Apple’s “Batterygate” has passed more than 4 years, and few big companies in the mobile phone industry dare to secretly reduce the performance of users’ phones by system upgrades.

However, similar incidents are happening every day in the increasingly popular electric vehicle industry.

“Locking Battery” and “Limiting Power”: Beware of OTA Becoming a “Magic Seal”

Nowadays, if an electric vehicle does not support OTA upgrades, it is embarrassing to come out and showcase it.

In the eyes of consumers, every system upgrade can bring more features and better experience, such as Tesla’s “Sentry Mode” and “Dog Mode”. They also consider the manufacturer’s software R&D ability when purchasing and are willing to bear a part of the premium.

However, after an OTA upgrade, your beloved car may be “locked” or “limited” in power. “Locking Battery” is to reduce the maximum voltage of a single battery through the battery management system BMS. The result is that the available capacity of the battery is reduced, and the range is significantly reduced. “Limiting Power” is achieved by reducing the output power of the motor through the motor controller. For example, I originally bought a car with a 2.0 T engine, but after the manufacturer’s operation, the power becomes that of a 1.5 T “lame duck”. Additionally, often, when “locking the battery,” a “gift” of “lowering the charging speed” is also given.

As a pioneer in the new energy vehicle industry, Tesla has also been sued several times for “locking the battery.” The latest case was in 2019 in Norway, where Tesla was ordered to pay $16,000 to each of the 30 Model S owners who sued. These users purchased models from 2013 to 2015, and after a software update in 2019, they found their car’s range had significantly decreased, with some dropping by 11%, while charging speed also decreased notably. Tesla’s explanation was exactly the same as Apple’s: “To protect the battery and extend its life.”

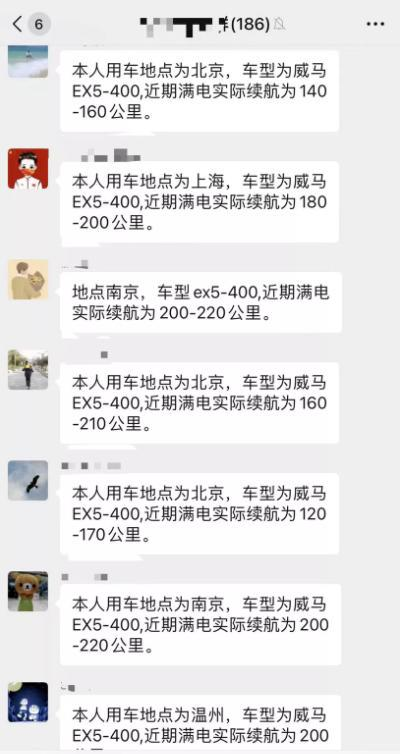

In China, examples of electric vehicle (EV) battery locking are not uncommon. In January of this year, 173 WmAuto EV owners jointly sent a lawyer’s letter to WmAuto Auto, questioning the vehicle’s battery being locked without informing the owner. Some claim that their vehicle, with a nominal 400 km range, could only run about 250 km before an official notification of a free maintenance check, and now can run less than 200 km. Another Chinese EV maker, XPeng Motors, faced similar accusations from some of the first 670 car buyers who reported significantly decreased battery outputs, with some batteries now showing only 70 instead of the advertised 80.3 degrees. However, XPeng officials denied the allegations of battery locking.

In China, examples of electric vehicle (EV) battery locking are not uncommon. In January of this year, 173 WmAuto EV owners jointly sent a lawyer’s letter to WmAuto Auto, questioning the vehicle’s battery being locked without informing the owner. Some claim that their vehicle, with a nominal 400 km range, could only run about 250 km before an official notification of a free maintenance check, and now can run less than 200 km. Another Chinese EV maker, XPeng Motors, faced similar accusations from some of the first 670 car buyers who reported significantly decreased battery outputs, with some batteries now showing only 70 instead of the advertised 80.3 degrees. However, XPeng officials denied the allegations of battery locking.

