On November 17, 2017, Tesla unveiled its Semi truck with a “One more thing” surprise reveal of the Roadster 2 sports car. Speculations about the production and delivery time of the Semi were active on various social media platforms.

It turned out to be a wait of five years.

Today, five years later, the delivery of the Semi has officially begun, and PepsiCo became the first company to take delivery. At the end of the event, Musk smiled and said:

“Five years is not short, but the Semi will bring a revolution on the highway.”

After watching the entire event, I agree with Musk’s statement. As is typical of Tesla, besides the necessary introduction of the Semi, this event was also full of surprises: the 1,000 V high-voltage platform, V4 supercharging, and technical details of the three-motor system were all revealed.

Unchanged, Excellent Industrial Design

Although it has been five years since the last event, the appearance of the Semi is still timeless. In our impression, most commercial trucks have a rough and unremarkable style, but the Semi clearly retains Tesla’s simple and elegant design style.

Whether it is the pure and clean feeling brought by the white car paint in official photos, or the personalized paint job of PepsiCo at the delivery site, visually, people will first have a good impression of this behemoth.

Even if the Tesla logo on the Semi is covered up, even if it is a truck, passers-by can tell that it is from Tesla’s hand. As an electric truck, aerodynamic optimization is key to energy consumption control, so Tesla explained at the event that the Semi can make the wind flow more smoothly through the body compared to traditional diesel truck cabs, minimizing turbulence, and the final 0.36 drag coefficient is excellent for a truck.

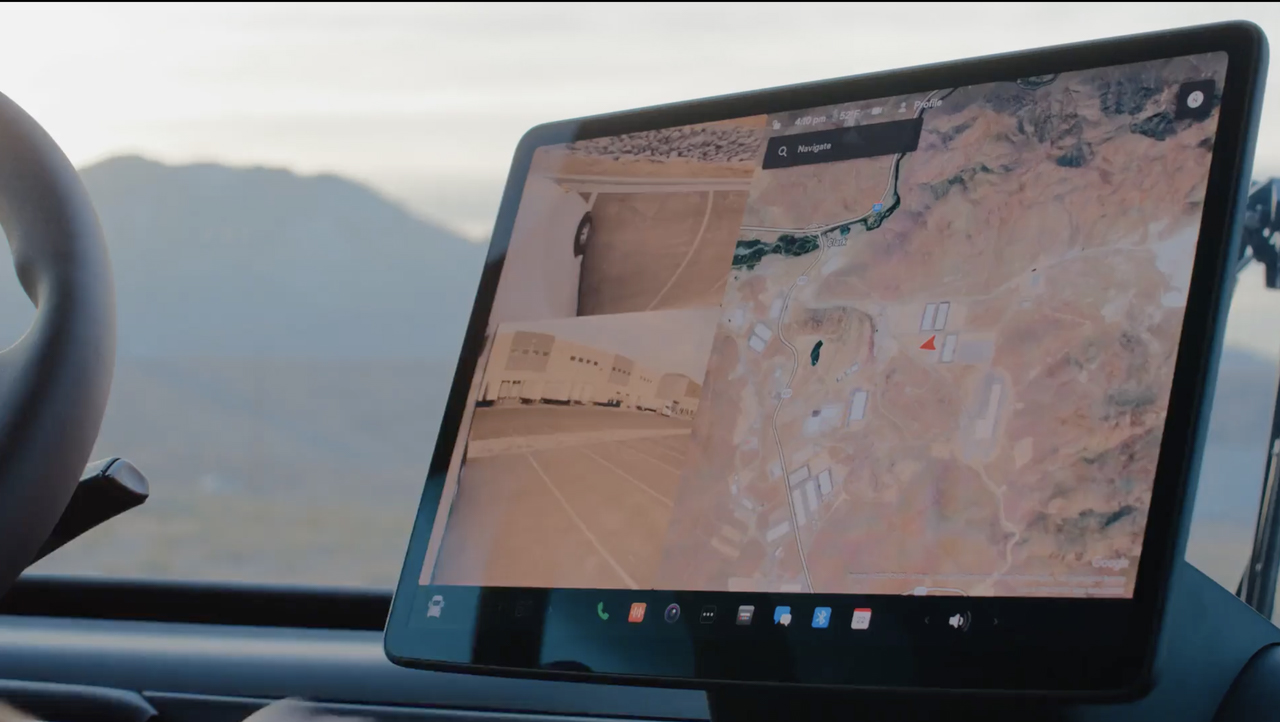

The concise and fluent exterior design of Semi is completely different from the “smoke-emitting” Optimus Prime in our traditional concept. If Semi were to join the Cybertron, it would definitely be teased by its companions as “wimp”. What’s more different from traditional trucks is the interior design. Semi adopts a central driving position and only has one seat in the front row. Surrounding the driver are two 15-inch large screens, which also replace the instrument panel and provide a more transparent forward vision.

