Author: Feng Jingang

On June 13th, SAIC Motor’s MG brand launched a new battery pack brand called “Mo Fang” and unveiled the first model of the battery pack – MG MULAN, commonly known as “Mu Lan”.

SAIC Group’s deputy chief engineer and JNCO’s general manager Zhu Jun introduced Mo Fang battery pack, and he is also known as the father of SAIC new energy. For reference, friends who need material can add “Electric Road” editor’s WeChat.

Mo Fang Battery Pack

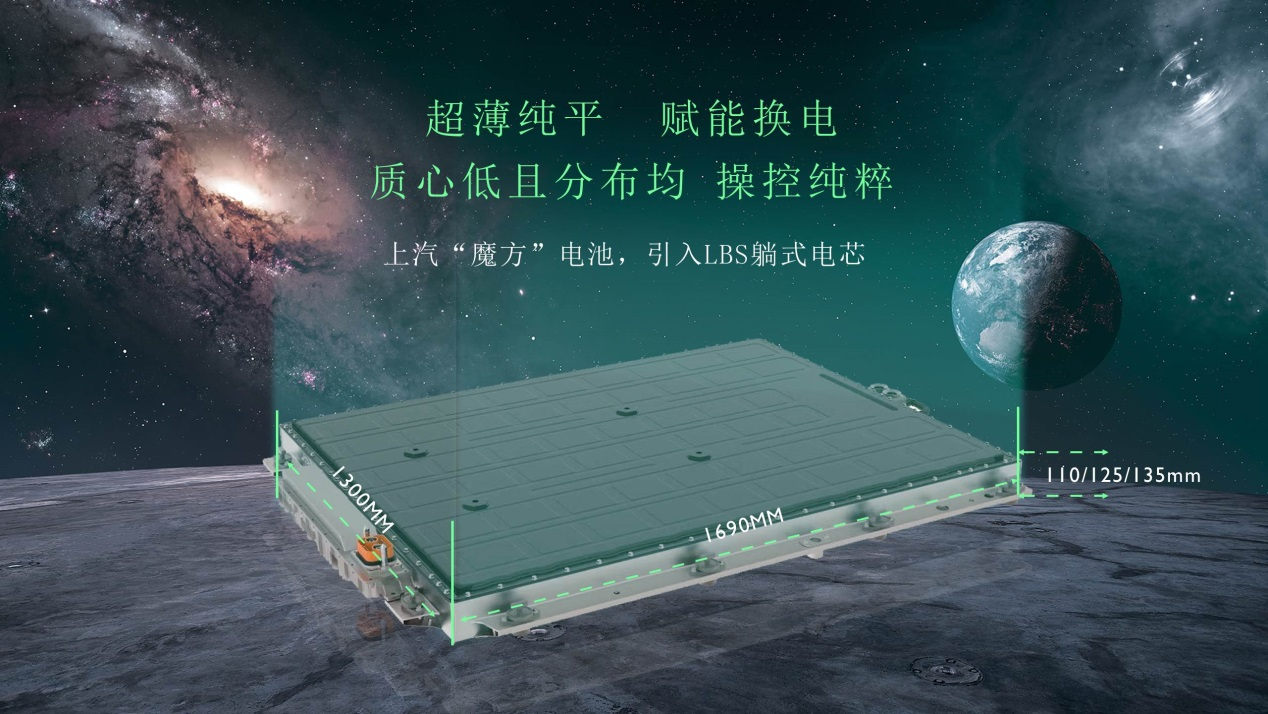

Zhu Jun introduced that the English name of the Mo Fang battery pack is ONE PACK, because the projection area of all batteries on this platform is the same, and the external connection pins are also the same.

Why is it called Mo Fang?

