On December 27th, VecSense Technology announced that its ONE-BOX drive-by-wire product – the Hydraulic Decoupling Braking System (HDBS) is officially in mass production, with an estimated annual production capacity of 600,000 sets. The system is produced within the intelligent manufacturing factory located in Jianhu County, Yancheng City, Jiangsu Province, which is equipped with advanced dust-free workshops and automated production lines – efficiently integrating management systems like MES, WMS, SAP while blending artificial intelligence, IoT, and machine vision technologies to enhance production efficiency and product quality.

In terms of product inspection, the HDBS was meticulously examined via 530 test cases, ensuring system stability and reliability. During the product development process, the system withstood multitudinous rigorous trials, including vehicle performance testing and system robustness validation, while bench durability testing exceeded up to 3 million times.

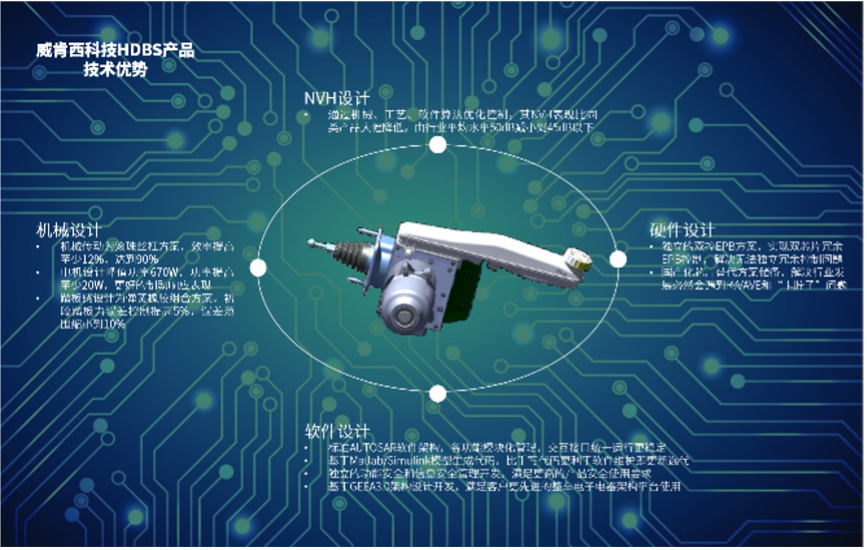

Remarkable in noise reduction, the noise level of HDBS is 3 decibels quieter under comparable testing conditions versus similar products, and the similarity of pedal feels surpasses 95%, ranking the system at a leading position within its industry. The system adopts a brushless motor and ball screw design, supporting brake assist, routine ESC functions, intelligent driving assistant functions, with system response times reaching within 150ms, significantly improving vehicle safety.

Moreover, HDBS possesses 23 functional configurations, structured on the autosar framework, and has achieved ASIL D grade protection level, ensuring its capability for information safety defense. Versatile in application, the system not only caters to gasoline-powered vehicles, pure electric vehicles, and hybrid vehicles, but it can also be applied to a range of light commercial vehicle models.

In the fiercely competitive drive-by-wire product market housing at least 40 enterprises, both domestically and internationally, Zhai Linduo, the CEO of VecSense Technology, stressed that the key to corporate competition lies in the stability of product quality. Hence, VecSense Technology has drawn from international procedures and standards, crafting their VCDP (VCS Chassis Development Process), and conducting stringent integration management on upstream suppliers, to ensure product quality and market competitiveness.

This article is a translation by AI of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.