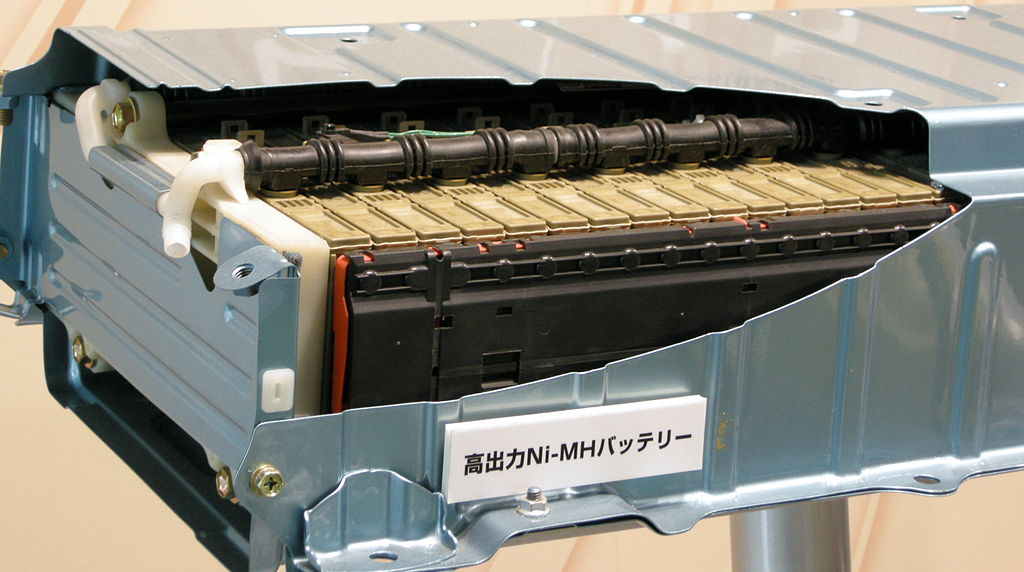

Battery locking is not unique to new Chinese EV makers. One GAC Toyota iA5 owner felt a decrease in their vehicles range and power output. When the car went for a checkup at an authorized dealer, the work order showed that the charged temperature was 50.5 degrees, while the optimal temperature should be 58.5 degrees. The GAC iA5 is a rebranded version of the GAC Aion S and LX EVs; these vehicles also faced similar complaints.

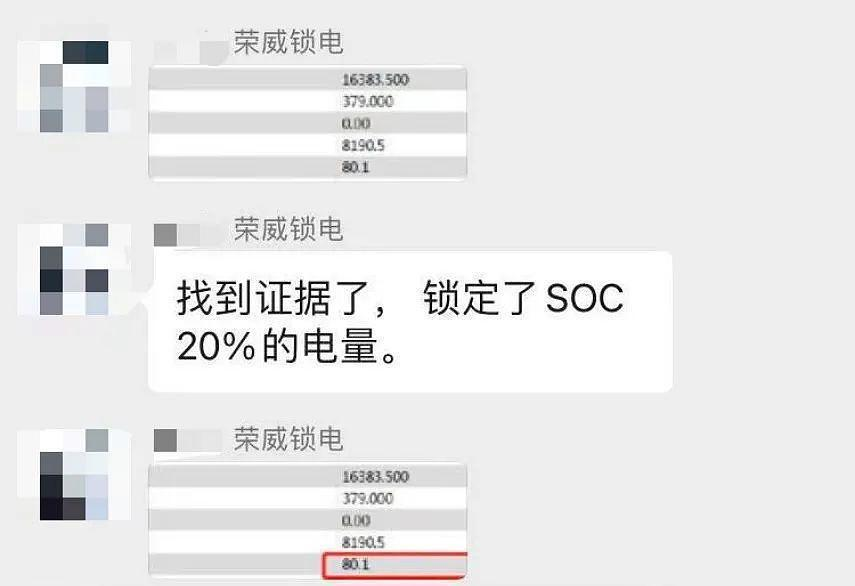

Other EV models, such as SAIC Roewe ERX5 and Great Wall Motor’s Ola IQ, also faced complaints of battery locking, which seems to have become an unwritten industry practice. Great Wall Motors eventually issued a recall for Ola IQ cars.

Why would carmakers take the risk of consumer complaints and forcibly lock the batteries? The answer is not complicated – to shift the risk. In recent years, numerous incidents of self-igniting EVs have caused significant damage to manufacturers’ images, adversely impacting sales figures. Additionally, recalls to address safety issues can become a considerable financial burden.

