This article is reproduced from WeChat official account “New Car Lecture”. The author is Chris Zheng. Please contact the author for reproduction.

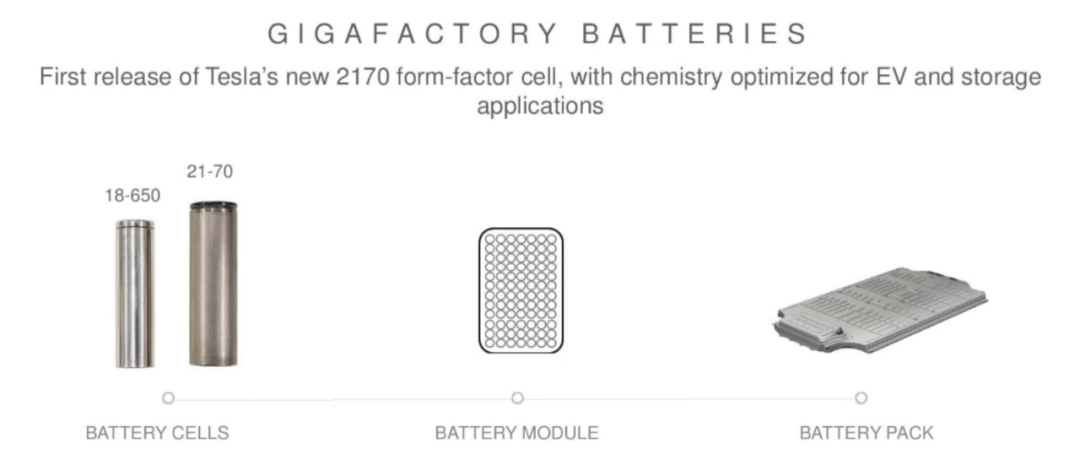

On September 22, 2020, Tesla CEO Elon Musk announced the new generation of Tesla batteries: the 4680 large cylindrical battery.

The new battery has a diameter of 46 mm and a height of 80 mm. Compared with the widely produced 2170 battery, the 4680 has made improvements in multiple dimensions such as energy density, fast charging/discharge performance, cost, and safety. It is the main battery in Tesla’s future product line.

It is the weapon for achieving over 100 kWh battery capacity for Tesla Model 3 & Y.

More Than Just a Battery

What makes the 4680 cylindrical battery standout?

As Tesla co-founder JB Straubel once said, there are some indicators that cannot be negotiated for power batteries, such as safety and performance. In addition, the most important thing is cost. To emphasize: safety, performance, and cost, are three dimensions in which Tesla has improved its batteries.

Let’s go back to Tesla Battery Day which was held two months ago and take a look at this PPT.

