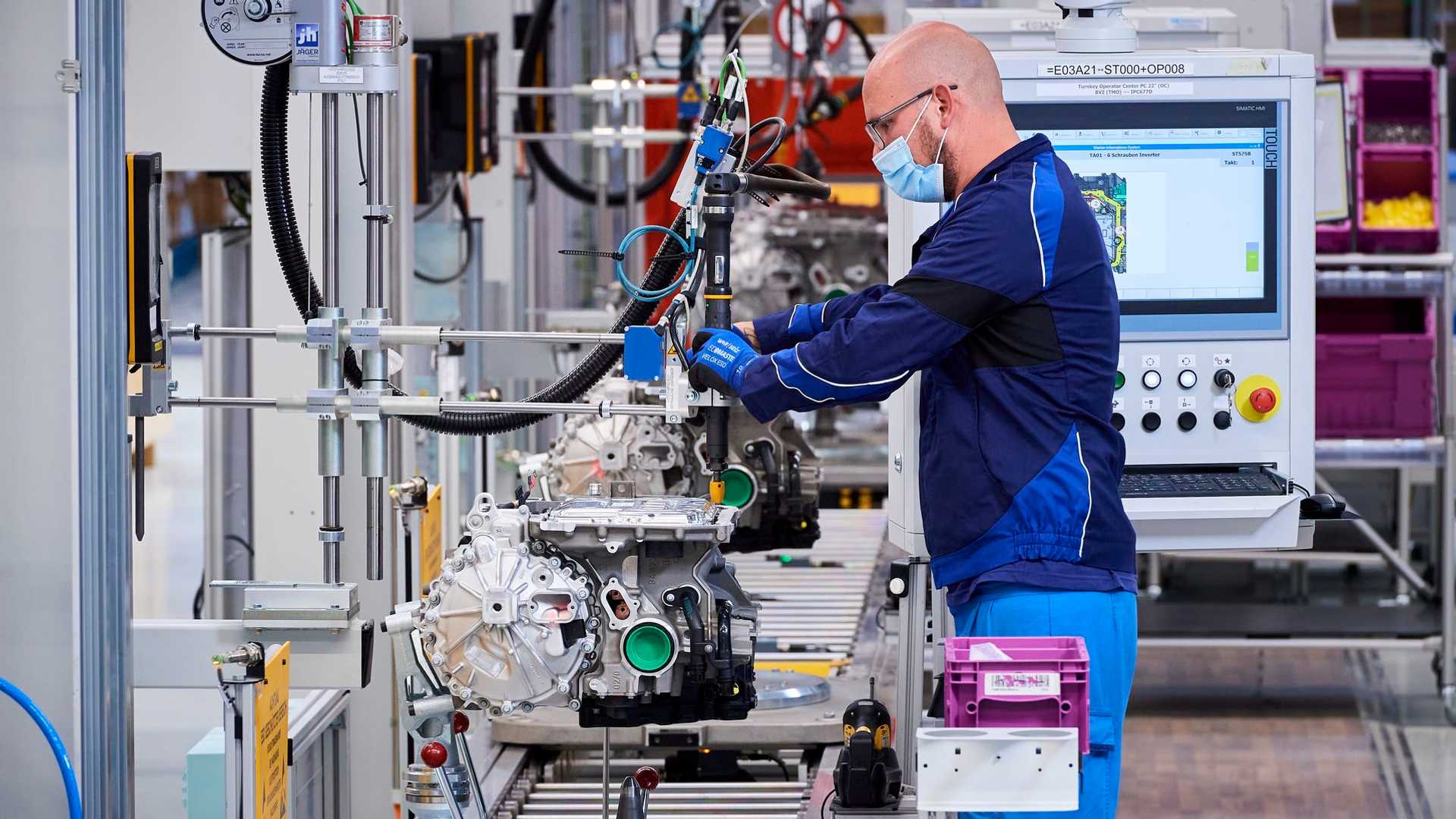

BMW Group opens new electric drive technology center in Dingolfing, Germany

The BMW Group has officially opened a new electronic drive technology center at its Dingolfing production site in Germany. The factory will primarily produce high-voltage batteries and electric motors, with a production capacity of over 500,000 electric vehicles by 2022.

The new plant will provide BMW with its fifth-generation electric drive system, which combines an electric motor, transmission, and power electronics in a central housing. The first model equipped with the fifth-generation E-Drive will be the BMW iX3.

To accelerate its transition to electromobility, BMW has been producing battery modules and packs (starting from the BMW i3) since 2013 and electric motors since 2015 at the Dingolfing factory.

According to BMW’s plan, the total investment in the Dingolfing electronic drive technology center is estimated to reach 500 million euros ($562 million) by 2022. The number of employees dedicated to electrification has increased from 600 to 1000 and is expected to further increase to 2000 in the midterm.

The BMW Group will produce powertrain components such as battery modules, high-voltage batteries, and electric motors on eight production lines at the Dingolfing electronic drive technology center. Four additional production lines will be added in the coming years to significantly increase production capacity.

Starting in 2021, the Dingolfing factory will produce the new all-electric BMW iNEXT, as well as conventional and plug-in hybrid 5-series and 7-series models, and the traditional 8-series. The next generation of the BMW 7-series will be produced in four versions, including gasoline, diesel, plug-in hybrid, and all-electric.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.