Tesla CTC Showcase

From integrated control modules to integrated cast car bodies, Tesla, the big fish, has been constantly stirring up the technological landscape of the automotive industry.

In October, at the “Giga-Fest” celebration held at Tesla’s Berlin factory, Tesla once again flexed its muscles and showcased the latest generation of battery technology – structured battery.

Friends who pay attention to battery technology have probably heard many hot words such as large module, CTP (cell to pack), and CTC (cell to chassis). So let’s first take a look at what these abbreviations mean.

The initial design of the battery pack was to integrate individual battery cells into modules, and then combine the modules into a battery pack.

The improvement of battery energy density relies on the proportion of battery cells in the entire battery pack. Therefore, people began to explore how to remove redundant structural components in the battery pack to increase the proportion of battery cells in the battery pack.

However, problems came along with it. Soft pack battery cells themselves can hardly bear weight and must be supported and protected by a shell. Therefore, on the large module, progress of the soft pack battery has been slow. Square and cylindrical batteries have been advancing in BYD and Tesla models respectively. BYD’s blade battery can basically be regarded as an application of large module and CTP. The so-called structured battery showcased by Tesla is also an attempt of CTC.

Musk used the example of an aircraft fuel tank (as shown in the picture below) to illustrate the integration of the battery pack and the car body structure. In concept, it is true that the aircraft fuel tank has changed from wing + fuel tank to wing = fuel tank. Therefore, the car body + battery pack can also become car body = battery pack. The difference between a fuel tank and a battery pack lies in the fact that fuel is liquid, while battery cells are solid. Of course, because of the structural shell of the battery cell itself, it has the potential to become a part of the overall load-bearing structure. Musk’s analogy seems reasonable.

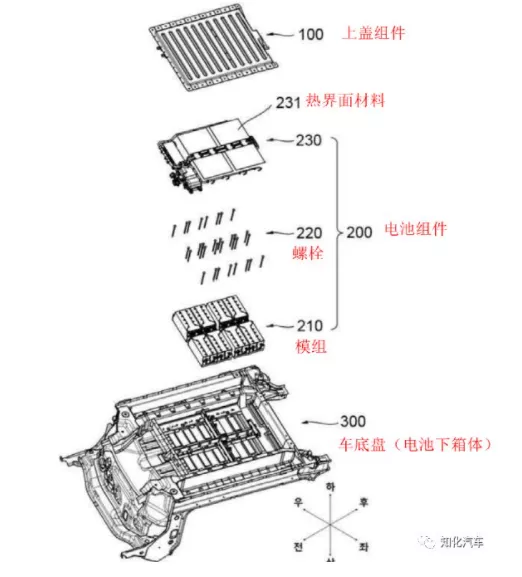

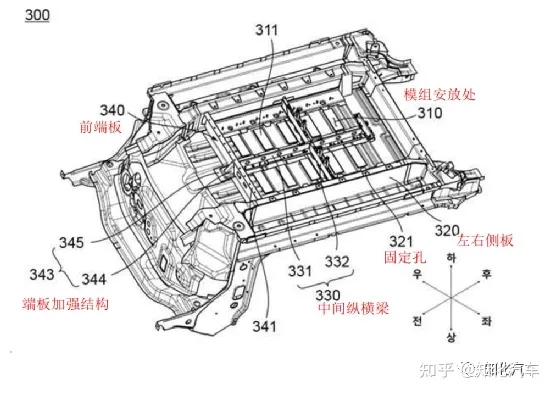

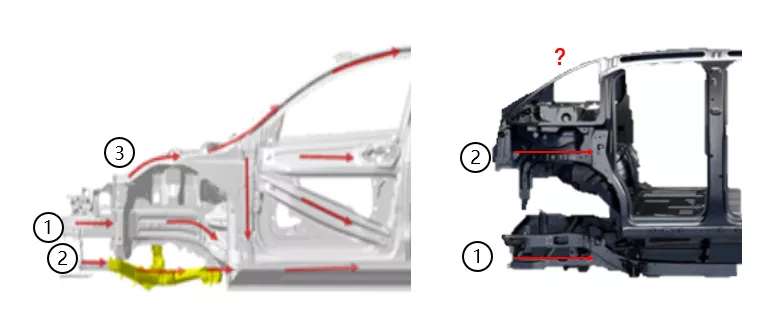

Returning to the battery technology, in Tesla’s structured battery, cylindrical battery cells are tightly arranged under the middle floor, and the upper cover of the battery also extends a cross-beam structure that overlaps with the threshold.Translated text:

The battery in the picture below no longer has a separate cover. The components on the surface of the battery are integrated with the vehicle structure, providing the functions of seat fixation and the body crossbeam (as shown in the image below), as well as sealing the battery.

