On October 10, 2021, in Chongqing, FAW-Volkswagen completed the industry’s first dual dummy side pillar impact test challenge.

As the market trend is increasingly favoring new energy vehicles, many new or replacement users are starting to prefer electric vehicles. However, safety concerns regarding electric vehicles have always been one of the core reasons that prevent many consumers from embracing electrification and intelligence.

The core of electric vehicle safety is battery safety. Although the puncture experiment is one of the indicators, real collision situations are far from being standardized by simply piercing the battery pack with one needle.

For new energy vehicles, in addition to considering the overall collision safety of the vehicle, battery safety after a collision must also be considered. The battery pack of new energy vehicles is usually arranged flatly on the bottom of the vehicle body. Compared with frontal and side collisions, the collision point of side pillar impact is closer to the battery pack, which means that the cushioning space is extremely small and the stability of the battery pack is more demanding. However, the most rigorous side pillar impact test in the side collision has not yet been officially implemented in domestic safety testing standards.

This time, FAW-Volkswagen’s ID.4 CROZZ dual dummy side pillar impact test placed a child dummy in the rear seats, and regarded the safety protection of rear-seat children as an important evaluation index. Actively challenging the dual dummy side pillar impact test that is more rigorous than the single dummy side pillar impact test in EURO-NCAP, it is of great importance for improving the safety standard of the electric vehicle industry. It also provides important reference value for the protection performance of the vehicle for rear-seat children.

In actual traffic accidents, single-vehicle accidents slip sideways and collide with large trees, utility poles, sign posts and other objects. These obstacles have large stiffness and small contact areas, which results in much greater partial intrusion of the vehicle’s side than frontal collisions, thus causing very serious injuries to occupants in the vehicle.

This test refers to the EURO-NCAP side pillar impact test regulations, that is, the test vehicle (formed a collision angle of 75°±3° between the longitudinal center lines of the vehicle) collides with a fixed pile at a speed of 32km/h from the side. The point of impact is the position of the car door in front of the weakest B pillar of the vehicle, which is also the closest position to the battery pack. By checking the deformation of the vehicle, the performance of the dummy, and the condition of the battery, the safety performance of the whole vehicle and the battery pack is verified, focusing on the structural strength of the vehicle body, the stability of the battery pack, and the protection ability of passengers.

This evaluation includes four items, which are the overall evaluation of the safety and battery safety of ID.4 CROZZ from different perspectives such as body structure, electric safety performance, functional performance, and restraint systems. The evaluation result shows that all items have passed the test successfully.

According to the body scan report, the car structure remained intact, and the intrusion depth was approximately 18.5 cm. The actual injury values for the head, chest, abdomen, and pelvis of adult occupants in the front row, and the head, neck, and chest of child occupants in the back row are better than the high-performance limit value (the smaller the injury, the better), and the overall rating is GOOD.