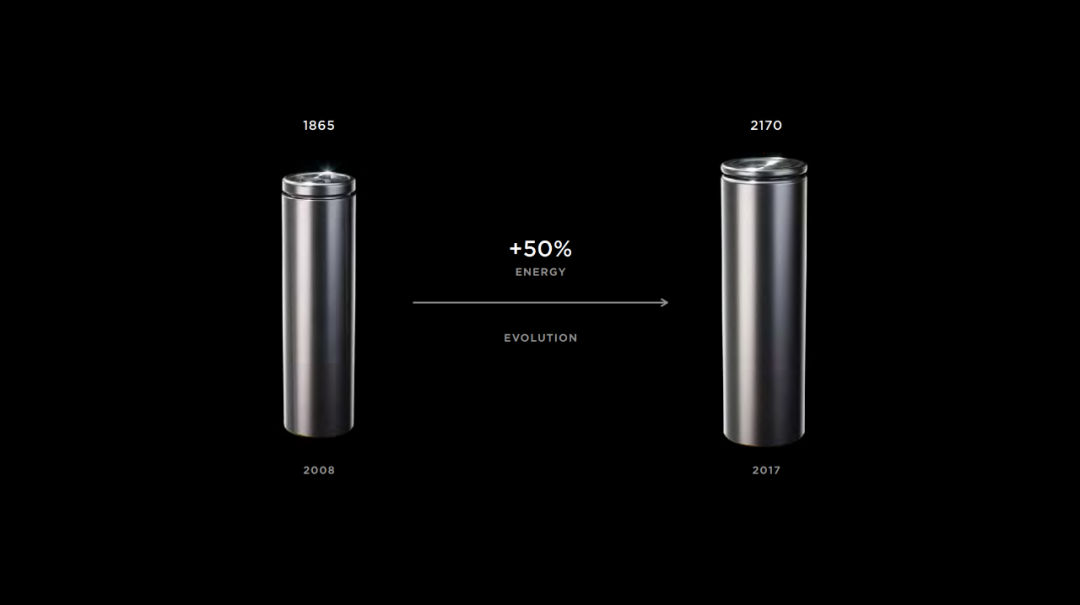

From 1865 in 2008 to 2170 in 2017, the rated capacity of Tesla’s battery pack has doubled, and the rated capacity of 4680 is five times that of 2170 and ten times that of 1865.

What benefits has Tesla gained from moving from “small” to “large”?

The Model S P85 battery pack specification is 85 kWh. To achieve this, Tesla needed to manage 7,104 1865 batteries. The Model 3 (Long Range) battery pack specification is also up to 80.5 kWh, but it only needs to manage 4,416 2170 batteries.

Reducing the number of individual batteries means a significant reduction in the difficulty of battery thermal management, reducing the complexity of the entire thermal management system, which in turn reduces costs.

Wait a minute, why 4680 instead of 5680 or 6680?

