Development of Driving and Parking Brake Systems

Author: Panjiang

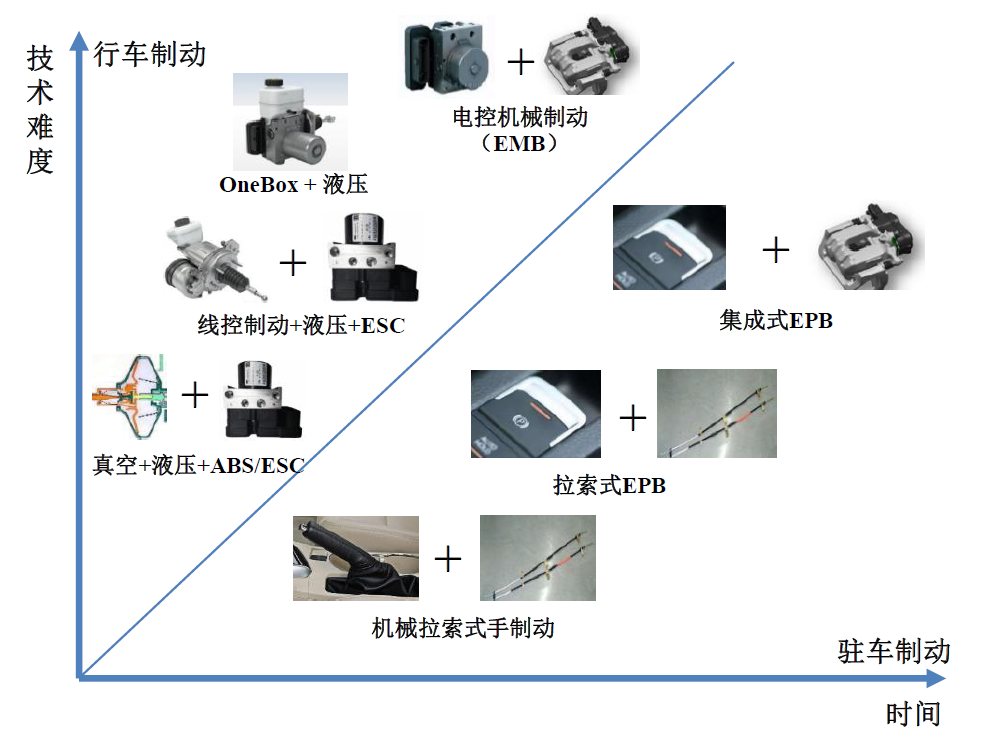

Since the birth of automobiles, the braking system has played a decisive role in achieving smooth vehicle operation and ensuring safety. The braking system has also continued to evolve with the changes in industrial technology and the development of the automotive industry.

According to the differences in braking scenarios, the braking system can be divided into two categories:

- Driving brake

- Parking brake

This article summarizes the development history of these two types of braking systems, providing readers with an overview and laying the foundation for subsequent articles on the working principles of mainstream braking products and their applications in intelligent driving.

