At the Tesla Q4 2021 Earnings Call, Musk announced a disappointing news for investors: Tesla will not release any new vehicles throughout 2022.

Months before the event, Musk teased on Twitter that he would update Tesla’s product roadmap during the conference, and most people expected good news about the Cybertruck mass production and the compact car starting at $25,000.

Musk’s explanation was quite sufficient, in short, the automotive industry is facing an industry-wide capacity shortage, and the delivery of existing models is already very tight, so even if new cars are released, only a few can be produced. It is better not to issue any new models and concentrate on increasing the production capacity of the existing cars first.

The important part of increasing production is to put new factories into operation, and Tesla’s two new factories this year are the Berlin factory that started delivery recently and the Giga Texas factory, which officially delivered the first batch of new cars today.

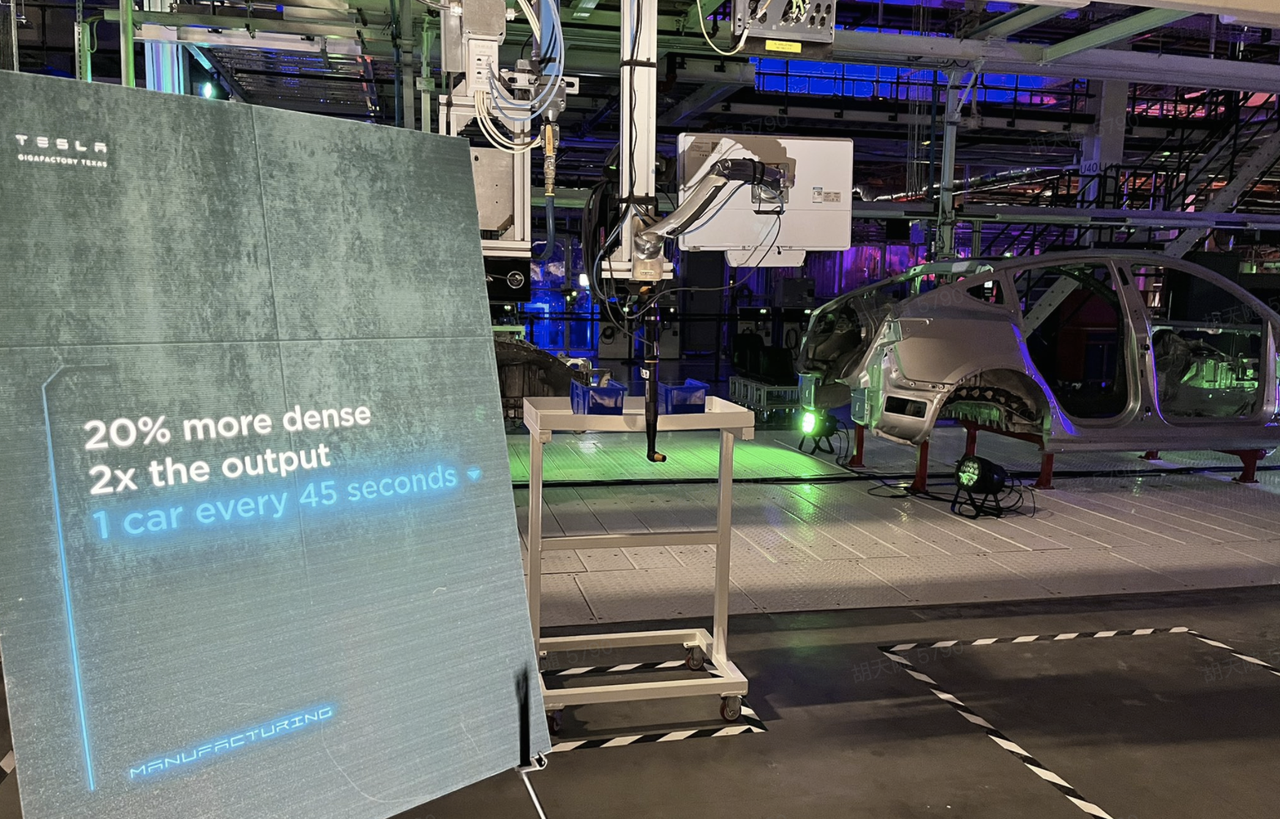

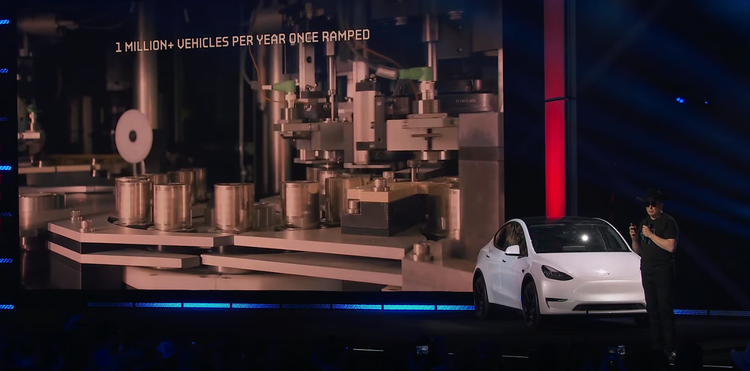

According to Tesla’s design plan, the annual production capacity of the Texas factory will exceed one million vehicles in the future, and the production line here can produce one car every 45 seconds.

