Musk said that expanding the capacity of the current four factories is still Tesla’s most important task, and it may build new factories in other places, perhaps making a decision in 2023.

Behind the dazzling parts and robotic arms at the Tesla Berlin factory, the most symbolic meaning lies in the fact that the pioneer of electric vehicles finally brought the battle to the homeland of fossil fuel-powered cars, Germany.

Next, let’s see how the traditional fossil fuel car giants will face this “electric shark” that swam to their front door.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.