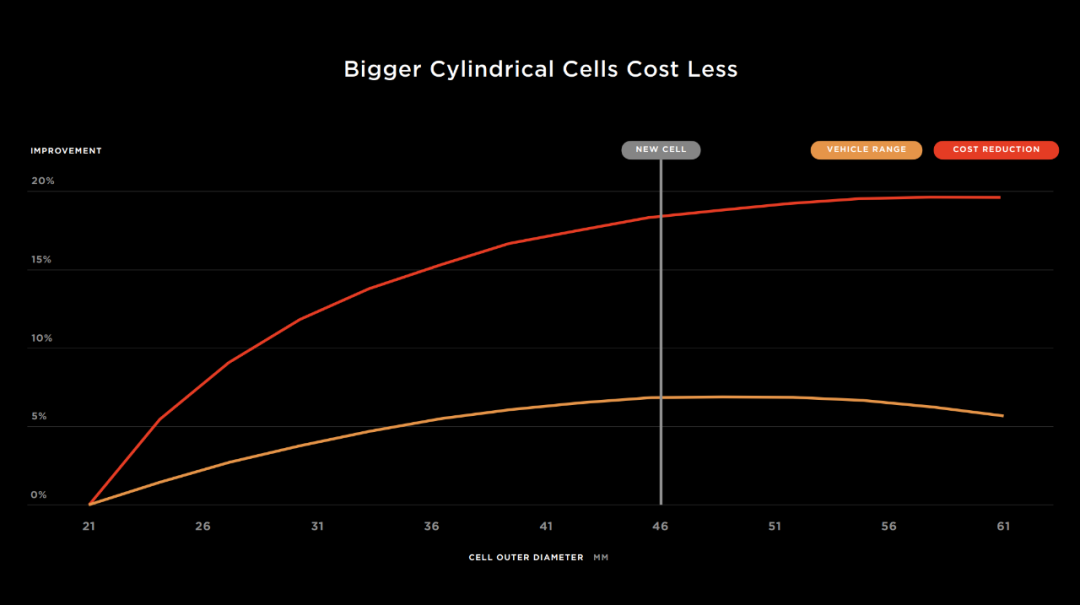

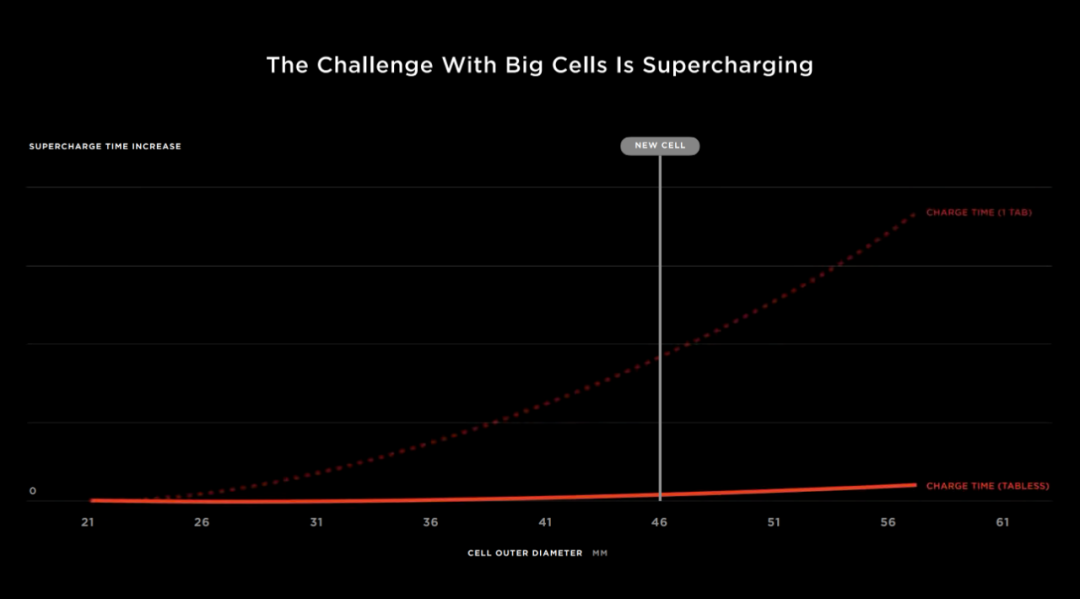

Let’s take a look at another PPT.

As the diameter of the small cylindrical battery increases, the cost reduction curve gradually flattens, while the curve for performance (reflected here as range) actually decreases.

The highest point of these two curves, the best balance point between performance and cost, is when the diameter equals 46 mm, which is the reason for the new battery’s diameter of 46 mm per individual cylindrical battery.Why is the height that of 80 mm? Why not 4,690 or 46,100?

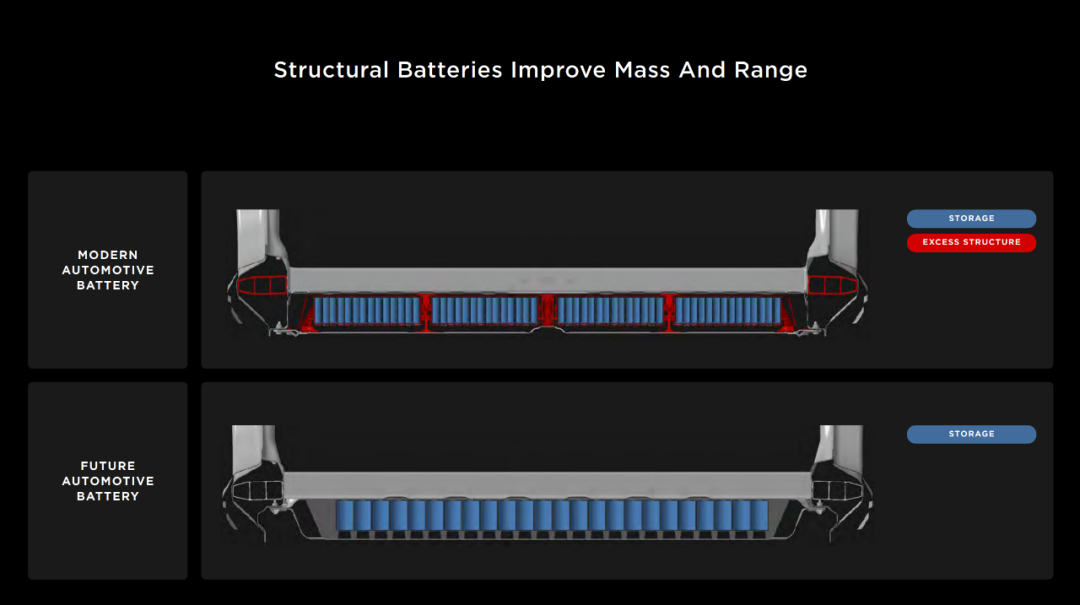

Now let’s take a look at this PPT.

