I am willing to stake all my achievements and reputation, to fight for Xiaomi Auto.

On March 30, 2021, at a press conference themed “Everlasting Life,” Lei Jun announced Xiaomi’s official entry into the intelligent electric vehicle industry, expressing his firm determination with a passionate tone and words.

1003 days later, on today’s date of December 28, 2023, Xiaomi Auto is finally here.

At this press conference, themed “Leap,” the first product of Xiaomi’s car-making endeavor, the Xiaomi SU7, officially debuted and was pre-launched. Along with this, Lei Jun also introduced a series of software and hardware technological development behind the Xiaomi SU7, as well as a series of hardcore industrial technology explorations and supports that Xiaomi has undertaken since it announced the building of cars.

While Lei Jun did not announce the price on site, our biggest takeaway after this conference is: The car that Xiaomi has created seems to be indeed reliable.

Here Comes the Xiaomi SU7, a Class-C High-Performance Tech-Eco Sedan

Let’s look first at the Xiaomi SU7 that debuted at this conference.

The Xiaomi SU7 is positioned as a Class-C high-performance tech-eco sedan. Its size and related parameters are shown below:

Lei Jun noted that the decision to make a sedan is because it represents the “spirit of the times” in automobile industry. High performance was emphasized, as it’s in Xiaomi’s DNA. Lei Jun made it clear that Xiaomi Auto’s target customer group is the elite of the times, with the Xiaomi SU7 emphasizing “tech leap, man and vehicle as one.”

The Lowest Drag Coefficient among Globally Produced Sedans: 0.195

Lei Jun spent a significant amount of time in the press conference discussing the car’s exterior appearance. For the specific appearance, you can refer to our video.

Evidently, the Xiaomi SU7 has a low posture, and the front and sides are marked with smooth and full body lines and a tension-filled front wheel cover design. The tail uses a small spoiler and a halo taillight. Simultaneously, the Xiaomi SU7, considering the above body parameters, greatly values the golden ratio of the wheelbase, wheel height, and width-height ratio in its design.

Thanks to such design, the Xiaomi SU7 has an ultra-low drag coefficient, with only 0.195. Lei Jun stated that this is “the lowest drag coefficient among globally produced sedans.”

In terms of color, the Xiaomi SU7 offers three color schemes: Gulf Blue, Elegant Grey, and Olive Green; Gulf Blue being the main color when Xiaomi Auto officially released images for the first time.Unlike the common door handle designs in the industry, the XiaoMi SU7 adopts a Unique semi-hidden car door handle design which optimizes the aerodynamic efficiency of the vehicle whilst resolving the icing problem in cold weather, and preventing the potential issue of the traditional pop-out door handle getting stuck.

Within the interior design, XiaoMi SU7 features a wrap-around cockpit and a floating dashboard. The car has a total glass area of 5.35 square meters, providing sunroof and front windshield sun and heat protection for users.

Instead of following the prevalent touchscreen design in the market, XiaoMi has chosen a physical button design making it more intuitive for the users. Of course, XiaoMi has applied ambient mood lighting and Dolby audio systems. In terms of the health aspect of the vehicle interior materials, XiaoMi has also specially achieved OEKO-TEX Level-I certification for the entire vehicle interior.

Additionally, the design of the XiaoMi SU7 also greatly considers spatial aspects, boasting 1,012 mm of vertical sitting space in the front row and 105 mm of knee space in the rear row. Notably, its trunk capacity is 517 L and the front boot holds up 105 L, reputedly the largest front boot in China’s electric vehicle.

In view of the design objectives, Lei Jun, the CEO, stated that he has scrapped the car’s exterior design three times. However, he emphasises that the design needs to “stand the test of time”. At the event, he introduced some representative individuals from the XiaoMi Car Design Team, including:

- Chief Designer of Xiaomi Car: Li Tianyuan.

- Head of Exterior Design: Chou Zhen.

- Head of Interior Design: Shin Muto.

