The days are not easy for the new car camp. On the one hand, after the subsidy transition period ended on June 25th, each new car company began to face a maximum of up to 70% subsidy reduction. On the other hand, several self-ignition accidents this year have severely hit consumers’ confidence in the safety of pure electric vehicles. As the saying goes, when the city gate burns, the fish in the moat are affected. If you are a pure electric car, you will inevitably be affected.

What should we do? Rebuilding consumer confidence and “reducing prices while improving product competitiveness” is the timeless law that promotes sales. On July 1st, WM Motor announced that it would provide lifetime free battery quality assurance service. Before this, WM Motor had updated its entry-level product: the new model, EX5 Mate WeiMeng version 400, was launched. From the update of WM Motor’s official WeChat account, the long-endurance WM vehicle model of the 500+ km club is also on the road. Let’s take a look together.

Lifetime Free Battery Quality Assurance Service from WM Motor

At the moment when the subsidy transition period ended, WM Motor announced its lifetime free battery quality assurance policy on July 1st. Here are several keywords: battery, lifetime, and free quality assurance.

“Battery” refers directly to the high-voltage power battery of the pure electric car. In the process of the gradual growth of the electric car market, the safety and reliability of power batteries are the most worrying or least understood key components for consumers.

“Lifetime” is relatively easy to understand, and it means that from the day of delivery to the final day before scrapping, it belongs to the quality assurance period of the power battery.

“Free quality assurance” is the most critical part: after the vehicle is put into the market, if the power battery needs maintenance or parts replacement due to product design, manufacturing, or raw material defects, WM Motor will bear the cost.

As mentioned earlier, even in 2019, a shocking fact is that the market share of pure electric vehicles is still less than 2%. This means that for most consumers, pure electric cars are still a new thing, and their safety, reliability, and residual value issues need to be spread and established by each pure electric vehicle company in the consumer group.

The introduction of lifetime quality assurance was originally a measure taken by WM Motor to educate the electric vehicle market and face consumers’ lack of confidence. However, it has invisibly brought pressure to new energy vehicle companies, especially new car makers. Will WM Motor’s lead in the lifetime battery quality assurance policy development evolve into a new industry maintenance benchmark?

The three electric powertrain systems are the most critical components of electric vehicles and the components with the greatest impact on safety in case of thermal runaway accidents. However, there are no clear regulations for the three electric systems within the traditional vehicle warranty policy. From another perspective, this is also a “new” symbol of the new car industry: the entire industry has not received sufficient and mature development, and the management and maintenance regulations are not standardized enough.

The significance of WM’s lifetime warranty policy to the industry is that it indirectly promotes progress in the field of after-sales service beyond products, technology, and service, gradually standardizing the industry. The far-reaching significance brought by the lifetime warranty is not only to increase consumer confidence and stimulate short-term sales growth but also to some extent solve the residual value problem caused by previous range degradation in the longer term.

This is the first step towards the benign development of the industry.

WM’s Three Electric Powertrain Competitiveness

Along with the lifetime warranty policy, the WM Mate Weimeng Edition 400 was launched. The launch of this model and the cessation of production of the WM Entry Discovery Edition 300 were simultaneously promoted.

In terms of core configuration, the battery pack specification of Weimeng 400 has been upgraded to 52.56 kWh, and the NEDC range has been upgraded to 400 km. The pre-subsidy price has increased by 15,000 yuan to 189,800 yuan, and the post-subsidy price is now 139,800 yuan. As an entry-level model, Weimeng 400’s core indicators of product strength have been significantly enhanced.

So far, there have been only three companies in the new car camp with an output of over 10,000 units: Nio, WM, and XPeng. XPeng G3 facelift and Nio ES8 facelift are coming soon, but it is actually WM’s Weimeng 400 that became the first company in the new car camp to complete product facelift and launch.

Let’s talk about WM’s three electric powertrain technologies, especially the battery technology capabilities of lifetime warranty. To dare to offer a lifetime warranty, WM’s confidence in its technical capabilities is evident. Otherwise, just the aftersales service would be a disaster.

