Author: Zhu Yulong

Today, I was reading LINGPAI's prospectus at home, looking for interesting information. Here is a summary of what I found:

- In 2021, a total of 43,748 vehicles were delivered (634 S01s, 39,149 T03s, and 3,964 C11s), resulting in a total revenue of CNY 3.132 billion but a significantly expanded loss. The company's shareholders' equity losses for 2019-2021 were CNY 901 million, CNY 1.1 billion, and CNY 2.846 billion, respectively. Adjusted net losses for the same period were CNY 810 million, CNY 935 million, and CNY 2.629 billion. Gross profit margins were -95.7%, -50.6%, and -44.3%, respectively.

- LINGPAI had CNY 4.338 billion in cash and cash equivalents. The company had previously completed multiple rounds of financing totaling CNY 8.8 billion, which is close to the current total loss of CNY 5 billion, leaving CNY 3.8 billion on the balance sheet.

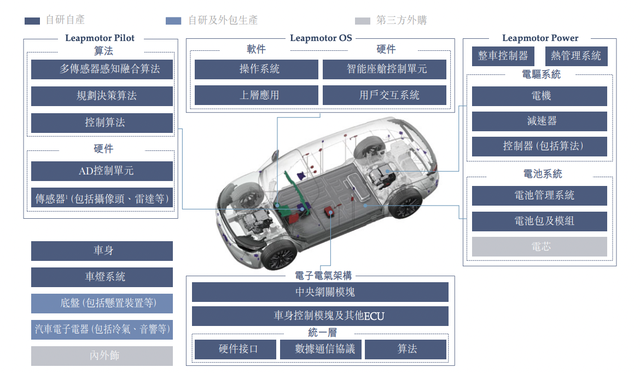

- LINGPAI has more than 1,000 research and development personnel, accounting for 33.9% of the company's total employees. R&D spending in 2019, 2020, and 2021 was CNY 358 million, CNY 289 million, and CNY 740 million, respectively (totaling less than CNY 1.4 billion). The company is producing its own electric drive systems, battery management systems, sensing systems, computing systems, and control systems, among other electronic components.

- The Jinhua factory has an annual production capacity of 200,000 vehicles (previously producing T03s and C11s, as well as C01s). The factory produces most of the core vehicle components, including battery packs, electric drive systems, headlights, and other core electronic components. A new factory in the Qiantang New District of Hangzhou is expected to begin construction in 2022.

- Combining with LINGPAI 2.0 plans, the C01, A01, and D01 models will be positioned at a price range of CNY 100,000-150,000, and CNY 250,000-300,000, respectively. The SUV product line, including A11 and A12, will have two models priced between CNY 100,000-150,000, and C12 will be priced between CNY 200,000-250,000.

Note: Before the price increase, the price of C11 was adjusted to between CNY 179,800 and CNY 229.800, an increase of up to CNY 20,000-30,000 compared to before.

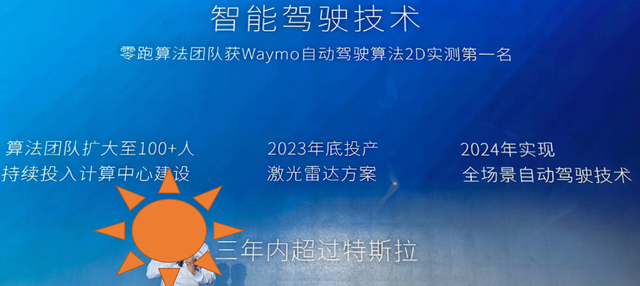

The 1082 engineers (inclusive of technical personnel) at Leapmotor are highly efficient, covering Leapmotor Power, Leapmotor Pilot (encompassing all algorithms, autonomous driving controllers and sensors), Leapmotor OS, electronic and electrical architecture, and vehicle body and lamps (yes, you read that right, the company designs and manufactures its own lamps!). Except for the battery cells and interior, the chassis including suspension design and electronic and electrical components are being developed jointly with suppliers.