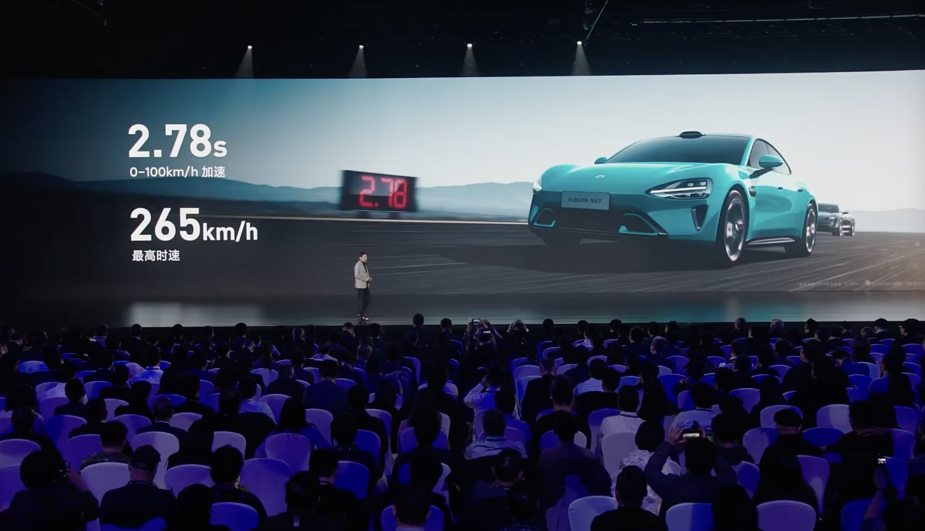

0-100 acceleration in 2.78 seconds, surpassing Taycan Turbo

As a pure electric sedan, XiaoMi SU7 tags itself as “high-performance”.

To be specific, the XiaoMi SU7 dual motor version delivers a maximum power output of 673 PS, peak power of 495 kW and peak torque of 838 N·m.

With such performance backup, the XiaoMi SU7 can achieve 0-100 acceleration in just 2.78 seconds, surpassing Porsche’s Taycan Turbo. Similarly, it can reach a maximum speed of 265 kilometers per hour, higher than both the Porsche Taycan Turbo and Tesla Model S.

In terms of maneuverability, the XiaoMi SU7 has a turning radius of 5.7 meters, the officials claim it can feature limitless freedom in customizing driving modes, and among which the Boost Mode supports 20-second over-torque output. Of course, launch mode is also present.The stopping power of the XiaoMi SU7 does not disappoint, with a braking distance of 33.3 meters from 100-0 km/h.

At the same time, Lei Jun announced at the launch that the XiaoMi SU7 Max is powered by the Ningde Times Kirin battery with a 101-degree angle. The CLTC endurance is 800 kilometers; in terms of charging, the model supports 800V super-fast charging, which can charge 200 kilometers in 5 minutes or 510 kilometers in 15 minutes.

Robust overall vehicle safety and privacy protection

The XiaoMi SU7 doesn’t fall short in terms of overall vehicle safety.

For passive safety, the XiaoMi SU7 features a cage-like body made of steel and aluminum, with high-strength steel and aluminum alloys accounting for 90.1% of the structure, achieving a maximum strength of 2,000 MPa and a vehicle torsional stiffness of 51,000 N·m/deg.

In addition, all four core structural parts of the XiaoMi SU7 are enhanced, including a digitally constructed composite ultra-high-strength frontal longitudinal beam, a unibody die-cast aluminum diagonal beam, and ultra-strong steel crossbeam and aluminum door sill beam that provide a vehicle lateral resistance to impact of 820 kN. Further, the XiaoMi rear floor uses a large die-cast one-piece molding manufacturing process.

Lei Jun stated that in order to test the safety of the XiaoMi SU7, the company conducted over 40 collision tests internally to ensure the car passed the strict standards, some of which were even more stringent than American regulations.

Furthermore, the XiaoMi SU7 is equipped with 7 airbags, including a 2,040 mm long curtain airbag.

In terms of active safety, the XiaoMi SU7 carries 16 active safety features, including forward protection, side protection, rear protection, and other measures. For this, XiaoMi developed an active safety simulation verification system, which includes a full-link lossless simulation verification system and a large-scale scenario library specific to China.

At the same time, XiaoMi’s proprietary road data 4D spatio-temporal annotation can predict the future trajectories of moving vehicles and vulnerable road users, with over 40% accuracy and 30% lower latency. Importantly, XiaoMi has specifically optimized for accidents involving two-wheeled vehicles in China, particularly in scenarios like a bicycle crossing the road at night, to enhance safety.

Lei Jun also mentioned, the XiaoMi SU7 supports forward emergency braking, designed to prevent mistaken triggering more than once every 300,000 kilometers, providing comprehensive active safety protection.Certainly, in terms of battery safety, XiaoMi has undertaken a series of actions, such as collaborating with Contemporary Amperex Technology Ltd. for the pioneering battery inversion technology – we will dedicate another section to elaborate on this later.

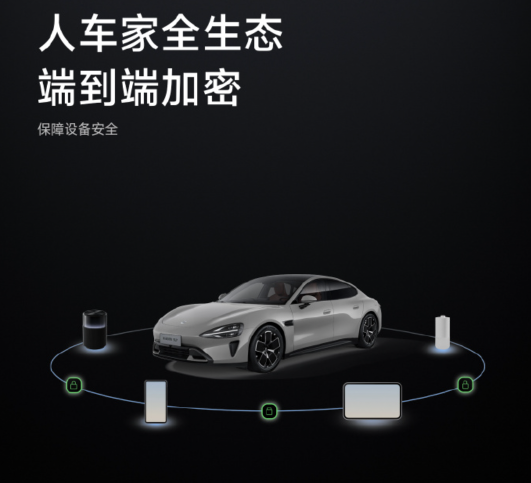

Additionally, Lei Jun has emphasized data confidentiality safety.

