Author: Tao Yanyan

With the increasing integration of power batteries and electric vehicles, the trend of power batteries has become apparent, focusing on how to optimize and adapt to a wider range of scenarios.

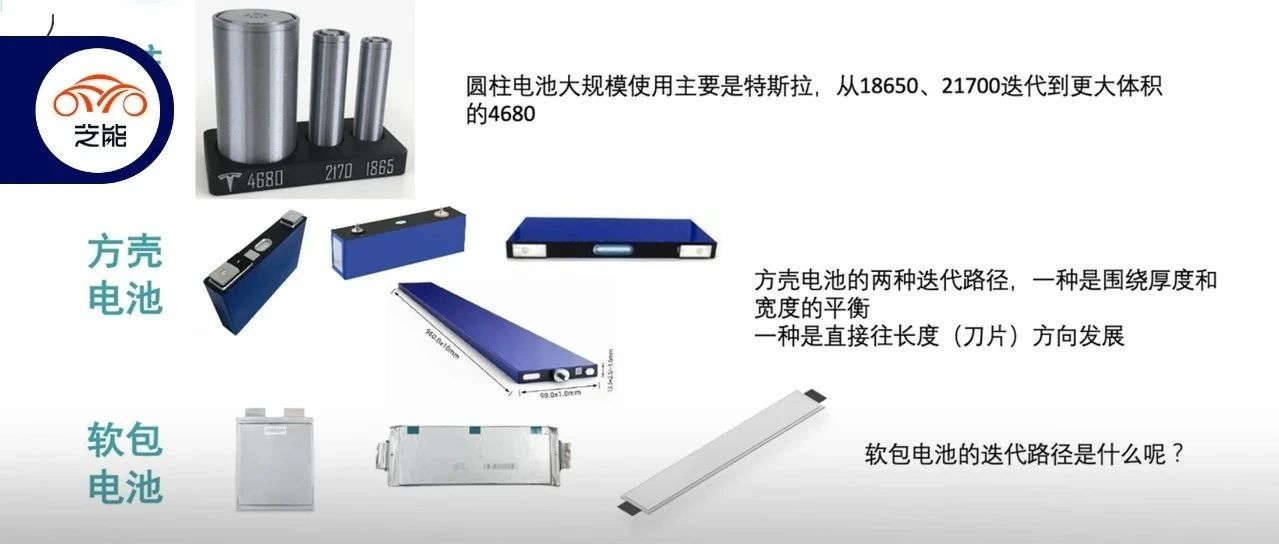

Firstly, the size and capacity of battery cells are increasing, not only for cylindrical, prismatic-shaped, and pouch-shaped batteries, but also getting larger.

◎Cylindrical batteries: evolved from 18650, 21700, to 4680.

◎Prismatic-shaped batteries: gradually become wider and thicker, from the original VDA size (14826.591mm).

◎Pouch-shaped batteries: also evolved from using VDA modules (length 300mm), to MEB’s 590 module (length 500mm+), with a trend of growing larger.

In terms of structure, it tends to be simplified, especially after the battery design trended towards CTP and CTC. This article focuses on the specification changes in pouch-shaped batteries.

Specification of Pouch-shaped Batteries

From the perspective of production and design, the size and volume of pouch-shaped batteries are flexible and can be customized according to the needs of different vehicle models and chassis requirements, making it more convenient for the structural design of future pure electric vehicles. Therefore, in the early days, General Motors and Nissan Motor respectively defined the dimensions of the batteries.

Customizable Cell Stage — GM and Nissan

The earliest applications of pouch-shaped batteries were around 2010, with typical models such as the Chevrolet Volt and Nissan LEAF, both using pouch-shaped batteries with single-sided pole ears. The specific cell and battery pack designs are as follows. These two specifications have been used for a long time, including the LEAF currently being sold.

### VDA Dimensional Specification and Evolution Specification of 590

### VDA Dimensional Specification and Evolution Specification of 590

With the demand for module universalization, the single-end pole ear mode is derived during the process of adapting the cell size to VDA standard size, 390 module and 590 module. At this time, the cell is used in a vertical position, and the whole structural design is developed around the direction of a module that is similar to a square cell module, but this also limits the development of soft pack batteries.

Advantages and Disadvantages of Soft Pack Batteries: Will the Future Direction Be Large Batteries?

For soft pack batteries, from a long-term perspective, it must be made to match the vehicle design. Its biggest advantage is flexible size, which can be made into various shapes. In terms of standardized manufacturing, better flexible design can be realized. Therefore, when thinking about what kind of soft pack cell size may be better, it must be based on the demand of the car itself. Here, Funeng Technology has proposed a solution, which I think is very valuable for reference.

We can compare the size parameters:

◎LG PHEV battery 177127

◎AESC BEV battery 2902167.1mm

◎VDA BEV cell 30110014.3mm

The soft pack cells designed by Funeng Technology cover a length range of 400-800mm, a width range of 150-300mm, and a thickness range of 8-20mm, which means that cells can be combined freely.