Development of Driving Brake Systems

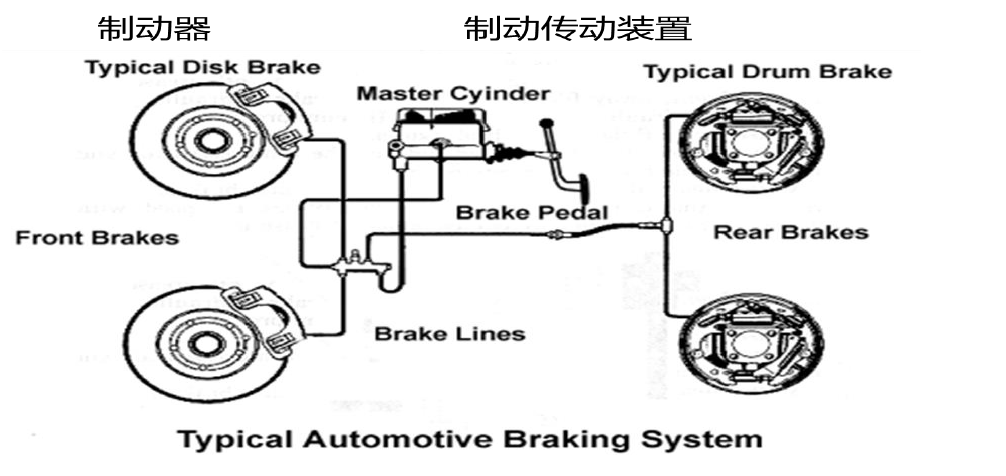

The driving brake system generally consists of a braking transmission device and a brake. The braking transmission device includes various components and pipelines that transmit braking energy to the brake, such as the brake pedal, brake master cylinder, wheel cylinder, and connecting pipeline. The brake is a component that generates a force that hinders the movement or trend of the vehicle, usually achieved through the frictional effect between the fixed element and the rotating element.

This series of articles focuses on passenger cars, and the development of driving brake systems in passenger cars can be summarized into three periods:

- Hydraulic Braking Period

- Electromechanical + Hydraulic Fusion Braking Period

- Electronic Control Braking Period

Hydraulic Braking Period

The earliest braking system used a simple mechanical device operated by the driver to directly apply force on the brake. At that time, the weight and speed of the vehicle were relatively small, and mechanical brakes could meet the basic braking needs of the vehicle.

As vehicles became heavier and heavier, mechanical brakes could no longer meet the basic braking needs. With the development of science and technology and the automotive industry, a new breakthrough was made in the design of vehicle braking systems, and hydraulic braking was a major innovation after mechanical braking.

The first car to use a hydraulic brake was the Duesenberg Eight, and Chrysler’s four-wheel hydraulic brake was introduced in 1924. General Motors and Ford adopted hydraulic braking technology in 1934 and 1939, respectively, and with several generations of product upgrades, hydraulic power-assisted braking systems gradually became mainstream.

A general passenger car hydraulic braking system consists of:

-

Brake pedal

-

Vacuum booster

-

Brake fluid

-

Brake pipe

-

Master cylinder

-

Wheel cylinder

-

Wheel brake (disk or drum brake)

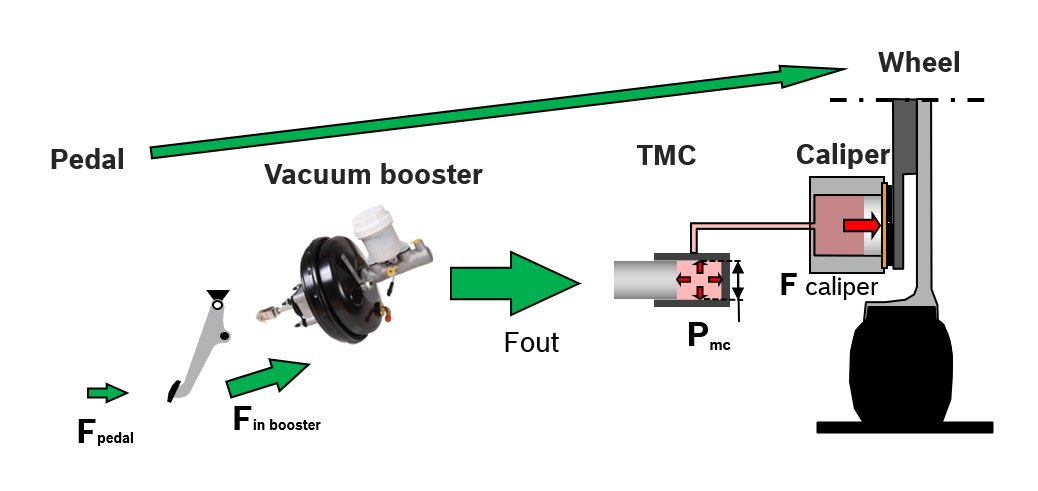

Taking the disk brake as an example, when the driver presses the brake pedal, the lever amplifies the pedal force and transfers it to the vacuum booster through the first stage. The vacuum booster amplifies the braking force and transfers it to the master cylinder through the second stage. The brake fluid in the master cylinder is pushed into the wheel cylinder and, under the pressure, produces greater braking force, pushing the wheel-end caliper to clamp the brake disc and impede its rotation, thereby achieving braking.