This integrated solution not only eliminates one layer of floor structure, but also solves the problem of gap reservation between the floor and the battery pack when designed separately. This extra space is a great addition whether it is used to expand the cabin space upward or the battery pack space downward.

However, there are also drawbacks to this approach. The battery can no longer be removed separately, so battery swapping is out of the question and maintenance is also compromised. Anyway, Tesla’s goal is to provide a future of autonomous driving without accidents, so the battery pack should not be touched unless necessary. Also, cylindrical battery cells are better suited for supporting weight in the vertical direction, while other directions have limited impact. This means that structural support is still needed in the width direction, and the issue of longitudinal stress also needs to be resolved. This part is not discussed in detail, it may involve the battery lower shell or internal filling structure to compensate for the missing internal beam structure after removal.

To summarise, what are the benefits of a structural battery?

- Reducing structural redundancy as much as possible, packing more battery cells into the same space and increasing energy density.

- The fusion of the battery pack with the vehicle structure improves overall stiffness, and centralising the battery cells reduces total inertia for more agile handling.

- The centralised battery cell position makes it difficult to contact the cells during lateral impact, resulting in better battery protection.

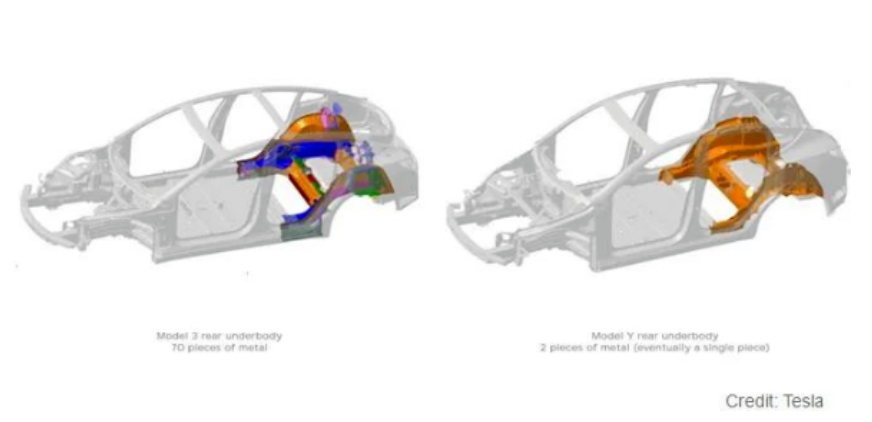

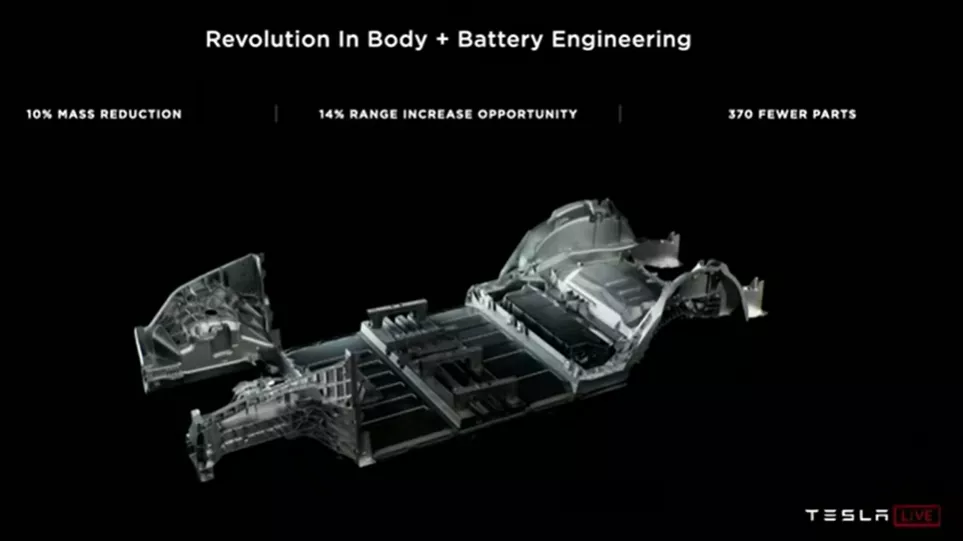

- In conjunction with Tesla’s integrated casting structure for the front compartment and rear floor, the number of parts is significantly reduced.

