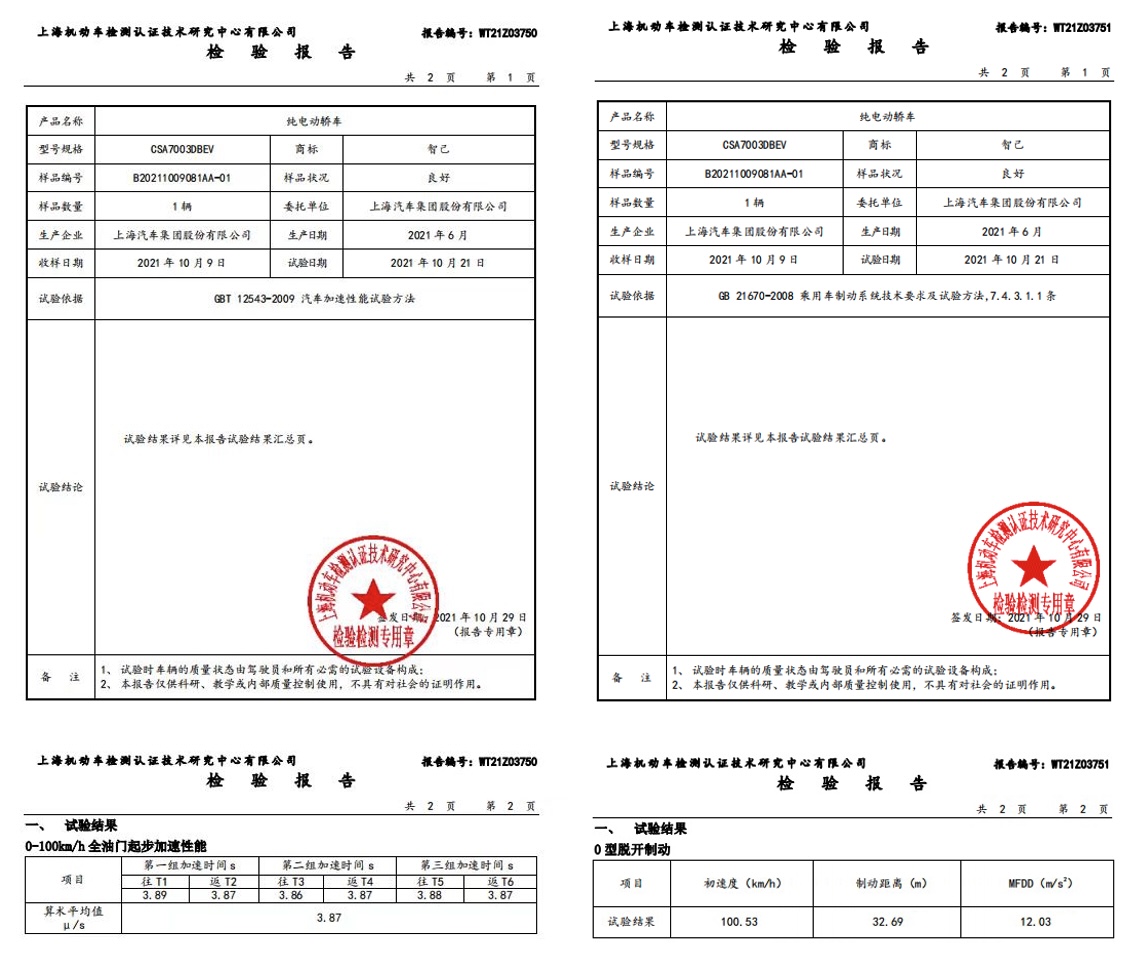

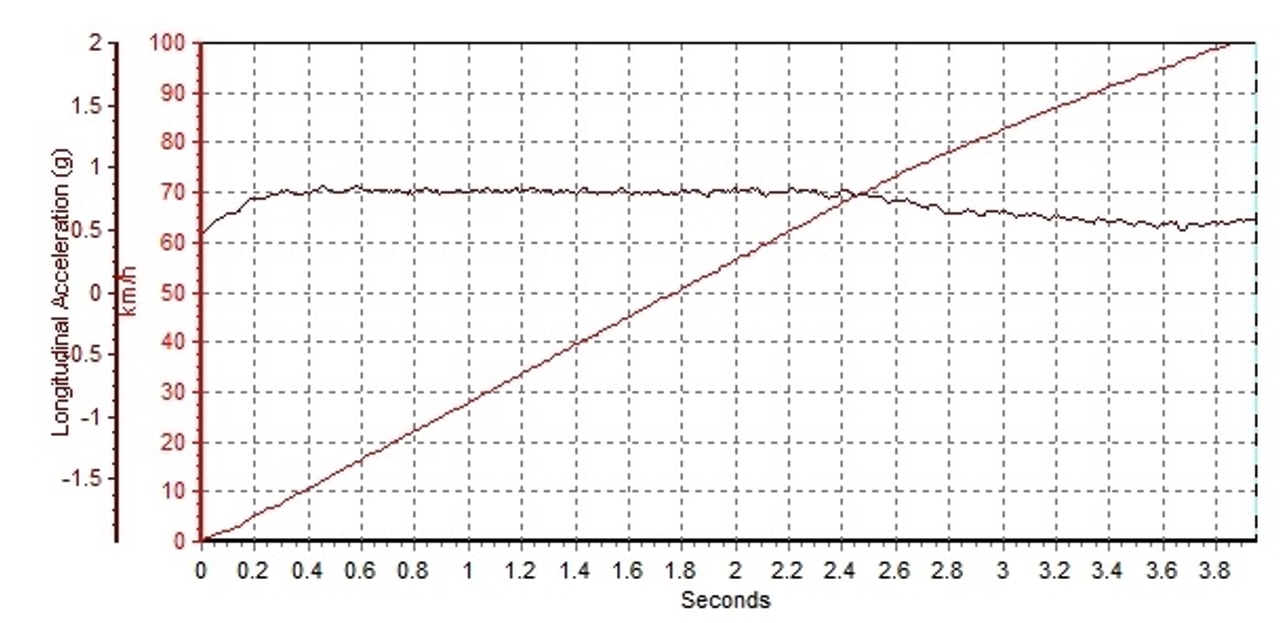

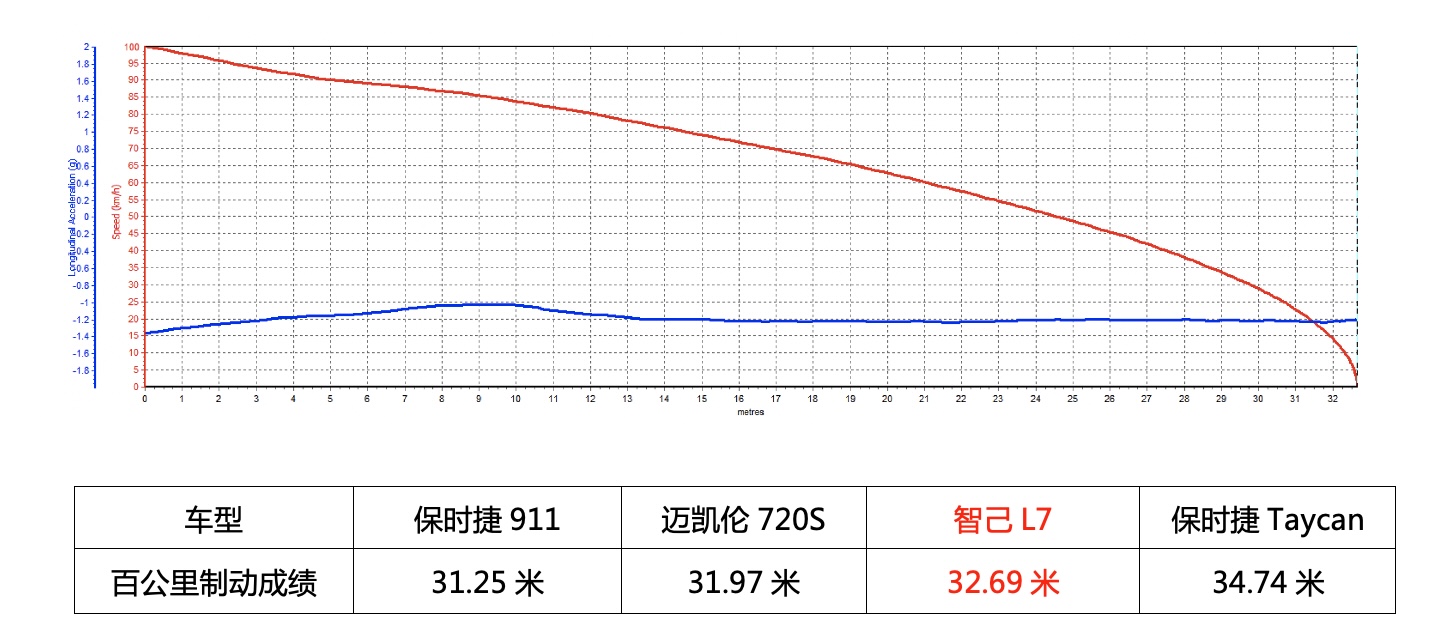

In just last month, IM L7 successfully obtained the certification from authoritative agency with a hundred-kilometer acceleration of 3.87 seconds and a hundred-kilometer stopping distance of 32.69 meters.

And today, on the afternoon of November 8, 2021, IM Motors showcased the dynamic performance of its first model, L7, at SMTC (SAIC Motor Technical Center). The outstanding results of L7’s limit cornering and turning radius were also eye-catching.

Acceleration: 3.87 seconds

The front and rear dual motors of IM L7 are both permanent magnet synchronous motors with an internationally patented direct cascade oil-cooled flat wire motor. The total output is 578 horsepower/725 N·m, equivalent