According to personnel estimates, we already know that Leapmotor Pilot algorithms require about 100 people, with a hardware ratio of 6:1, we still need 15-25 people, meaning that approximately 130 people are required for this development. It is estimated that 100 people are needed for cabin design and that less than 200 people will be needed in the new energy vehicle field.

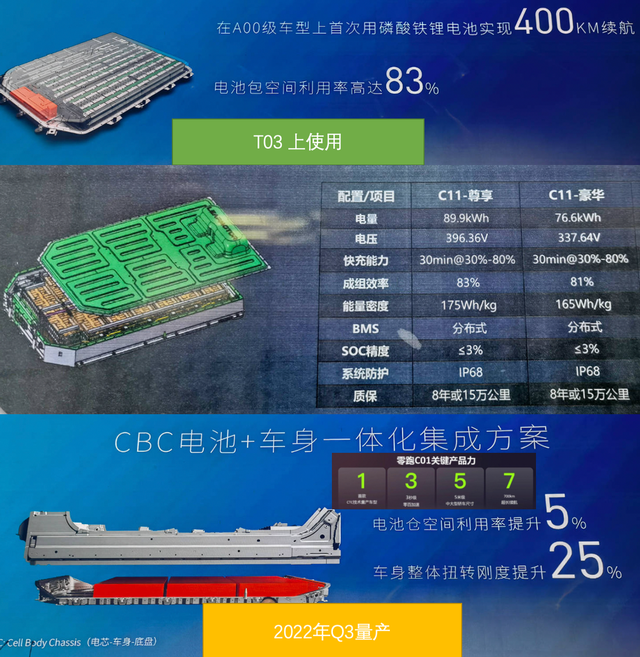

Leapmotor’s battery research and development capabilities

Regarding the three-electricity system, let’s talk about the power battery first. Leapmotor adopts a self-developed composite design, and the battery cells are researched and manufactured by suppliers. The company also uses a self-built battery factory in PACK mode. Leapmotor was the first company in China to enter the CTC design, and it is expected to be launched in Q3 2022. The picture below shows the current large module design for the C11 (the whole PACK has only three modules).

Note: What is CTC? We will cover it in our later reports. In any case, we are already on the move.

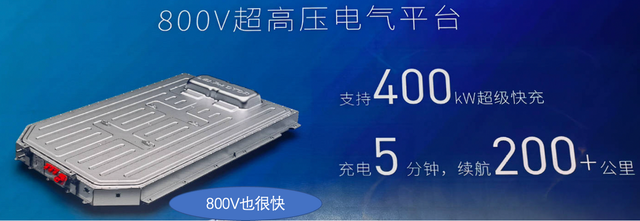

Of course, Leapmotor is also very efficient in developing 800V batteries at CTC. In 2022, the company will produce fast-charging power with a power support of 400 kW, enabling a range of 200 kilometers in just 5 minutes.

Note: Those working with batteries know that the conversion from 400V to 800V is quick.

Electric drive research and development capabilities and others

Based on the prior information, Leapmotor has constructed a factory in Jinhua, Zhejiang, with an annual production capacity of 200,000 battery packs and 250,000 drive motors. The first-generation permanent magnet motors have a maximum power of 200 kW, peak torque of 360 Nm, and a maximum speed of 13000 rpm. Leapmotor will introduce more powerful and efficient oil-cooled motors for mass production in Q3 2022. It follows that SiC electric drives will be paired with 800V systems.

All I can say is that the research and development capabilities and speed per capita are amazing.

I don’t have much to say about this, see for yourselves. The official announcement is based on the experience of Dahua Technology in visual recognition, such as facial and license plate recognition, which are globally leading technologies. The traffic environment in China is more complex and special, providing more fertile ground for the development of autonomous driving technology, which helps Chinese teams to succeed in this field in the future.

Summary: Currently, all domestic new forces have gone to the Hong Kong stock market. After stabilizing and making profits, we will see if we can return to the A-share market. The larger strategy is to transition first and then return to the big market to rely on capital market for funding. Many promotion materials follow the logic of the mobile phone industry where Apple dominates other brands, but this method is not supported at all after salary and R&D costs become transparent.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.