The two main reasons for battery locking in EVs: over-discharge and insufficient battery management

As mentioned earlier, the primary goal of battery locking is to prevent EVs from catching fire and to avoid negative media attention or expensive recalls. But how does battery locking prevent the risk of self-ignition?

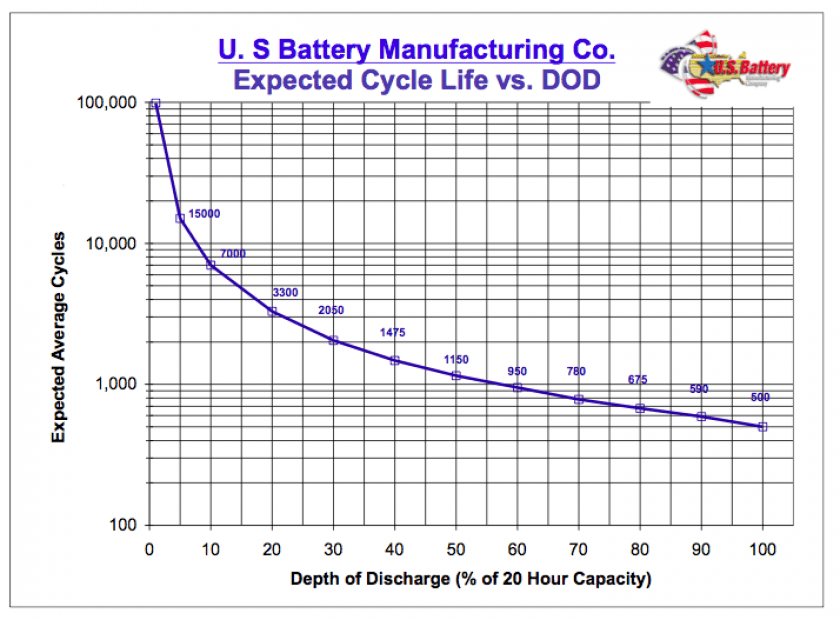

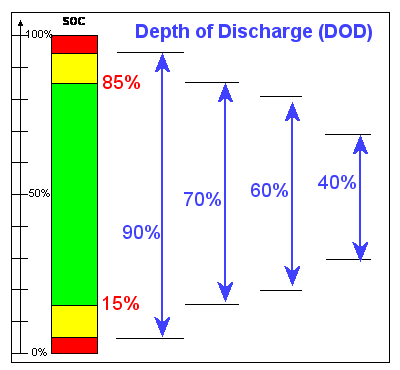

Here, we introduce the concept of Depth of Discharge (DOD). DOD refers to the percentage of battery capacity used during discharge, with the higher the DOD, the shorter the battery life-span, and the higher the risk of self-ignition.Actually, it’s not difficult to understand. If you are a martial arts master with amazing skills, although your internal strength is high (rated capacity is high), you cannot use super ultimate move (almost 100\% depth of discharge) against a small fry. Using some small moves (low depth of discharge) usually helps prolong your life. Using super ultimate move every day will cause combustion spontaneous combustion (ignition).

This explains why Toyota’s THS HEV battery capacity is so small and has been in a state of charge and discharge, and there is a high probability that its lifespan is longer than that of pure electric vehicles because the depth of discharge is only 40\%, and SOC is always in the range of 40\%-80\%.

The core competitiveness of electric vehicles is endurance, and the battery is also the most expensive component in the car. Therefore, the depth of discharge is basically above 80\%, but whether it is 80\%, 90\%, or even more than 95\%, the strategies of each automaker vary widely.

Some automakers are “conservative”, and the discharge depth of the battery calibrated at the factory is relatively low. This makes the battery longer in life and lower in the risk of spontaneous combustion, but it will “lose” in terms of cost and endurance mileage. Another group is the “radical”, and the factory-set discharge depth of the battery is very “greedy”. In order to control costs and promote longer endurance to consumers, they usually mark the discharge depth to above 90\%. According to reports, some new players dare to set the depth of discharge to over 95\%.

The result is that after the car is sold, the risk of spontaneous combustion is very high, and the battery life will be greatly reduced. At this time, the manufacturer can greatly reduce the battery depth of discharge by “locking” the car, so that the brand’s model doesn’t have to worry about spontaneous combustion making headlines, nor bear huge recall costs.