The current Model Y is 475 centimeters long, so if we calculate based on this length, the speed at which Giga Texas builds cars is 11 centimeters per second.

The Next Generation of Super Factories

The Escape from San Francisco in Giga Texas Prologue

California is where Tesla was founded, and it is the largest market for new energy vehicles in the United States. In order to win Tesla’s heart, the California government went through many “Musk-style” PUA competitions and provided many highly competitive preferential policies to invest and build factories here.

However, at the end of 2021, Tesla suddenly moved its headquarters from California to the Giga Texas factory, and Musk himself has also settled in Texas.

Why move? In short, to save money.

The biggest driving force is to pay less taxes. California has the highest individual income tax rate of 13.3% in the United States, while Texas has a rate of 0. From the perspective of net income, moving to Texas is good news for Tesla employees. In addition, California’s highest corporate tax rate is 8.84%, while Texas is only 2.7%. It is estimated that after Tesla’s headquarters move from California to Texas, it can save billons of dollars every year.

In addition to high housing costs and living expenses, many companies and talents have fled from California in recent years. Moving to Texas also has the benefit of a SpaceX launch site in the southern part of the state, which allows Musk to better manage both companies.

In addition to high housing costs and living expenses, many companies and talents have fled from California in recent years. Moving to Texas also has the benefit of a SpaceX launch site in the southern part of the state, which allows Musk to better manage both companies.

Therefore, the Texas factory has become the development focus of Tesla’s next level. As a rapidly expanding technology car company, the Texas factory has made sufficient consideration for future development, and the area it covers is the most intuitive reflection of this.

How can a small factory be called a “gigafactory”?

At today’s Tesla factory gathering in Texas, Musk stated that the space at the California factory is no longer sufficient and that Tesla needs a large enough place to build a factory, and Texas is undoubtedly the chosen place.

How big is Texas to make Elon Musk feel big enough? We can see it intuitively from the comparison chart of existing Tesla factory land area made by a netizen.

The Texas factory covers an area of 8.5 square kilometers. For comparison, the Berlin factory’s 300 hectares of land covers only about one-third of the Texas factory’s land, despite the fact that the two factories opened only two weeks apart. Although the production capacity of the Shanghai factory is strong, it is even more impressive when compared to the Texas factory.