Specifically, in terms of security, XiaoMi kicks off its protection from the operation system layer of HyperOS, providing users with comprehensive protection starting from the foundational layer to the application layer. At the same time, regarding account security, XiaoMi SU7 achieves privacy isolation among accounts – a dedicated service for individual usage ensures multi-level protection of private data.

Moreover, in terms of device safety, XiaoMi intends to devote to full ecosystem end-to-end encryption, ensuring the safety of all user devices.

‘Human-vehicle-home Ecosystem’ based on HyperOS

Based on the long-standing techno-ecosystem of the XiaoMi Group, one of the highlights of the XiaoMi Car undoubtedly lies in ‘Human-Vehicle-Home Ecosystem’ based on HyperOS.

Hence, from a product perspective, XiaoMi SU7’s Smart Cab is one of the main attractions of this product.

Regarding hardware, XiaoMi SU7 is equipped with the Qualcomm Snapdragon 8295 chip considered as standard for current intelligent cabins, providing a smooth operating experience; simultaneously, the XiaoMi SU7 features a 16.1-inch 3K ultra-clear central control screen and an exceptionally large 56-inch HUD.

With this hardware foundation, the XiaoMi SU7, aided by XiaoMi HyperOS, presents immersive interaction experiences consistent with mobile tablets. Mobile phone users can quickly master the working mechanics without previous learning. On the display, it has a 3D digitized vehicle model that changes with the environment, XiaoMi’s most advanced multi-task flexible frame which supports window size adjustment; passengers can also directly adjust the passenger seat and air conditioning from the control centre by simply swiping down the right side.

The Connection between Mobile and Car is the Highlight, CarIoT Ecosystem set to Open

Of course, the cross-end user experience between mobile phones and car component is undoubtedly a star feature of XiaoMi SU7.

Centred on XiaoMi SU7 and XiaoMi mobile, the car component and phone can achieve seamless cross-end connection, such as directly continuing to play a half-watched video on the vehicle screen; familiar navigation applications can be called out on the mobile phone and can be displayed full screen.

In terms of application ecosystem, the XiaoMi SU7 cockpit system has deeply adapted the mainstream vehicle applications, seamlessly incorporating Xiaomi’s tablet ecosystem; even more, the user can also ‘Pin to car’ any mobile application, directly presenting it in the native card format.

In both software and hardware ecosystems, based on XiaoMi’s long-term accumulation, the XiaoMi SU7 also boasts an enormous hardware ecosystem in the industry.

In both software and hardware ecosystems, based on XiaoMi’s long-term accumulation, the XiaoMi SU7 also boasts an enormous hardware ecosystem in the industry.

To be specific, devices of the same Mi account can realize password-free connection and an effortless boarding experience. At the same time, XiaoMi crafts an exclusive CarloT ecosystem for the car. Various locations, including the central control screen, storage console, and back of the seats all support hardware expansion, with the plug and play convenience. XiaoMi also declares to open up the XiaoMi CarloT ecosystem to global ecological developers, not only providing a unified standardized interface and most diverse communication protocol standard but also enabling system-wide underlying.

Meanwhile, to cater comprehensively for Apple users, XiaoMi’s automobile also improves support for Apple devices.

The XiaoMi SU7 entirely supports wireless CarPlay on-board and can realize media transference based on AirPlay. Even expansion for iPad in rear seating is supported, controlling air conditioning, music, and seating—as Lei Jun stated, with these supports, Apple users will also have a great experience after hopping on a XiaoMi automobile.