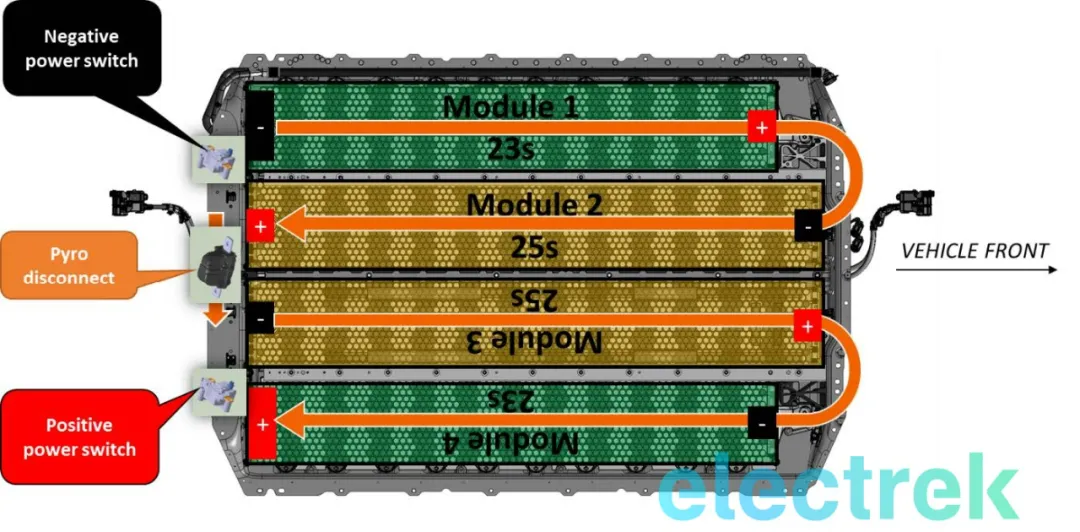

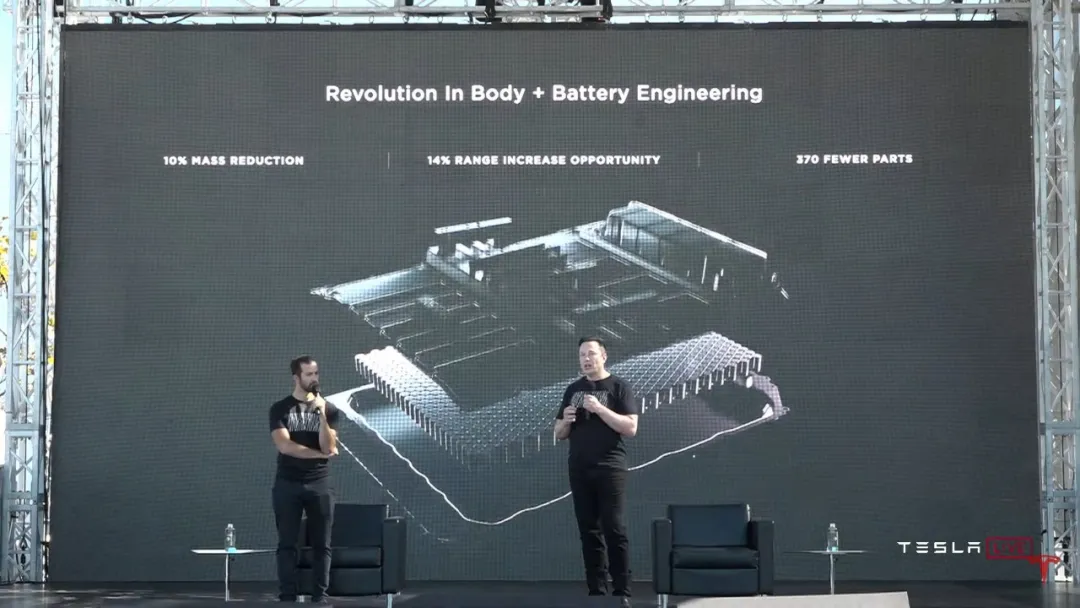

In the upper half, there are two red horizontal energy-absorbing cavities on the left and right, and the battery pack is divided into four parallel rectangular modules by three red supports in the center, with blue 2170 single cells filled in between.