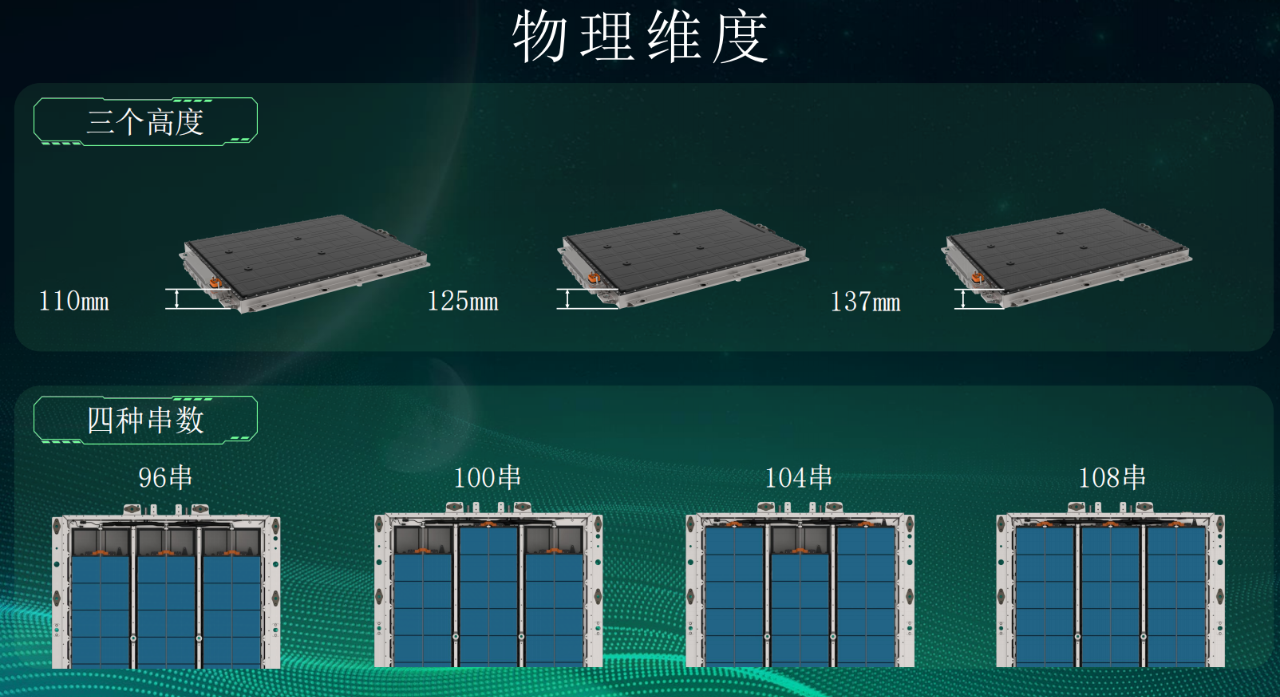

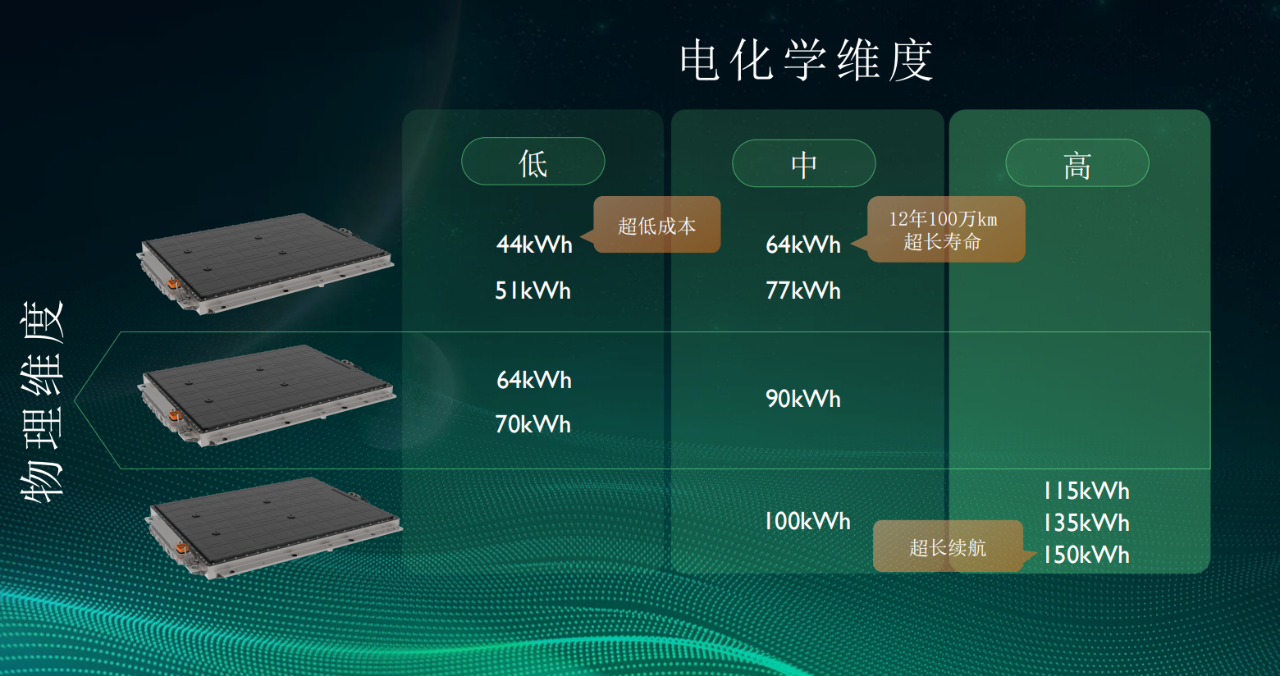

First, although the projection area of this battery pack is the same (length: 1690mm, width: 1300mm), there are three thicknesses: 110mm, 125mm, and 137mm, and four series: 96 series, 100 series, 104 series, and 108 series.