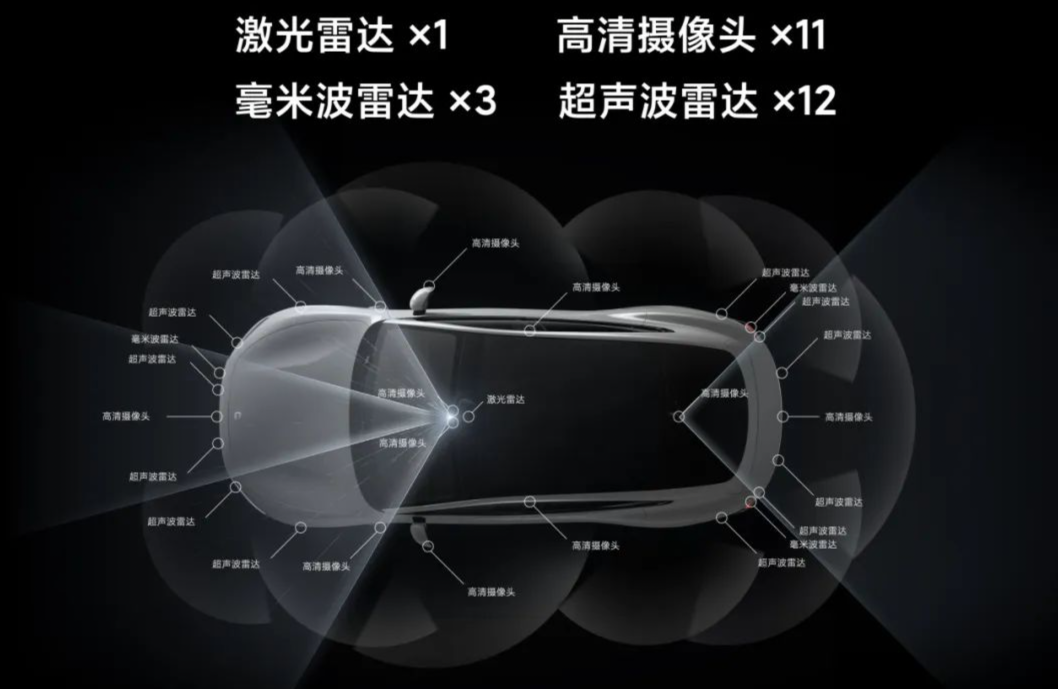

XiaoMi Smart Drive: NOA realization in 100 cities by 2024

In smart driving, XiaoMi essentially adopts the industry’s mainstream software and hardware technology route too.

In terms of equipment configuration, XiaoMi uses dual Orin-X chips, its computing power reaching 508 TOPS, which is also the commonly adopted standard in the industry. In the aspect of perception equipment, XiaoMi’s config adopts 1 lidar, 11 high-definition cameras, 3 millimeter-wave radars, and 12 ultrasonic radars, not deviating much from the mainstream choice.

On the software algorithm side, XiaoMi’s smart driving team utilizes the latest generation of base-level algorithm—where the typical BEV + Transformer + occupying network structure comes in—and integrates large model technology entirely.

At this launch, Lei Jun also introduced three distinct technologies:

Firstly, the adaptive zooming BEV technology.

The core of this technology is essentially that users exhibit different perception ability needs when using the car in different contexts. For instance, in highway driving, users need to see further into the distance; in city driving, users need a wider view; whereas reversing necessitates more precision.

Based on these scenarios, XiaoMi developed adaptive zooming BEV technology, that is, utilizing different BEV perspectives in different driving contexts, consequently augmenting the practicality of perception ability in various scenarios.

Secondly, the debut of Super-Resolution Occupancy Network Technology.

Put simply, XiaoMi incorporated super-resolution vector algorithms into the commonly used occupancy network technology in the industry, transforming all visible objects seen on the road into stereoscopic items modeled after continuous curvy surfaces, enhancing identification accuracy to less than 0.1 m. This approach significantly boosts identification precision.### III. Road-Large Model Technology

In essence, Xiaomi’s Road-Large Model technology can generate road topographies in real time where high-precision maps are not available or inaccurate. Its performance is comparable to high-definition maps and can judge road conditions in real time like a human. A typical scenario is when the road ahead is under construction, and it can generate intelligent guiding lines to smoothly navigate around the road.