Due to the consideration of reliability and cost, many entry-level family cars still use hydraulic braking systems assisted by vacuum pumps.

The era of mechatronics + hydraulic hybrid brakes

With the development of the automotive industry, the maximum speed of cars has been increasing year by year, and the degree of injury in traffic accidents has also been increasing. Therefore, while improving the braking performance of the braking system, the industry has also explored ways to improve safety.

In fact, since the 1930s, the automotive industry has been studying anti-lock brake systems (ABS), but because of the limitations of the technology at the time, there was no mass-produced program. It was not until the late 1970s that the development of digital electronic computer technology and hydraulic control technology had a revolutionary impact on the ABS system. Bosch in Germany launched an ABS based on hydraulic control, which had a quite ideal control effect, and was officially put into mass production in 1978. Since then, many companies such as Bosch, ITT Automotive, Kelesy-Hayes, and Wabco have continuously strengthened research on ABS. Various new types of ABS have emerged, and their performance has been continuously optimized, while the price gradually decreased, making more and more cars equipped with ABS as a standard configuration.

The superiority of ABS is reflected in the following aspects:

- It can effectively use the adhesion between tires and the road surface, shorten the braking distance, and can shorten by 10%-15% under icy and snowy road conditions;

- During the braking process, the wheels can still roll, maintaining the maneuverability of the front wheels, preventing sideways slippage of the rear wheels, and maintaining the stability of the driving direction;

- Due to brake anti-locking, the wheels will not lock up and drag, reducing tire wear, extending the service life of tires, and reducing pollution in the air.However, ABS also has its limitations. First and foremost, ABS is only activated when the driver applies the brakes and causes the wheels to lock up, which means ABS is helpless in ensuring stability during driving conditions where slipping and sliding occur (such as on icy roads during acceleration). In order to address this stability issue during driving, in 1986, Bosch introduced the traction control system (TCS) and integrated it with the anti-lock braking system (ABS) in the Mercedes-Benz S-Class sedan, marking the beginning of the era of ABS/TCS integration.

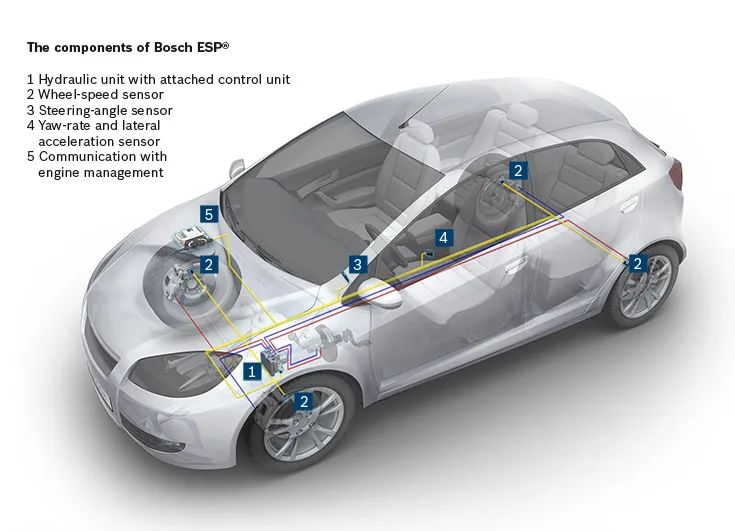

As ABS only functions during braking and TCS only functions during driving, the integration of ABS/TCS can only solve the longitudinal stability issue of the vehicle, and cannot solve the lateral stability issue caused by extreme driving conditions such as accelerating and braking while turning at high speeds. In 1992, Bosch developed the first-generation Vehicle Dynamics Control (VDC) system based on ABS/TCS to address the lateral stability issue, and named the product that integrated ABS/TCS and VDC functions as the Electronic Stability Program (ESP).

The birth of Bosch’s ESP was an epoch-making product in the history of automotive development. In 1995, the ESP system was mass-produced and first applied in the Mercedes-Benz S-Class sedan. Other manufacturers have also introduced similar products, but cannot continue to use the abbreviation ESP, hence a variety of different names exist, but they are generally referred to as Electronic Stability Control (ESC) systems. Research shows that the VDC function can reduce the number of traffic accidents caused by skidding by 80% and reduce the number of serious car accidents by 50%. Therefore, ESC, with inherited VDC function, has been called the “life-saving ESC” by many world-renowned automakers and research institutions.