However, for consumers, they have paid for an automaker’s product with “exaggerated promotion” and design flaws. Because whether it is a “recall” or “locking the car” after the vehicle is shipped, it is only a remedial measure, and the losses brought by the latter are entirely borne by the consumer, and can even be done stealthily and secretly.

In addition to the excessive depth of discharge, poor battery management capability is another major sin of automakers’ “locking the car”.

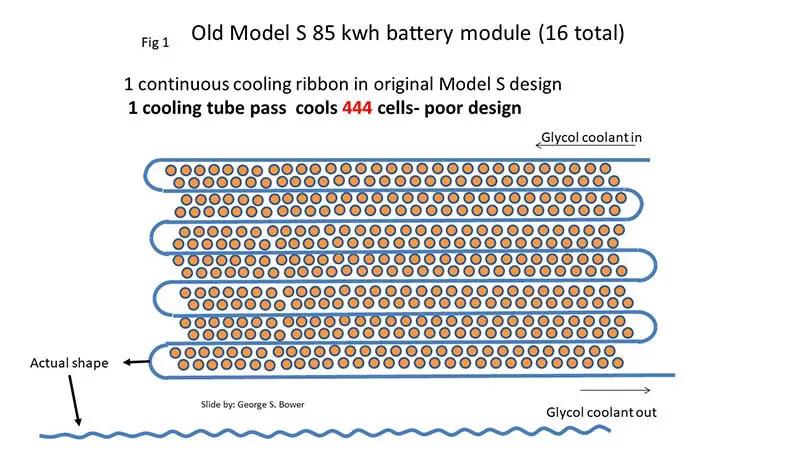

Lithium batteries have advantages such as high energy density, strong power endurance, and no memory effect, but they are extremely sensitive to the environment, especially temperature. Needless to say, everyone tries their best to cool the batteries during high temperatures. Most ternary lithium batteries now use efficient methods such as “liquid cooling” and “direct cooling”. For example, Tesla’s cylindrical battery uses cooling plates inserted between the batteries. This method has a high cooling efficiency, but the structural design difficulty is relatively high.

However, even though every company values battery cooling management, the phenomenon of electric vehicle combustion during the summer is still common. At this time, “locking the battery” to further reduce the depth of discharge has become a “crooked idea” among car companies.

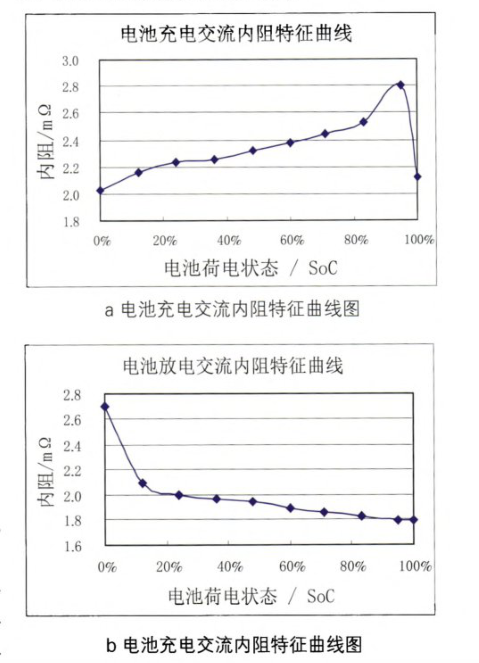

This is because when the State of Charge (SOC) of the power battery is less than 20\%, the internal resistance of the battery will begin to increase sharply. At this time, when the current remains unchanged, the heat generated by the battery will also increase sharply. If the car company “locks” the bottom range of SOC, it can significantly reduce the internal heating of the battery at low power levels. At the same time, we found that many vehicle fires occur during charging. On the one hand, this is due to the poor charging management capability of the battery. On the other hand, when the SOC of the battery is higher than 80\% during the charging process, the internal resistance also increases significantly. In this case, the car company will consider further “locking” the upper range of SOC. Locking these upper and lower ranges will reduce the usable part of the battery, resulting in poor endurance.

In addition to high temperatures, low temperatures are also a major “killer” of power batteries.