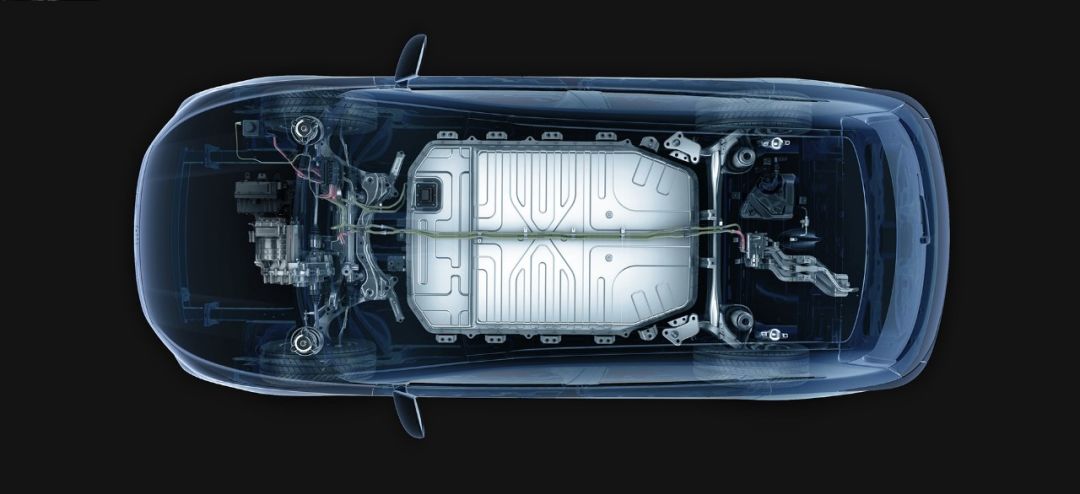

The suppliers of WM’s square-shaped battery pack are EVE Energy and Tianjin Lishen. We know that the so-called thermal runaway is caused by the large voltage difference between cells due to a short circuit in the battery, which leads to the accumulation of heat and ignition. Therefore, voltage difference is a crucial indicator. WM requires that the voltage difference between cells be less than 25 mV, and the voltage difference between modules be less than 30 mV, and the temperature difference between cells be controlled within ± 2℃. This indicator has already caught up with Panasonic, a tier-one supplier of power batteries.

Another result of good heat management is that according to WM Motor’s acceleration aging test, the battery pack’s degradation in range is lower than 5% after driving 160,000 kilometers. Conservative heat management is a strategy based on safety considerations that allows for the “unexpected gain” of low degradation.

Another result of good heat management is that according to WM Motor’s acceleration aging test, the battery pack’s degradation in range is lower than 5% after driving 160,000 kilometers. Conservative heat management is a strategy based on safety considerations that allows for the “unexpected gain” of low degradation.