The Era of Wire-Controlled Brakes

Wire control technology originated from aircraft control systems, which converts the pilot’s commands into electrical signals, and transmits them directly to self-contained servos through cables. Its greatest advantage lies in its precise and rapid response. However, its disadvantage is that it replaces traditional mechanical parts with a large number of electronic and electrical components, which challenges its reliability, and requires relatively high costs to reduce the failure rate of wire control systems. It was precisely for this reason that although the automotive industry had explored the application of wire control technology as early as the late 1920s, it did not achieve large-scale production.The development of new energy vehicles, especially pure electric vehicles, has brought about opportunities for the popularization of wire-controlled technology in automobiles. Due to the replacement of the engine by the motor, the use of vacuum boosters that rely on the engine to generate vacuum sources is limited. On the other hand, due to the existence of the drive battery, the traditional braking system that converts kinetic energy into heat energy through friction is not energy-efficient. The braking system needs to explore ways to convert kinetic energy into chemical energy stored in the battery for energy recycling.

In this trend, as a global leader in chassis wire-controlled technology, Bosch of Germany has launched a new generation of brake booster products: the iBooster intelligent booster.

The iBooster does not rely on a vacuum source and replaces the traditional vacuum pump and vacuum hose. It has a smaller volume and lighter weight, does not need to consume energy to establish a vacuum source, and only consumes electricity when braking. It can also recover energy, thereby achieving energy-saving and carbon-reducing goals. It is suitable for all powertrains, including hybrid and electric vehicles, and is more in line with future development trends. Therefore, it is favored by mid-to-high-end vehicle models and its market share is increasing.

On the other hand, the advantages of wire-controlled technology of precise and rapid response can be continued. The iBooster senses the force and speed of the driver stepping on the brake pedal through the sensor, and after signal processing, transmits it to the electronic control unit. The electronic control unit controls the corresponding torque of the booster motor. Under the driving of the mechanical-electrical amplification mechanism, it pushes the brake pump to work, thereby achieving electronic-controlled braking, with faster response speed and precise pressure control.

After Bosch, new intelligent booster manufacturers have emerged in the domestic and foreign markets, with Continental, ZF, and China NaiSen being the mainstream ones. Although each manufacturer has a different product name, they are collectively referred to as eBoosters.

Currently, many mainstream mid-to-high-end new energy vehicles are equipped with the “eBooster+ESC” combination, also known as the “Two-box” solution, which realizes basic braking functions and stability functions. To further reduce costs, an “One-box” solution that integrates basic braking functions and stability functions into one is becoming popular with automakers.

Compared with the eBooster, another advantage of the “One-box” solution is pedal decoupling. The driver’s pedal force does not act on the master cylinder, and the pedal feel is simulated by a simulator, while the braking force is realized by a servo motor, so the freedom of adjusting the pedal feel is greater. Currently, the mainstream “One-box” products in the market include Bosch’s latest generation of IPB, Continental’s MK C1, and BENTELER’s WCBS.

Under the wave of electrification and intelligence in the automotive industry today, there is a growing demand for increasingly sophisticated intelligent systems, driven by the popularization of advanced driver assistance systems (ADAS) like ACC and AEB, and the gradual rollout of autonomous driving systems. As a result, there are increasingly higher safety requirements for brake systems in autonomous driving, making it essential to guarantee safety and system redundancy, even in the event of a single malfunction. Therefore, the development of redundant braking systems is vital to meet these safety requirements.

Under the wave of electrification and intelligence in the automotive industry today, there is a growing demand for increasingly sophisticated intelligent systems, driven by the popularization of advanced driver assistance systems (ADAS) like ACC and AEB, and the gradual rollout of autonomous driving systems. As a result, there are increasingly higher safety requirements for brake systems in autonomous driving, making it essential to guarantee safety and system redundancy, even in the event of a single malfunction. Therefore, the development of redundant braking systems is vital to meet these safety requirements.