At low temperatures, the mobility of molecules is significantly reduced, making the transport of lithium ions/atoms in the positive electrode lattice inside the battery and between the graphite (negative electrode) layers very sluggish. If the depth and speed of charging and discharging remain the same as at normal temperatures, a large amount of lithium will accumulate on the positive and negative electrodes and electrolytes, forming metallic lithium. The chemical properties of metallic lithium are very active, and it is easy to have irreversible reactions with the electrolyte and greatly exacerbate the accumulation of “lithium dendrites” in the negative electrode, which will become “dead lithium” and cause permanent capacity loss. If lithium ions are squeezed on the surface of the positive electrode lattice, it is also easy to cause the rupture of the positive electrode.

At low temperatures, the mobility of molecules is significantly reduced, making the transport of lithium ions/atoms in the positive electrode lattice inside the battery and between the graphite (negative electrode) layers very sluggish. If the depth and speed of charging and discharging remain the same as at normal temperatures, a large amount of lithium will accumulate on the positive and negative electrodes and electrolytes, forming metallic lithium. The chemical properties of metallic lithium are very active, and it is easy to have irreversible reactions with the electrolyte and greatly exacerbate the accumulation of “lithium dendrites” in the negative electrode, which will become “dead lithium” and cause permanent capacity loss. If lithium ions are squeezed on the surface of the positive electrode lattice, it is also easy to cause the rupture of the positive electrode.

Therefore, whether it is a car manufacturer or a battery factory, it attaches great importance to creating a “greenhouse” for the battery at low temperatures. In addition to ordinary PTCs, heat pump air conditioners are also becoming more and more common. Some car manufacturers even use “external packages” for “diesel heating”. If the car manufacturer cannot guarantee the battery temperature at low temperatures, it will consider “locking” the battery discharge depth and reducing the charging and discharging power. The result is a “triple gift package” of reduced endurance, weakened power, and decreased charging speed.

Both excessive factory discharge depth and insufficient battery management capabilities are issues that the manufacturer must address. “Locking up” and “power-locking” through OTA and other methods means transferring all losses to the consumers. The most critical problem is that this kind of method is often very concealed, and consumers are often unaware of it, even taking no effective actions against the manufacturer.

Protecting consumers’ rights is difficult, how can they check whether they have been “battery-locked”?

Compared with traditional cars, new energy vehicles will emphasize “intelligence” more, which involves more new technologies such as electronic and electrical architectures, batteries, smart cabins, and smart driving. On the one hand, users are not familiar with these new technologies, and on the other hand, these essential technologies and data are almost all controlled by car manufacturers. Car manufacturers may conceal or tamper with relevant parameters, which is difficult for ordinary people to detect and even harder to successfully prosecute. Currently, the basic principle of civil law is “whoever claims, has the burden of proof.” Those who cannot produce evidence will bear the risk of losing.

In the case of last year’s “Tesla Brakegate,” Tesla’s attitude was very rigid. After the strong intervention of relevant departments, Tesla finally provided some relevant data, but it was not complete.

So how can ordinary consumers check whether their cars have been “battery-locked” when facing car companies holding dominant positions?# First, currently, the vast majority of “battery lock” operations are completed through OTA upgrades. Every time you perform an OTA upgrade, be sure to carefully read the relevant terms and pay attention to the battery management content. If you encounter something you don’t understand, you can ask the manufacturer’s personnel for help.

Second, if you suddenly feel that your vehicle has a significant decrease in range, motor power output, and charging speed under similar conditions, communicate promptly with other car owners in the car friend group for verification and discussion.

Third, since the range and battery level displayed in the car can be tampered with, the charging degree displayed on the charging station is more reliable. Usually, you can simply record the charging conditions, including temperature, charging power, charging station brand, charging time and other information. If the required degree is significantly reduced during charging under similar conditions, then you may be a victim of the “battery lock.”

Of course, to completely eliminate the “battery lock” behavior by manufacturers, we must rely on national legislation and regulations. In August of last year, the Ministry of Industry and Information Technology issued the “Opinions on Strengthening the Management of Smart Networked Vehicle Production Enterprises and Products Admission.” It standardized the requirements for software online upgrades but emphasized that “automobile automatic driving functions cannot be added or updated through online software upgrades without approval.” Regarding the OTA upgrade of “battery lock”, it still primarily requires filing.

Therefore, before relevant regulations are thoroughly improved, there is no guarantee of harmony between new energy vehicle owners and manufacturers, and strategizing is one of the main themes.

Finally, do you think that automotive companies’ “battery lock” behavior will be exposed in this year’s “315”?

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.