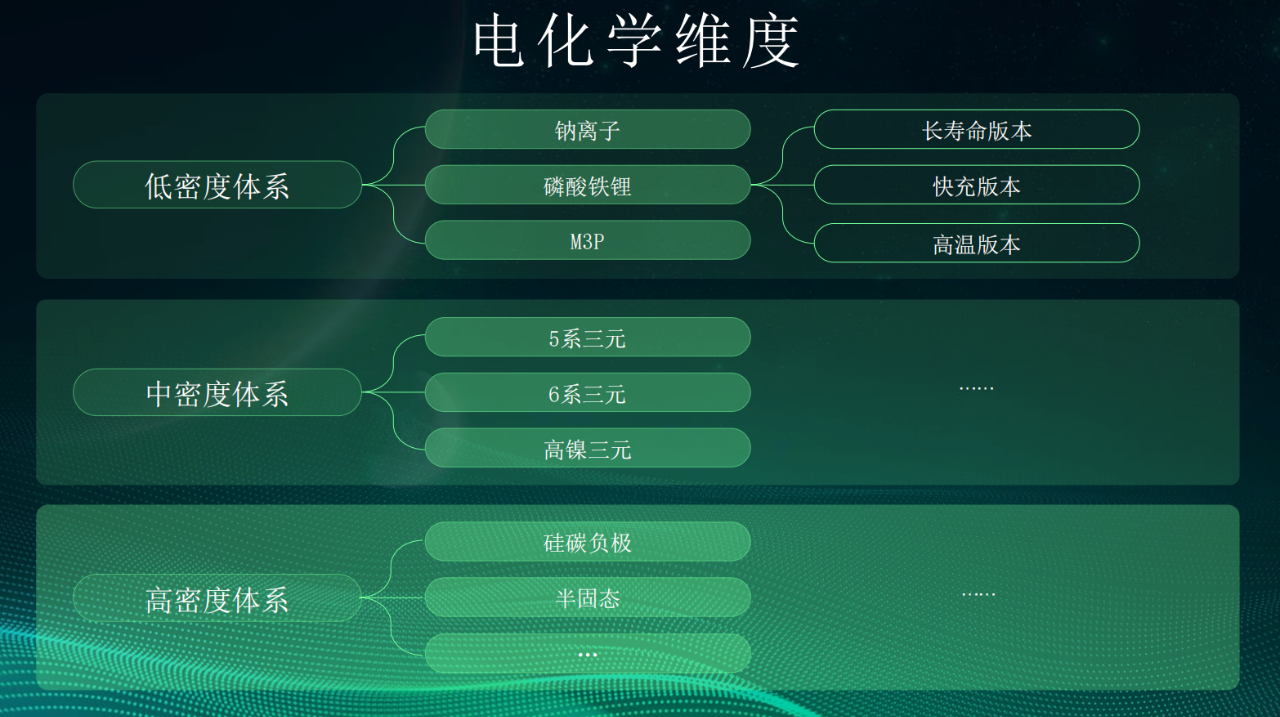

Second, from the electrochemical perspective, different electrochemical systems of batteries can be selected on this battery platform.

Low-density systems, including sodium ion, lithium iron phosphate, and M3P (a ternary battery system of phosphate), with lithium iron phosphate version divided into long-life, fast charging, and high-temperature versions.

Medium-density systems, including 5-series ternary, 6-series ternary, and high-nickel ternary.

High-density systems, including silicon-carbon negative electrodes, semi-solid electrodes, etc.

Through the combination of physical and chemical dimensions, Mo Fang battery pack realizes different performance, with an energy range of 44kWh-150kWh, meeting the battery pack requirements from level A0 to D.

Zhu Jun revealed that Mo Fang battery pack will soon be put into mass production, with super low cost, over 1 million kilometers of ultra-long life in 12 years, and ultra-long endurance, which can support electric vehicles to run up to one thousand kilometers.

Laying Cell

The biggest technical feature of the Mo Fang battery pack is the use of a layout of the laying cell.Zhao Jun explained that when the battery cells are placed in a battery pack, the size of the battery pack is determined by the size of the cells. If the cells are placed vertically and the height needs to be reduced, the cells have to be made shorter, but this will result in a significant decrease in the effective volume utilization rate. Therefore, a lying cell arrangement is adopted.

Due to the use of lying cells, Mofang Battery has carried out a series of redesigns of battery structure and cooling. As shown in the figure, its structure mainly includes a lying cell dedicated pressing plate, a lying CTP cell group, a vertical cooling component, and a bottom tray.

In the cooling design, the battery needs two things: one is expansion compensation material and the other is insulating material required for thermal isolation. Most batteries use aerogels for insulation.

When using traditional vertically arranged cell design, five large thermal insulation and expansion compensation materials are needed between six cells. After adopting the lying cell design, only two very small materials are needed.

Zhao Jun pointed out that Mofang Battery has three major advantages: ultra-high integration, ultra-long life, and “zero thermal runaway” safety protection.

Ultra-high Integration

From the video, it can be seen that in a vertically arranged cell, only the green area contains electrochemical energy storage materials. After the cells are laying flat, most of the space can be used to accommodate effective electrochemical materials.To demonstrate the advantage of the volume and weight energy density of the flat-lying battery cells of the Magic Cube Battery, SAIC has produced the following two charts. Let’s first look at the volume density advantage:

Firstly, in the PK comparison at 50 degrees, the SAIC Magic Cube Battery, with a capacity of 51kWh and a three-element lithium-ion battery, has a volume of 250L, while the T brand, with a capacity of 55kWh and an LFP battery, has a volume of 341.9L.

In the 60-degree PK comparison, the SAIC Magic Cube Battery, with a capacity of 64kWh and a three-element lithium-ion battery, has a volume of 250L, while the X brand, with a capacity of 60.2kWh and an LFP battery, has a volume of 399L.