Semi has achieved the same usage of many parts with other models, which will greatly reduce its production cost. The two large screens mentioned above are likely to be the same as those of Model 3. The steering wheel of Semi is a combination of Model 3 and the new Model S, retaining the left and right levers and adding touch buttons.

Due to the central seat layout of Semi, the area to the right of the driver is almost all given to storage space. Wireless charging board, large grid for placing iPads, card slot, cup holder… For a truck that needs to drive long distances, the driver’s time on the vehicle may even exceed that at home, so it is necessary to have sufficient storage space.

From the demonstration video taken on the spot of the press conference, it is shown that there is a foldable seat in Semi’s rear row. However, the backrest angle is very straight and it doesn’t look very comfortable. Many domestic heavy trucks often prepare a simple bed in this area to facilitate a short rest during long-distance driving. Perhaps this is the direction of future third-party market’s modification of Semi.

As for the interior, what I want to praise most about Semi is its effort to eliminate blind spots in heavy trucks. If you open the accident collection of the video software, you will find that most accidents are related to heavy trucks, and the vast majority of the accident reasons are due to the large visual blind spots of traditional trucks, and vulnerable participants in traffic approaching the blind spots resulting in tragic accidents.

In addition to eliminating the transparent perspective brought about by the dashboard and the large angled windshield, Semi displayed real-time images of four blind spots from the vehicle’s cameras on the large screen: left front, right front, left and right sides. Tesla obviously understands the impact that blind spots have on truck products, and all blind spot monitoring images are placed in the location closest to the driver on the display screen. From the perspective of interaction logic, the most important information is often placed here.

In this section, it’s worth mentioning that Semi’s forward perception is divided into two groups: there are three cameras on the upper and lower edges of the front windshield, respectively. This is also the most powerful combination of forward perception hardware in Tesla products up to now.

The truck version of AP will also be re-optimized: control the positive and negative torque of each wheel separately during the braking process to avoid dangerous situations of semi-trailer “twisting” and folding during braking. Considering the needs of convoy driving, Semi can even achieve “convoy driving” in the future: the first truck is driven by the driver, and the convoy following the front truck is automatically driven in an unmanned FSD state, further reducing labor costs and wind resistance.And in terms of active safety, Semi will also be equipped with functions such as AEB emergency braking and forward collision warning, just like passenger cars.

So, the impact of Semi on commercial vehicles is not just limited to electrification. With the accumulation of FSD technology, the potential for innovation and expansion of Semi in the future is high.

Finely Tuned Technology and Cost Control

Before discussing Semi’s propulsion system, let’s review Semi’s parameters:

In empty state, Semi can accelerate to 100 kilometers per hour within 5 seconds, while in full load state (36.7 tons), it only takes 20 seconds to reach 100 kilometers per hour, compared to the traditional diesel truck’s full load acceleration time of 40 seconds.

In fact, its 5-second acceleration ability in empty state is even faster than that of a single motor Model 3/Y. Just imagine the funny scene of a truck accelerating at a traffic light and passing cars!

It is expected that Semi will offer two versions of the model, one with a full-load range of 300 miles (483 km) and another with a full-load range of 500 miles (805 km), with the ability to charge from 0 to 70% in 30 minutes.

Do you remember the plot in Iron Man where Howard, Iron Man’s father, left a video message for his son, saying that he was not able to land the idea of a miniaturized nuclear fusion reactor during his time due to technological limitations? So he had to pass it on to Iron Man to finish.

Similarly, Semi’s five years have not been wasted, strictly speaking. In many cases, the technology used in Semi was matured only because it relied on the shoulders of the Model series, as well as the supply chain and cost control. Next, let’s look at the changes Semi has undergone in terms of electric motors, batteries, and fast charging over the past five years.

