Author: Michelin

In the age of gasoline cars, engineers focused on engine technology to increase acceleration by even a fraction of a second. In contrast, the obsession in the era of electric cars is the ultimate pursuit of range.

For example, although the 600km range offered by mass-produced cars currently satisfies the majority of travel needs, 1000km is like the Himalayas in the eyes of climbers, serving as a benchmark and driving various carmakers and battery suppliers to compete for it, using different means like ultra-low drag design, lightweight structures, and improved electric drive efficiency to improve range. Among all the factors that affect range, the most significant and direct impact comes from the power battery.

And just when I was marveling at the significance of power batteries for electric vehicles, CATL (Contemporary Amperex Technology Co. Ltd.) released its next-generation product, called the “Kirin” battery, attempting to achieve the goal of producing mass-produced cars with 1000km range with a stronger battery.

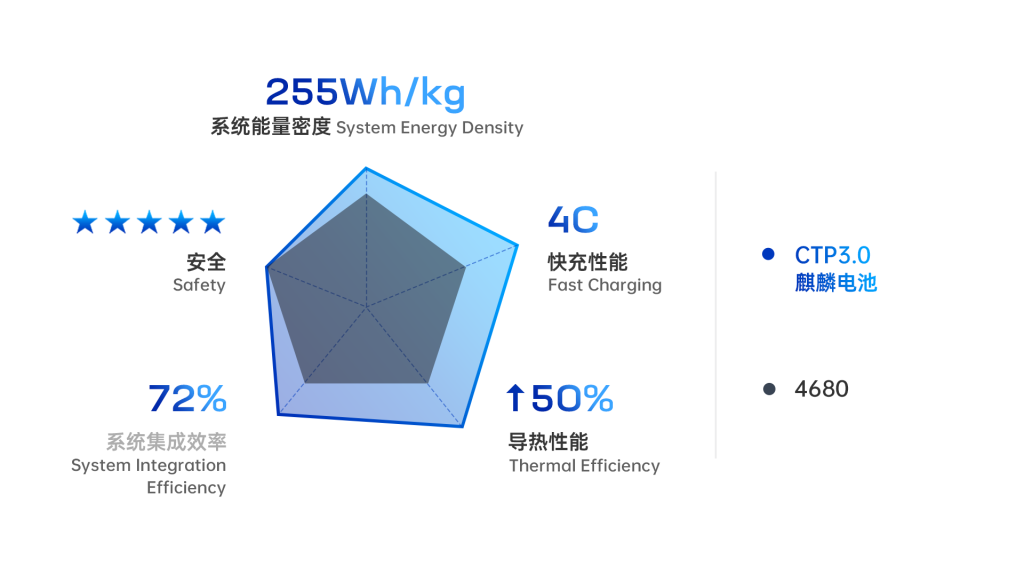

On June 23, CATL released the “CTP 3.0 technology” bombshell, also code-named the Kirin battery, for achieving 1000km range. With the new technology, the energy density of the Kirin battery will be increased to 255Wh/kg, which means that in the same chemical system and battery pack size, the Kirin battery’s capacity will be 13% higher than that of the 4680 battery.

Will the Kirin battery be the closest path for us to achieve mass-produced cars with 1000km range?

Highly Integrated CTP 3.0 Technology: Dual Strategies for Range and Fast Charging

Safety and reliability in providing more significant power and energy supplementation within a limited space are the constant goals of power batteries. Under these conditions, the evolution of batteries is like that of the Huashan faction’s sword sect and inner energy-based martial art: one faction focuses more on “internal cultivation,” increasing performance through the chemical properties of the battery cells; the other places more emphasis on external form optimization, improving battery performance through production processes and structure, and this is more like the module-less battery pack CTP 3.0 technology adopted by the newly released Kirin battery.

