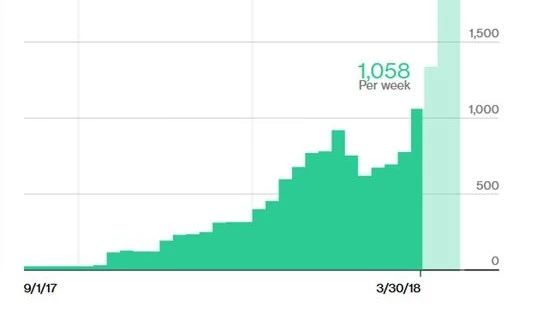

These days, the automotive and stock markets have been disrupted by the explosion of Tesla. Bloomberg reported that it tracked production based on VIN codes continuously issued by NTSB, estimating the current weekly output of 1058 units. This number has increased by about 300 units from two weeks ago when we discussed Tesla’s production bottleneck. However, it is still less than half of Tesla’s goal of producing 2,500 units per week at the end of the third quarter last year. The target of producing 5,000 units per week has been postponed until June.

Therefore, based on this dismal production situation, after Tesla’s stock fell 8.2% on Tuesday, it continued to decline by 7.67%. Moody’s downgraded Tesla from B2 to B3, cut its outlook from stable to negative, and further downgraded its debt to junk bond status (overdue debt of $2.4 billion, due in November $230 million and due in March next year $920 million), warning that more downgrades may occur. Standard & Poor’s also warned of a possible downgrade.

To make matters worse, when it rains, it pours.

Last Friday, an Apple engineer driving a Model X caught fire while driving in Mountain View, California, and the engineer named Huang died in the accident. Therefore, the focus of attention was on Tesla’s Autopilot system. NTSB also began investigating the cause of the accident.# Tesla’s Autopilot complaint and production challenges

According to sources, Tesla’s Autopilot has been complained about 10 times by the brother of the deceased, who claimed that during the self-driving process, the car turned towards the same obstacle every time. Despite Tesla’s investigation, the issue could not be replicated nor resolved.

This week has been really tough for Tesla, with their production challenges and fatal accidents. Rumors of bankruptcy have spread quickly.

Unfortunately, despite having their Roadster on Mars, Tesla still needs to survive on Earth. In order to do so, they need to get rid of any accusations that they are not responsible for.

In response to the complaint, Tesla firmly states that they searched their records thoroughly and found no indication that customers had complained about Autopilot performance. While some had previously expressed concern about navigation issues, Autopilot performance had nothing to do with navigation.

The response seems to be quite assertive, and to date, the National Transportation Safety Board (NTSB) has not commented on the matter.

Currently, it is unclear if the self-driving system was active in the minutes leading up to the crash or not. Moreover, the severity of the damage is such that Tesla has failed to recover any data from the vehicle so far.

As a result, Tesla is better off distancing itself from this issue as much as possible.

However, in order to survive on Earth, they need to focus on improving their production speed, despite being heavily criticized.

Today (March 30th), Tesla plans to shift workers currently producing Model X to the Model 3 production line, which they already hinted at during an investor meeting previously.1. The current annual production capacity for Tesla Model S and X is 100,000 units (24 hours, 3 shifts), which was reduced by about 10% in October 2017 by deploying labor to Model 3 and reducing to 20 hours and 2 shifts. With a focus on potential benefits and maintaining profit margins, the company prefers to use funds to expand the Model 3 production line, and there are no plans to expand the Model S and X production line scale in the next few years. The target is to increase production capacity to 100,000 units/year by improving production efficiency. In addition, due to the high cost of redesigning the battery layout, there is no plan to upgrade to the 2170 battery in the next few years, but it is estimated that a major upgrade to the 2170 battery will be made when the 2170 and Model 3 production stabilizes in a few years. However, existing car owners cannot replace their batteries.

-

Before December 2017, the weekly production capacity of Model 3 did not reach 100 units. The previous production bottleneck was the assembly process of attaching cells to the cooling liquid pipe in the first stage (zone 1-2) of the battery module, which is now done manually. The latter stage (zone 3-5) is fully automated, and the front production line has been redesigned. The most critical bottleneck has gradually improved, and during the production capacity climbing period in the next five months, only unexpected situations need to be handled, and the production capacity can be greatly increased after the full-line automation production in the original design is achieved. The Model 3 assembly line is highly automated, and only about five parts are manually assembled, most of which are softer parts such as cables (because robots are not good at grasping soft parts). The length of the Model 3 cable was halved to only 1.5 km, benefiting from the design with almost no buttons and only one central control screen.