Three Electric motors, and decoupled power delivery

At that time, Semi was prepared to use the same four electric motors as the Model 3. However, the disadvantage of doing so was that energy consumption control was not ideal. Today’s delivered Semi uses the same three-motor assembly as the Model S Plaid.Tesla did not provide details on the power output of the Semi’s electric motor, but the same electric powertrain in the Model S Plaid can deliver a maximum power of 1,020 horsepower and 750 kW. During the presentation today, Tesla openly introduced the structure of this electric powertrain:

The Semi is equipped with three motors, and when there is a high demand for power, such as during full acceleration, all three electric motors can drive the vehicle together. Conversely, when the power demand from the Semi is not as great, the system can decouple two motors by sliding the clutch to achieve single motor cruising and increase the cruising range.

Therefore, it is natural to speculate that the Model S/X Plaid will also have such a design, becoming a single-motor front-wheel drive vehicle during cruising. We have already seen similar designs on Xpeng P7.

Full-load range of 804 km

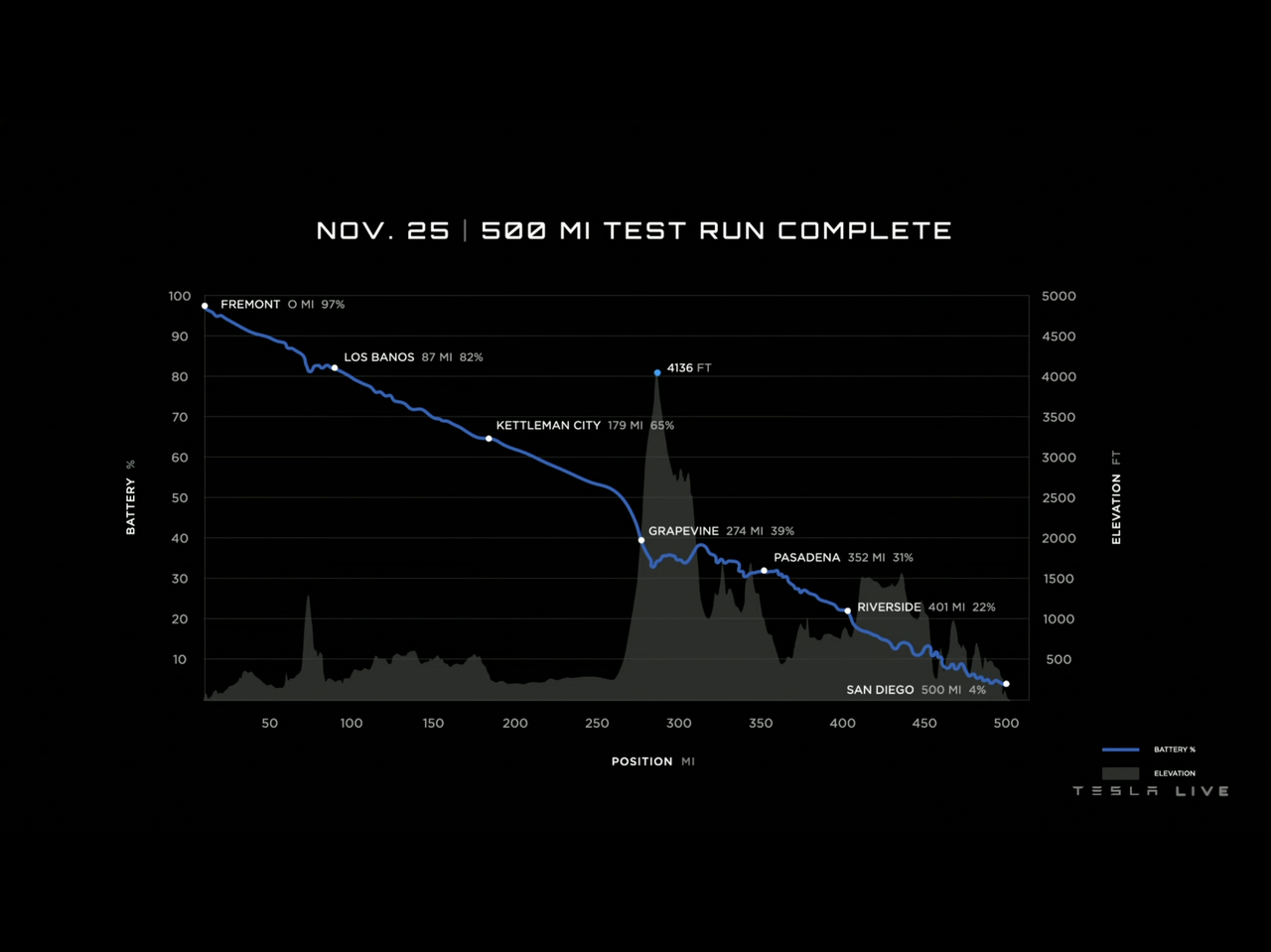

During the presentation, Tesla released a time-lapse video recording of the Semi’s range test: from Fremont to San Diego, the fully loaded Semi achieved a range of 500 miles (804 km), which is exactly the same as the official range claim, even more impressively, during testing the battery was not fully charged (SoC 97%), still having 4% of battery left at the end point.

During the test process, the vehicle was driven at high speeds throughout, loaded to 36.7 tons, and there was even an elevation gain of over 1,000 meters.