Now let’s look at the PK comparison of the same chemical system battery cells at 80 degrees. The SAIC Magic Cube Battery, with a capacity of 77kWh and a three-element lithium-ion battery, has a volume of 250L, while the T brand, with a capacity of 75kWh and a three-element lithium-ion battery, has a volume of 341.9L.

In the 100-degree PK comparison, the SAIC Magic Cube Battery, with a capacity of 100kWh and a three-element lithium-ion battery, has a volume of 310L, while the N brand, with a capacity of 100kWh and a three-element lithium-ion battery, has a volume of 340L.

As can be seen, no matter whether it is compared with battery cells of the same chemical system or different chemical systems, the volume efficiency conversion rate of the SAIC Magic Cube Battery is more outstanding.

Now let’s look at the weight density advantage:

In the 50-degree PK comparison, both are in the LFP system. The SAIC Magic Cube Battery has a capacity of 51kWh and a weight of 385kg, while the T brand has a capacity of 55kWh and a weight of 455kg.

In the 80-degree PK comparison, both are in the three-element lithium system. The SAIC Magic Cube Battery has a capacity of 77kWh and a weight of 435kg, while the T brand has a capacity of 75kWh and a weight of 469.5kg; the X brand has a capacity of 80.9kWh and a weight of 503kg.

In the 100-degree PK comparison, both are in the three-element lithium system. The SAIC Magic Cube Battery has a capacity of 100kWh and a weight of 520kg, while the N brand has a capacity of 100kWh and a weight of 540kg.

Compared to the brands listed, the SAIC Magic Cube Battery has a more outstanding weight efficiency conversion rate in batteries of various capacities.

From both charts, an interesting point can be found: in the low-capacity comparison, the volume and weight density advantage of the SAIC Magic Cube Battery is relatively large, while in the high-capacity comparison, the volume and weight density advantage of the SAIC Magic Cube Battery is relatively reduced compared to other brands.### Ultra-long Life

