ZEEKR has been encountering some recent ‘problems’, especially in terms of the battery.

“Is piercing and non-combustion sufficient for safety? Why does everyone boast about charging speed but never mention low temperature performance? People can’t even wait for a 30 second ad, so why should they wait 30 minutes for charging?”

Since new energy vehicles entered the public’s view, the safety and charging efficiency problems reflected by ZEEKR’s soul-searching questions have been causing anxiety for owners of new energy vehicles.

However, it is clear that with the continuous advancement of technology, battery combustion issues are becoming increasingly rare. Charging replenishment efficiency is also getting higher, but problems still exist, and user requirements and needs are far from being met.

The gold brick battery, released by ZEEKR on December 14th, offers a promising solution to the battery issue.

The Gold Content of Golden Brick Battery

The Golden Brick Battery is essentially a lithium iron phosphate battery, but it sets its standards on the ternary lithium battery.

We know that compared to lithium iron phosphate batteries, ternary lithium batteries have a higher energy density, faster charging speed and are more suitable for long-range or high-performance models. However, in terms of safety and cost, ternary lithium batteries fall short of lithium iron phosphate batteries.

An Cong Hui, the CEO of ZEEKR, opened the discussion on Golden Brick Battery by raising the question: Why can’t lithium iron phosphate realize super fast charging?

With the release and production of the Golden Brick Battery, the question posed by An Cong Hui has been resolved.

Let’s summarize some of the core features of the Golden Brick Battery:

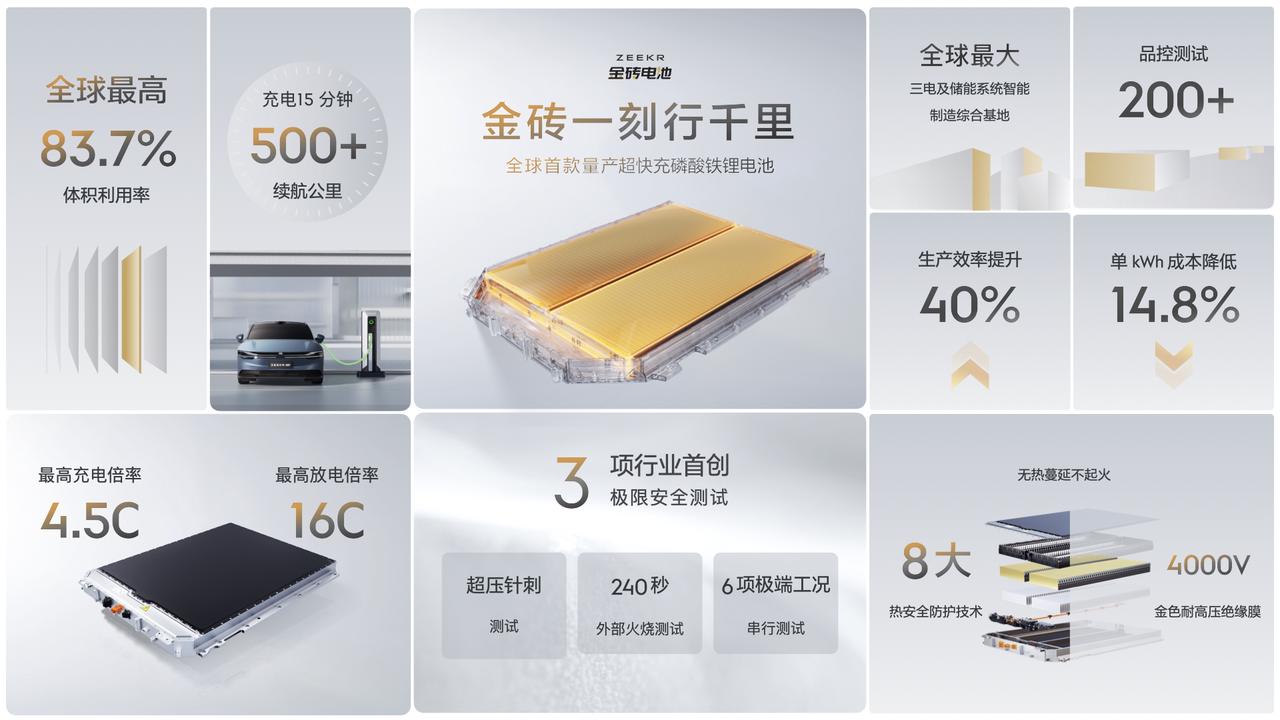

- Volume utilization rate is 83.7%

- Maximum charging multiplier is 4.5 C

- Fast charging speed increases by 25% at -10 degrees Celsius

- 15 minutes of charging replenishes 500km of range

- 3-second pulse discharge multiplier is 16 C

- Production efficiency increased by 40%, single kWh cost decreased by 14.8%

From the above data, it is clear that the Golden Brick Battery has broken through the limitations of previous lithium iron phosphate batteries, achieving performance improvement and cost reduction.

In order to achieve such performance, ZEEKR has put in considerable effort.

Firstly, in order to achieve an energy density comparable to ternary lithium batteries, the Golden Brick Battery opts for a larger design. However, ‘larger’ in this context does not mean increasing battery size, but rather improving volume utilization rate – i.e., packing in more battery cells of the same volume.

In order to maximize cell space, ZEEKR’s engineering team carried out a major overhaul of the battery structure. Compared with traditional designs, the total length of sampling circuits in the Golden Brick Battery has been shortened by 157m, and the number of core components has been reduced by 35%.

The final result is that Golden Brick Battery’s volume utilization rate reached 83.7%, becoming the world’s first power battery with a volume utilization rate exceeding 80%. Thanks to the improved volume utilization rate, the energy density of the Golden Brick battery weight also increased by over 10%.

Next is the charging and discharging capability of the Gold Brick Battery.

The reason why the Gold Brick Battery can achieve a maximum charging ratio of 4.5 C and a 3-second pulse discharge ratio of 16 C, is due in part to ZEEKR’s full-domain 800 V architecture and the use of extreme charging piles. On the other hand, it also results from structural innovation in the battery cell and the use of full-process lithium-ion acceleration technology to increase the overall efficiency of lithium-ion release, transmission, and acceptance.

Finally, safety is emphasized. “Safety” has always been ZEEKR’s golden benchmark. Up to now, ZEEKR has delivered more than 180,000 cars, and no spontaneous combustion has been recorded. The emergence of the Gold Brick Battery provides robust support to this golden benchmark of “safety”.

In order to ensure the safety of the Gold Brick Battery, ZEEKR applies 8 safety measures and designs a special gold insulation film on the surface of the battery cell which can withstand 4,000 V DC high voltage, this also happens to be the origin of the Gold Brick Battery’s name.

Furthermore, in order to test the safety of the Gold Brick Battery, ZEEKR has gone to great lengths to test it under extreme conditions such as overvoltage needle puncture, 240 seconds of external fire, and 6 extreme conditions series testing, etc.

It’s worth mentioning that in the 6 extreme conditions series testing, the Gold Brick Battery went through immersion, burning, freezing, dragging, rolling, and high dropping; still, it can be normally installed and used.

Currently, ZEEKR has announced that the Gold Brick Battery will be initially installed in the ZEEKR 007. Once the ZEEKR 007 is officially released on December 27, you can follow our evaluation to see if the Gold Brick Battery performs as well as it promises.

The Perfect Match for ZEEKR 007

The R&D groundwork for the Gold Brick Battery actually had been laid since 2016.

According to the official, when the Geely SEA architecture was under development in 2016, the 800 V high-voltage platform had already been included in the plan. The emergence of the Gold Brick Battery as a dark horse today largely owes to ZEEKR’s future-proofing strategy.

In fact, as a company that positions itself as a technology-driven tech company, making in-house batteries that reflect this vision is the only logical choice. At the same time, it is also a reasonable response to the current transition of the auto industry.

From the perspective of user requirements, the criteria for assessing a new energy vehicle are quick charging, long range, high performance, and safety of power batteries. Vehicle manufacturers naturally strive to meet these user requirements.

From the perspective of the automaker’s development, self-developed batteries can help enhance the automaker’s core competitiveness in cost, which was also emphasized by An Conghui at the launch of the Gold Brick Battery.The power battery accounts for the highest cost of a new energy vehicle, exceeding 35%. It is far higher than the proportion of the power system cost of fuel vehicles to the total cost of fuel vehicles. Due to the high cost of power batteries, Zeng Qinghong, Chairman of GACGROUP, once stated at the World Power Battery Conference: “Am I not working for CATL now?”

