Author: Gao Shangpei

Under the impact of the epidemic, the Shenzhen-Hong Kong-Macau Auto Show became the first large-scale auto show of the year. Various automakers also unveiled their new products one after another. Electric vehicles remained the main theme of this auto show. Among so many new cars, there was one booth that was crowded, and that was the booth of Leapmotor.

In the recent sales ranking of new forces, the world is no longer dominated by “Weltmeister Xiaoli”. The rising star at the top of the sales ranking is Leapmotor, which mainly focuses on cost-effectiveness. This time, they set their sights on the C-class car market. Recently, after Leapmotor‘s mid-to-large-size pure electric sedan, Leapmotor C01, was officially pre-sold, the number of orders exceeded 20,000 in just four hours. After the pre-sale of 48 hours, the order volume of Leapmotor C01 exceeded 30,000. As of May 27th, the order volume of Leapmotor C01 has exceeded 45,000. For a new car that has not yet been launched in the market, this is definitely a hit product.

Even netizens photographed BYD’s leader Wang Chuanfu personally leading the team to visit the Leapmotor booth. What magic does Leapmotor C01 have to attract so much attention?

Leapmotor did what Tesla and BYD have not

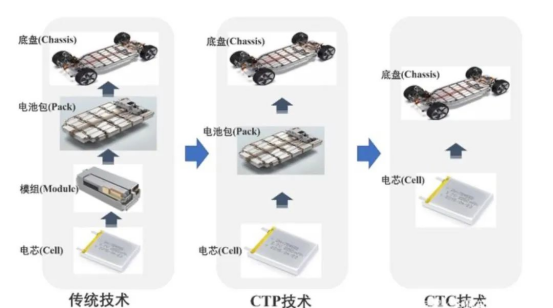

As we all know, most of the batteries of electric cars are placed in the bottom of the car. However, unlike the four-wheel drive cars that we played with when we were young, just stuffing two batteries would be sufficient. Currently, the main integrated technology of electric vehicles consists of battery cells forming modules, modules forming battery packs, and the battery packs being placed into the chassis. This design is not only complex but also requires more additional parts, which increases the production cost. Moreover, the utilization rate of space is not high, which invades the space for passengers in the car and has a certain impact on the cruising range.

Later, automakers introduced the CTP (cell-to-pack) technology, which directly forms battery packs from battery cells and integrates them into the vehicle body floor as part of the entire vehicle structure. This solution improves the utilization rate of space compared to the traditional solution, reduces manufacturing costs, and is represented by BYD’s blade battery.

With the development of technology, battery technology has derived the CTC solution. So what is CTC technology? CTC stands for “Cell-To-Chassis”, which refers to the battery chassis integration technology that combines the battery and the chassis together. The advantage of this technology is that the connection between the battery tray and the vehicle body threshold and crossbeam is tighter and more robust. It creates a high-rigidity chamber structure with the vehicle body battery compartment, significantly enhancing the torsional and bending rigidity of the vehicle body.

With the development of technology, battery technology has derived the CTC solution. So what is CTC technology? CTC stands for “Cell-To-Chassis”, which refers to the battery chassis integration technology that combines the battery and the chassis together. The advantage of this technology is that the connection between the battery tray and the vehicle body threshold and crossbeam is tighter and more robust. It creates a high-rigidity chamber structure with the vehicle body battery compartment, significantly enhancing the torsional and bending rigidity of the vehicle body.

Currently, only a few companies can achieve the CTC solution, such as the new energy leader Tesla. In 2020, Tesla released the CTC solution for the whole package encapsulation technology. The principle is to remove the vehicle body floor, and the battery pack’s upper cover integrates the floor and seat support, making the upper cover of the battery pack serve as the vehicle body floor. As Tesla adopts integrated die-casting body technology, there is no crossbeam in the chassis, leaving more space for foam filling laterally. As a result, the lateral force and bending moment during cornering are fully borne by the battery pack, which does not have significant improvement on the NVH and body rigidity of the vehicle.

In addition, the domestic new energy leader BYD also launched a CTB solution similar to CTC, integrating the independent battery pack with the floor function. It provides lateral strength and twist stiffness of transverse steel beams that are reserved on the vehicle body instead of being integrated on the upper cover of the battery pack. The lateral space reserved by BYD CTC solution is smaller than that of Tesla. The technology solutions proposed by Tesla and BYD can increase the vertical space for passengers. However, due to the need to strengthen or buffer the design of the upper part of the battery pack, the layout space of the battery under the same boundary conditions will decrease. From the underlying logic, the structure of the battery pack is not essentially different from the traditional battery pack since there is still an independent battery pack, which is essentially closer to the traditional electric vehicle PTC (Pack to Chassis) structure.

Currently, the world’s first mass-produced CTC integrated body belongs to Leading Ideal C01. The Leading Ideal brand has always given people the impression of possessing strong self-developed technical capabilities. In the Leading Ideal’s CTC solution, it completely abandons the concept of traditional battery pack, cancels the battery pack box and upper cover, leaving only the lower tray, directly integrating the battery and chassis together. This structure is more compact, has a higher integration degree, is more technologically advanced, and puts higher requirements on the manufacturing process, which can significantly reduce the number of battery parts and improve space utilization.

According to official data from LI, the CTC plan for the LI C01 reduces the number of components by 20%, with a lightweight coefficient of 2.4, resulting in a 20% improvement, and increases battery layout space by 14.5%, resulting in a 10mm increase in overall vehicle vertical space. With the increase in battery capacity and reduction of weight from fewer parts, the vehicle’s range has improved by 10%, and the maximum range can reach 717km on the CLTC condition, making the LI C01 the most cost-effective model with a range exceeding 700km.