to the performance of a high-performance V8 car with twin turbochargers. The front motor is 238 horsepower/275 N·m and the rear motor is 340 horsepower/450 N·m. The rear-wheel drive setting can obtain more flexible dynamics in the cornering and higher efficient utilization of torque during acceleration.

Among them, the rear axle motor adopts 8-layer hairpin flat wire winding technology, which improves the slot filling rate of the motor by 20%, and greatly reduces the motor volume compared to the traditional round wire motor, with increased energy density.

The Netflow full-network direct cascade cooling oil channel design can accurately and controllably provide turbulent direct jet cooling to the stator silicon steel sheet and the end winding, which can improve the sustained performance by 46% compared to the traditional water cooling scheme. In contrast, ordinary oil cooling can only achieve end cooling and cannot effectively cool the core heating of the motor. With the electronically controlled oil pump technology for on-demand cooling flow distribution, the motor can be actively and intelligently lubricated with targeted lubrication, ensuring that the lubrication is more accurate and efficient, and greatly improving the cooling efficiency.

A more intuitive performance indication is that IM L7 can maintain the peak power state continuously for nearly 30 seconds (ordinary motors are about 10 seconds), and its constant power can reach about 70% of the peak power (ordinary motors are only 50%). This heat-resistant performance is enough to provide L7 with more than 10 experiences of a hundred-kilometer acceleration.