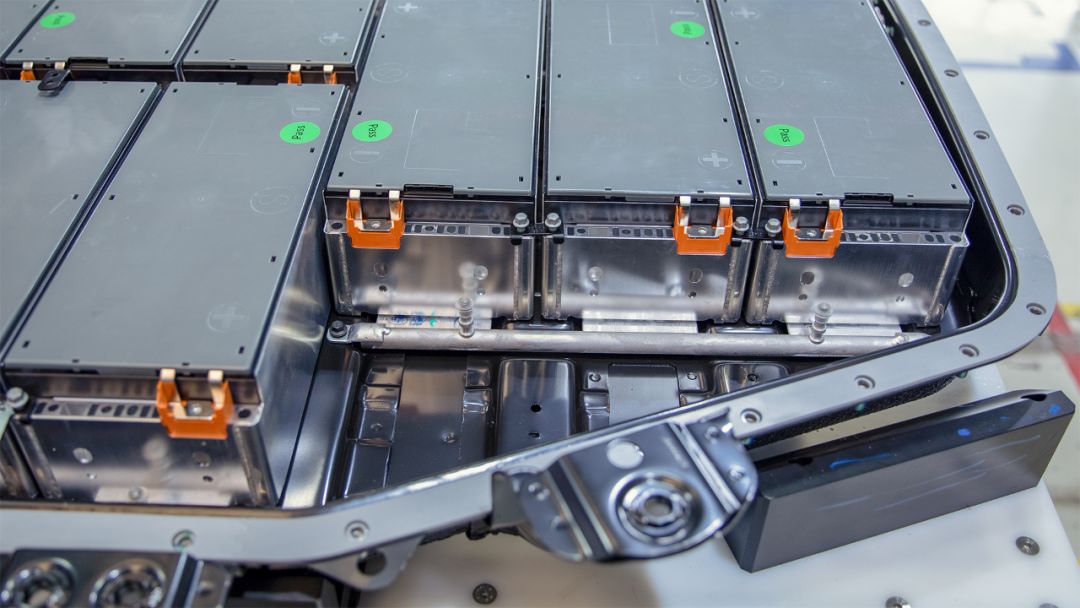

In addition, leaving insufficient expansion space for the battery module can cause friction and short circuit of the wiring harness, which is a major risk of battery pack self-ignition. WM Motor’s battery cell encapsulation technology is based on the German VDA standard, which is nothing unusual. There is a close-up of the WM Pack below.

The edge and corners of the Pack are designed with sufficient buffering space. On the one hand, this avoids the possibility of battery collision, compression and short circuit of the wiring harness. On the other hand, the more sufficient buffering area is an additional barrier for the module and battery cell after the Pack shell collapses in the event of an accident.

Finally, speaking of the Pack itself, WM Motor’s Pack box is based on DP 780 high-strength steel and has been reinforced with vertical and horizontal ribs to prevent potential impact and compression caused by collisions.

In short, heat management, safety protection, charge and discharge management, explosion-proof and pressure relief are all software engineering problems, while high-strength steel, reinforced ribs and buffering space are hardware engineering problems.

On this basis, considering that WM Motor does not make battery cells like Tesla or BYD, WM Motor needs to output rigorous technical standards, such as a voltage difference of less than 25 mV, to ensure the high consistency of battery cells.

Creating a new car in a rush is very dangerous. The appearance of WM Motor’s battery design was heavily influenced by the fact that 70% of the founding team had a traditional automotive industry background and a deep obsession with safety and reliability.

The Magna executive responsible for outsourcing the production of the Jaguar I-PACE electric vehicle previously stated publicly that there is a widespread misconception that EVs are simpler than internal combustion engine cars. Making a safe, reliable, and stable performing electric vehicle is not easy at all.

However, after increasing the entry-level NEDC range to 400 km, WM Motor has another problem: the difference in range between the entry-level and top models is only 60 km, which is clearly not enough when it comes to range. NIO and XPeng have successively launched models with a range of more than 500 km. Where is WM Motor’s range of 500+ km?

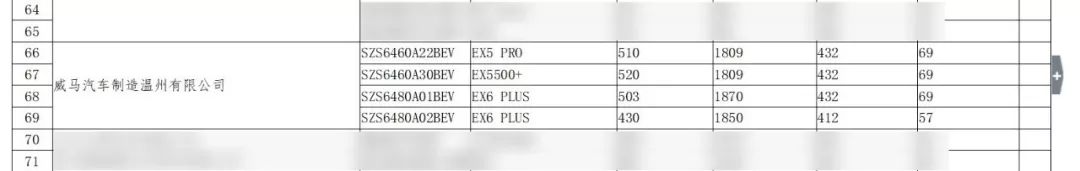

On June 12th, the Ministry of Industry and Information Technology (MIIT) released the catalog of new energy vehicles exempted from vehicle purchase tax (the 25th batch), including four models declared by WM Motor Manufacturing (Wenzhou) Co., Ltd., with the largest battery pack specification of up to 69 kWh and NEDC range of up to 520 km.

I suddenly recalled September 21, 2016, when WM Motor announced its 128-product plan strategy. Nobody expected the intensity of subsidy reduction today, and WM Motor CEO, Shen Hui, said during the forum that WM Motor’s top priority is to make a mainstream intelligent vehicle with reasonable price, stable supply, and reliable quality, which users are willing to buy without a license or subsidies.

WM Motor didn’t stand out, WM Motor just did things according to its own ideas.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.