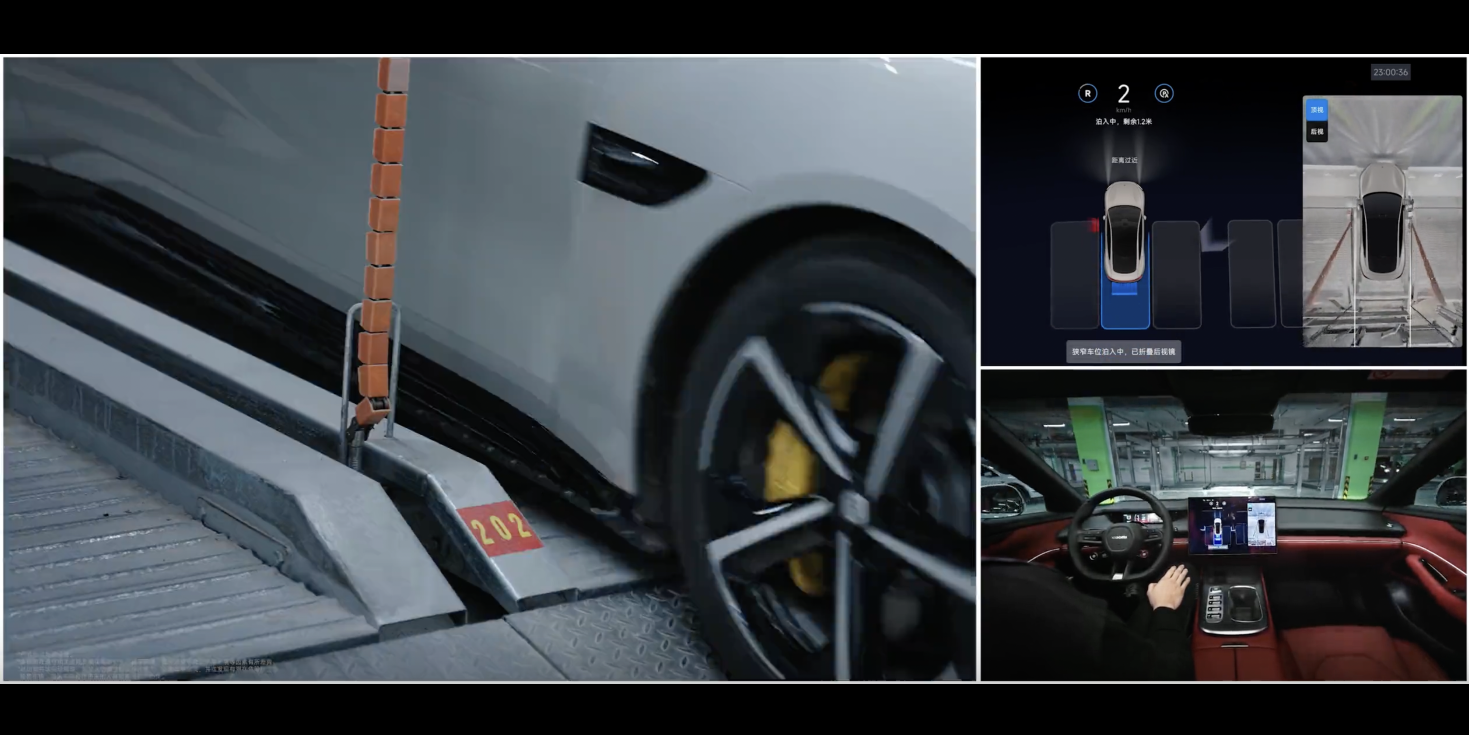

It’s worth mentioning that at the launch, Xiaomi also demonstrated the abilities of end-to-end large model perception-decision based on its self-research; Specifically, vehicles can successfully dock in a mechanical parking space with a width of 2.1 meters.

Lei Jun stated that Xiaomi aims to reach the top tier of the industry in intelligent driving by 2024. Functionally speaking, Xiaomi’s intelligent driving can support functions such as Highway NOA, City NOA, and AVP Intelligent Valet Parking – regarding City NOA, Lei Jun stated that Xiaomi plans to initiate NOA in 100 cities by 2024.

The “Hardcore Tri-weapon” behind Xiaomi SU7’s Car Manufacturing

Besides Xiaomi SU7 car, Lei Jun also mentioned the very hardcore car manufacturing technology from Xiaomi in this conference.

Although Xiaomi is already a Fortune 500 company, it’s considered a rookie with little manufacturing experience in an industry dominated by big companies. Compared to new car manufacturing forces like “Wee Xiao Li”, Xiaomi’s experience in this area is generally lacking internationally.

However, after nearly three years of financial investment and forward R&D, Lei Jun debuted the “tri-weapon” of their car manufacturing technology at this conference, where this technology is entirely focused on the closely related technologies of a good car itself, such as “three-electric” and car body.

Xiaomi hopes that this will prove its seriousness in car manufacturing and its absolute capability to get it right.

27,200 RPM, Challenging the Global Electric Motor Speed Ceiling

Being one of the most crucial components of an electric vehicle, Xiaomi chose to self-develop for the electric motor.

At this conference, Xiaomi introduced three electric motors, namely:

- Xiaomi Super Motor HyperEngine V6, RPM is 21,000.

- Xiaomi Super Motor HyperEngine V6s, RPM is 21,000.

- Xiaomi Super Motor HyperEngine V8s, RPM reaches 27,200.

Among them, the Xiaomi Super Motor HyperEngine V6/V6s (being named after an engine equivalent to a petrol engine V6 and V6 mPerfomance) operates at 21,000 RPM, leading the industry. Respectively:

- HyperEngine V6’s RPM is 21,000, with a peak torque of 949 Ps, power output of 220 kW, and torque of 400 N-m.* HyperEngine V6s, with a rotation speed of 21,000 rpm, maximum horsepower of 374 Ps, power of 275 kW, and output torque of 500 N·m.

To create the HyperEngine V6/V6s, XiaoMi partnered with two companies, namely United Automotive Electronics Co. Ltd. and Huichuan Technologies Ltd.

Beyond the V6/V6s, XiaoMi has introduced the XiaoMi super engine HyperEngine V8s, touted as the “global peak performance of motors”, with a rotation speed as high as 27,200 rpm, currently the highest in the world.

Specifically, the product features of this HyperEngine V8s include:

- The industry’s first 960 MPa high strength special silicon steel sheet.

- Redesigned motor cooling system, adopting bidirectional stereo oil cooling technology, successfully improving the heat dissipation efficiency by more than 50%.