Clearly, electric brake-by-wire systems will play an even greater role in the automotive industry in the future, given the ever-increasing demand for intelligent systems. Brake-by-wire systems will also need to adapt to keep up with these new requirements in a constantly evolving automotive landscape.

The Development of Parking Brakes

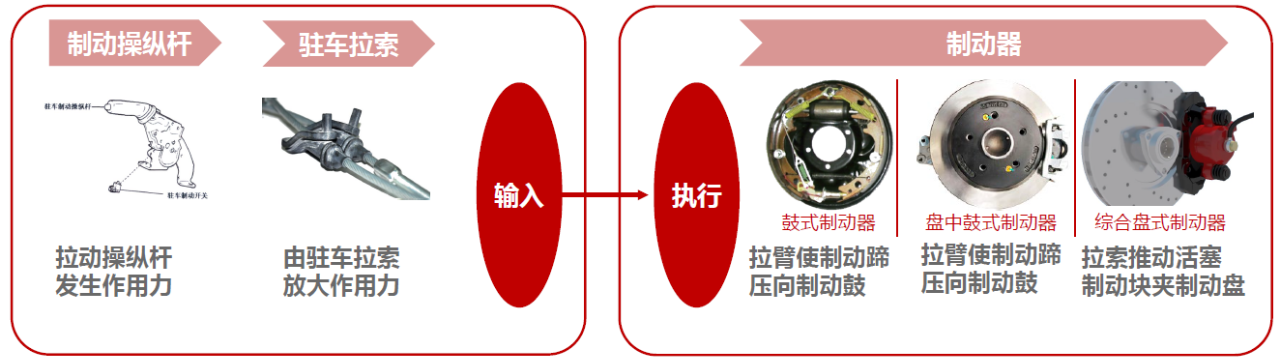

The development trajectory of parking brakes is similar to that of driving brakes, in that it has moved from traditional mechanical systems to electro-mechanical systems.

Traditional mechanical handbrakes consist of a brake lever, cable, and brake mechanism, which includes a return spring for take-up purposes. The brake lever is locked in place by means of a locking pawl, which is engaged by a ratcheting mechanism that requires only a small amount of force to actuate.

At present, electronic parking brake systems (EPB) are gradually replacing mechanical handbrakes, and it is predicted that their market penetration rate will reach 90% by 2025. The EPB consists of two parts:

- A parking actuation mechanism that generates parking force (caliper and motor)

- An electronic control unit (ECU) that controls the parking actuation mechanism, which contains software and hardware.

At present, the market share of EPBs is mainly occupied by foreign brands such as Bosch, Continental, and ZF. However, as EPBs belong to static parking brake systems that have relatively lower requirements compared to driving brake systems, the process of localization in the Chinese market is expected to accelerate. Domestic automakers such as BYD, with their advantages in cost performance and rapid response, have realized some degree of localization and are gradually moving into the high-end automotive market.In the wave of electrification and intelligence in the automotive industry, the electronic parking brake (EPB) system is also taking a new stage. For example, Remote Parking Control (RPA) and Automated Valet Parking (AVP) have mature solutions currently available. However, many OEMs consider that implementing a “two-box” solution for achieving redundancy in braking is costly. Against this background, the EPB integrated electronic parking system, which is based on standard EPB systems with “modification” for achieving autonomous parking with redundant braking, is becoming more and more popular among major automakers. (The design details of this braking redundancy solution will be discussed in a subsequent article.)

Furthermore, under the evolution of autonomous driving, the driving brake system and the parking brake system are also trending towards “integration.”

Currently, the main electronically controlled brake system is the electro-hydraulic brake (EHB), which is not purely electronically controlled but instead consists of a hydraulic control unit and a computing unit. However, if the four hydraulic wheel cylinders can be replaced by four electric motors and calipers, the braking instructions can be transmitted to the wheel-end motors, the motors can directly control the calipers to generate braking force at the wheel-end, and fully electronic control can be achieved. This approach is called electro-mechanical brake (EMB). Currently, EMB is constrained by its cost and has not yet achieved mass production. However, as autonomous driving gradually evolves to level 5, EMB as an ultimate solution for electronic brake control will fully exploit its advantages over EHB. By then, it will no longer be necessary to distinguish between the driving brake system and the parking brake system.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.