Dan Priestley, the engineering senior manager of Semi, joked that there were no gimmicks during this test, and no additional fairings were added to optimize aerodynamics. Elon Musk also said that if Tesla wanted to, it could make some changes to make this range test even more impressive.For a 36.7-ton truck, such a range performance may be counterintuitive. What is the reality?

Recently, Tesla announced that the production of 4680 batteries at the Berlin factory was hit by a “technology bottleneck” and had to be shut down. Therefore, the 4680 battery cells produced by the Fremont factory currently can only be supplied to Model Y. There may be a chance to see them in Cybertruck when the production increases, but battery-heavy vehicles like Semi will have to wait.

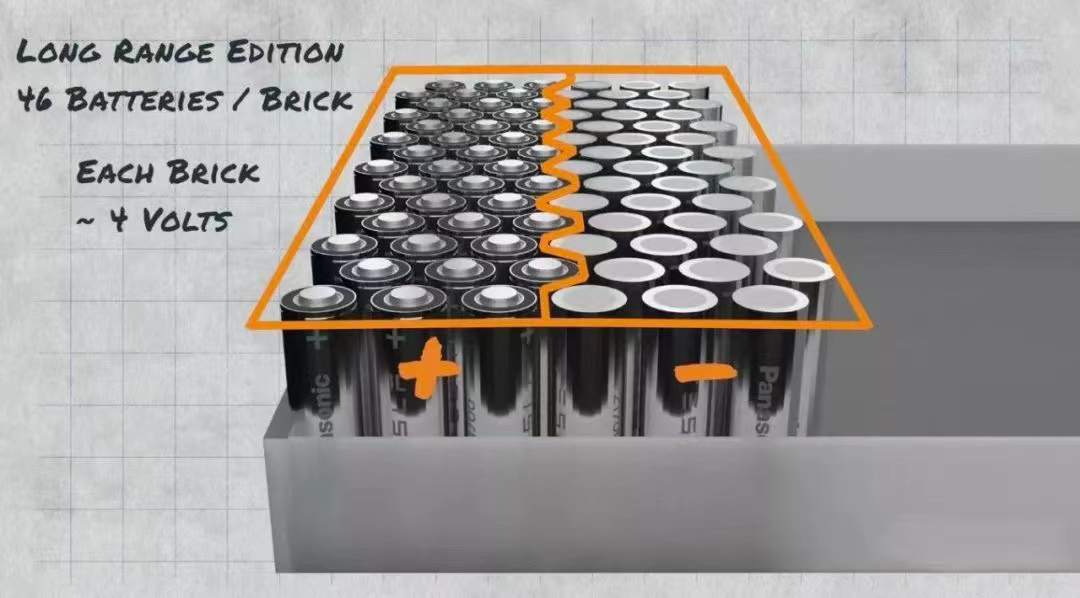

So the Semi currently delivered is still equipped with a 2170 battery pack. Tesla did not explicitly state the battery capacity of the Semi. We can make a simple calculation based on the clues provided on the official website: the official website states that the energy consumption of the Semi is less than 2 kWh per mile. Assuming 2 kWh, the battery capacity of a Semi with a range of 300 miles is 600 kWh, and a Semi with a range of 500 miles would have a battery capacity of 1,000 kWh.

What is the weight of the battery pack? Let’s make another estimation. An 2170 battery pack with a capacity of 80 kWh weighs 477.3 kg. Therefore, the weight of the battery cells in a 600 kWh battery pack is about 3,580 kg, and that of a 1,000 kWh battery pack is about 5,966 kg, equivalent to about 3.58 tons and close to 6 tons.