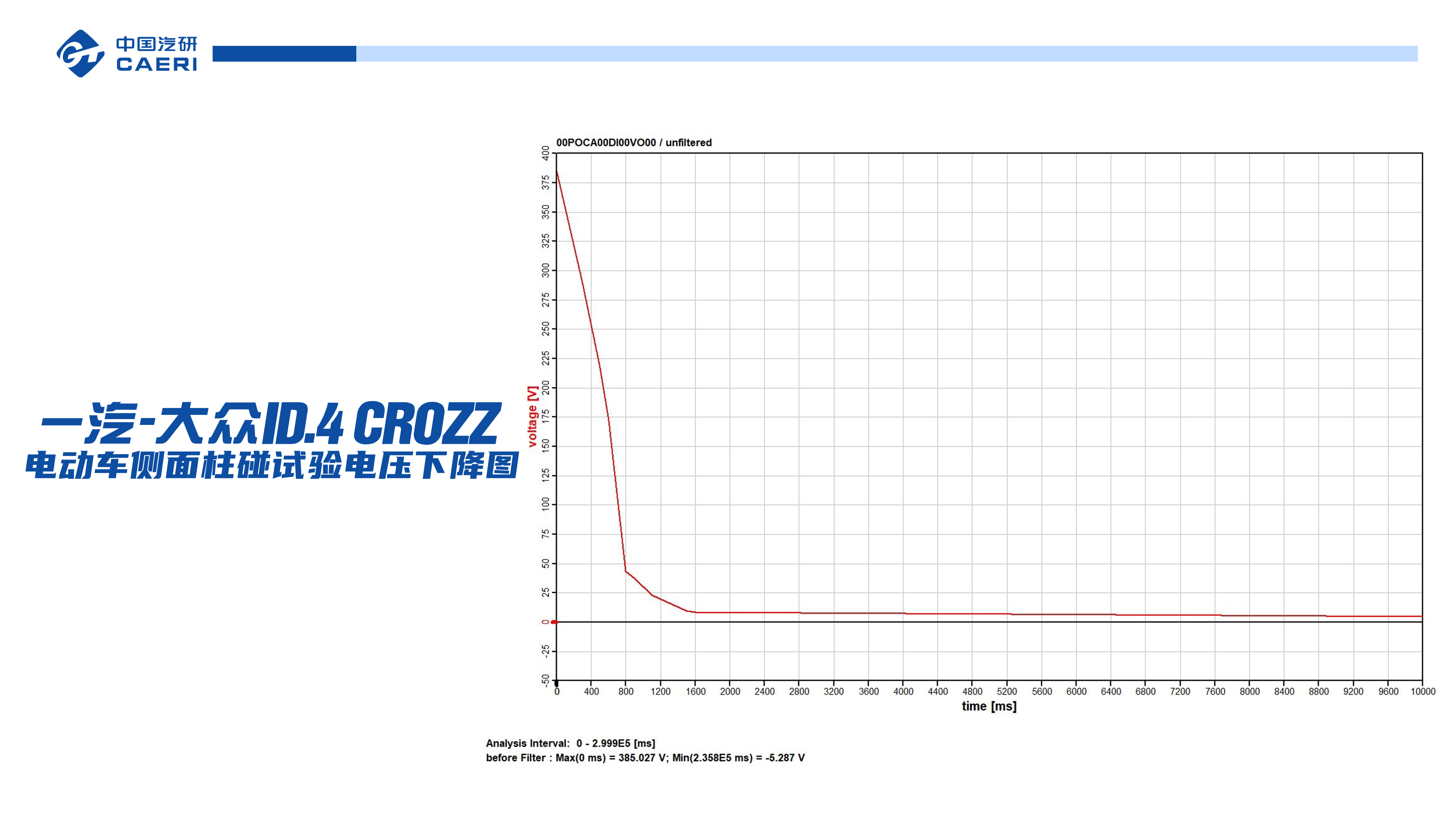

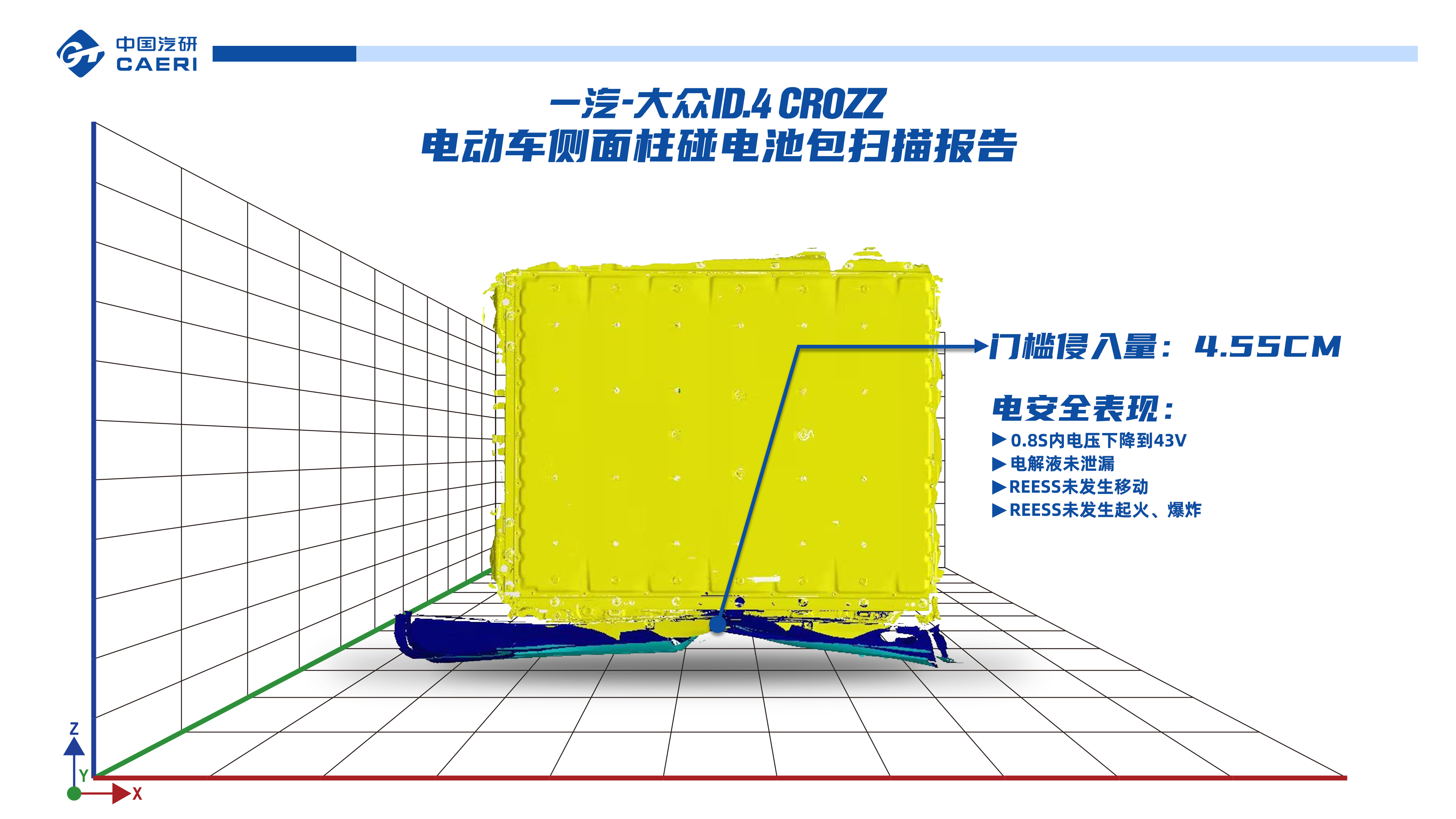

The voltage of the battery pack of FAW-Volkswagen ID.4 CROZZ drops to 43V within 0.8s, far exceeding the national standard requirement (national standard: drop to 60V within 60s). The insulation resistance is 4437 Ω/V, more than 40 times the national standard requirement of 100 Ω/V.

The threshold intrusion is 4.55 cm, which does not cause the battery pack to be crushed.

According to the official, the overall safety of the ID.4 CROZZ was developed in strict accordance with the C-NCAP five-star rating and the China Insurance Research Institute for Traffic Safety (C-IASI) Good standard. The vehicle body is made of hot-formed steel plates, and the high-strength body is created with reasonable energy absorption design, advanced laser welding technology, and automated manufacturing technology to ensure that the whole vehicle can withstand more stringent collision tests.In terms of the safety of the three-electric system, the ID.4 CROZ Z battery and high voltage system meet Volkswagen’s internal L4 electric safety requirements, and the battery pack meets the requirements of the new national standard. First Automotive Works-Volkswagen conducted up to 197 safety tests on the ID.4 CROZZ battery pack, while only 18 are required by the national standard.

Regarding passive safety, the ID.4 CROZZ is equipped with six airbags, including the driver’s airbag, front passenger airbag, front-side airbags, and front and rear head airbags.

It is worth mentioning that the front passenger seat of the ID.4 CROZZ is equipped with a 140L large-volume airbag, which ensures better compatibility with the body size and seating position of passengers in China.

This collision test proves that traditional German car manufacturers still have a certain depth of accumulation in terms of safety. However, before autonomous driving can be fully popularized and truly reliable, the structural safety and passive safety of vehicles will remain the most critical factors in automotive engineering.

🔗Source: FAW-Volkswagen

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.