Of course, there are also downsides, and the author believes that the following points need further discussion:

- The battery pack cannot be dismantled independently, so how do we inspect and repair it? What if it is damaged in a collision?

- How is the battery pack’s sealing and safety certification process carried out?

- How are the structural connections between the battery pack and the front and rear vehicle body and side structures made? How should the assembly sequence be changed?

- How should the brake and high-pressure lines for front and rear connections be routed, and how should they be protected?

Structural solutions for cylindrical batteries are already available, but can square batteries and soft packs keep up?

Square battery cells are larger than cylindrical ones, but less flexible. However, if the cells can be matched to the width of the vehicle and placed under the floor, it is still possible to achieve comparable results, although the series production may be slightly worse.The soft pack battery is somewhat awkward because it cannot bear weight without additional structure. It can only be loaded onto the chassis by means of a module, which is referred to as MTC (module to chassis). The following image shows LG’s CTC plan for a soft pack battery. In my opinion, it would be more appropriate to call it MTC.

In strict terms, the concept of the structural battery is not difficult to follow. The focus is on how to solve practical problems, guarantee reliability and usability, and particularly how to cope with the series of changes brought about by highly integrated solutions.

The reuse rate of scrapped parts for the cast-in-one battery is quite high. What about the integrated battery case? It is necessary to ensure the sealing of the battery case as well as the connection and bearing strength with other body structures, and the tolerance control requirements are issues that need to be addressed.

According to the current manufacturing system of traditional automakers, I believe it is difficult to follow a CTC plan similar to that of Tesla. But is such a plan the ultimate form? Perhaps not. Since it is possible to integrate battery cells into the supporting structure, is there still an opportunity to change the structure of the entire vehicle body, with more changes in materials and disassembly of parts? I look forward to seeing more innovations in the future.

The Possibility of Integrated Chassis

You may ask, is the hotly discussed CTC so simple? Is there nothing else?

In my opinion, the structural battery can only be considered as part of CTC. True CTC may be able to expand even further, as the chassis encompasses more than just the battery. In traditional terms, the steering, braking, and driving units are all part of the chassis. Upon closer examination, aren’t all the core components of an electric vehicle included here, not just core components but also high-profit components? Therefore, whether it is Rivian or Canoo rebuilding the skateboard-style chassis architecture, or suppliers like CATL and NIO joining this technology race that can change the automotive industry structure altogether.

Following this technological logic, cars will no longer be a combination of three compartments, front, passenger, and rear, but will become a chassis plus an upper body structure. The chassis and different forms of upper body structure are separated on the hardware side, while on the software side, intelligent chassis control and intelligent passenger cabin can also be separated. In this way, the same chassis can be paired with different body forms to produce various models such as sedans, pickups, MPVs, SUVs, and so on. The concept of “Super Chassis” thus emerged.Slow down, is it really possible to produce completely different car models with the same platform? As an employee in the traditional automotive industry, it is highly unlikely. Not only would no company be willing to become an OEM factory to install someone else’s “soul” into their own cars, but it would also be difficult to satisfy such a wide range of vehicle demands, from sedans to pickups, SUVs, and MPVs, under the premise of using a single platform. Because different car models have different requirements, if it’s just about hauling goods, then different bodies of varying height and width can be interchangeably used to adapt to different cargos. But when it comes to humans, with their different postures, visual demands, and personal protection requirements, things aren’t so simple.

Let’s take a closer look at the problems that “universal platforms” need to solve.

Have you noticed the familiarity between Canoo’s chassis and cockpit combination and the one shown in BMW’s i3 released as far back as 2014? At the time, BMW called it the “LifeDrive structure,” which was composed of an aluminum chassis and a carbon fiber reinforced cockpit.