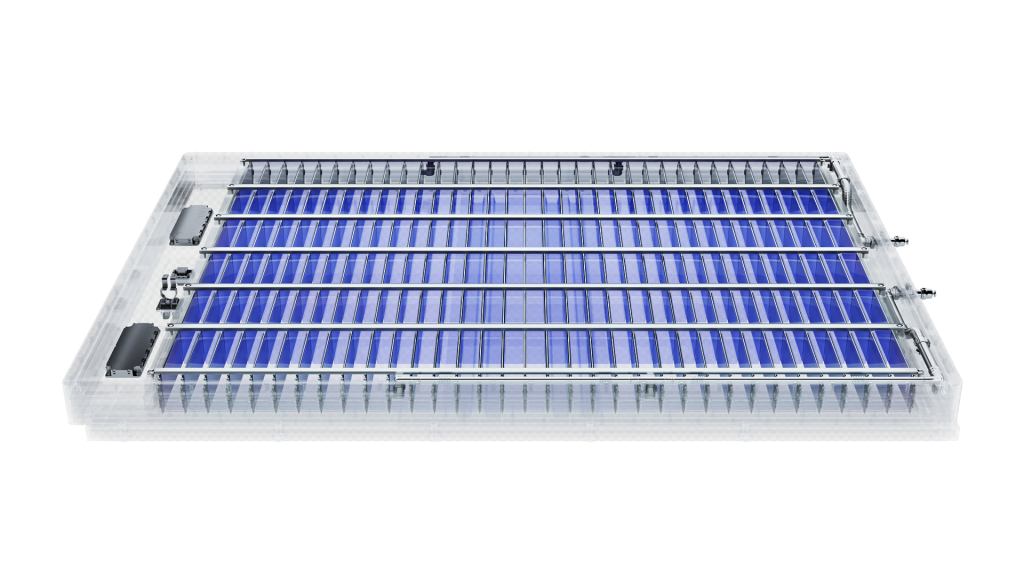

The Elastic Interlayer of “Three in One” Enhances Energy Density

Originally, power batteries are composed of battery cells assembled into modules, and then into a battery pack. With this structure, the module does support the battery cells and guarantee their strength and safety, but it also takes up a lot of space and weight. Under the battery cell-module-battery pack technology, battery cells only account for 40% of the battery pack’s volume, while the remaining 60% is occupied by modules, water cooling systems, and protective structures, which are essential and indispensable parts of power batteries.Therefore, optimizing modules, liquid cooling systems, and protective structures to maximize the volume occupancy rate of battery cells in the battery pack has become the goal of continuous iteration of CTP technology.

In 2019, CATL launched CTP 1.0 technology, which removed the side plates between modules and increased the volume utilization rate from 40% to 55%. Now, CTP 3.0 technology has been released, further increasing the volume utilization rate to 72%.

Using a module-less design, the 4680 system has a volume utilization rate of 63%. Of course, the specific performance comparison between Kirin Battery and 4680 Battery still needs to be further evaluated after mass production. However, from the perspective of volume utilization rate, Kirin Battery is able to pack more battery cells per unit volume, and it makes sense that it outperforms 4680 Battery by 13% in terms of energy capacity.

In order to achieve a volume occupancy rate of 72% without compromising safety and performance, Kirin Battery has greatly simplified its structure by removing the horizontal and vertical beams on the battery case and integrating them with the water-cooling plate and insulation pad into a multifunctional elastic sandwich layer.

This sandwich layer is capable of constructing a force structure perpendicular to the direction of travel, improving anti-vibration and anti-impact capabilities, while also providing water cooling and insulation effects.

After optimizing the previously large space occupied by the horizontal and vertical beam structures through the “three-in-one” approach, CATL also used AI simulation technology to design the boundary of the battery’s entire lifecycle application scenarios. This cleverly distributes the functional modules of structure protection, high-voltage connection, and heat loss exhaust, further releasing 6% of the energy space.

With these improvements, Kirin Battery’s volume utilization rate has increased to 72%, and the maximum energy density of the power battery has also increased to 255Wh/h.

The capillary tube water-cooling system significantly improves fast charging efficiency.For power batteries, the module that integrates cells can not only provide support, but also dissipate heat through partition plates between modules. Therefore, a question arises for the module-free batteries such as the CATL blade battery, the Tesla 4680 battery and the BYD blade battery: how to solve the heat dissipation between cells without the module’s partition?