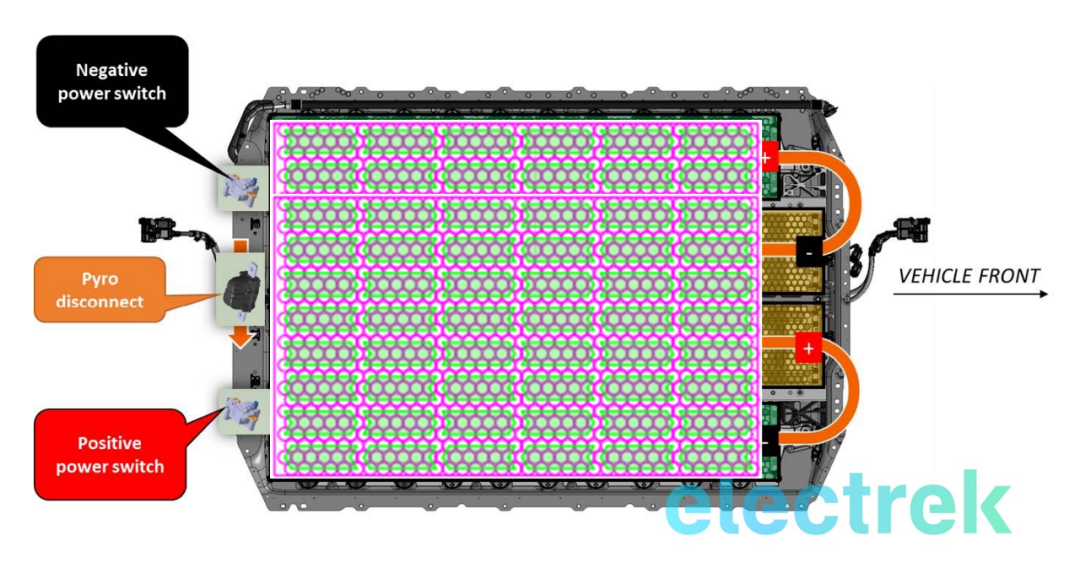

In the lower half labeled as “future electric vehicle batteries,” Tesla has removed the physical battery pack and module, and directly integrated the 4680 large cylindrical battery cells into the vehicle chassis.

Let me give you some background: How many steps does it take to install a battery into a car?

In the past, Tesla required three steps:

- Assembling individual cells into shoebox-sized modules

- Assembling modules into battery packs

- Integrating battery packs into the chassis

However, with Tesla’s “future electric vehicle batteries,” the process is simplified to just a single step:

- Integrating individual cells into the chassis

By completely removing the module and battery pack, the battery cells are much more compact, the number of battery components is greatly reduced, space utilization of the chassis is greatly improved, and system costs are reduced.

According to Tesla’s data, replacing 2170 cells with 4680 cells and integrating them into the chassis will increase vehicle range by 30% and reduce costs by 39%. Investment cost per unit battery production capacity will decrease by 49%.