- Redesigned the entire rotor and stator, fully equipped with self-developed leading SiC power control module, with a conversion efficiency up to 99.85%.

- Applied for 155 patents throughout the R&D process, with 60 patents authorized.

At the press conference, Lei Jun said that the XiaoMi super engine HyperEngine V8s can be considered the world’s top motor.

In terms of production time, the XiaoMi super engines HyperEngine V6 and V6s have been mass-produced, and will be equipped in the XiaoMi SU7 series models that will hit the market in 2024 – while the XiaoMi super engine HyperEngine V8s will officially be mass-produced in 2025.

It is worth noting that XiaoMi is continuing to conduct pre-research on super motor technology, continuing to explore the apex of technology, and has achieved a super high speed of 35,000 rpm in the laboratory pre-research by adopting carbon fiber laser winding process.

Building its own battery factory, first to introduce inverted battery cell design

Aside from the self-developed motors, XiaoMi has also put significant efforts into the automotive battery system.

Specifically, in collaboration with CATL, XiaoMi has independently developed an 800 V high voltage silicon carbide platform, reaching an actual voltage of 871 V, surpassing comparable products.

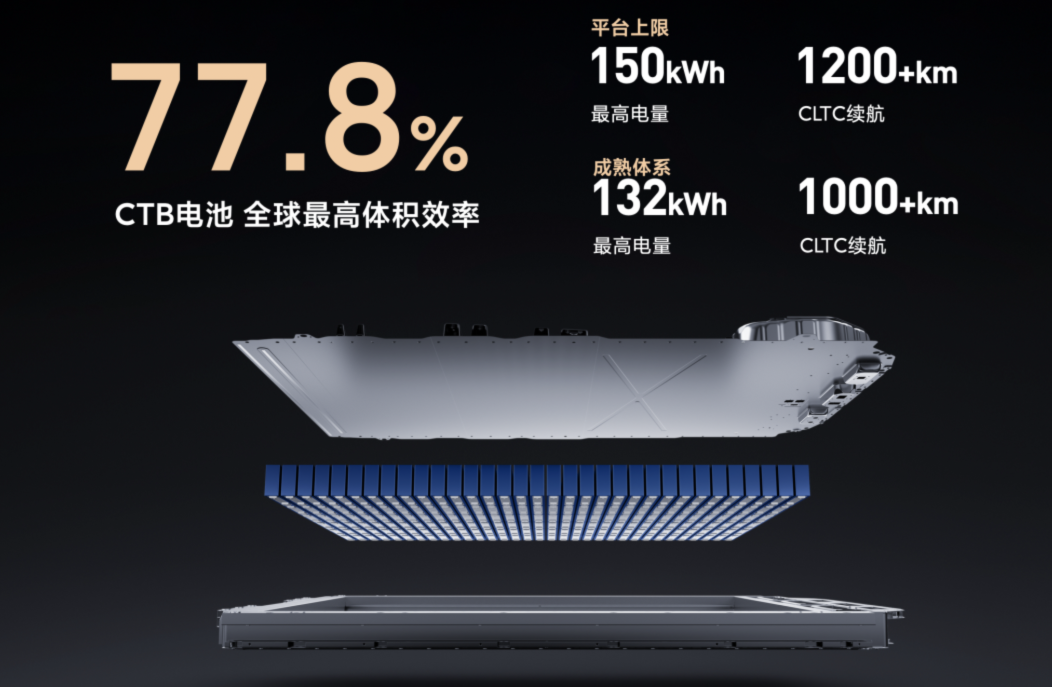

To maximize the spatial experience of a sedan, XiaoMi has independently developed the CTB integrated battery pack technology, with its CTB integration efficiency reaching 77.8%. To achieve such integration efficiency, XiaoMi has used methods such as a two-in-one floor cover, inverted battery cells, multi-functional elastic layers, minimalist wiring, etc., increasing the integration efficiency by 22.4% and freeing up a height of 17mm. Specifically:

- The body floor and battery pack cover are integrated into one, freeing up 10 mm of height and improving integration efficiency by 9.1%* The initial launch of inverted battery cells, share the base space with multiple modules, releasing 7 mm in height, with an increased efficiency integration by 5.8%.

- Multi-function elastic lamina (which is a liquid-cooled plate and also a structural piece), insulation board, water-cooled plate and longitudinal beam three-in-one, with an increased efficiency integration by 6.5%.

- Wiring reduced by 91%, with an increased efficiency integration by 3%.

Lei Jun stated that with such a structural design, without changing the current chemical system, it could theoretically hold a 150-degree battery, theoretically reaching a driving range of 1,260 kilometers with CLTC.

In terms of batteries, XiaoMi cooperates with CATL to use Kirin batteries. Not to mention, for the safety of the battery, XiaoMi’s battery pack uses an explosion-proof valve downward design, in a large amount of cooperation with CATL, this is the industry’s first cell explosion-proof inverted valve Kirin Battery design.