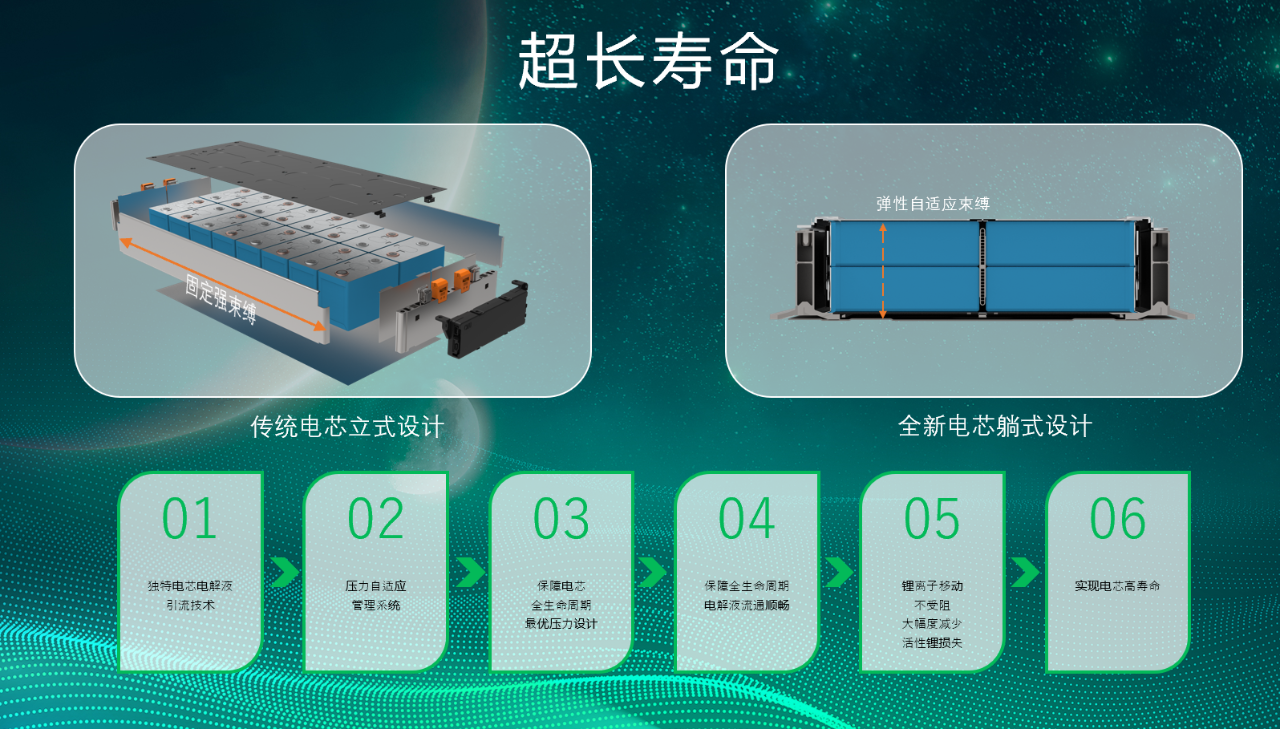

As for how to improve the lifespan of the Magic Cube battery, SAIC uses a physical approach rather than the chemical method we usually understand.

According to Zhu Jun, there are strong constraints at both ends of a general battery or module. During the charging and discharging process, the volume will expand and contract. As the battery gradually ages, it will continue to expand, and over time, the lifespan of the battery will be greatly affected.

Regarding the structure, the flat battery has only two batteries without constraints at the top and bottom. Zhu Jun stated that the Magic Cube battery has designed an adaptive constraint device, which can adjust the constraint force almost flatly in accordance with the charging amount and aging degree of the battery, which will help to improve the lifespan of the battery significantly.

Zhu Jun gave an example. The lifespan of a 64-degree Magic Cube battery is 12 years and 1 million kilometers, and the attenuation of the cycle life does not exceed 20%. In contrast, if a conventional vertical battery is used to achieve the same attenuation, the lifespan can only reach about 500,000 kilometers, which is basically half of that of the Magic Cube battery.

Another example is the 77-degree battery pack, which has a warranty period of 8 years and 660,000 kilometers, with attenuation not exceeding 20%.

Zhu Jun emphasized that the data of any battery, whether it is a Magic Cube battery or not, is much better than those of other cars on the market. Moreover, the cost is achieved through structural methods, rather than sacrificing energy density and cost of the battery.

Zero Thermal Runaway

Regardless of what battery pack it is, ensuring safety and controlling thermal runaway is a top priority.

Zhu Jun explained that the currently vertically placed battery cell adopts forced heat isolation, which can prevent it from spreading to a certain extent. However, unless a lot of materials are used, it is still uncontrollable.

Zhu Jun believes that the battery cell cannot be made larger, as one cell is equivalent to one degree of electricity, and releasing it in a short period of time will cause diffusion, affecting the membrane of the adjacent battery cell unless the heat insulation is very good. This is the limit of the vertically placed battery cells.The general idea of MoFang battery to solve the heat dissipation problem of lying-flat battery cells is to not isolate the upper and lower battery cells from each other, but use insulation material for isolation between adjacent battery cells, which can be made thicker.

<video controls class="w-full" preload="metadata" poster="https://upload.42how.com/article/image_20220615210913.png"> <source src="https://upload.42how.com/v/%E8%A7%86%E9%A2%91%E7%B4%A0%E6%9D%90/5%E9%B8%9F%E8%AE%A2%E5%8D%95.mp4"> </video>

In addition to insulation between battery cells, for the entire battery pack isolation, cooling plates and isolation structures are used. Taking the video battery pack as an example, two isolation plates and three cooling plates are used. Compared to the cooling plates of vertically placed battery cells, the cooling plates of lying-flat battery cells use a vertical layout.