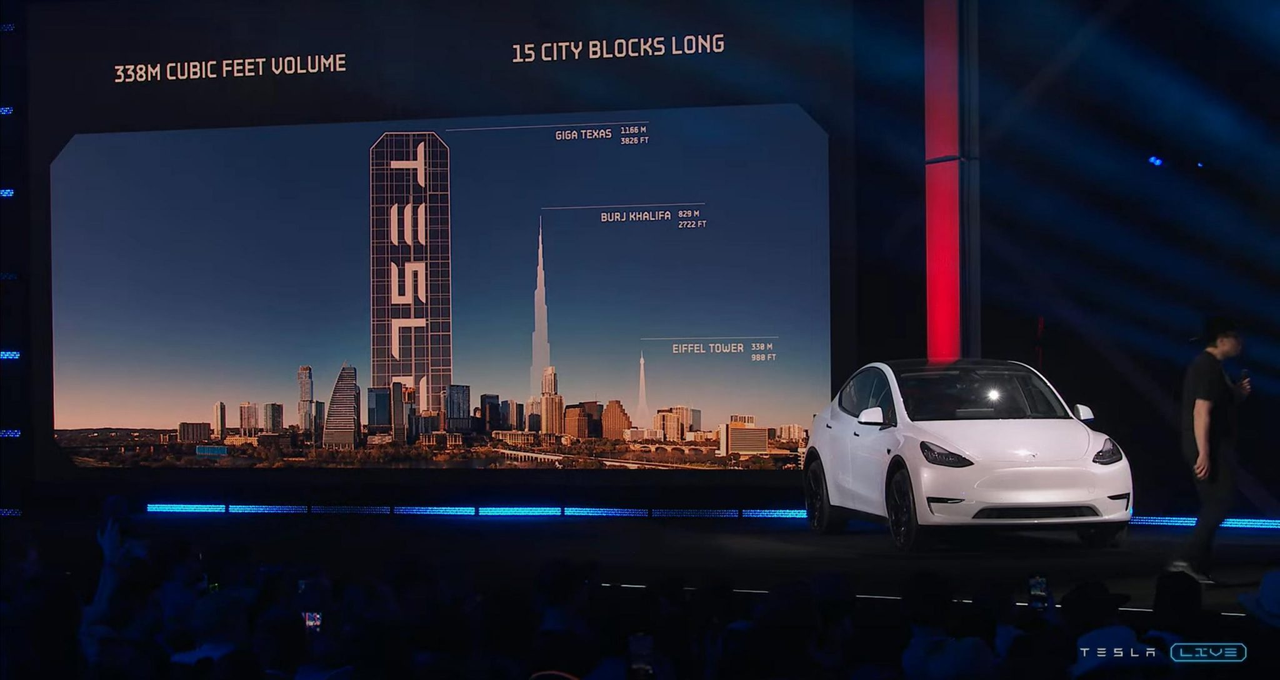

The length of the main building of the Texas factory is 1,166 meters, and the height in a vertical comparison is 1.4 times that of the Burj Khalifa in Dubai. It has to be said that Tesla knows how to play; comparing the length and height of the factory, although it may be exaggerating to describe the Texas factory as a giant, we are afraid that we will see discussions online about “Tesla building the world’s tallest building” someday.

The most important consideration for the size of the Texas factory is production capacity. Moreover, compared with the large size of the Texas factory, Musk spent more space today to introduce the advanced features of this factory.

The most advanced factory in the world, said by Musk

Speaking of the Texas factory, Musk, who is not stingy with superlatives when it comes to his own business, called it “the most advanced factory on earth”. When Musk says “most advanced”, it does not simply refer to its scale, but to the layout of the Texas factory.

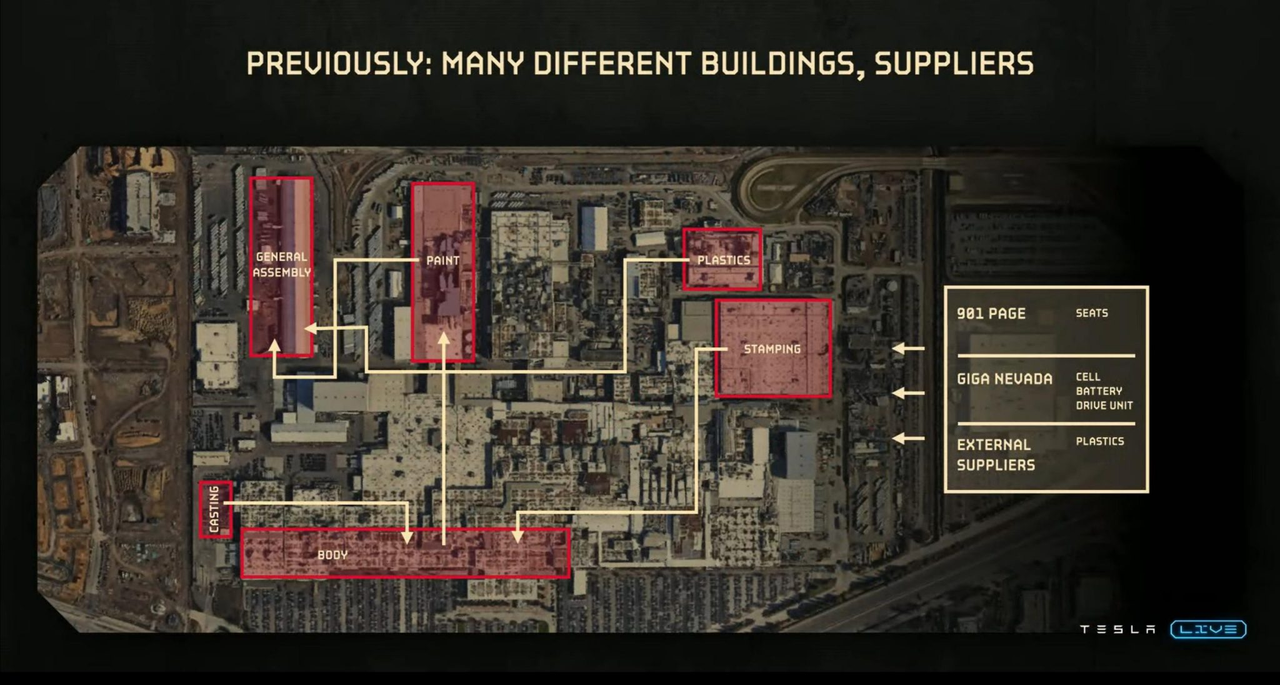

Today, to evaluate whether an electric car is advanced or not, one perspective is integration. Is the motor, controller, and reducer multi-integrated? Is the electronic and electrical architecture distributed or centralized? Is the thermal management system multi-domain and interlinked, etc.? Musk also introduced such criteria when evaluating a super factory, emphasizing “Dense” integration.The background board used is the Fremont factory of Tesla in California. The red-labeled departments and manufacturing processes on the diagram are located in different buildings, giving a feeling of distributed architecture. Therefore, there are many transportation links of components during the vehicle production process, which increases the waste of valuable time and decreases the manufacturing efficiency, leading to an increase of production costs.