However, this is just an estimate that does not take into account the weight of the cooling system, battery frame, and other parts. The actual weight of the battery system will definitely exceed the result calculated above. However, the US truck has a classification system. Semi belongs to the 8th level, and the maximum total weight allowed by regulations is 80,000 pounds, which can be relaxed to 82,000 pounds for electric truck. Therefore, Tesla tested its range with a weight of 81,000 pounds (36.7 tons) of cargo, which is not considered overloaded.

So, you can see that the battery pack accounts for about one-tenth of the fully loaded weight of the vehicle. Therefore, the statement made by a senior executive of Daimler’s trucks that “an 804 km range is contrary to the laws of physics” is not accurate. Tesla is actually balancing between increasing battery capacity, increasing charging speed, and controlling weight and cost.So choosing the Semi that is delivered at this time can already share components with the Model series in terms of motor and controller and interior components to reduce costs, and the supply of Tesla 2170 batteries is already quite stable, and the North American version of Model S Plaid has even been delivered ahead of schedule.

In addition, according to Electrek, Tesla is expanding its Nevada factory, with the expansion portion being used for battery manufacturing. The 2170 production line produced in partnership with Panasonic and the production of the Semi also come from here.

Tesla doesn’t do losing deals. If the unit price of the 2170 battery falls to $100/kWh, the cost of the battery cells will be less than half of the cost of the Semi vehicle, bringing considerable profit margins.

V4 Supercharging and 1,000 V Platform

The announcement of Tesla’s V4 Supercharging brought the conference to a small climax, and V4 Supercharging is expected to be deployed next year. The Semi is Tesla’s first product that uses a 1,000 V voltage platform, with a maximum charging power of 1 MW, or 1,000 kW.