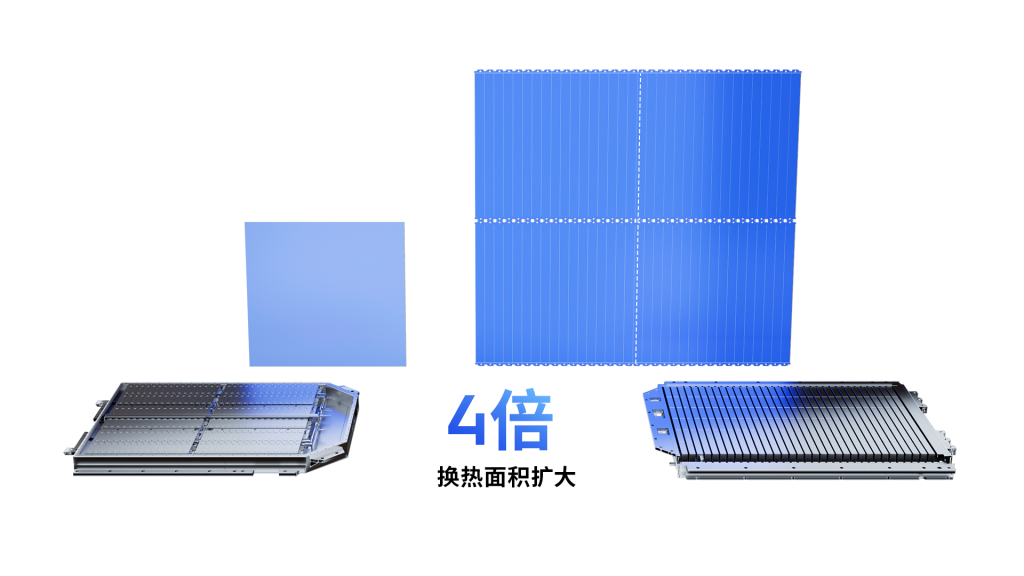

In traditional power batteries, the water cooling plate is usually placed on the top or bottom of the battery pack, and the cooling effect is achieved through the contact between the water cooling plate and the upper and lower ends of the cells, such as the direct cooling plate design of the BYD blade battery. However, the contact area between the ends of a cell is limited. In order to increase the heat dissipation area of the cell, the water cooling plate is sandwiched between cells, so that the larger sides of the cells can directly contact the water cooling plate, which is the direction of the evolution of the module-free batteries.

For example, the Tesla 4680 battery places the water cooling plate between cells, through the gap between cylindrical cells and the water cooling plate to achieve the heat dissipation effect.

Similarly, the CATL blade battery replaces the water cooling plate originally set at the bottom of the battery module with a sandwiched water cooling plate between cells. The originally one-piece straight water cooling plate is now split like a louvered window placed between each cell, and the cells originally cooled only at the bottom will now be cooled on both sides at the same time.

With the water cooling plate between cells, on one hand, the heat exchange area of the cell is increased, and the heat exchange area is expanded by four times, shortening the temperature control time of the cell to half of the original time; on the other hand, the water cooling plate isolates the contact between adjacent cells. In extreme cases, the cell can be rapidly cooled down, effectively preventing abnormal heat conduction between cells, and improving the reliability of the cell’s entire life cycle while ensuring the strength of the battery pack.

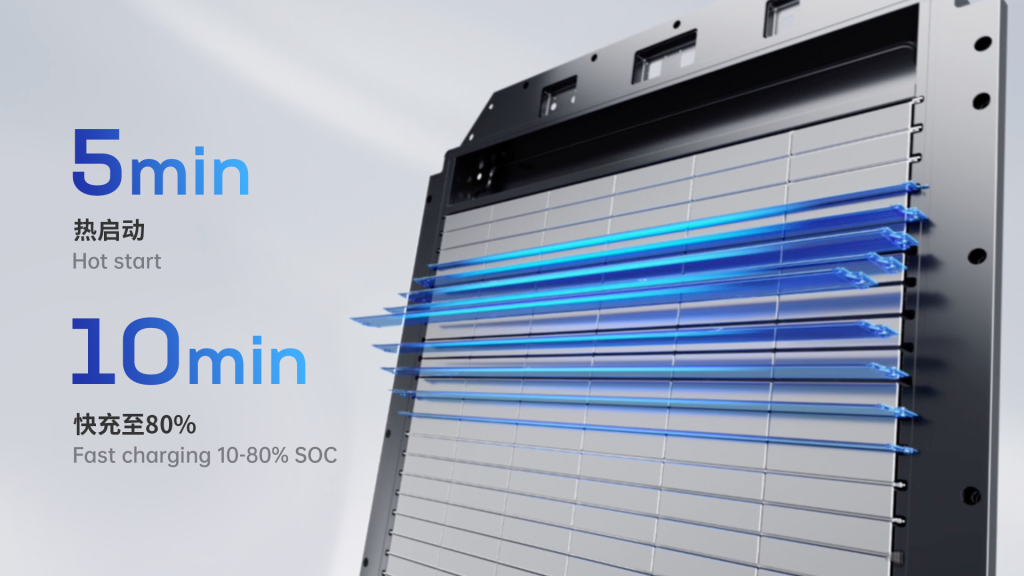

The capillary-like water cooling system is particularly advantageous to the design of fast charging for the CATL blade battery.

When the battery is fast charged with high power, the large amount of heat generated in a short time not only reduces the charging efficiency, but also poses a danger to the safety of the battery. Thus, excellent heat dissipation is an indispensable attribute for a battery to achieve high-voltage fast charging. With the water cooling system between cells, the heat exchange area of the CATL blade battery is expanded four times, which can achieve a charge/discharge rate of up to 4C, and realize 5-minute hot start and 10-minute fast charge up to 80%.

Breathable Micron Bridge Improves Battery Cycle Life

In addition to the increase in energy density and charging rate, Kirin Battery has built a freely stretchable micron bridge connector in the three-in-one sandwich layer.