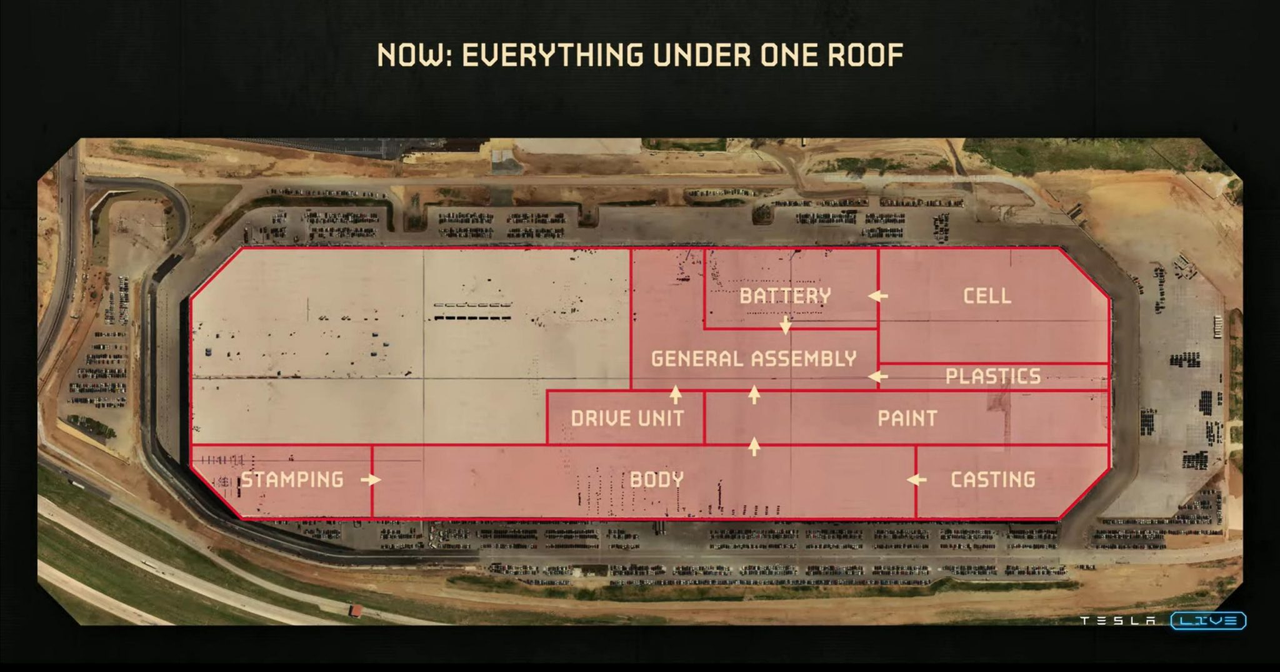

The scene shifts to the Texas factory, where the entire plant gives a different impression. It is no longer like the Fremont factory that is “scattered” but includes all processes and departments in an octagonal main building.

On the lower floor of the main building in the picture, the left side is the stamping workshop, and the right side is the body press workshop. The two workshops carry out welding and riveting on the middle body assembly line to complete the white body part of the body, then enter the next process, the painting workshop.

The completed painted body enters the final assembly workshop, where the white body is assembled with parts from the electric drive department, plastic parts department, and battery department. Finally, a complete electric vehicle is produced.

In the Texas factory, Tesla almost completes the manufacturing and assembly from the previous process and then enters the next process with minimal transportation. Even parts such as battery cells are manufactured and installed directly in the factory and then mounted on the vehicle body. The blank area in the upper left corner is reserved for future production expansion. In the Texas factory, raw materials are input at one end, and the factory can complete the manufacturing of a series of components such as battery cells, electric drive systems, and vehicle bodies. After passing through the remaining assembly processes, the output is a complete vehicle.