<video controls class="w-full" preload="metadata" poster="https://upload.42how.com/article/image_20220615211205.png"> <source src="https://upload.42how.com/v/%E8%A7%86%E9%A2%91%E7%B4%A0%E6%9D%90/16cahjj.mp4"> </video>

Zhu Jun said that through this passive heat dissipation method, MoFang batteries can truly achieve zero thermal runaway. Even if a battery cell experiences thermal runaway, at most only the upper and lower battery cells will burn and it will not spread to other battery cells.

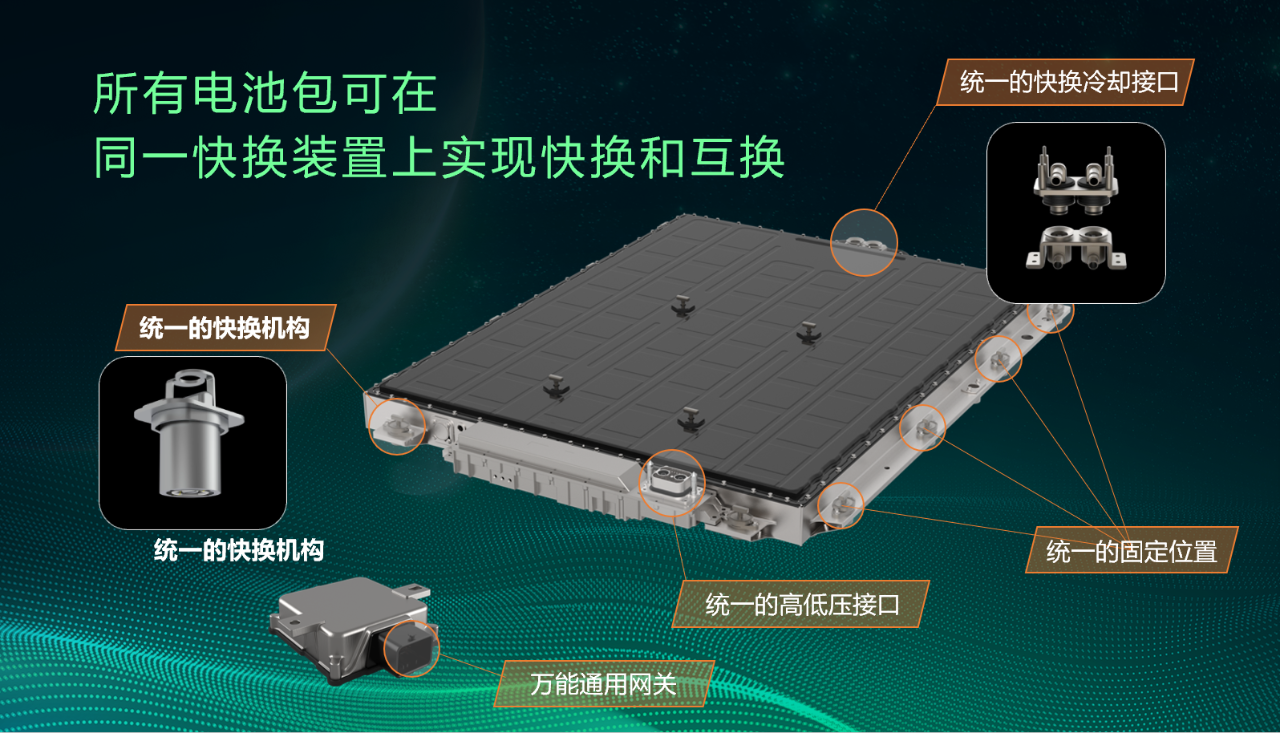

Renewable, interchangeable, and upgradable energy systems

This concept is most well-known for being proposed and implemented by NIO, although a few years ago people were questioning it, it is now widely understood. The MoFang battery pack introduced by SAIC also has a similar design idea.