In the process of using the power battery, the battery cell will expand with charging and discharging and aging, and the gap between the battery cells will gradually become smaller, and they will begin to squeeze each other. This squeezing of the battery cells severely affects the cycle life of the battery.

Therefore, the freely stretchable micron bridge device between the battery cells adjusts the gap between the battery cells. Initially, when the battery cell is not yet aged, they keep a relatively large distance. The micron bridge expands to fill the gap between the battery cells, making the battery pack a tightly integrated energy unit, improving the battery pack’s resistance to vibration and shock. When the battery is used for some time and gradually ages, the battery cells begin to expand. At this time, the micron bridge will automatically shrink to keep the battery cells tightly together without squeezing each other.

Is Kirin Battery the Solution to “Electric Car Anxiety”?

As an electric vehicle owner, seeing the release of Kirin Battery, in addition to admiring the technological progress, the biggest curiosity is: With Kirin Battery, will our range anxiety and charging anxiety be resolved?

Two months ago, Mercedes-Benz held an “Efficiency Journey” in Europe – VISION EQXX’s ultimate energy-saving design and electric drive technology, paired with the power battery provided by Ningde Times, achieved a journey of more than 1,000 kilometers on a single charge for 11.5 hours. Maybe, in the short term, we cannot experience the ultimate energy-saving design of VISION EQXX on mass-produced cars, but stronger batteries are not far away.

According to the disclosure of Ningde Times, the Kirin Battery using CTP 3.0 technology can increase the energy density of the ternary battery system from the currently used 200Wh/kg to 255Wh/kg, an increase of 27.5%, while the energy density of the lithium iron phosphate battery system is also increased to 160Wh/kg.

When Kirin Battery increased the energy density by 27.5%, 1,000 kilometers of range was no longer a breakthrough that ordinary users on concept cars can only dream of but hardly reach, or a technology that is still seeking landing in the laboratory. Instead, it is a product that will achieve mass production in 2023, and it is possible to experience 1,000 kilometers of range on mass-produced cars as soon as possible.For users who prioritize city commuting and are not sensitive to range, the speed of charging may be more important than the range itself. The pleasure of being able to “charge for five minutes and talk for two hours” in an anxious situation is unparalleled, and cannot be replaced by a long range.

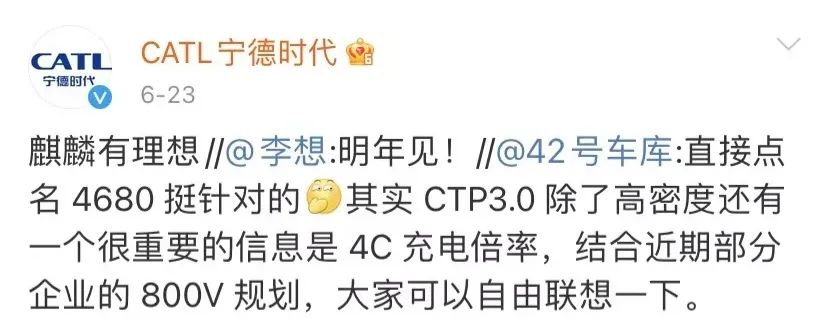

Therefore, the leading electric vehicle brands on the market seem to view pure electric high-voltage platforms and fast-charging systems as the trump cards for their next generation of products and platforms. Most of them have planned to release high-voltage platforms and fast-charging products in 2023, such as Ideal’s pure electric vehicle models.

Previously, Tesla’s supercharging system had a maximum power of 250 kW, and the battery could achieve a charging rate of up to 3.1C. Therefore, it seems that Kirin’s battery with a charging rate of 4C can easily meet the demands of 800V high-voltage platforms and fast-charging, which is just right.

Finally

Each car has its own focus and different design considerations, and people have their own opinions. However, when it comes to electric vehicles, hardly anyone would question the importance of the battery for an electric vehicle, whether in the eyes of automakers defining cars or in the eyes of each consumer who votes with their wallet. The power battery is an important hard strength that cannot be underestimated.

Therefore, when Kirin’s battery was released, we saw frequent interactions between automakers on Weibo, and the competition for the upcoming mass production of Kirin’s battery was intense. The small goal of driving a mass-produced car with a range of 1000 km is not far away.

From the CTP 1.0 technology in 2019 to the Kirin battery with CTP 3.0 technology today, we see the simplification of battery structure and the gradual improvement of power battery performance, surpassing oneself.

As I write this article, my phone just popped up with the news that “Ningde Times’ solid-state battery is under development”. In terms of technology leadership in the battery industry, it seems that Ningde Times has never slowed down.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.