This highly integrated and vertically integrated approach saves a lot of costs and allows the Texas factory to theoretically achieve a rate of 45 seconds to take a Model Y off the line, whereas traditional car companies usually take several minutes to make a car. Tesla has already pulled ahead of them by several times in terms of factory manufacturing efficiency.Under this efficiency, the Texas factory, upon completion of the ramp, will have an annual production capacity of over one million vehicles, making it the world’s largest single automotive factory, with a production capacity of 500,000 for the Model Y, which will also make it the factory with the highest single-model production capacity in the world. The battery factory in the factory will also become the world’s largest single battery factory in the next few years, achieving three world records in one fell swoop, with its efficiency and integration beyond compare.

Speaking of efficiency, Tesla’s revolutionary vehicle manufacturing method Mega Casting must be mentioned, which was announced in 2020.

Front, middle, and rear, the lower body is done

Early versions of the Model Y had the rear body made from dozens of parts that were complexly welded and riveted, making the manufacturing process complicated and time-consuming.

Tesla was the first in the industry to adopt the Mega Casting manufacturing technology, which simplifies the manufacturing process by using high-pressure casting to directly combine dozens of parts into one for the entire lower body. A large casting machine can produce one part in 80-90 seconds, with a daily production of 1,000 castings. Traditional processes, which assemble 70 parts by punching, welding, and assembling, require at least 1-2 hours. If you include the research and development cycle of the 70 modules behind the 70 parts, the efficiency advantage of integrated casting will become even more apparent. In addition, the cast components produced by the final casting process also have improved weight reduction and mechanical properties.

Not only that, Tesla also streamlined the production line for the lower body of the vehicle through this manufacturing process. Previously, each production line for the front and rear lower bodies required about 300 industrial robots and took up a considerable amount of space. Now, a single large casting machine can do the same job.

At the event, Tesla once again showcased the large casting machine from Italy’s IDRA, which has become a major trend in the automotive manufacturing industry. For now, the Model Y produced in the Shanghai factory has already used castings for the lower rear body. As for the new factory in Texas, it uses a one-piece casting for both the front and rear lower body, just like the factory in Berlin.Compared to the Berlin factory, the Texas factory has an edge in that it uses an integrated CTC battery pack chassis. As a result, the Model Y produced in Texas is divided into front, middle and rear sections, and this structure may become another well-known “three-in-one” outside of the electric drive system in the future. It is reported that the Tesla Texas factory currently has four integrated die-casting machines, with the main one on the Model Y being the 6,000-ton (maximum pressure) specification, and the Cybertruck production line will use an 8,000-ton specification in the future, with large die-casting machines of 9,000 tons and above also planned to be purchased. For Tesla, die-casting manufacturing is a win-win situation that improves efficiency, body structural performance, and component consistency while reducing manufacturing costs and equipment footprint, which the Texas factory will continue to promote. However, the Model Y, which has been sold in China for over a year after using die-casting for its body, has also revealed several drawbacks in this technology during this time. On the one hand, many users have reported low-frequency resonance in the vehicle’s tailgate, which Tesla has not given a specific explanation for yet, but one possible factor is the increased body stiffness due to the single-piece die-casting of the lower body. At the same time, if the rear body of the Model Y suffers a large collision, the damage to the single-piece die-cast parts in the side frame and elsewhere can also lead to higher maintenance costs. For this newly applied technology, there may be more time needed to fully expose its potential problems, but it still has ample advanced attributes from an industrial manufacturing standpoint, and we believe that there will be better solutions to the problems that currently exist as this technology becomes more widely used in the industry. With the factory out of the way, let’s discuss some vehicle-related things.