According to official data from LI, the CTC plan for the LI C01 reduces the number of components by 20%, with a lightweight coefficient of 2.4, resulting in a 20% improvement, and increases battery layout space by 14.5%, resulting in a 10mm increase in overall vehicle vertical space. With the increase in battery capacity and reduction of weight from fewer parts, the vehicle’s range has improved by 10%, and the maximum range can reach 717km on the CLTC condition, making the LI C01 the most cost-effective model with a range exceeding 700km.

In addition to space and range, LI’s CTC plan and the battery compartment form a high-rigidity chamber structure in the vehicle, greatly enhancing the rigidity and bending stiffness of the LI C01, with a 25% improvement in torsional rigidity. The higher the body rigidity, the stronger the vehicle’s durability, handling, and safety, as well as reducing body noise and vibration, and improving the vehicle’s NVH performance. During maintenance, the battery tray can be removed and repaired separately, making maintenance more convenient, which is a more advantageous point compared to Tesla’s CTC and BYD’s CTB.

A pioneering battery technology industry, and unconventional electric drive technology. The LI C01 is equipped with the industry’s first variable-structure oil-cooling electric drive, with a maximum speed of 16000rpm. The LI C01 630 Pro + four-wheel drive high-performance version is equipped with two oil-cooling electric drives, with a maximum output power of 400kW and a maximum torque of 720N·m. It only takes 3.66 seconds to accelerate. In comparison, the horizontal comparison shows that the acceleration of the XPeng P7 Performance version is 4.3 seconds per 100km, the acceleration of the BYD Hanbaoba is 3.8 seconds per 100km, and the Model 3 Performance acceleration time is 3.3 seconds per 100km. Except for the smaller size of the Model 3 Performance, the LI C01 high-performance version beats them all. Even as a brand entering the market just a few years ago, LI can produce the world’s first mass-produced CTC model, with the size of a C-class car sold at the price of a joint venture A-class car, and the performance is even better than the BYD Hanbaoba. With such excellent technological reserves, it’s no wonder that even Liang Jun, the CEO of LI, would personally come to the exhibition booth to take a look.

Besides CTC, why is the LI C01 a top model at the auto show?

Apart from its ground-breaking battery technology and outstanding driving performance, what sets the LI ONE C01 apart is that it never forgets its identity as a C-class electric car. At 5050mm long, 1902mm wide, and 1509mm high, with a wheelbase of 2930mm, it is longer than the Tesla Model S, XPeng P7, and BYD Han, and only slightly shorter than NIO’s ET7. Its wheelbase falls between that of the XPeng P7 and the BYD Han, making it a solid C-class vehicle in terms of size.

Apart from its ground-breaking battery technology and outstanding driving performance, what sets the LI ONE C01 apart is that it never forgets its identity as a C-class electric car. At 5050mm long, 1902mm wide, and 1509mm high, with a wheelbase of 2930mm, it is longer than the Tesla Model S, XPeng P7, and BYD Han, and only slightly shorter than NIO’s ET7. Its wheelbase falls between that of the XPeng P7 and the BYD Han, making it a solid C-class vehicle in terms of size.

It’s easy to make a big electric car, but the LI ONE C01 is not only spacious, it is also made with high-quality materials. Its fully leather-wrapped door inner panels, NAPPA leather steering wheel, standard luxurious suede headliner, optional NAPPA leather seats, and the only rear electric boss seat in its class, all contribute to the LI ONE C01’s level of luxury that can rival that of BBA’s C-class.

Moreover, as an electric car, the LI ONE C01 comes with the Leapmotor Pilot intelligent driving assistant system as standard, which includes up to 23 intelligent driving assistance functions achieved by 28 high-precision perception hardware sensors. It also has advanced intelligent assistance such as AR real-time navigation, APA intelligent parking, and NAP intelligent navigation assist system. Compared to many of its entry-level competitors who either don’t have or have reduced intelligent driving functions, the LI ONE C01 is truly a heart-warming choice.

Looking back at the LI ONE C01’s pricing strategy, its cost-effectiveness is still very high. The pre-sale price ranges from RMB 180,000 to RMB 270,000. Even the top-of-the-line model costs just RMB 270,000, which can buy a genuine, high-acceleration, and top-notch C-class sedan. Its high cost-effectiveness does not mean it is unreliable. The CTC technology battery system is no more difficult to maintain than traditional electric cars, and the maintenance cost will not increase. In addition, the LI ONE C01 provides an 8-year or 150,000-kilometer warranty for the battery system and a 4-year or 120,000-kilometer warranty for the entire vehicle. Moreover, there is a “zero deposit” promotion available for C-class customers.

Customers can place a “zero deposit” order via the LI automobile APP, official website, WeChat Mini Program, or official WeChat account. A deposit paid during the pre-sale period will also entitle them to a lifetime warranty on the three main components of the car. The warranty begins as soon as the vehicle is delivered, which is undoubtedly reassuring for customers.For LINGPAI, C01 is a powerful attempt for the brand to move up. Judging from the market heat, Chinese consumers are becoming more and more rational and confident in domestic brands. As the highest-priced model currently sold by LINGPAI, the C01 sets a good benchmark in the field of C-class electric sports coupes while maintaining a high cost-performance ratio. We remind you not to miss this car when visiting the Deep Hong Kong and Macao Auto Show.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.