Woof Woof Hu

Whether it’s fully electric or plug-in hybrid, the three-electric system, especially the battery pack, has made the cars much heavier – a fact that everybody knows. Simultaneously, the large capacity battery packs that lie on the chassis are also changing the “body shape” of EVs.

The thickness of the battery pack in the current fully electric vehicles is generally above 100mm. For example, Model 3 uses 2170 cylindrical battery cells, which have a height of 70mm. After adding the thickness of the battery pack’s outer shell, internal pipeline, reserved clearance, etc., the entire battery pack is about 120mm in height.

XPeng, for example, specifically mentioned that the P7, as a pure electric sedan (rather than an SUV) was one of the few models at the time that used all sorts of methods to reduce the battery pack thickness from 140mm to 110mm. When the thickness of the battery pack is reduced to nearly 100mm, it is already at a bottleneck.

Reality is not like a game, so all of this physical thickness cannot be overcome. In order to make electric vehicles look as normal and appropriate as possible in terms of use and appearance, people have tried every conceivable way.

Either Up or Down

When the “oil-to-electric” transformation was in full swing, the impact of battery pack height was particularly apparent.

There are only a few ways that space can be acquired to add a battery pack to a gasoline-powered car’s chassis or undercarriage: hang it directly below the chassis, sacrificing the ground clearance; move the vehicle floor up, sacrificing interior space, especially vertical height; design the battery pack as an irregular shape rather than a flat surface, fitting it in wherever there is space. Of course, there are also mixed approaches.

Adding an external battery pack is usually an old-fashioned method, and in the early years, one could observe with a glance whether a car had undergone the “oil-to-electric” transformation. During the process of purchasing a vehicle, most consumers pay little attention to the ground clearance and are more concerned about the interior space. It might not be until after swiping the card and hitting the road that they realize there is a problem: why is it so easy to scrape the bottom of this car?

Raising the floor height is also a common practice; even now when you take a ride-sharing car, you might come across some early, low-cost EVs, especially sedans. You are likely to notice the abnormal height difference between the car’s interior floor and the outside ground, the strange angle of the rear seat cushion, and the posture resembling that of a squatting toilet. If the car is a compact or sleek model, even if the head touches the roof, there is still not enough space. If interior space cannot be compromised, the only solution is to raise the entire vehicle higher.

With the prevalence of pure electric platforms, a more systematic design structure has made rush tactics such as raising the floor or lowering the ground clearance disappear. However, the battery still occupies vertical space, and even in battery packs with a thickness of over 100mm, a certain part of the thickness is still not “smoothed out”.

Pure electric SUVs can choose to reduce the ground clearance to the level of sedans to ensure that the interior space and overall height of the vehicle are not too outlandish. City SUVs already have relatively good passage ability, and pure electric SUVs can lie flat. Especially since SUVs already have a higher body, if the external dimensions continue to increase, it will hinder passage in daily use in cases of height restrictions.

In normal mode, the Model X has a ground clearance of 166mm, and even in the highest mode of the air suspension, it is only 206mm, which is not much larger than many sedans. The BMW iX3, as the electric version of the X3, has a ground clearance of 179mm, which is even smaller than that of the X3 at 212mm (the 3 Series sedan on the same platform is approximately 165mm), and this is already a good standard among electric vehicles on a common platform.

The space that sedans can expand downwards is much smaller. The new i3, on the same platform as the 3 Series, has a ground clearance of 140mm, and the Tesla Model S has a ground clearance of 126-158mm (in normal and highest modes of the air suspension), and the reduction relative to their fuel or SUV counterparts is minimal because they have already reached their limit. To reduce the thickness of the battery pack by over 100mm, space can only be found within the car or through increasing the overall height of the vehicle.

It is difficult for all electric vehicles to avoid the increase in the height of the interior floor. However, since SUVs inherently have a higher floor, decreasing the ground clearance does not significantly change the floor height and passengers usually do not feel a significant difference. For pure electric sedans, especially small ones, the increased floor height is not easy to conceal.

Is there a way to have best of both worlds?

Pure electric sedans, especially three-compartment sedans designed to cater to current trends, often have to put more effort into the vertical space in the rear row. If it is a relatively small pure electric three-compartment car, the roofline, rear headroom, and battery pack thickness under the car form a triple conflict.In the high-end electric vehicle market, there has been a practice of sacrificing battery capacity to ensure the first two factors. Porsche Taycan and Audi e-tron GT use the “footwell” design in the rear seats, where the battery pack is hollowed out from the foot space without placing battery cells or modules, sacrificing some battery capacity to make the rear roofline smoother without overly sacrificing rear vertical space.

Taycan’s battery pack has 33 modules and about 93kWh of energy, and the space left by the footwell can accommodate at least 6 more modules. Without the “footwell” design, it could have added 18%, or about 17kWh of battery capacity. However, Porsche and Audi did not put range in the absolute first place for this J1 platform.

Originally, this design seemed like a compromise on range for the J1 platform because it was derived from the MSB internal combustion platform. However, Mercedes-Benz’s concept car, AMG Vision, recently announced that it will consider using the “carved-out” approach to free up rear foot and vertical space after mass production, which can be understood as the Mercedes version of “footwell.”

Similar to Porsche Taycan and Audi e-tron GT, the AMG Vision concept car, indicated by the AMG prefix name, previews a high-performance, high-specification luxury four-door coupe. Luxury, four-door, coupe is probably the most subdivided model that needs to balance exterior lines (coupe) and four-seat space (four-door).

Although the interior has not been announced, and it is still a preview concept car without even side windows, from the AMG Vision’s “ruthless” rear roofline, if it were not for the “footwell”-like design, the rear seats would probably be quite mediocre.