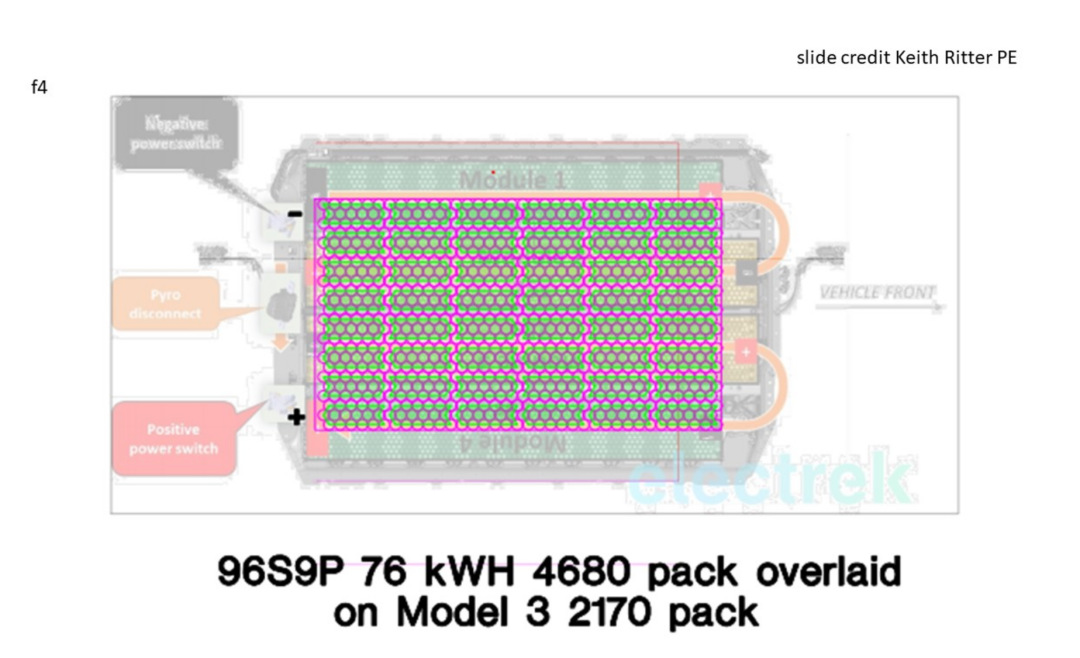

Two American electrical and electromechanical engineers, George Bower and Keith Ritter, who have been following Tesla for a long time, designed a 96S9P battery pack with a total of 76 kWh using 4680 cells, which is stacked on top of the Model 3 battery pack.

If these pictures are not intuitive enough, then here is the effect of a 95 kWh 4680 battery pack. It can be seen that the utilization rate of the entire chassis is not very high. Following Tesla’s consistent style, switching from 2170 to 4680 to achieve more than 100 kWh is not surprising.

Let’s now talk about safety concerns.

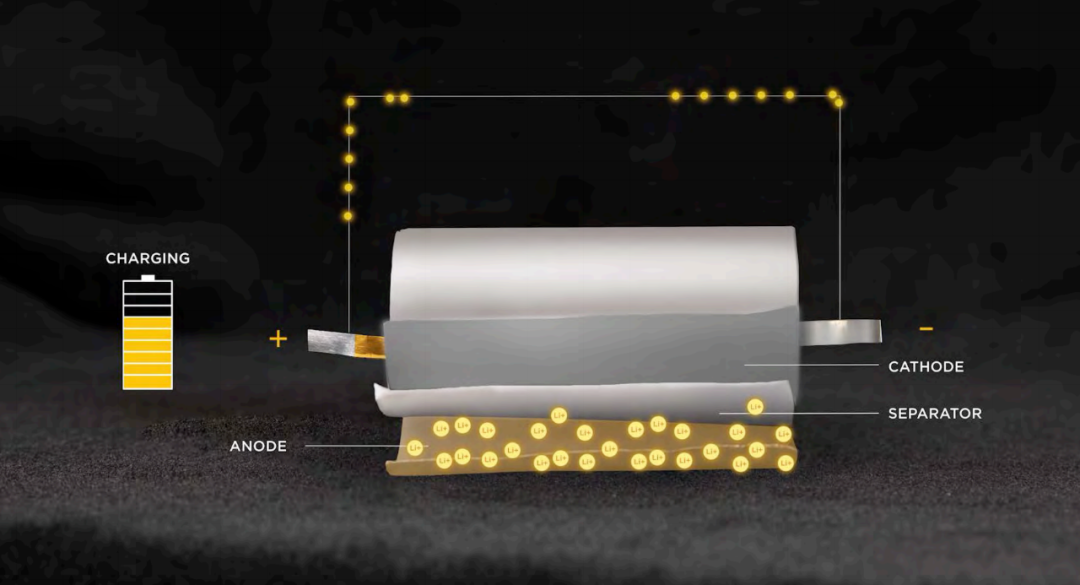

In middle school physics, we were taught the charging and discharging process of batteries:

- During charging, electrons on the positive electrode flow through an external circuit to the negative electrode, and positively charged lithium ions (Li+) move from the positive electrode through the electrolyte to the negative electrode.