Tomorrow’s Rising Star in the Super Factory

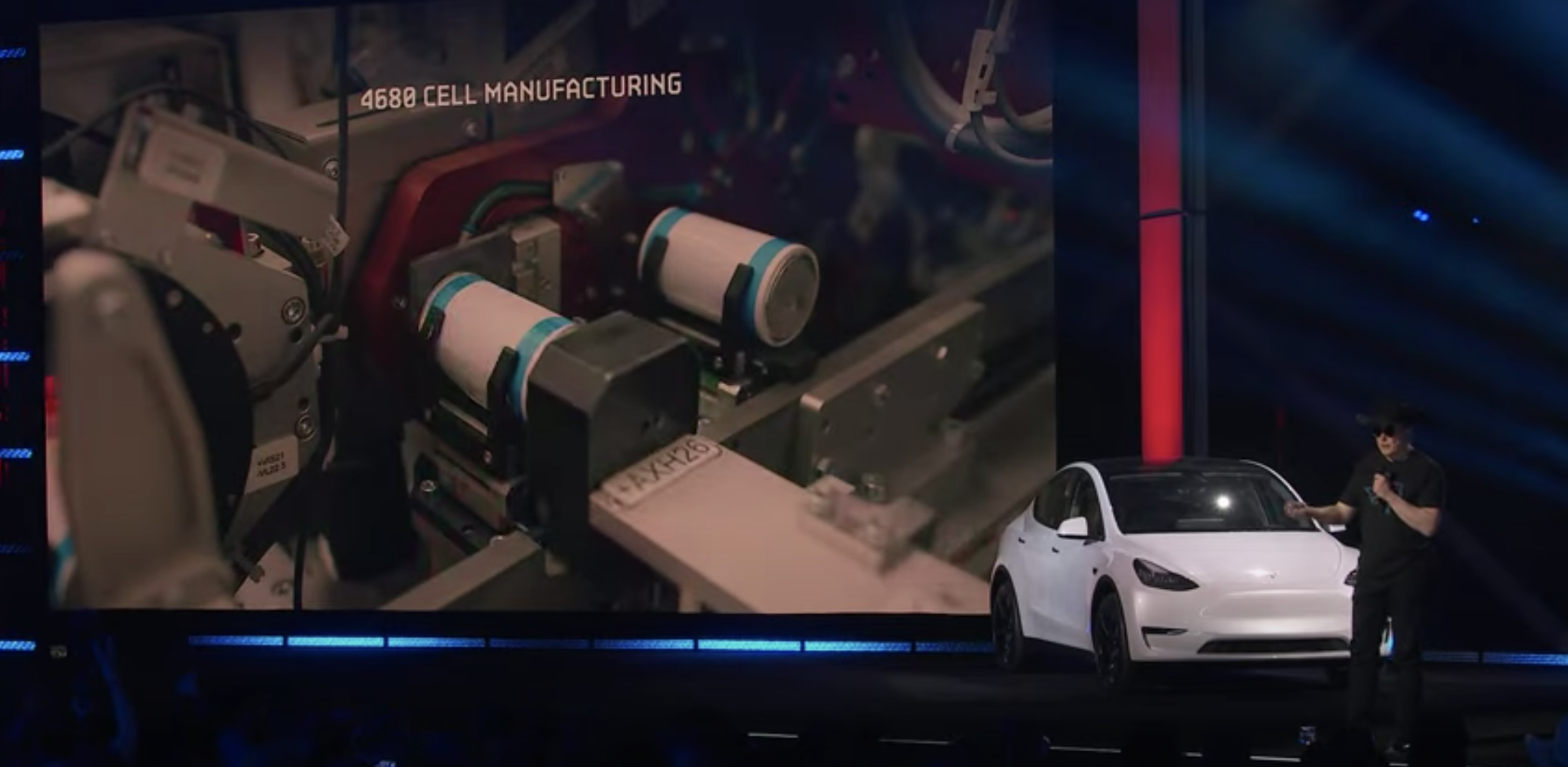

The Hidden Star of the Party: The 4680 Battery Cell

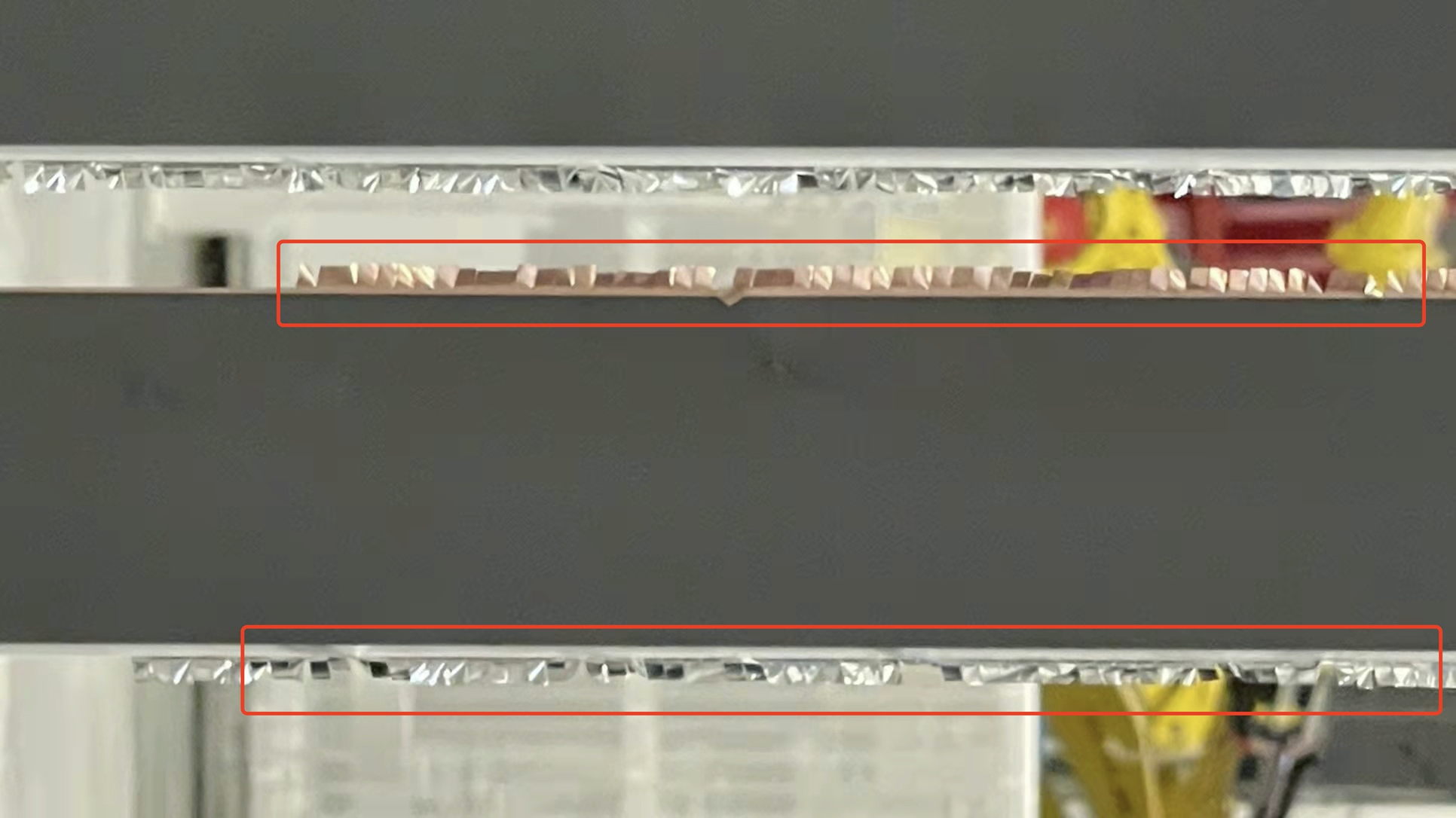

Almost two years after Battery Day, the Texas factory has finally started production of the highly anticipated 4680 cylindrical battery cell.Compared with the 1865 and 2170 cylindrical batteries, the 4680 battery is not just about size increase. The Tabless technology effectively reduces the internal resistance of the 4680 battery, reduces heat generation, and can balance energy density and power density. It not only has a longer endurance, but also supports super high-power fast charging. Today, the Texas factory also showcased the full tab electrode of the battery in an unrolled state.

In addition, under the application of CTC technology, the battery pack itself has also become a structural component of the vehicle. This is easy to understand. Originally, only the “outer shell” was subjected to force. Now, through structural design, the battery and the outer shell have closer mechanical cooperation, and the neatly arranged 4680 cells also undertake some of the tasks of torsion and bending resistance.

Now, the Texas-produced Model Y’s seats are directly fixed on the seat bracket on top of the battery cover. A simplification process directly reduced half of the battery pack production line.