Additionally, in order to ensure better battery safety, XiaoMi has undertaken a series of technology explorations:

- Industry-first inverted battery cell technology, pressure relief valve facing down, can rapidly release energy downwards under extreme conditions, guaranteeing maximum passenger compartment safety.

- 14 layers of hardcore physical protection, 3 layers of top support + 3 layers of side protection + 8 layers of bottom protection.

- Industry-leading heat dissipation, insulation design, adopting dual large-area cooling schemes. Both larger surfaces of the battery cell have heat dissipation plates. The cooling area is 7.8 square meters, the largest in the same class (4 times the average of the industry).

- Also, each side of each battery cell has used 0.6 square meters of gas-gel insulation material in total. This insulation material used by spacesuits can withstand high temperatures up to 1,000 degrees, with extreme insulation performance, but costly.

Simultaneously, XiaoMi has also incorporated battery cloud safety, it can collect data in real time, analyze and give early warnings through a private network with encrypted cloud, which includes 3-layer heat out-of-control redundant monitoring and warning strategies, “round-the-clock” precise warning. Likewise, XiaoMi employed a battery management system that is developed in-house, achieving the highest functional safety level of ASIL-D, and an active power cut-off within 4ms.

In terms of safety testing, Lei Jun stated that XiaoMi applies the global most stringent battery safety testing standards, which include:

- Over 1,050 safety testing verifications, 96 times the international durability testing duration.

- 7 safety design optimizations, 16 supra-standard verifications.

- XiaoMi has already applied for 128 patents in the battery field and has been authorized 65.

It’s worth mentioning, in order to ensure the safety and design innovation of the battery pack, Xiaomi also chose to build its own battery pack factory.

Additionally, to solve the battery endurance problem of electric vehicles in winter, Xiaomi has released two heat management technologies. The first is the “Xiaomi High-Efficiency Dual-Mode Heat Pump” technology, which can still draw heat from cold air at -20 degrees; the second is the “Xiaomi’s First Three Heat Sources Step-by-Step Energy Gathering” technology, which can gather the waste heat produced by the electric drive, compressor, and heater step by step and transfer it to the cabin, with the maximum battery heating power reaching up to 18kW.Lei Jun stated that, based on XiaoMi’s thermal management system, XiaoMi automobiles can achieve faster low-temperature air-conditioning heating speeds, higher low-temperature endurance retention rates, and faster low-temperature charging speeds than their counterparts in winter.

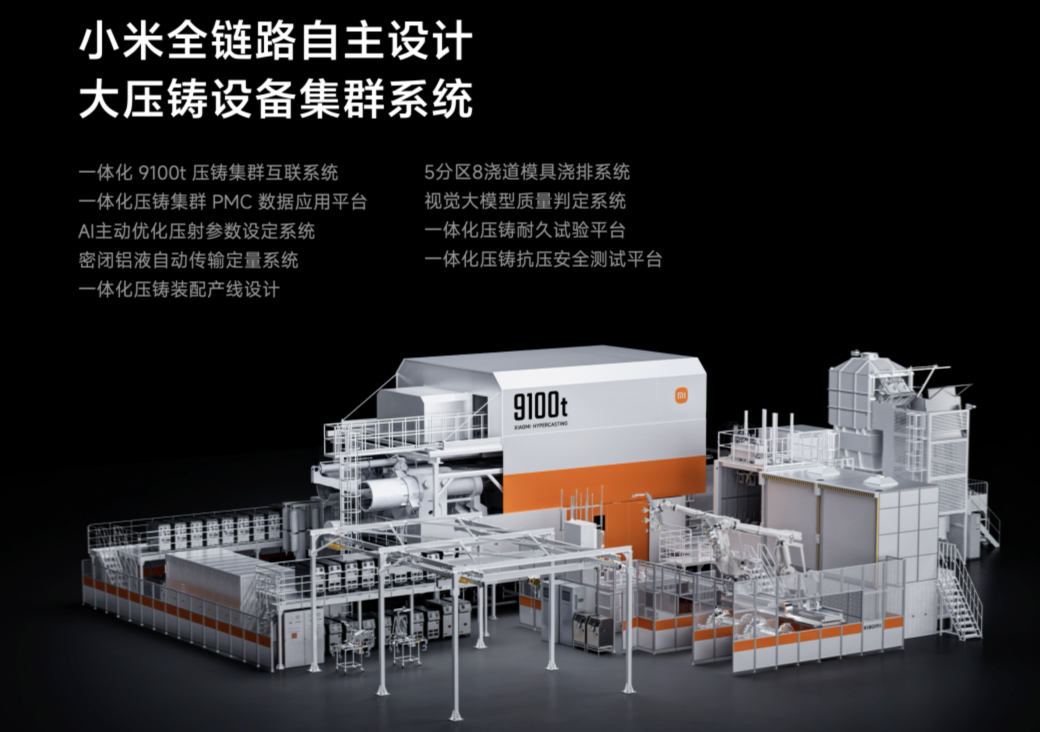

Self-developed 9,100-Ton Equipment Large Die-casting Cluster

To build a good car, XiaoMi has even integrated casting into its research and development focus, becoming the only automaker in China to self-develop a “large die-casting equipment cluster” and “die-casting materials”. For the investment in die casting, XiaoMi has invested several hundred million yuan.

