Author: Zhu Yulong

In early October, Tesla announced that it would no longer use ultrasonic sensors (USS) in its self-driving sensor suite, instead opting for the “TeslaVision” system which uses only cameras. Over the next few months, USS will be removed from the manufacturing process of Model 3 and Model Y, while Model S and Model X will begin removal in 2023. From a logical standpoint, USS is not expensive, so why abandon this technology that is already relatively mature?

USS is mainly used for short-range object detection, such as for automated parking and low speed collision warning, primarily used to alert consumers.

This is what I think:

-

Tesla is considering both cost and installation speed — although USS is not expensive, it has 12 of them and the entire cable interface is relatively complex, eliminating it can save a lot of cable.

-

Tesla is using a new generation of cameras to improve the quality of close-range image detection.

-

From an algorithmic point of view, Tesla removes millimeter-wave radar first, then ultrasonic sensors, and focuses on using big data for image detection.

Cost of Ultrasonic Sensors

Ultrasonic sensors are standard equipment on most vehicles, and the main differences between different types of ultrasonic sensors are detection distance (10 meters) and accuracy. Because their main function is to avoid collisions between vehicles and other objects at low speeds, they are usually distributed using six in front and six in the rear.

As shown in the following figure, in addition to the body of the ultrasonic sensor, each sensor requires a bracket to secure it to the front and rear of the vehicle.

In Tesla’s design, there is no separate parking controller, so the 12 ultrasonic sensors are connected to the vehicle’s right controller via front and rear cable bundles.

According to the calculation, the controller of the Tesla’s ultrasonic sensor has one HSD and one ground loop. In total, the controller occupies 14 pins, including power output, ground return, and 12 communication wires.

According to the calculation, the controller of the Tesla’s ultrasonic sensor has one HSD and one ground loop. In total, the controller occupies 14 pins, including power output, ground return, and 12 communication wires.

Based on the cost estimation of Mr. Munro, each Tesla car has 12 ultrasonic sensors, costing about $8 each (a total of $96). The bracket for parts and installation costs about $0.15 each (a total of $1.80). The cost of connecting the sensor harness is estimated to be $2.20 each, with a total of $4.40. The total cost of each car is $114.

Personally, I think that Mr. Munro overestimated the unit price of the ultrasonic sensor and underestimated the installation cost of the cable. The cost of a single AK2 ultrasonic sensor is $4-5, and the cheapest ultrasonic sensor in China is about 15-20 yuan. This is not really a cost issue.

In my understanding, the original Autopilot control relied on ultrasonic sensor results as a reference for parking and low-speed processing. Removing the ultrasonic sensor and improving the processing capability of image sensors are the next steps.

Next-Generation Image Sensors

After removing USS, Tesla used multiple perception cameras to cover the original functions, mainly 8 vision sensors, from 1.2MP to 5MP.

The 5MP camera was previously given to Samsung Motors and LG Innotek by Tesla, mainly for replacement and upgrade of all future vehicles.

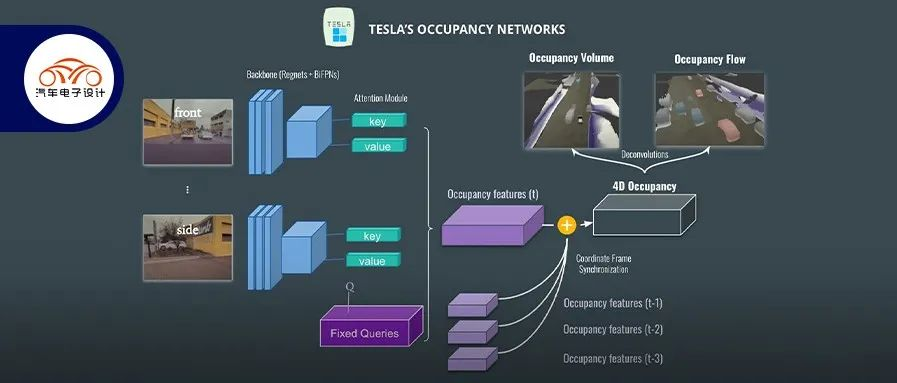

By integrating images from 8 sensors, Occupancy Network reads the region model, and regardless of whether or not Autopilot is enabled, Tesla uses this perception system to analyze the surrounding environment.

This means that even if the driver is in control, Autopilot can identify and analyze potential collision risks in the surrounding environment and improve the driving experience with the adjustments and enhancements in strategies.

Tesla’s perceptive algorithm improvement is directly related to the hardware adjustments that removed the millimeter-wave radar and ultrasound sensors, and increased the pixel density of image sensors and the transmission speed between the image sensors and controllers. Objectively speaking, this simplified the entire installation process and saved a significant amount of time in terms of installation labor.

Conclusion: Tesla’s software iteration follows both the trajectory of advancing the functionality of assisted driving and simplifying the vehicle’s installation to increase manufacturing efficiency as much as possible.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.