Under the “Three-In-One” chassis of front, middle, and rear, the first batch of four-wheel drive Model Y with standard endurance and 4680 cells from Texas achieved an EPA endurance of 279 miles.

It should be noted that this is the data of the standard endurance (small battery capacity) dual-motor four-wheel drive Model Y version. The data of the single-motor rear-wheel drive Model Y with standard endurance sold in the early stage of the US market is 244 miles. The EPA endurance of the Model 3 single-motor rear-wheel drive version with lower wind resistance and smaller body is 272 miles.

In other words, with the 4680 cells from Texas factory, the Model Y with one more motor and a larger car size achieved longer endurance than the Model 3.

Although the Model Y is not a new car, such adjustments are no longer the incremental progress of traditional “facelift” for vehicles.

Cybertruck, Roadster 2, Semi, Coming next year?

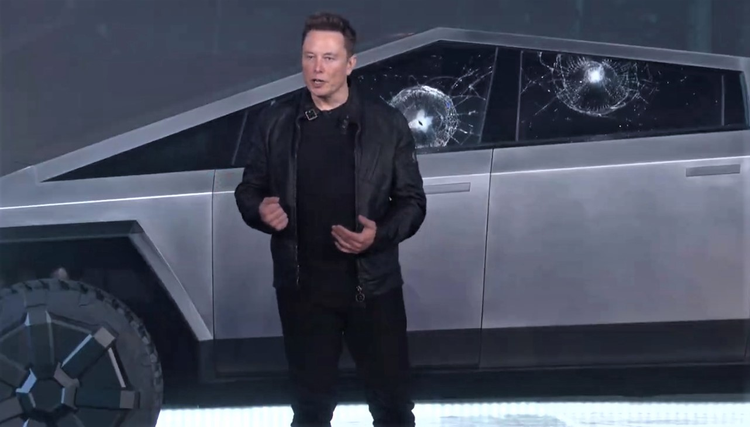

Model 3 and Model Y are undoubtedly Tesla’s most popular products, but if you ask us what Tesla’s coolest car is, the answer is likely to be the Cybertruck.Believe it or not, the scene of Tesla’s chief designer Franz von Holzhausen smashing the glass is still vivid to us in 2019. At that time, Tesla claimed that the glass was extremely hard and bulletproof, but it was broken twice in a row during the demonstration by steel balls.