The design of the entire die-casting island includes over 60 pieces of equipment, 9 major processes, and 433 process parameters. Currently, there are two die-casting islands located in the Yizhuang factory, with a total area of 840 square meters each.

Specifically, XiaoMi independently designed a 9,100-ton integrated large die-casting equipment cluster system. A single large die-casting equipment cluster covers an area of 840 square meters, roughly equivalent to the size of two basketball courts, and has a total weight of 1050 tons. It’s worth mentioning that to complement the large die casting system, XiaoMi also developed an automatic visual model quality determination system, capable of completing inspections in 2 seconds, 10 times more efficient than manual checks, and at least 5 times more accurate.

The result of the large die-casting process allows XiaoMi to combine 72 parts of the car’s rear floor into one, reducing the number of welding points by 840, decreasing the weight by 17%, and reducing production time by 45%. This further results in a rear floor projection area that is 17% larger than the Tesla Model Y.

Furthermore, to complement its large die-casting system, XiaoMi has developed a Titan alloy independently.

Specifically, the Titan alloy developed by XiaoMi is a high-strength, high-toughness, heat treatment-free, environmentally-friendly die-casting material. As such, XiaoMi has become the only car manufacturer in China to hold a patent for mass production of its self-developed die-casting alloy material.

In order to develop the Titan Alloy, XiaoMi partnered with national key material laboratories to implement trace elements such as rare earth and zirconium into the formula. Alongside this, XiaoMi developed a “Multi-Material Properties AI Simulation System” to recommend the best 5 formulas from over 1,016,000 potential combinations. Engineers then selected three optimal alloy formulas that balance strength, toughness, and stability. This formula was only finalized after 1,550 trial and testing samples.

Additionally, in consideration of repairability, XiaoMi has adopted a considerate three-section repairable design, enhancing structural strength. This design ensures that there is no need to replace large die-casts during medium and low speed collisions, and also meets the collision standard of 90 km/h during high speed collisions.

Regarding XiaoMi’s self-developed large die-casting technology, Lei Jun says: While the whole industry is mainly focusing on the locking force tonnage of large die-casts, XiaoMi’s large die-casts are different. They are entirely self-developed, encompassing not only materials but also the equipment cluster system. The near completion of all links in the large die casting production chain demonstrates XiaoMi’s huge determination to deeply cultivate underlying technology.## In Conclution

For XiaoMi, this is undeniably a momentous launch event.

On one hand, in terms of the development of XiaoMi’s automotive venture, after exceeding 1,000 days of research and development, it’s vital that they fully display their authentic technological prowess. This encompasses a series of major investments and hardcore accomplishments in automobile manufacturing, which will validate their serious commitment to automobile production and their capability in the same field.

Unquestionably, based on the various hardcore innovative technologies launched in this event, XiaoMi has thoroughly embodied its high ambitions.

On the other hand, through its new product, the XiaoMi SU7, XiaoMi is striving to leverage its advantages accumulated over 13 years of advancement in various fields including smart phone industry, intelligence, operating systems, IoT ecosystems, etc., in order to achieve a ‘whole ecosystem’ strategy enveloping people, cars and homes, thus paving the way for greater potential in XiaoMi’s development.

To further push this strategy, it is pivotal that the sales of the XiaoMi SU7 be strong.

From XiaoMi Group’s development perspective, XiaoMi is also making a significant ‘leap,’ which is transitioning from a smart phone company to a true automobile corporation. Conveying this transformation and brand impression to consumers is challenging in itself – as it appears now, with the XiaoMi car launch event, XiaoMi has made a solid step forward.

Returning to the XiaoMi SU7 itself, whilst XiaoMi indeed has high expectations, noticeably, XiaoMi aspires to cease the cost-effectiveness strategy previously adopted by XiaoMi phones; Although no price has been announced, Lei Jun, the founder of Xiaomi, has repeatedly emphasized at the conference that this car is not inexpensive.

Then we come to a crucial question: Who is the XiaoMi car made for?

Lei Jun’s own answer is: the modern elites.

Nevertheless, for the increasingly competitive smart electric vehicle market, 2024 is a year of severe competition; In the challenging automotive market with severe competitors, XiaoMi, who has entered late into the game, must prove its efforts and establish its position in the automotive industry through a truly high-volume breakout model, hence how to price might be the most significant challenge that XiaoMi automotive faces before its official launch.

This article is a translation by AI of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.