Volvo’s Battery and Fast Charging Plan

I watched Volvo’s Tech Day last night, which covered autonomous driving, software and computing platforms, and internet experience. Of course, for me, the most important part was their battery and

Currently, from BMW and Daimler to Volvo, they are all very determined to use thin and small battery cells. BMW has done a lot of parallel connections for battery cells on Inext. Whether this is the point that European car companies insist on not compromising or not is still uncertain. Of course, this may also be related to Europe’s belief that the 800V system will replace the 400V system in the future. If this is the case, small cell capacity is indeed sufficient, and large-capacity battery cells are not needed. We understand that whether the battery cells are two or three times thicker, the benchmark charging rate is 1.2C. At present, European car companies are increasing the charging rate.

The goal of the 10%-80% charging time is to reduce it from 30 minutes to about 18 minutes by reducing internal resistance and improving the thermal management system for heat dissipation. The fast charging power will be further increased from 150kW, 200kW, and 250kW to 350kW.

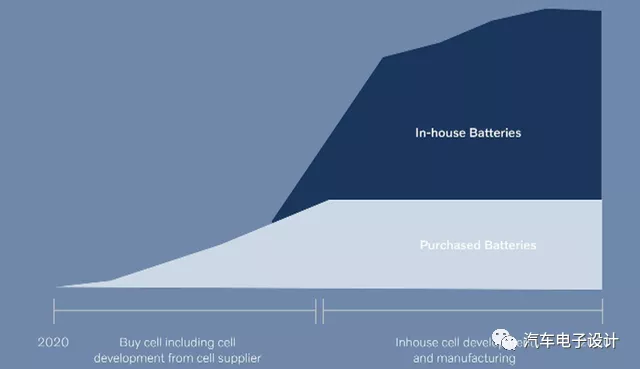

In-house Battery Production

Currently, most wealthy car companies are still making batteries, and the time point is basically set in 2023 for the market, climbing around 2024. From this situation, all subsequent European car companies may adjust this procurement strategy. After all, with the increase in the expected proportion of pure electric vehicles, outsourcing all of them will really make European car companies work for Asian battery factories.

I don’t know if this is correct or not, and currently the slogan is 100% pure electric by 2030. According to this proportion, if in-house battery production is successful, this pure electric proportion can be increased. If it is not successful, it is highly likely to be stuck at a certain stage in the pure electric proportion and to negotiate with EU regulations. If we cannot produce batteries and still insist on achieving 100% pure electric, the benefits would be very low.

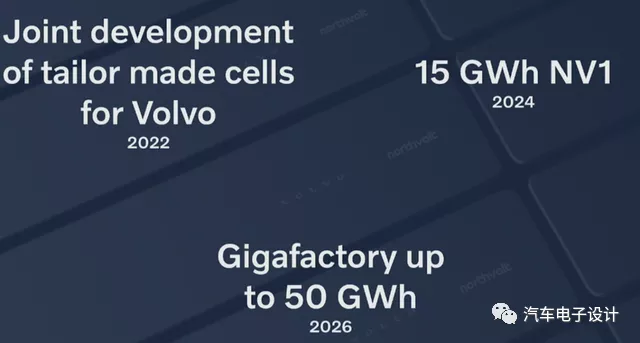

Step 1: Starting from 2022, Volvo will have custom-made battery cells. By 2024, the production capacity will be 15GWh, and by 2026, it will increase to 50GWh (equivalent to 100kWh, 500,000 vehicles).

From the perspective of battery cell design, Volvo is a firm advocate of high energy density and has no plans for LFP.

In conclusion, in terms of electrification transformation and battery investment, Volvo and Volkswagen are currently two particularly active players in Europe. Under their stimulation, BMW and Daimler will definitely follow suit.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.