Today Franz comes again, stating in his conversation with Musk that the glass still needs to be broken once to make up for Tesla’s previous blunder. However, he seems to have left his tools at home today, so he will have to do it next time.

As for this pure electric pickup truck that has been delayed for three years, the two of them once again appeared on the scene to promote it and said that the car is quite good, with many surprises and cool features. The design of the handle-free doors will be retained, and the vehicle can sense when passengers are approaching and automatically open and close the doors. Franz believes that the Cybertruck is one of a kind and if you buy it, you will not need to look at other pickups anymore. He almost said the statement, “All other pickups in this room are XX”.

The product seems good, but when will it be available for purchase?

Tesla’s answer is 2023. Usually, when manufacturers say Q1, it means the end of March, but when Tesla says 2023, it can only mean that it is possible to be released in 2023. However, compared to previous appearances, this time the Cybertruck has a series of details that look more like mass-produced cars, such as rearview mirrors and giant wipers, and with the start of mass production of 4680 batteries, this time’s release is likely to be the most reliable one.

Two long-delayed car models are the Roadster 2 sports car and the electric Semi truck. The former is Tesla’s flagship with an acceleration of 0-60 mph in 1.9 seconds and a top speed of 250 mph (400 km/h). The latter has a maximum EPA range of 600 miles (996 km) and can replenish 400 miles (644 km) of charge in just 30 minutes in fast charging mode.

Two long-delayed car models are the Roadster 2 sports car and the electric Semi truck. The former is Tesla’s flagship with an acceleration of 0-60 mph in 1.9 seconds and a top speed of 250 mph (400 km/h). The latter has a maximum EPA range of 600 miles (996 km) and can replenish 400 miles (644 km) of charge in just 30 minutes in fast charging mode.

If these parameters of the Semi can be achieved in the production car priced at $150,000, it will undoubtedly overturn the commercial vehicle industry with a huge cost advantage.

At the event, attendees also saw the V1 Optimus robot that was unveiled at Tesla’s AI Day last year. Elon Musk said that robots will completely solve the problem of labor shortage, and over time, Tesla’s robot business may even have the potential to surpass its automotive business. When Tesla’s AI experts have trained Optimus to replace human labor, there may be nothing but machines and robots in Tesla’s factories.

In conclusion, it has been almost five years since the initial release of the Tesla Roadster 2 and Semi, and the Cybertruck incident happened three years ago. Even today, there are still many uncertainties about the production of these vehicles. But this has little impact because no other vehicle in the same category can surpass these three models, regardless of whether it has already been produced or not.

In other words, if you have placed an order during the launch event and hope to buy the most exciting and innovative electric vehicle in the world, these Tesla “PPT models” can still meet your demand.

What’s even more incredible is that the two mainstays of Tesla’s sales, the Model 3 and Model Y, come from 2016 and 2019 respectively, and even in 2022, there are still very few electric vehicles that can compete with these two cars in terms of overall strength in this category, and this may continue to be the case.Remember when Musk boasted about his own products in 2019, claiming that the Model S, which was introduced in 2012, was the best electric car on the planet, and there was no competitor that could come close to it, even after seven years.

In such a rapidly evolving industry like the automobile industry, few manufacturers have the ability to create evergreen models, especially in the electric vehicle field. This undoubtedly reflects Tesla’s high level of long-term product strength, scalability, and overall industrial design and comprehensive foresight.

That’s also why Tesla dared not make any new cars for three years after the Model Y, and was able to rank first in the new energy vehicle sales of all manufacturers in 2021 with a sales volume of 936,172 vehicles.

But in the global auto market, this achievement only helped Tesla occupy a market share of just over 1\%, a long way from the goal of 20\% market share, as shown on the PPT. Capacity expansion is and will continue to be Tesla’s key goal, whether in the past, present or future.

After the Berlin and Texas factories started one after another, the Model Y officially began to aim for the goal of becoming the world’s best-selling single model. A $60,000 “electric dad” is going to challenge Toyota’s top-selling Corolla globally, and that’s what we’re experiencing now, and we might personally witness it in the next two years. This process will accompany a revolutionary change in automobile manufacturing and drive the transformation of the global automotive and energy industries.

As an important player in this process, Giga Texas will produce one electric car after another at a speed of 11 cm per second, and continue to accelerate this process.

Finally, welcome to download Garage App to learn about the latest new energy news. If you want more immediate communication, you can click here to join our community.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.