- During discharging, electrons on the negative electrode flow through an external circuit to the positive electrode, and positively charged lithium ions (Li+) move from the negative electrode through the electrolyte to the positive electrode, where they combine with electrons.

We understand the principle, but the problem is that, in actual scenarios, the charging and discharging processes of a battery put the small and thin tabs, called “tab-to-cell,” under extreme pressure.

As mentioned earlier, the process from the 18650 “small cylinder” to the 4680 “large cylinder” increased the rated capacity of the battery tenfold. However, the tab-to-cell design remains the same, causing the electron transport pathways to become infinitely crowded.

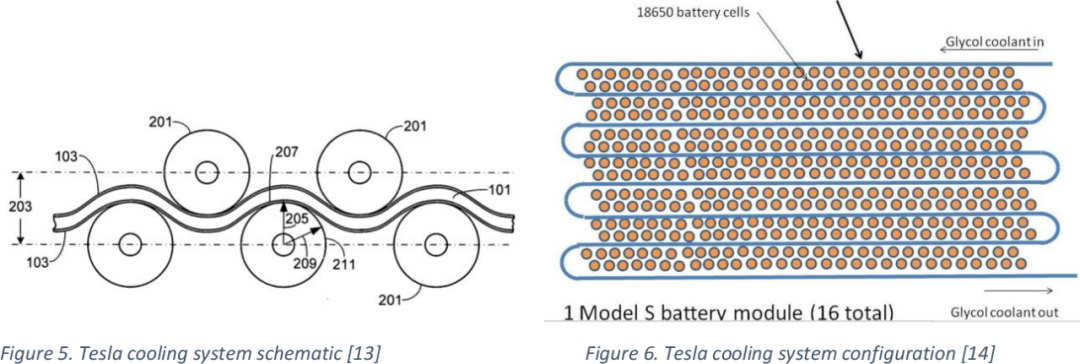

At the same time, due to the doubled diameter of the individual cell, the battery’s side heat dissipation capability begins to deteriorate. This means that the side-inserted liquid-cooled snake-shaped tube thermal management plan used from Roadster to Model S to Model 3 is no longer applicable.

During the rapid charging and discharging process, if there is no efficient heat dissipation design, a large amount of heat will accumulate inside the battery in no time. This is why Tesla said on Battery Day that the biggest challenge of the large cylinder battery is cooling.

To solve this problem, Tesla has introduced the tab-less design and bottom liquid cooling.

The tab-less design, also known as Full Pack, as estimated by Ravi Kempaiah, an energy storage material scientist at the University of Illinois at Chicago, reduces the internal resistance of the battery to only 2-3 milliohms for the 4680 battery, compared to 20-23 milliohms for the 2170 battery.

The former is one-tenth of the latter, in accordance with what the Tesla tab-less patent says, which is that “the internal resistance of the battery will be reduced to 5%-20% of that of a traditional battery”.

Moreover, as mentioned earlier, during rapid charging and discharging, a large amount of heat is spewed from both the positive and negative electrodes. Tesla has replaced the side snake-shaped tube cooling with its bottom liquid cooling plan, which is much more efficient at removing heat.

Taking Tesla’s Supercharger as an example, if the unipolar ear design of 2170 cells is continued, due to the inability to effectively dissipate a large amount of heat, the charging time will be greatly extended (dashed line), but with the use of a bipolar ear design, the charging time of the 4680 and 2170 cells with the same specifications has hardly changed.