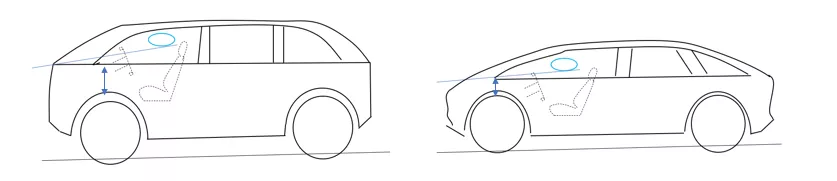

The i3’s E-NCAP score at the time was four stars. Of course, there were differences brought about by the carbon fiber body, but it doesn’t prevent us from identifying the first major challenge of universal platforms – collision safety. The collision safety requirements of passenger cars mainly include: passenger protection, pedestrian protection, and active safety. In terms of passenger protection, whether it’s a rigid barrier crash or a 40% overlap deformation barrier crash, there are very high demands placed on the force transmission of the entire vehicle structure.

Traditional car bodies generally have three load-bearing paths, with the middle path usually being the main one. The design of separating the chassis from the cockpit must change this distribution, and from the image released by Canoo, there seem to only be two paths. How to connect and allocate these two paths is a big question. Combined with its extremely short front suspension structure, we believe that the challenges will only become greater.

The driver’s vision, especially while driving, is a major challenge. More than 80% of the information drivers need comes from visual cues, with hearing and other senses only providing 20% of what is needed. Therefore, good visibility is essential for safe driving and should be a basic prerequisite. It is not realistic to produce significantly different car models based on the same chassis. Ensuring a certain level of visibility means that reducing the seating position also reduces the height of the suspension. While it is common for different car models to use the same platform, claiming that different car models can be produced using the same chassis amounts to misdirection. To produce cars with different heights and seating positions requires significant suspension adjustments and modifications, and the corresponding development and verification processes are also essential. Can this still be called the “same chassis”? Probably not.

The driver’s vision, especially while driving, is a major challenge. More than 80% of the information drivers need comes from visual cues, with hearing and other senses only providing 20% of what is needed. Therefore, good visibility is essential for safe driving and should be a basic prerequisite. It is not realistic to produce significantly different car models based on the same chassis. Ensuring a certain level of visibility means that reducing the seating position also reduces the height of the suspension. While it is common for different car models to use the same platform, claiming that different car models can be produced using the same chassis amounts to misdirection. To produce cars with different heights and seating positions requires significant suspension adjustments and modifications, and the corresponding development and verification processes are also essential. Can this still be called the “same chassis”? Probably not.

Therefore, a highly integrated “super-chassis” can only be regarded as the same as the platform architecture of traditional automakers. The only difference is that the development team shifted from the automaker to the supplier.

So, what is the difference between the automaker and supplier now that the developer has changed? It depends on who the supplier is targeting with their series of chassis hardware and electric drive systems. I believe that this solution will only be offered to internet-based car companies that want to build cars quickly. These companies may not focus on driving experience, but rather need a platform to support intelligent driving and smart cockpits. Currently, internet-based car companies require a reliable, high-endurance chassis and electric drive system, which will play a significant role in smart driving and smart cockpits.

It seems that traditional car brands may ignore the driving experience in this race. However, it is uncertain whether this race can differentiate enough to make consumers impulsively buy a product. After all, different car brands provide different driving experiences when it comes to traditional cars. Regardless of the product, the ultimate goal is to offer something consumers are willing to pay for. If self-driving is the key to a new pathway, enabling cars without drivers, then perhaps buying a journey is all that is required, and there is no need to purchase a car.

In summary, battery technology has progressed from custom-shaped batteries designed for traditional vehicle structures to compact, adaptable flat batteries that can meet various endurance requirements. From large modules to CTP testing, the goal has always been to improve the energy density of batteries and the level of integration with the vehicle. CTC intends to break the barriers between batteries and cars, with the “super-chassis” concept being a game-changer for car development. Integrated designs that combine the battery and chassis can indeed increase the range and save development time, but there is no guarantee that suppliers will be able to sell these “super-chassis” to the right customer base. Consumers still need differentiated standards-setters to differentiate between car models. Standardized electric drive integrated-chassis models might be more suited to commercial vehicles with a cargo focus rather than passenger vehicles.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.