-

Due to some car owners choosing to defer delivery, Model 3 delivery progress has already reached reservations for the second day (April 1, 2016), and canceling/deferred orders are mainly due to waiting for AWD, leasing, or the short-range version. Due to the huge demand for the AWD version, it is estimated that the AWD version will begin production at the end of April, and the short-range version will start production around the middle of 2018. In terms of regions, orders in the eastern United States have already started delivery, and estimates for China and Europe will start in the middle of 2018. The number of orders in China is far less than what most people think.

-

China’s factory progress is still under negotiation with the Chinese government. Eight months ago, it was possible to establish a battery factory independently, but it is currently not possible to establish an assembly line independently. Although the plan is not to have significant investment within three years, Tesla is a fast decision maker, and once it obtains permission to establish an independent factory, the company should invest rapidly. The Chinese factory will mainly be used to produce Model 3 and Model Y.> 5. Autopilot 2.0 believes that its current performance has completely caught up with AP 1.0 in the Mobileye era and will provide more information on February 7th.

6. Tesla Semi is estimated to use Samsung SDI batteries similar to those used in Powerwall and Powerpack to meet the daily charge and discharge needs and ensure a mileage of 1 million kilometers. The Model Y is estimated to be mass-produced in 2020, with the production line completed in 2019, and will be the model that helps Tesla achieve annual sales of one million vehicles. The announcement to delivery time will be shorter than that of the Model 3, so it may not be announced until the end of 2019. The production of the Model Y will indeed use SpaceX technology.

7. Insurance planning is under research and it is believed that purchasing a car should be a one-stop service, but there is no time plan yet.

8. Solid-state batteries are not suitable for use in new energy vehicles because of their short lifespan and fast decline. Currently, Tesla is cautiously considering adopting a battery technology that can significantly increase energy density, but cannot disclose the specifics at the moment.

February 2nd, 23:42 from Giga iPhone X

Looking at the numbers for weekly production this month, from 618 units at the beginning of the month to 693 units in the middle of the month, then 774 units on the day of the accident last Friday, and today 1058 units.

The production numbers have not changed since the 25th.

Suddenly increasing the number of workers means an increase in workload. Is it a sprint to meet the goal at the end of the month?

It still seems difficult to increase from 1058 to 2500 in just two days.

Failing to meet the goal will not look good to investors. Tesla is always very cruel to its employees at the end of each quarter.

Despite the hard work, the harsh reality is that the first quarter goal has far from been achieved. This conclusion has been included in the reports given to clients by various analysts.

Among the many investment institutions that scoff at Tesla, there are also voices that view it positively, and the reason is clear: after all, Model 3 is a car with 400,000 orders. As one analyst from Loup Ventures said, Musk will definitely emphasize that having such a large number of orders can only indicate demand outstrips supply.

Yes, in addition to these 400,000 orders, there are still many spectators, but whether or not they can be converted into car owners still depends on delivering the orders on hand in a timely manner.

Recently, a view has emerged that Musk’s pursuit of automated production capacity has affected the production schedule of the Model 3.During the release of last year’s financial report conference, Tesla explained that the automation production lines designed by outsourced suppliers could not cope with large-scale production, so they started to develop their own. Given Musk’s absolute position at Tesla, it was something he had to do.

Perhaps less automated production lines can actually provide higher production capacity at the moment, but since an automation production line that can bring higher production capacity is foreseen, it must be tried.

Actually, to be honest, maybe in the end, this automation production line didn’t meet the current expectations.

But it’s possible that it far exceeds your imagination.

Being too far away from this production line, we can only admire Musk’s persistence in using 400,000 orders as a bet on his vision.

History has shown that in the face of A/B two choices, Musk always chooses the more difficult one. Musk has always won every difficult bet, except for the promotion of Autopilot, which everyone agrees is too exaggerated.

Here, let me quote the words of Weibo reader @楼顶的葫芦_火山: “The first quarter has ended, and it’s Musk’s Schrödinger’s time again. Being in between the American version of Jia Yueting and Steve Jobs, when the production meets expectations, he is Steve Jobs. When the production does not meet expectations, he is the American version of Jia Yueting. We can also conclude that Musk has the duality of both, MarbuTing.”

New evidence! Uber self-driving car accident analysis* What does the Model 3 production uncertainty bring?

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.