How to balance the size and efficiency? The more mature direction is still the direction of the soft pack large cell, making the cell longer and wider, which is helpful for overall design and layout. From the perspective of structural design, the improvement of structural design brought about by the readjustment of the size is significant.

## The Direction of Contemporary Amperex Technology’s Flexible SPS Battery Specification

## The Direction of Contemporary Amperex Technology’s Flexible SPS Battery Specification

In order to maintain the chassis size of the battery system, Contemporary Amperex Technology’s (CATL) SPS battery can adjust the thickness of its flat layout large pouch cells to flexibly adjust the height of the battery system without changing the platform of the cells. With only one type of cell, the same chassis can be used for a range of passenger cars. Changing the thickness of the cells allows the height of the SPS to be adjusted from 85mm to 145mm. Different energy densities of the large pouch cells enable the battery system to have a different capacity, ranging from 80kWh to 150kWh.

In fact, if an automotive enterprise were to cover all of their vehicle types with pure electric options, several tricky issues would have to be considered:

- The size of the battery pack and platform must be considered.

- The coverage of battery power needs to be relatively balanced and comprehensive.

- The internal systems of the battery need to be considered.

This is why there is a requirement to cover all power levels from 50kWh to 150kWh, and the use of flexible pouch cells enables adjustment to size, thickness, and width in order to solve these problems.

Battery Dimension Design Optimization

CATL’s pouch cell design has a flexible size (length 400-800mm, width 150-300mm, thickness 8-20mm) and can thus be used to begin a modular design pattern. From a foreign perspective, the technical routes of battery manufacturers such as LG and SK On involve moving from the original module concept to a non-module direction.

Different design ideas lead to significant differences in the products.

### Size Efficiency Brought by Module Structure

### Size Efficiency Brought by Module Structure

The efficiency differentiation brought by stacking mode, we can see that Funeng Technology has a volume utilization rate of 75%.

Volume utilization rate = X direction utilization rate * Y direction utilization rate * Z direction utilization rate.

◎X direction utilization rate: This mainly refers to the direction of the tabs of the long strips. If controlled properly, a utilization rate of 90% can be achieved.

◎Y direction utilization rate: Mainly judging the spacing between the long strip designs, which can also be estimated at 90%. Because the size is relatively long, the space can be designed relatively well.

◎Z direction utilization rate: For cylinders and rectangular shells, this parameter is generally relatively low. Since a heat dissipation structural plate is added, the thickness of the structural support and other components need to be deducted here. The utilization rate is estimated to be above 92%.

Therefore, from the current development trend, if you want to improve utilization rate, you must do something about the Z direction. In the SPS design, the biggest defect before the entire soft pack design was made up for, which is still very outstanding, fully displaying the flexibility of the soft pack. In addition, as the size of the battery cell increases and the total series and parallel connection decreases, some structural components and connection designs of traditional modules can be saved.

What are the difficulties when the size specification of battery cells becomes larger, and how does large-scale manufacturing cope?

In the field of blade batteries, we see that there is a high requirement for the accuracy of the stacked sheets- if the alignment precision is not high enough, it will affect the final performance of the battery.

Similarly, the requirements for manufacturing of large soft pack batteries are also higher. Therefore, after upgrading the battery production, the adjustment of the entire process is critical, and it is not easy to accomplish. From the development of the industry, many enterprises are constantly improving the stacking technology. The challenging path is to use polar sheet hot compounding and multi-sheet stacking fusion technology to pre-bond and cut the diaphragm and polar sheets in advance to solve the problem of wrinkles caused by the release of diaphragm tension during the stacking process.

In addition, how to improve the efficiency of stacking? The industry has been experimenting with multi-blade cutting and multi-piece stacking technologies. The stacking machine integrates the functions of extreme film unwinding, cutting, hot compounding, multi-piece flying stacking, and hot pressing. By shortening the material transfer between extreme film rolls and stacking, the processing accuracy errors between extreme film cutting and stacking are reduced, ensuring that the extreme group and extreme film are in a stable and cohesive state after hot pressing.

On the manufacturing end, the integrated CCD defect and dimension detection system has been used to improve the product defect detection capabilities, ensuring that poor alignment during the stacking process can be monitored and eliminated in real time. This has also provided a substantial path for the improvement of the size of pouch cell batteries.

In summary, from a global perspective, battery cells are developing towards greater size for the purpose of improving manufacturing efficiency and reducing costs. Prior to the localization of aluminum-plastic film production, soft-pack batteries had been in a relatively weak position in the domestic market. With the progress of domestic material production and the continuous accumulation of soft-pack technology, the technical path of large soft-pack batteries represented by Funeng Technology is also expanding in size and structurally optimized. The development pace of this path is consistent with that of the prismatic and cylindrical cell batteries.

We look forward to Funeng Technology’s SPS truly achieving technological breakthroughs, competing with the other two paths, and becoming one of the mainstream technical solutions for power batteries. With the gradual emergence of the details of the SPS plan, we can indeed see that this is already a very important direction worth long-term observation.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.