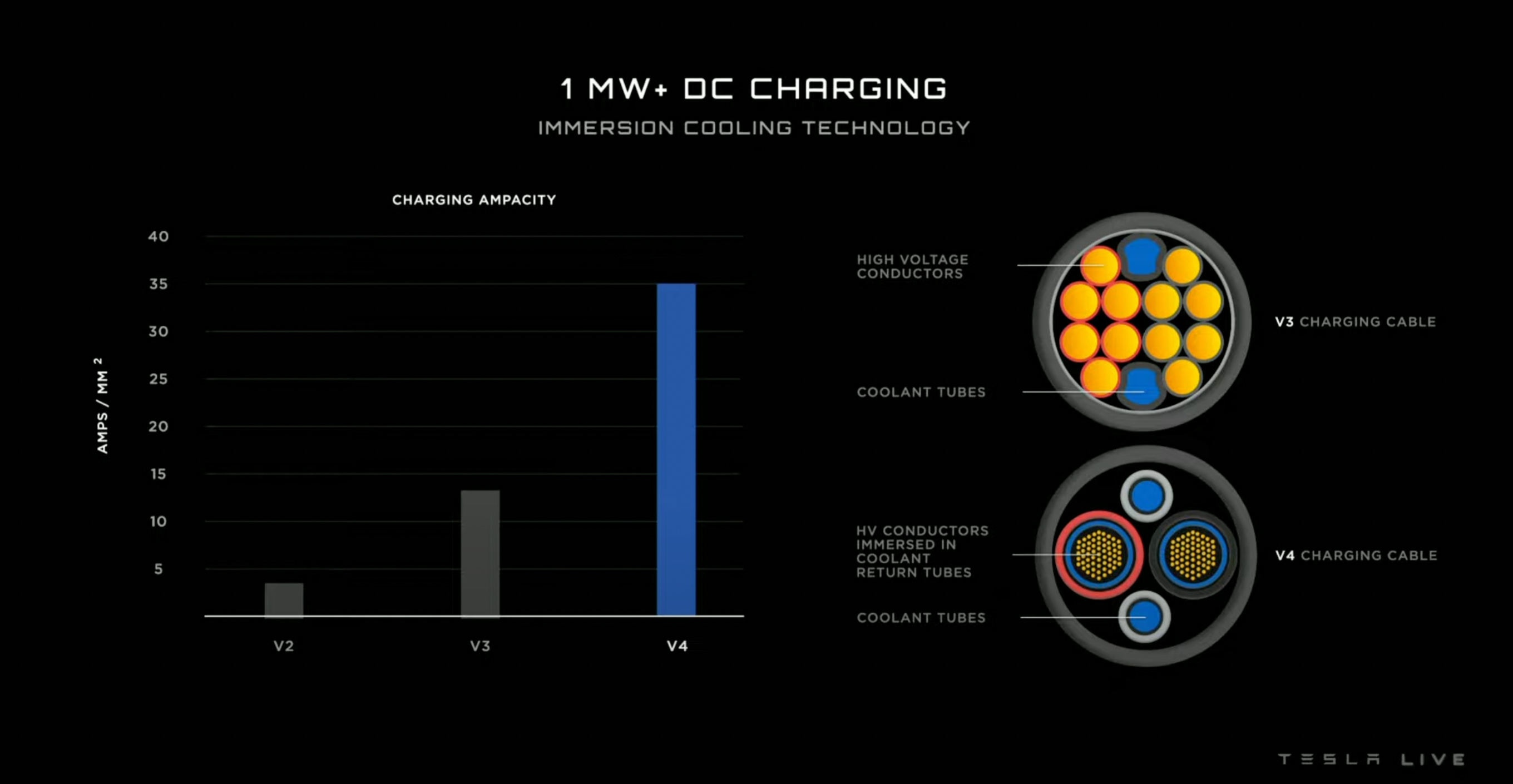

Let’s do a quick calculation. With a charging voltage of 1,000 V, the current must be 1,000 A. For comparison, the maximum current for the Model series on the V3 fast charging of the 400 V platform is 600 A. So V4 Supercharging needs to solve two problems: first, how to continue to increase the “AMPACITY” of the charging gun, which is the “load current capacity”; second, how to solve the heating problem under high current.

As can be seen from the sectional diagram below, the yellow part of the V3 Supercharging is the cable, with water-cooled pipes interspersed. The V4 Supercharging increases the cross-sectional area of the cable (thicker) and the cooling waterway after cooling is directly wrapped around the outside of the cable (red circle). In this way, the “load current capacity” of V4 Supercharging per square millimeter is 2.5 times higher than that of V3, coupled with the improved heat dissipation capacity, can it withstand the terrifying heat generated by Semi’s 1,000 kW fast charging.

During the presentation, Musk said that Semi would not be the only 1,000 V platform product and that’s typical of Elon Musk to leave a suspenseful moment. Let’s count which pits have been unfilled by Tesla: Cybertruck, Roadster 2, the new Model 3, the new platform that costs half the Model 3’s cost…

Starting the deliveries of the Semi is a huge pit to be filled, but Tesla has new pigeons to be born in the future.

Shark in the commercial vehicle market

Why is the Semi such a revolutionary product? We need to do some math.

First, the Semi has fewer mechanical components, which can save a lot of maintenance costs. Maintenance of diesel trucks involves brake systems, oil and gear components maintenance, and urea injection (required by regulations), which can be expensive. The Semi, on the other hand, does not have these problems and only needs to spend money on minor parts such as wipers and windshield washer fluid. By utilizing kinetic energy recovery, not only can energy consumption be saves, but the working time of the brake system can also be effectively extended.

Tesla has also released data that shows the charging cost per mile for the Semi is 2.5 times cheaper than refueling diesel. For a company, it translates to saving about $70,000 per year per Semi, with $200,000 saved over three years.

If the FSD is applied to the Semi in the future, when driving in formation, only the lead vehicle requires a driver, and more labor costs can be saved. However, this is all off-topic. Just focusing on the current state of the Semi, it is already attractive enough to lure major American enterprises to place orders frenetically: besides Pepsi, DHL and Walmart have also signed contracts.

The United States is also accelerating its subsidy for the commercial electric vehicle transformation: according to recent legislation passed by the US government, businesses that purchase an electric truck may be eligible for a federal tax deduction of $40,000. Thus Pepsi, who signed a contract for 100 Semis in 2017, has been waiting painfully until now and does not dare to speak out.

Behind this is an even deeper reason, which is that there is no pure electric truck product on the market that can compete with Semi in terms of product strength. The FH Electric launched by Volvo only supports 250 kW fast charging and has a range of about 300 km; while the Scania 45R has a battery capacity of 624 kWh, but a full load range of only 350 km. Not to mention some domestic electric trucks that focus on closed scenes and short-distance cargo transportation, with a range of only about 200 km. Compared with these traditional automakers, almost no one can compete with Tesla in terms of vertical integration capabilities in the field of electric commercial vehicle manufacturing.