No automaker wants to work for a supplier, but the current market of new energy vehicles is rapidly growing with high demand for power batteries. In the power battery market, automakers generally lack decision-making and dominance. To escape this state, self-research and production has become a necessary path.

However, leading suppliers like CATL have built high technical and cost barriers in the power battery market. If an automaker is not resourceful, they will find it challenging to break through. NIO is an example of this challenge, deciding to spin off its battery business.

Nonetheless, ZEEKR has the advantage of being supported by the Geely system, where resource abundance is inherent.

Relying on this advantage, ZEEKR has changed the battery structure and reduced cabling and components. In production, ZEEKR has set up an advanced intelligent manufacturing management system at its Quzhou factory, ensuring the quality and output of their brick batteries. Compared to the ternary lithium battery of the same performance, the cost per kWh of the brick battery was reduced by 14.8%.

By developing their batteries, ZEEKR achieved further vertical integration of the vehicle supply chain, giving them deeper control of production costs. This means ZEEKR has enhanced capabilities to compete in the current price war while facing narrowing growth space.

Lastly, in terms of the product itself, the brick battery is an excellent partner to ZEEKR 007’s product strength.

Compared to fuel vehicles, new energy vehicles have a higher level of integration. Power batteries are core components highly related to the vehicle’s performance. Automakers adopting a self-research strategy will inevitably bring better results for the vehicle’s synergistic design, making the product more competitive.

For ZEEKR, the ZEEKR 007 is its first pure electric sedan facing a wider consumer market, especially the fiercely competitive market priced between 200,000 and 300,000. To achieve good sales of ZEEKR 007, ZEEKR needs a noticeable advantage in areas most concerned by users.

Therefore, it’s easy to see that the brick battery, with its apparent cost and performance advantages, is the driving force behind ZEEKR 007’s sales. Furthermore, if ZEEKR 007 sells well, it will further dilute the cost of the brick battery and pave the way for it to be used in more ZEEKR models.

Apart from the brick battery, ZEEKR is also building an advanced SuperCharge system from its brand’s inception.

Now, ZEEKR SuperCharge pole ownership has reached industry-leading levels. According to official data, as of November 30, ZEEKR has built nearly 2,300 SuperCharge poles, covering 100 cities across the country.

It’s noteworthy that, ZEEKR’s super charging stations haven’t adopted a mixed construction method of super charging piles and regular piles, but uniformly use super charging piles. And through intelligent power sharing technology, they maximize the use of power pool, ensuring the charging power of each super charging pile.

Reportedly, the super charging stations like this one will be accumulated to more than 1,000 by ZEEKR by the end of next year, and by the end of 2026, the number of super charging piles will reach over 10,000.

In addition, ZEEKR has integrated the whole process of power replenishment into the vehicle ecosystem, and users can realize intelligent pile searching, ground unlocking, and instant charging. This function will be given to users with the latest OTA from ZEEKR.

Final Thoughts

The trend of self-research and construction of power replenishment system has been blowing for not only a year or two. Few in the mainstream new energy brands do not build their own power replenishment system, and even if the battery is not self-researched, it will also involve in joint development with suppliers.

The reason is that the main engine manufacturers are competing with each other, focusing on the products, and starting a battle on comprehensive system capability, including technology, capital, marketing, and service capability including power replenishment system.

ZEEKR, in this battle, is also outputting its system capability backed by Geely- it’s implementing vertical integration of supply chain internally and launching highly lethal products externally. However, from the current status of ZEEKR, its system capability needs to be continuously enhanced and sustainedly outputted.

At present, ZEEKR’s monthly sales have stabilized at more than 10,000, but to achieve higher sales, ZEEKR 001, ZEEKR X and ZEEKR 009 are somewhat lacking in stamina, while ZEEKR 007 and the BRIC battery are the key weapons to make up for ZEEKR’s sustaining capability, which are powerful proofs of the continuously enhanced and sustained output of system capabilities.

With the launch of ZEEKR 007, the group appearance of ZEEKR 007 and BRIC battery is going to make this already fiercely competitive market even more fierce. Perhaps some competitors have already started having sleepless nights.

This article is a translation by AI of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.