Having to achieve a low-slung coupe roof and at least passable rear space, the battery volume/capacity, which once had absolute priority on other electric vehicles, has now become the target of surgical operations. The positioning and demands have changed, and so have the priorities.

Before this, the battery pack rendering image given by Lucid Air also had a footwell design similar to Taycan’s in the rear seats. However, the actual mass-produced Lucid Air did not incorporate this design, the reason for which is unknown.

Recently, Mercedes-Benz has been pursuing lower drag coefficients by using “footwells” to generate lift. The EQXX concept car achieves a ultra-low drag coefficient of Cd=0.17 with its long-tailed design, which was expected to be surpassed by the AMG Vision. However, the current AMG Vision is not as advanced as the EQXX, so it is not necessary to disclose the drag coefficient.

The current exterior design shows that AMG Vision also has the idea of reducing drag by elongating the rear. However, the elongated effect is achieved through a low and short rear roof and longer wheelbase, which is closer to reality than EQXX’s long rear overhang design. With reference to the EQS’s persistence in low drag and its disdain for traditional proportions, an openly low-drag style may become the design language for Mercedes-Benz’s future electric cars.

However, to reduce drag with such a long and low rear body, the headroom in the rear seat, especially for the head, is greatly suppressed. So it is not difficult to understand why the “footwell” design was proposed. The highest energy consumption and the most difficult charging scenario for electric cars is on highways, so reducing drag may be another better option than the familiar battery stacking.

Therefore, for electric sports cars like the AMG Vision, which are positioned as high-end, high-performance, and focus on styling and aerodynamics, the “sacrificing battery for height” solution has value to consider and adopt.

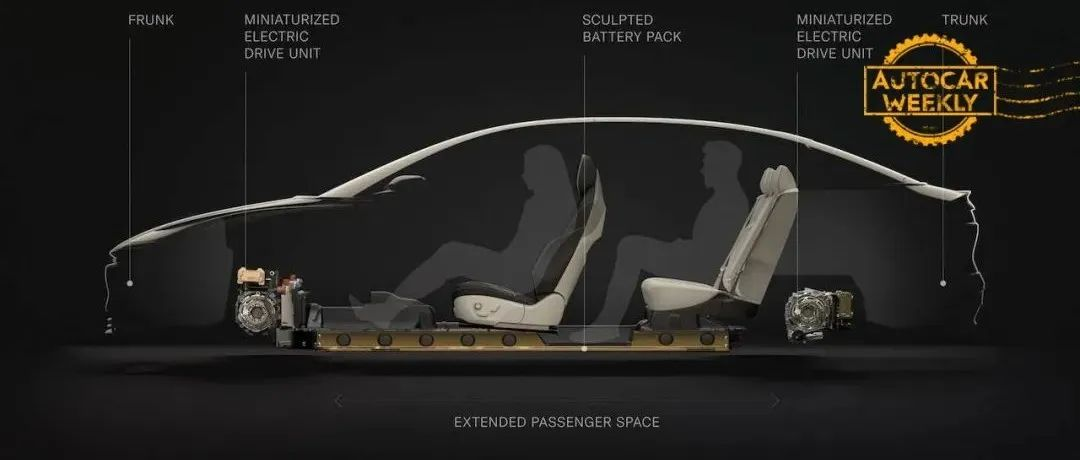

Another way to reduce the thickness of battery pack is to change the vertical battery unit to a horizontal arrangement. The battery pack of SAIC’s E2 architecture uses horizontal battery units, with a thickness of 110mm, which is already among the top tier. However, it has not yet reached its limit. General Motors’ Altium platform provides multiple cell arrangement options, including horizontal. With this, the thickness of the battery pack can be significantly reduced while reducing the capacity.No longer pursuing the maximization of battery capacity, the determination to reduce thickness is the premise. The arrangement of battery cells inside the battery pack is not easily changed. Even for horizontal cells, a separate design is needed for the water cooling system. Multiple cell arrangement methods like those of OTN Energy need to be decided at the beginning of the platform development, which is not difficult, but more importantly, the brand has practical needs and uses for this.

The increasingly popular CTC battery pack is also helping to free up space for electric vehicles, but “removing one layer of board” only contributes about 10mm vertically. Compared to the current conventional battery pack thickness of 110-140mm, the role of CTC is at best negligible.

For large luxury car companies capable of building or improving their own charging network, it may not be necessary to continue compromising in other areas for single-charge range, such as ground clearance, vehicle height, and rear space. As previously discussed in “A Range of 1000km, I Can But I Won’t Give It to You,” the importance of a self-operated fast charging system is already showing signs of overtaking the single vehicle range.

The standard Model 3’s range has never been the best on the market, but it has long dominated the sales charts for mid-to-high-end electric vehicles. Models with significantly longer ranges than the standard versions of Model 3 and Model Y have already appeared, but Tesla’s supercharging station system’s speed, reliability, and high density remain an unshakable advantage. Consumers’ pursuit of long-range is just an avoidance of charging difficulties.

At least until the overall reliability of third-party charging stations improves significantly and becomes more widespread, an electric vehicle with a range of 700km but no self-operated charging stations may not necessarily be more convenient than a Model 3 with a range of 500km. Under the current circumstances, the mentality of almost sparing no effort and using most of the energy to increase the range of the vehicle at almost any cost may be outdated.

Traditionally, in order to make way for battery capacity and range, vehicle height, floor height, vertical space, and so on have been “exploited” repeatedly. Finally, there are signs of stopping. At least for some cars, it is time to consider lowering “internal height” again.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.