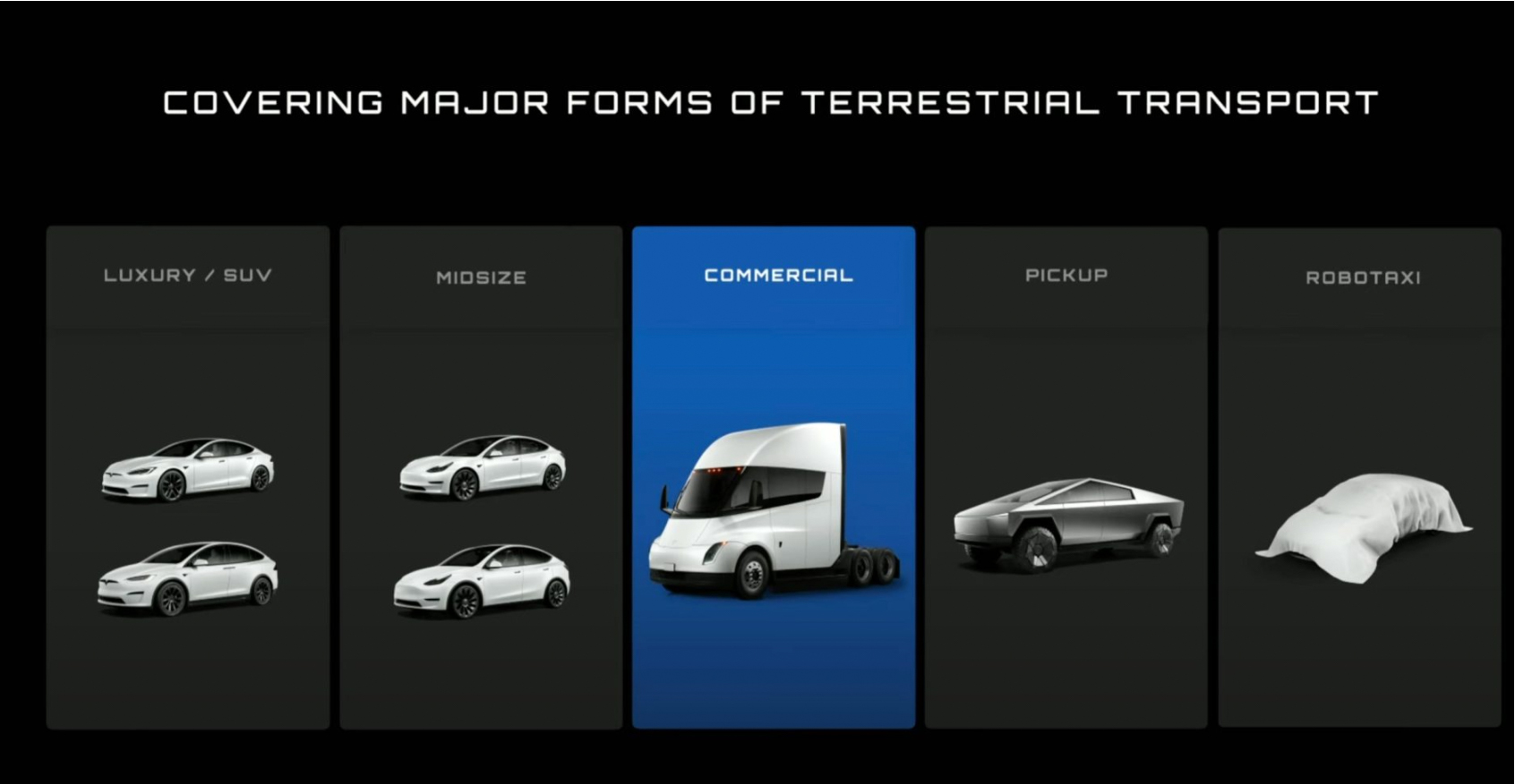

So in the end, we still have hope. The above picture is the product plan released by Tesla today. After the Cybertruck and Semi, what people are most looking forward to is the Robotaxi covered by half the curtain. This also proves that this mysterious model has been put on the agenda seriously.

It seems that the next pigeon king will have to make way for Roadster 2.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.