Taking Tesla’s Supercharger as an example, if the unipolar ear design of 2170 cells is continued, due to the inability to effectively dissipate a large amount of heat, the charging time will be greatly extended (dashed line), but with the use of a bipolar ear design, the charging time of the 4680 and 2170 cells with the same specifications has hardly changed.

Therefore, the 4680 is not just a change in the “small cylinder” to “large cylinder” form of the individual cells, behind it lies Tesla’s new generation of thermal management design, cell, and vehicle chassis integration design. In short, 4680 means Tesla’s next generation of vehicle engineering technology.

So, when will it go into production?

Domestic Model Y, Domestic 4680

After the financial conference of Tesla, Panasonic, and LG Chem, we finally have the opportunity to sort out the global production capacity layout of Tesla’s 4680 battery.

On October 21st, Elon announced at Tesla’s financial conference: We expect that Giga Berlin will establish Tesla’s first self-developed battery (i.e. 4680) production line.

Drew Baglino, Senior Vice President of Tesla’s Powertrain and Energy Engineering, stated: We will use the 4680 pilot production line in Fremont, California to support the (battery) demand of the Berlin factory.

However, Elon also mentioned: We are postponing the self-developed battery to 2021 to reduce risks and minimize the dependency on our internal cell production. It’s very, very small.

What if Tesla’s self-developed battery “production hell” occurs? It’s Panasonic’s turn.

On October 29th, Panasonic CFO Hirokazu Umeda said at a financial conference: We immediately started research and development after Tesla Battery Day and are preparing to establish a prototype production line (for 4680).

On November 18th, Panasonic, energy company Equinor, and industrial group Hydro signed a memorandum of understanding to explore the establishment of a super battery factory in Norway.

No information related to Tesla can be seen in the cooperation announcement. However, the senior executive (first on the left) responsible for signing the contract for Panasonic is Allan Swan, the president of Panasonic Energy North America.

A factory in Europe was signed by executives responsible for North American business? Let me clarify the problem: Allan Swan is based in Tesla Nevada’s Gigafactory and is responsible for the production and delivery of Tesla batteries.

A factory in Europe was signed by executives responsible for North American business? Let me clarify the problem: Allan Swan is based in Tesla Nevada’s Gigafactory and is responsible for the production and delivery of Tesla batteries.

Panasonic’s spokesperson further clarified the purpose of the factory after its official announcement: The factory can provide cylindrical batteries for Tesla’s first automobile factory in Europe.

What about China? For Tesla, battery supply in China depends on two companies: CATL and LG Chem.

Let’s first talk about CATL. Tesla has indeed been testing and adapting CATL’s NCM 811 battery for a long time. It is expected that the domestic Tesla CATL ternary version will be launched in 2021.

However, compared with the production of the 4680 large cylindrical battery by CATL, it is not even a challenge in the same dimension. Judging from CATL’s history, the probability of developing and establishing 4680 large cylindrical battery production lines for Tesla is not high.

Next is LG Chem. On October 21, Lun Cha, head of the LG Chem Energy Solution Strategy Division, said that LG Chem has developed new cylindrical products with a rated capacity increased by 5 times and output power increased by 6 times-these parameters are exactly the same As Tesla’s 4680 battery.

However, Lun Cha also said that LG Chem is considering building new factories in Europe and North America, increasing capacity from 120 GWh/year to 260 GWh/year, with the only absence in China.

What about China?

Well, as early as October 7, Elon announced a wave of new technologies for Tesla, not limited to 4680 batteries, cell integration into chassis technology, and Tesla’s next-generation painting system. These new technologies will be put into production in the Berlin factory.

After the new technology is fully verified and the production capacity climbs, the Shanghai factory and the California factory will complete technology iterations within the next 2 years.

Whether it is Model 3 or Model Y, Chinese geek users have not been able to experience the cutting-edge technology that leads the industry in the first batch.

But then again, Tesla has always been aggressive in commercializing cutting-edge technologies. The first batch of Model 3s were tested by “white mice” in North America, and the first batch of Model Y was tested by “white mice” in Europe. Isn’t it a good thing?

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.