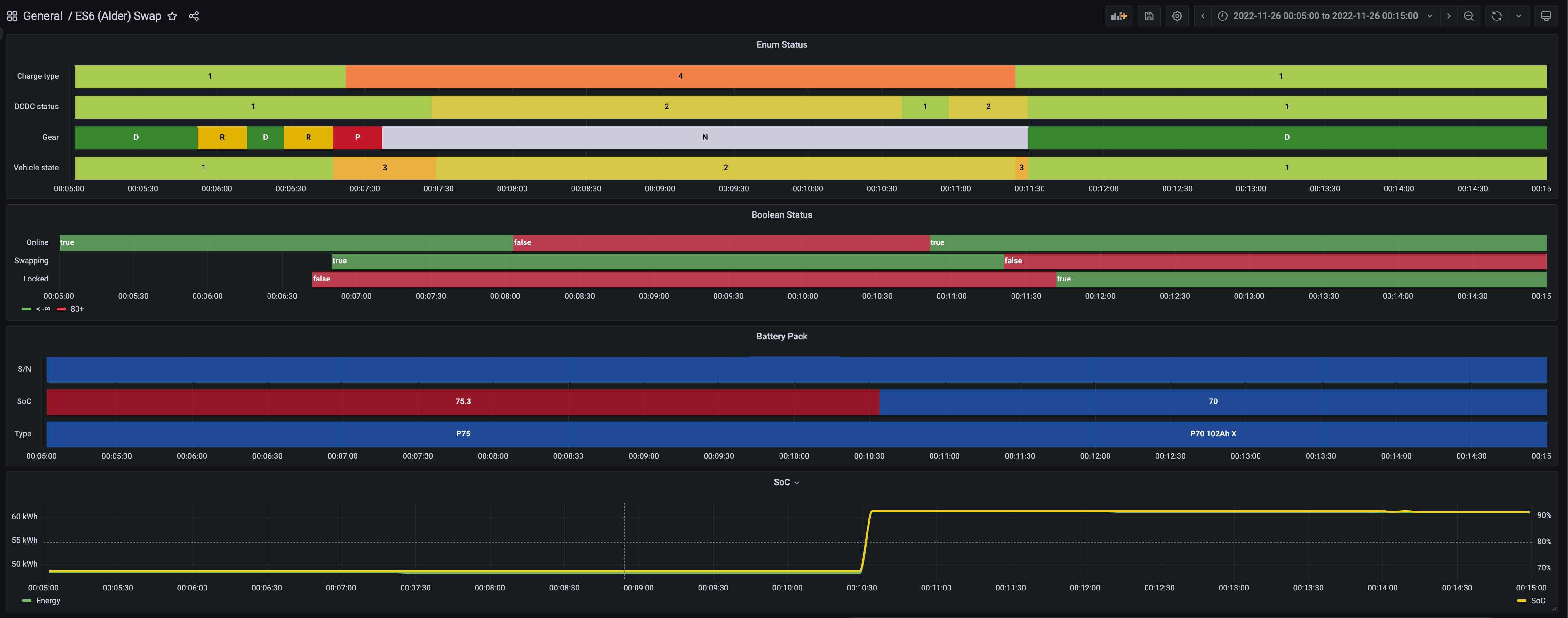

The image below shows the communication data captured during the battery swapping process of ET5 at NIO. The entire process is plotted against time with intervals of 10 minutes, recording changes in various states. Let’s take a different perspective to examine the whole process of NIO battery swapping.

The first group represents changes in enumerated states.

The first row “Charge type” represents the current charging status where 1 indicates not charging, 4 indicates in battery swapping process, and we can assume that 2 and 3 represent AC and DC charging, respectively.

The third row “Gear” indicates the car’s gear position. “D-R-D-R-P” represents the entire automatic parking process into the battery swapping station with a steady entry for two minutes. After waiting in “P” gear for the vehicle communication to complete, the battery swapping process starts and the car shifts to “N” gear.

The car swings into the slot of the battery swapping station to begin the battery disassembly process. After the car is re-energized, it will be shifted back to “P” gear, waiting for the car owner to drive out.

The second row “DCDC” indicates the connection status between the large and small batteries. When the battery swapping process starts, the status changes from 1 to 2, indicating that the connection between the large battery and the car has been disconnected. After a short period of electrification for testing, the battery will be disconnected again. When the swapping process is complete, the car will be re-energized to start the 8155 vehicle equipment. The startup time is approximately 30 seconds.

The second group represents changes in boolean values.

The last row shows the status of the vehicle’s central locking system. When the car is shifted to “P” gear to enter the battery swapping process, the car will be automatically unlocked. After re-energizing and driving out of the swapping station, the car will reach a certain speed and the central locking system will be automatically activated.

The third and fourth groups represent battery data.

After the car is re-energized, the vehicle will recognize the serial number and battery type of the new battery. Since the new battery is also a 70-degree battery, the type and design capacity have not changed. At the same time, the SoC% instantly rises from 25% to 93%, and the power capacity increases from 15 kWh to 60 kWh.Here are some things worth considering. You might be able to switch to a lock battery with a designed capacity of 70 but a battery type of P100. You’ll also find that the same designed SoC% is 93%, sometimes the power is 59.9kWh, and sometimes it’s 62.1kWh.

The entire process took 6 minutes, with 1 minute spent parking the car, and 30 seconds spent starting the vehicle. The actual battery swap process took 4 minutes and 30 seconds.

Below is another record of the ES6 battery swap process after upgrading to 8155, which took similar time and had similar status changes. Perhaps Aspen’s car consumes a little more time when starting the car machine, but unfortunately I no longer have an Aspen to test.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.