### Stop It: 32.69 Meters

### Stop It: 32.69 Meters

The IM L7 is equipped with a complete set of Brembo custom front brake system, including Brembo custom high-performance opposing four-piston all-aluminum calipers, and Brembo custom FNC carbonitride infiltrated 365mm high-performance brake discs. The size of the rear brake disc also reaches 356mm, and it is matched with the Continental’s frame-style single-piston caliper customized for IM. Compared with traditional single-piston caliper, it not only has a beautiful appearance, but also has higher stiffness. The exclusive P ZERO high-performance tires customized for IM by Pirelli, focusing on key details such as tire formula and structure (triangle rubber form, fabric reverse envelope height, steel belt angle), are jointly selected and tuned by the IM and the Williams Advanced Engineering team, with a front 245mm and a rear 275mm tire width configuration to increase the grip force of the rear axle and better adapt to the rear axle electric drive torque. Also, the extra rear axle grip ability, together with more balanced weight distribution, provide more balanced braking performance for both front and rear wheels.

The IM L7 adopts the Onebox electric brake system provided by the renowned European supplier Continental. Unlike the traditional Twobox electronic brake assist system, the Onebox system integrates the ESP pump and the brake master cylinder, which is smaller in size and more convenient in space layout. As it is a fully decoupled brake control system, it can establish a brake cylinder pressure of 100 bar within 150 milliseconds, which is 200 milliseconds faster than the mechanical brake system of traditional vehicles, resulting in a faster braking response speed and a shorter braking response distance, which is more advanced.

Simply put, in this system, your brake pedal is just a switch. And it is a switch that can have a custom foot feel. That means the braking of this car can be both linear and comfortable. Another extra benefit of mechanical decoupling is that it will not bounce your foot when the ABS intervenes and it will not press your foot when the AEB intervenes, meaning that the experience will be more comfortable and it will not affect driving confidence.

Regarding the kinetic energy recovery efficiency, since the Onebox’s step does not have mechanical connection, the actual use of mechanical brakes depends entirely on the calibration, which can maximize energy savings by utilizing kinetic energy recovery. In contrast, the non-decoupled Twobox solution inevitably applies mechanical brakes when the pedal is stepped on, which cannot maximize the recovery of kinetic energy.

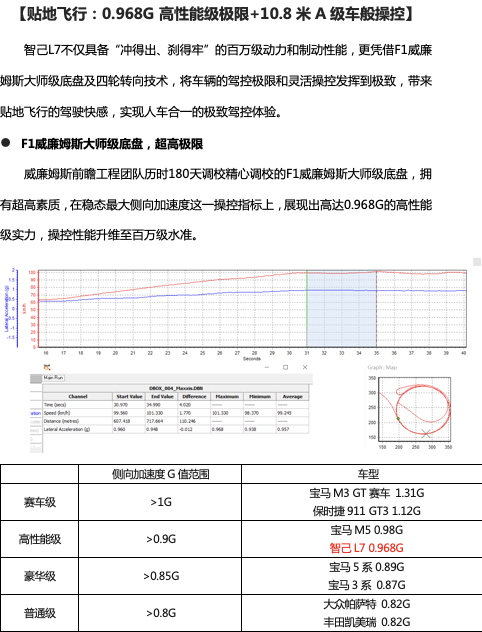

Lateral Performance: 0.968 G Steady-State Limit + 10.8 Meters A-Class Agility.

The front double-arm and rear multi-link chassis, meticulously calibrated over 180 days by the WAE Williams Advanced Engineering team, is equipped with CDC intelligent electronically controlled shock absorbers. With the dual-effect of a 490 mm ultra-low center of gravity and P Zero tires, it can achieve a maximum lateral acceleration of 0.968 G in steady-state operation. This data is second only to the lighter BMW M5, which is 0.98 G.

Practicality cannot be sacrificed even if the limit is higher. The IM L7 adopts the ZF second-generation AKC rear-wheel steering system on the same platform as Mercedes-Benz, which can achieve dual-direction steering of up to a maximum of 12°. The minimum turning diameter is only 10.8 meters, which is 10 cm shorter than the Golf and 1.2 meters shorter than the BMW 5 Series. For high-speed driving, the same-direction control can further enhance lane changing stability.

🔗Source: IM Auto

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.