Zhu Jun said that the external design of the MoFang battery pack is the same, including high and low voltage connections, cooling connections, unified lifting positions, and fixed positions, etc.

Based on this same design, it means that the MoFang battery pack can achieve quick replacement and interchangeability. Quick replacement refers to replacing the batteries, while interchangeability means, for example, replacing a 51-degree battery pack with a 77-degree battery pack.According to Zhu Jun, SAIC Motors had a fast-swapping rental car service a few years ago in Beijing and Shanghai, but with only one 40 kWh battery pack that does not support liquid cooling.

Compared with the previous fast-swapping scheme, the battery-swapping scheme with the Mo-Fang battery at its core is more advanced.

As for the technology, Zhu Jun mentioned that the Mo-Fang battery can be adapted to all models, including sports cars, sedans, MPVs, and SUVs. In addition to the MG MULAN, other SAIC brands and models will also use the Mo-Fang battery.

In terms of promotion strategy, Mo-Fang batteries can be purchased, rented, and upgraded.

If fast-swapping and interchanging are connected, SAIC will achieve a truly commercial model of separating vehicle and electricity, thereby building an energy ecosystem.

For example, if a user’s car battery is damaged, they can purchase a new battery; if the user’s car is damaged, the battery can be sold since it is still in good condition.

Zhu Jun revealed that SAIC has been negotiating with influential energy companies in recent years, hoping to build a new business model as well as an ecological chain, and may soon announce it publicly.

Zhu Jun also said that since only the thickness of the battery is different, and everything else is the same for the Mo-Fang battery, this means that all links in the industrial chain can obtain efficient operation with the entire industrial chain connected. Especially in the current situation where the price of battery materials is skyrocketing, the graded utilization and recycling of the Mo-Fang battery have enormous significance.

Zhu Jun emphasized that the SAIC Mo-Fang battery is a platform-oriented solution that is truly suitable for all vehicle types.

The first product—MG MULAN

In addition to releasing the Mo-Fang battery, SAIC passenger car MG brand also launched the “Global Pure Electric Super-Crossover Vehicle” MG MULAN.

MG MULAN is based on the SAIC Star Cloud pure electric dedicated system platform, built to global standards, equipped with “ultra-thin and flat” Mo-Fang batteries, innovative use of LBS lying battery core, CTP technology, and the first-time use of the super-electric drive system.

The Mo-Fang battery packs for MG MULAN come with three capacity options, which are 51 kWh, 64 kWh, and 77 kWh. All three battery packs have the same thickness of 110 mm, and in terms of materials, there are lithium iron phosphate and ternary lithium. Among them, the energy density of the ternary lithium battery can reach 180Wh/kg.In terms of performance, MG MULAN can achieve 0-100 km/h in 3.8 seconds, ranking fifth on the electric car acceleration list and also being the fastest accelerating model in the same level. In addition, it has a turning radius of 5.3 meters, a 50:50 front-to-rear axle load ratio, and a super low center of gravity height of 490mm.

MG stated that the pricing of MG MULAN will be below 200,000 yuan and will be launched simultaneously in the Central European market.

As a pioneer of Chinese brands going global, MG has won the “Chinese single brand overseas sales champion” for three consecutive years, and has successfully entered more than 80 countries and regions, ranking in the top ten of single-brand sales in 18 countries worldwide.

In order to export to the world, MG MULAN has introduced the world’s most stringent environmental standards, meeting the stringent European standards such as REACH and E-MARK, which have the highest threshold in the world’s automobile manufacturing system.

Zhang Liang, Vice General Manager of SAIC Data Business Department, Chief Digital Officer (CDO) of Passenger Vehicle Company, and CEO of MG Brand, stated, “For the positioning of MG MULAN, we hope that it can be a globally influential car like the Volkswagen Golf.”

Zhu Jun said that in addition to the Volkswagen Golf, the benchmark model for MG MULAN, there are also rumored but yet-to-be-released Tesla “Model 2”.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.